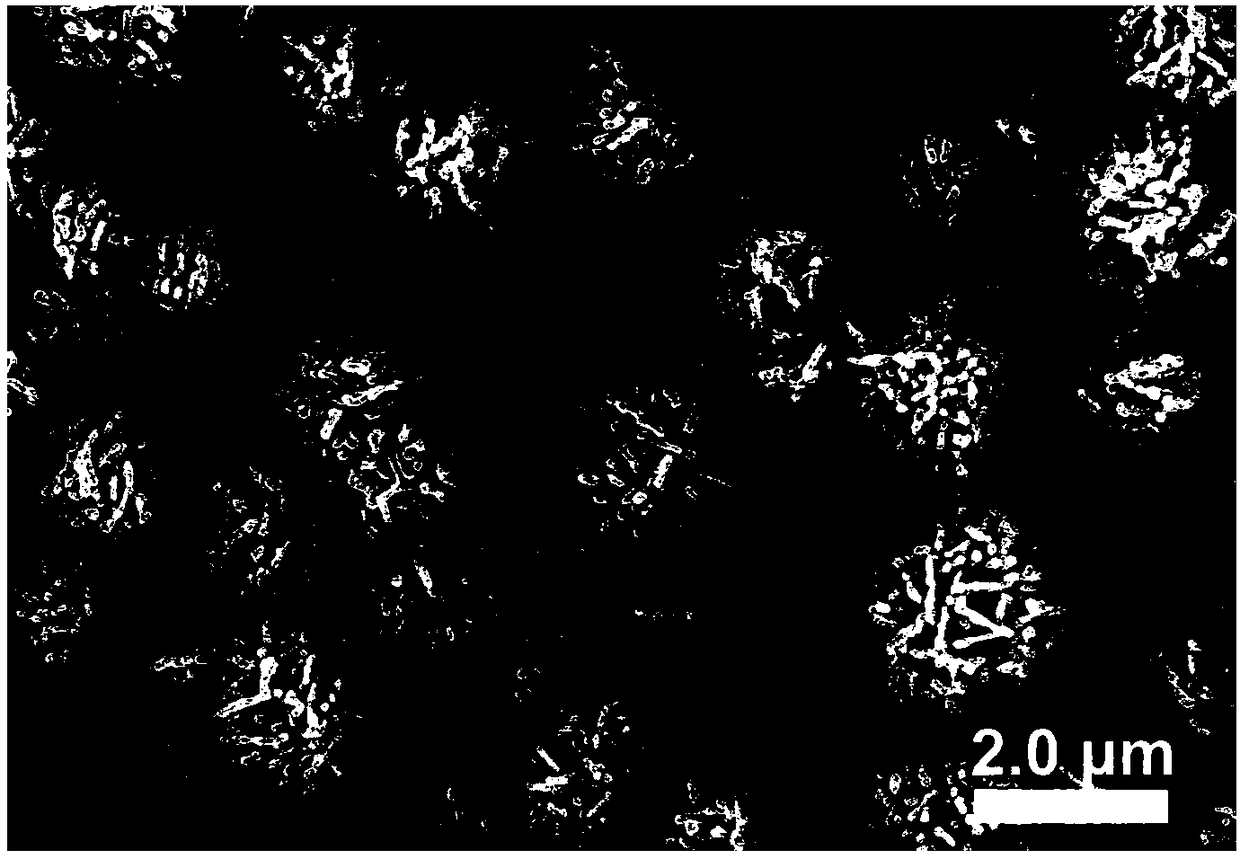

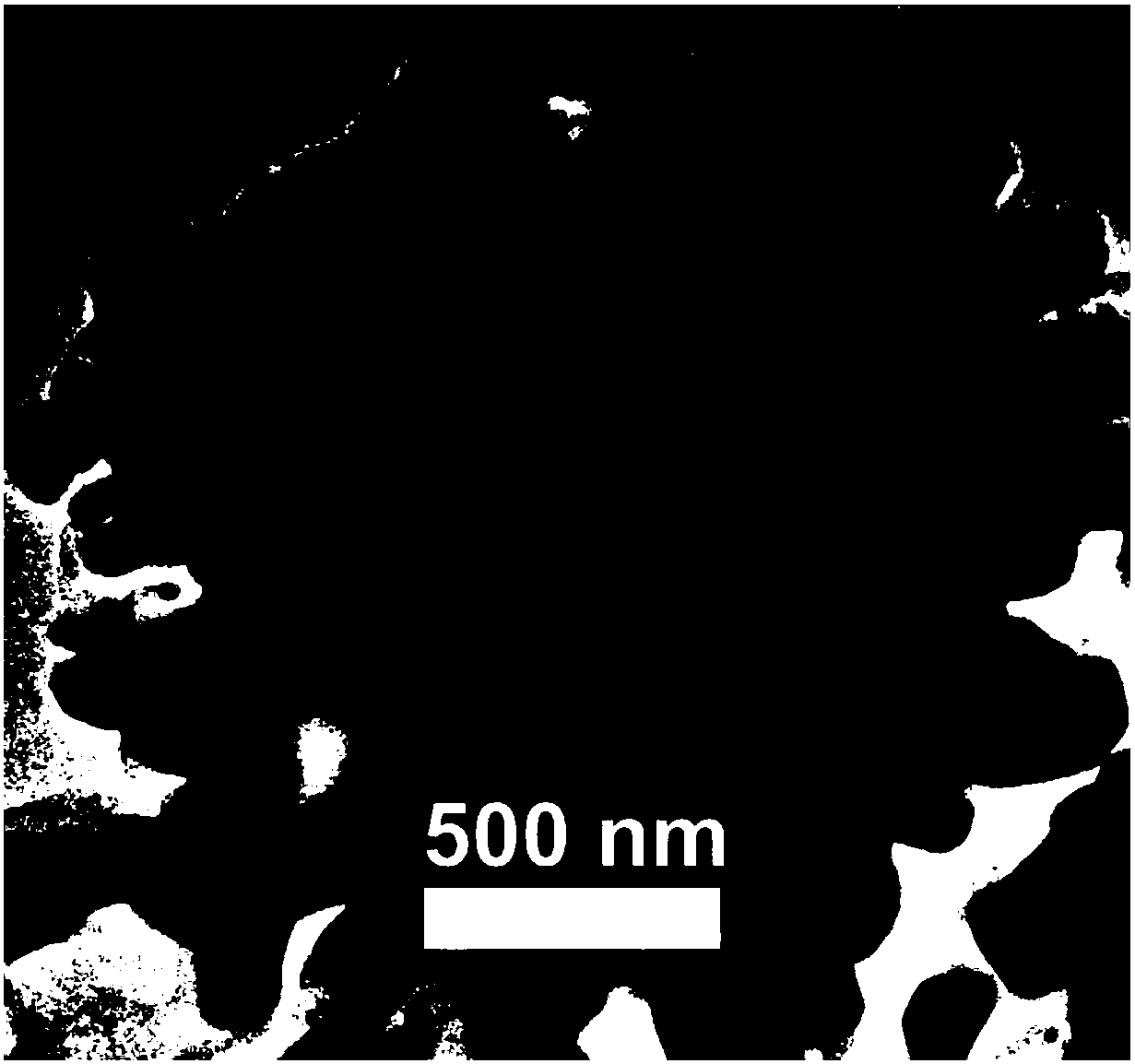

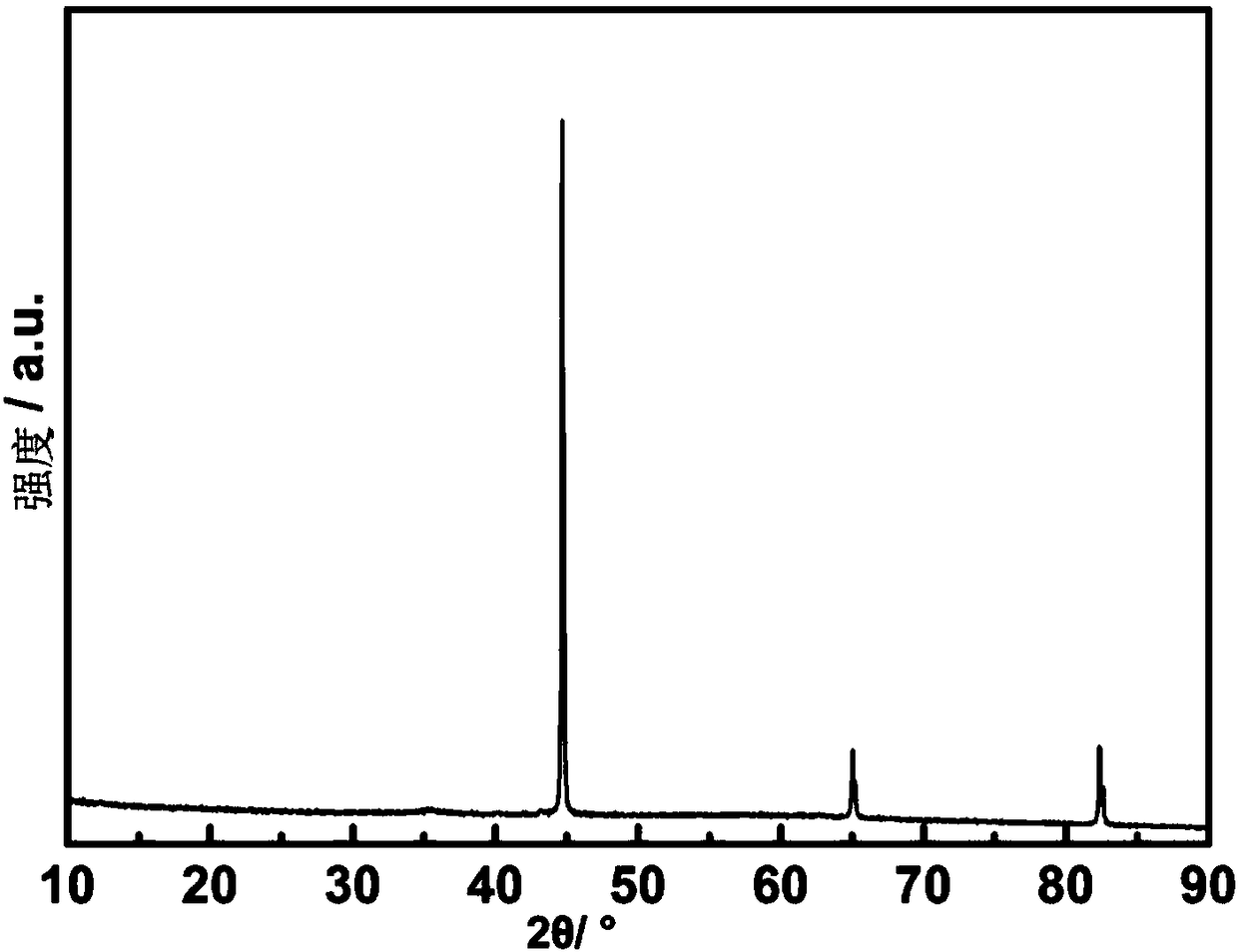

Preparation method of nano-particle assembled flower-shaped iron sub-micron particles

A technology of submicron particles and nanoparticles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of wide particle size distribution, easy aggregation of iron particles, low energy utilization rate, etc. Achieve the effect of good stability, low heat treatment temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1.20g of ferric chloride hexahydrate, 5.40g of urea and 7.20g of tetrabutylammonium bromide in 180ml of ethylene glycol under mechanical stirring to obtain an orange-yellow solution; heat the above solution to reflux at 180°C After 45 minutes, cool naturally to room temperature; centrifuge the cooled solution to separate the green precipitate, wash the green precipitate 3 times with absolute ethanol, and dry it in vacuum at 60°C to obtain a light green powder; place the prepared light green powder in In the quartz boat, put it into the temperature-controlled area of the tube furnace quartz tube, heat treatment at 400°C for 2.0 hours in an air atmosphere, pass argon gas into the tube furnace quartz tube for 1.0 hour, and then inject it into the tube furnace quartz tube Introduce the mixed gas of argon and hydrogen, the volume ratio of argon and hydrogen in the mixed gas is 10:3, and keep warm at 400°C for 2 hours under the mixed atmosphere, and cool to room tem...

Embodiment 2

[0026] Dissolve 1.20g of ferric chloride hexahydrate, 2.70g of urea and 3.60g of tetrabutylammonium bromide in 180ml of ethylene glycol under mechanical stirring to obtain an orange-yellow solution; heat the above solution to reflux at 150°C After 30 minutes, cool naturally to room temperature; centrifuge the cooled solution to separate the green precipitate, wash the green precipitate 4 times with absolute ethanol, and dry it in vacuum at 60°C to obtain a light green powder; place the prepared light green powder in In the quartz boat, put it into the temperature-controlled area of the tube furnace quartz tube, heat treatment at 400°C for 2.0 hours in an air atmosphere, pass argon gas into the tube furnace quartz tube for 1.0 hour, and then inject it into the tube furnace quartz tube Introduce a mixture of argon and hydrogen, the volume ratio of argon and hydrogen in the mixture is 10:3, and keep warm at 400°C for 3 hours under the mixed atmosphere, and cool to room temperatu...

Embodiment 3

[0028] Dissolve 1.20g of ferric chloride hexahydrate and 5.40g of urea in 180ml of ethylene glycol under mechanical stirring to obtain an orange-yellow solution; heat the above solution to 195°C and reflux for 60 minutes, and naturally cool to room temperature; The cooled solution was centrifuged to separate the green precipitate, washed with absolute ethanol for 3 times, and vacuum-dried at 60°C to obtain a light green powder; the prepared light green powder was placed in a quartz boat and placed in a tube In the temperature-controlled area of the furnace quartz tube, heat treatment at 400°C for 2.0 hours in an air atmosphere, pass argon into the tube furnace quartz tube for 1.0 hour, and then pass a mixture of argon and hydrogen into the tube furnace quartz tube , the volume ratio of argon and hydrogen in the mixed gas is 10:3, and it is kept at 400°C for 4 hours under the mixed atmosphere, and cooled to room temperature with the furnace under the argon atmosphere, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com