Self-rotation valve with vertical magnetic anisotropy

An anisotropic, spin-valve technology, applied in magnetic field-controlled resistors, spin-exchange coupled multilayer films, magnetic recording heads, etc., can solve problems such as magnetic vortex effects, large noise, and system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

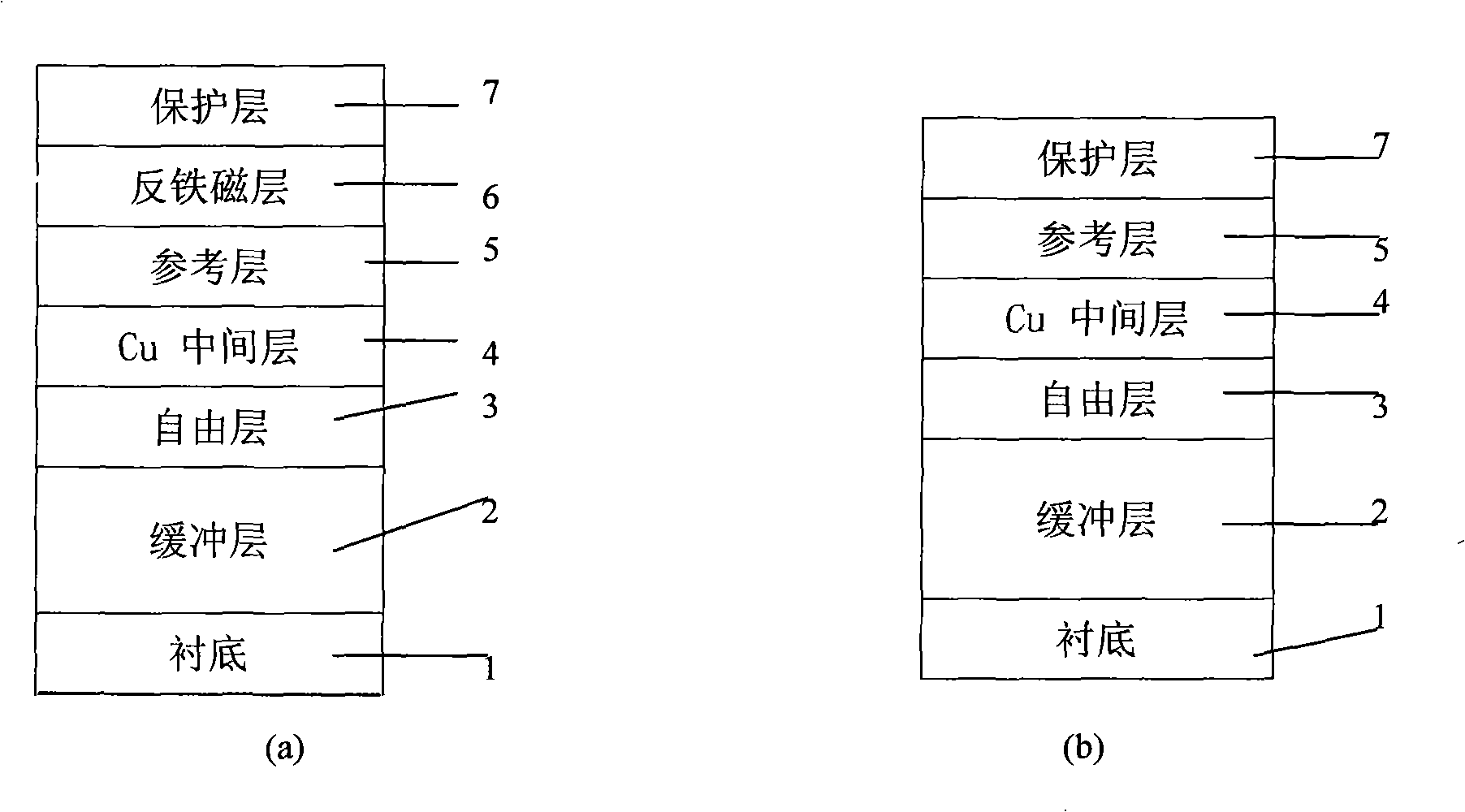

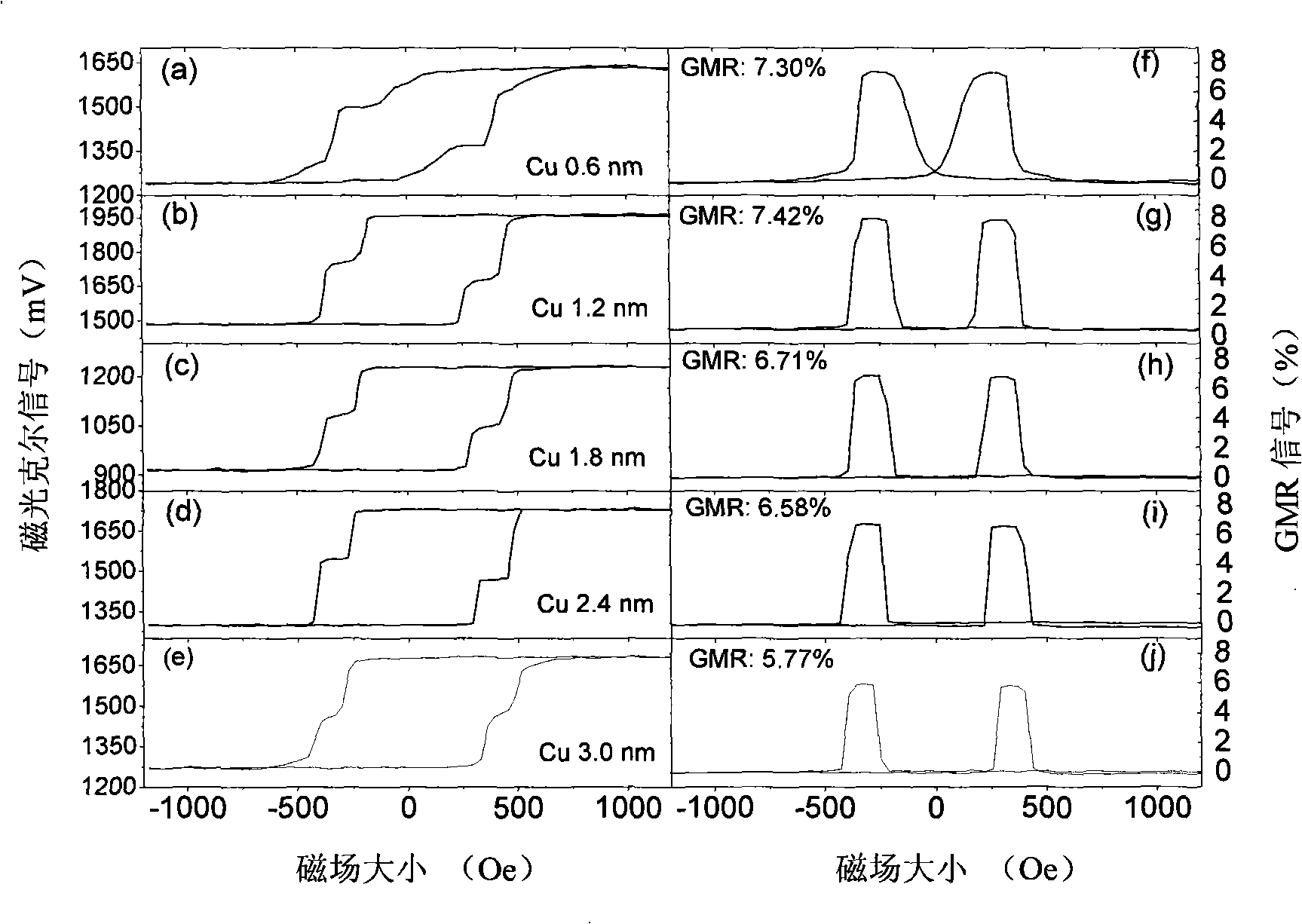

[0028] Structure: Corning Glass / Ta 3nm / Cu 0.6-3.0nm / [Ni 0.59nm / Co 0.33nm] 3 / Cu 2.3nm / [Co 0.25nm / Ni 0.59nm] 5 / Ta 3nm.

[0029] This example is a set of pseudo-spin valves with a Cu buffer layer thickness of 0.6nm-3.0nm. like figure 2 As shown, when the thickness of Cu changes from 0.6nm to 3.0nm, this group of pseudo-spin valves all exhibit relatively good magnetic perpendicular anisotropy, and the GMR signals are above 5.7%. A Cu buffer layer smaller than 0.6nm will destroy the magnetic perpendicular anisotropy, and a Cu buffer layer larger than 3.0nm will make the GMR signal too small.

Embodiment 2

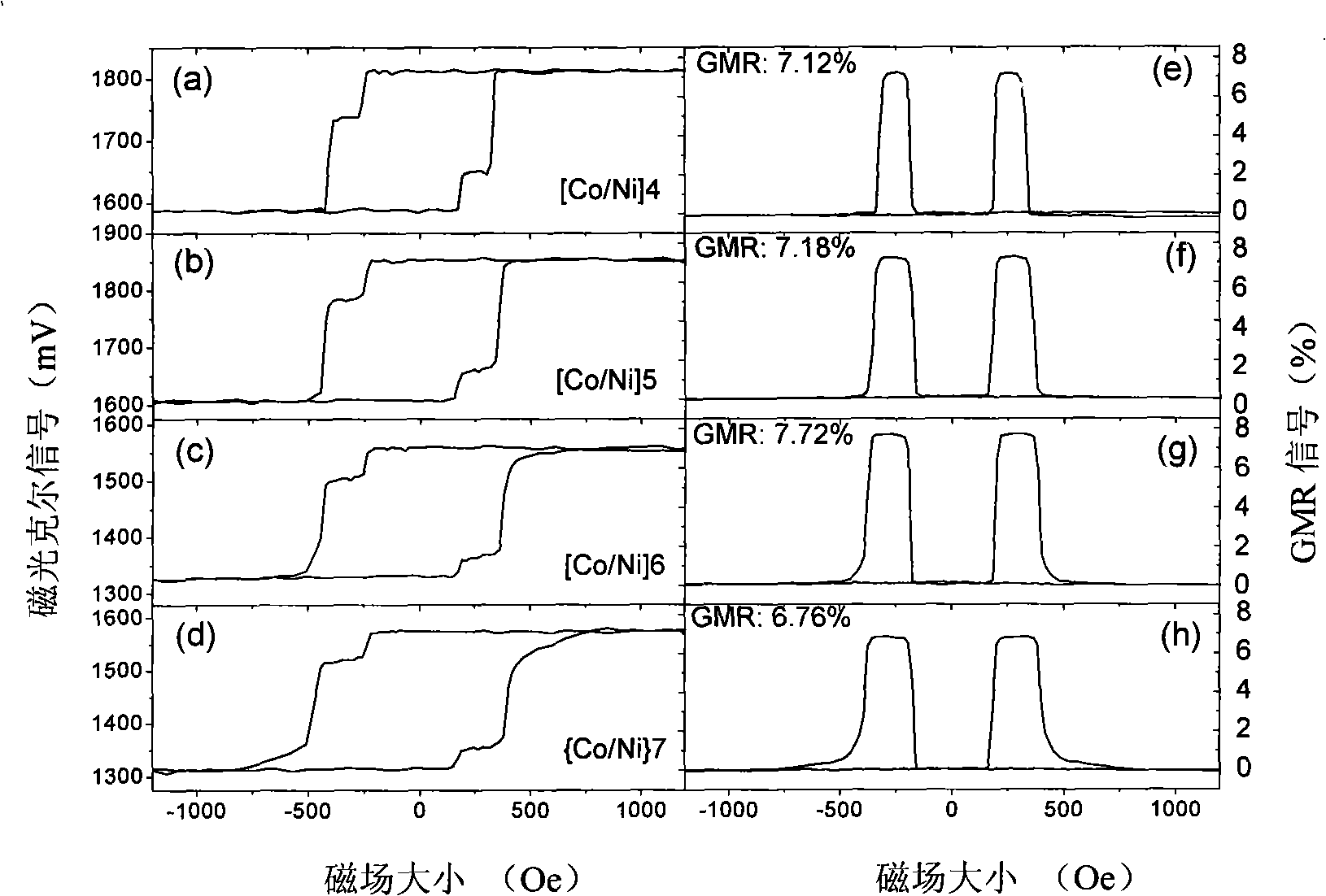

[0031] Structure: Corning Glass / Ta 3nm / Cu 1.4nm / [Ni 0.59nm / Co 0.33nm] 3 / Cu 2.3nm / [Co 0.25nm / Ni0.59nm]4-7 / Ta 3nm

[0032] This example is a group of pseudo-spin valve samples whose period number ranges from 4-7 for the reference layer Co / Ni multilayer film. like image 3 As shown, when the number of cycles increases from 4 to 6, the GMR signal increases from 7.12% to 7.72%, and all have better magnetic vertical anisotropy.

Embodiment 3

[0034] Structure: Corning Glass / Ta 3nm / Cu 1.4nm / [Ni 0.59nm / Co 0.33nm] 3 / Cu 2.1-3.3nm / [Co 0.25nm / Ni 0.59nm] 5 / Ta 3nm

[0035] This example is a series of pseudo-spin valves with Cu thickness in the middle layer ranging from 2.1-3.3nm. like Figure 4 It is shown that the thickness of the intermediate layer increases from 2.1nm to 3.3nm, and the GMR signal decreases from 7.69% to 5.68%, all of which can meet the requirements, and the magnetic perpendicular anisotropy is not affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com