MnAs nanowires and preparation method thereof

A technology of nanowire and crystal orientation, applied in the field of MnAs nanowire and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of MnAs nano wire of the present invention comprises the following steps:

[0024] 1. First complete the various growth preparation procedures of the MBE equipment: confirm that Mn, Ga, and As sources are installed in the system; cut the GaAs (001) single crystal substrate in the ultra-clean room and adhere it to the sample stage with In; The substrate and sample stage are dehydrated and baked in the chamber, and the substrate and sample stage are baked to remove organic impurities in the buffer chamber; the growth chamber is cooled with liquid nitrogen to increase the background vacuum to 5×10 -10 Torr below.

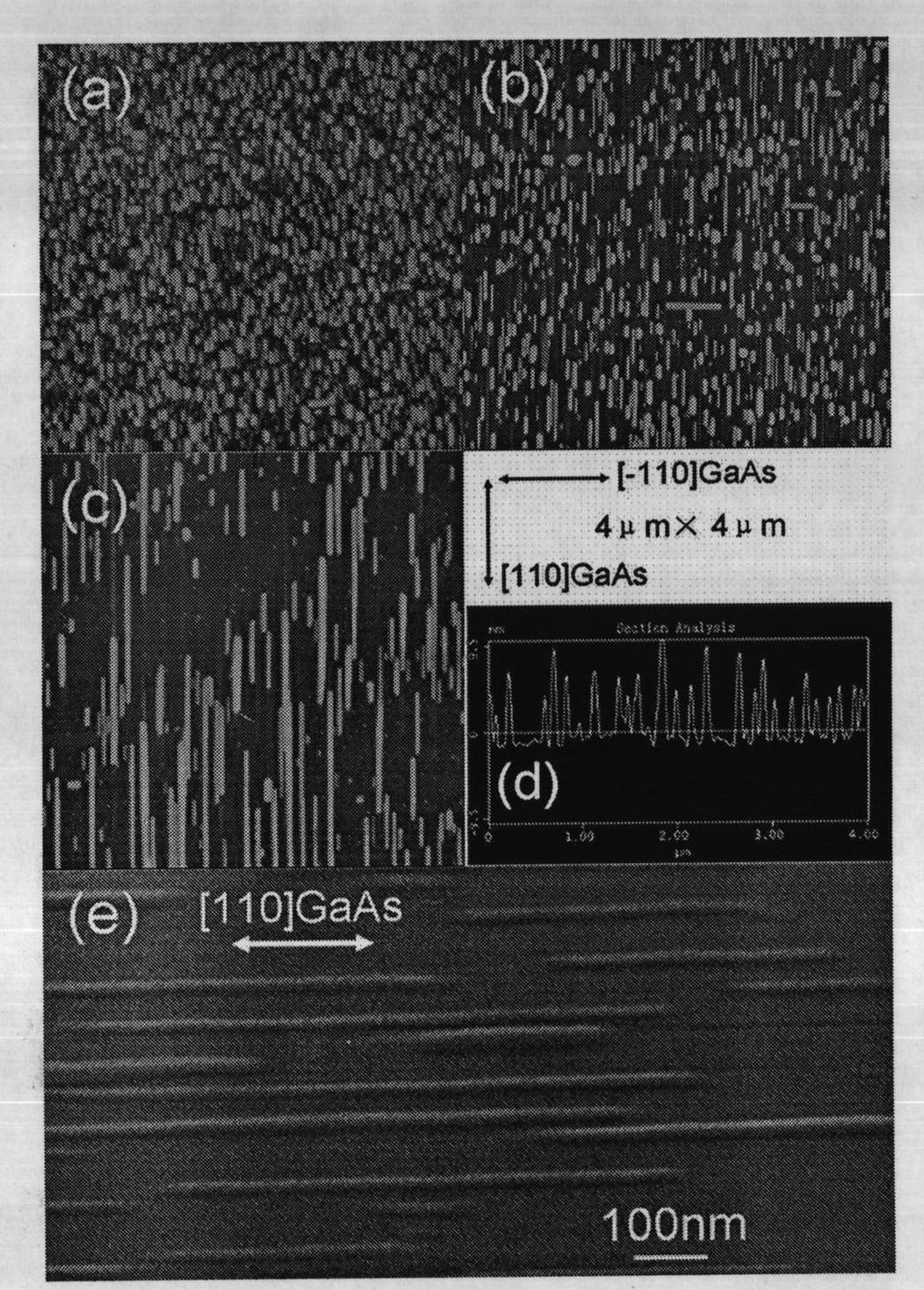

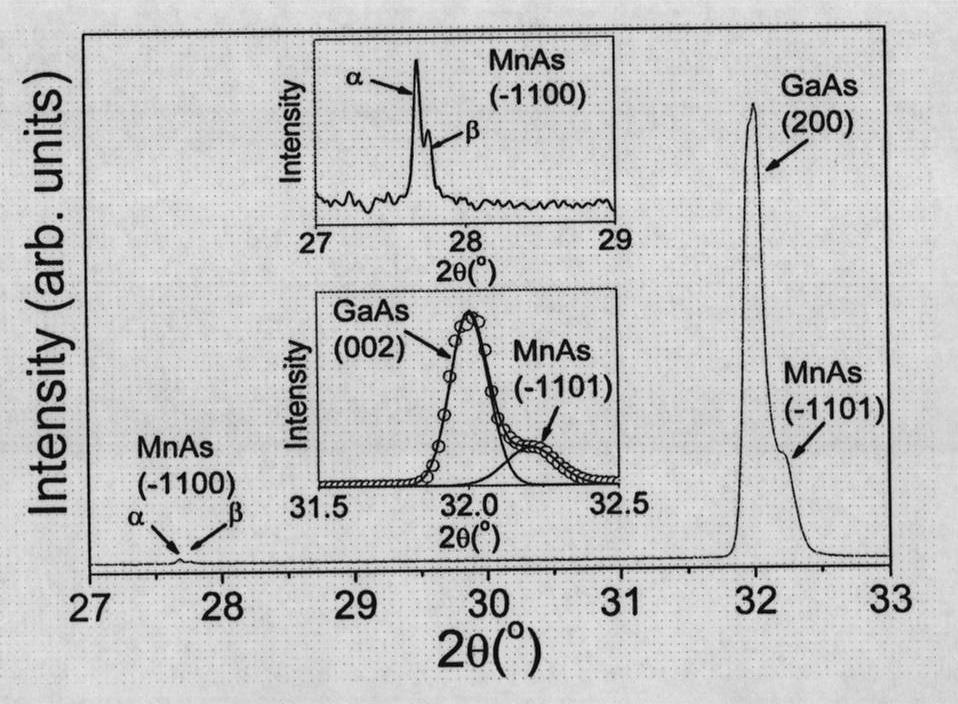

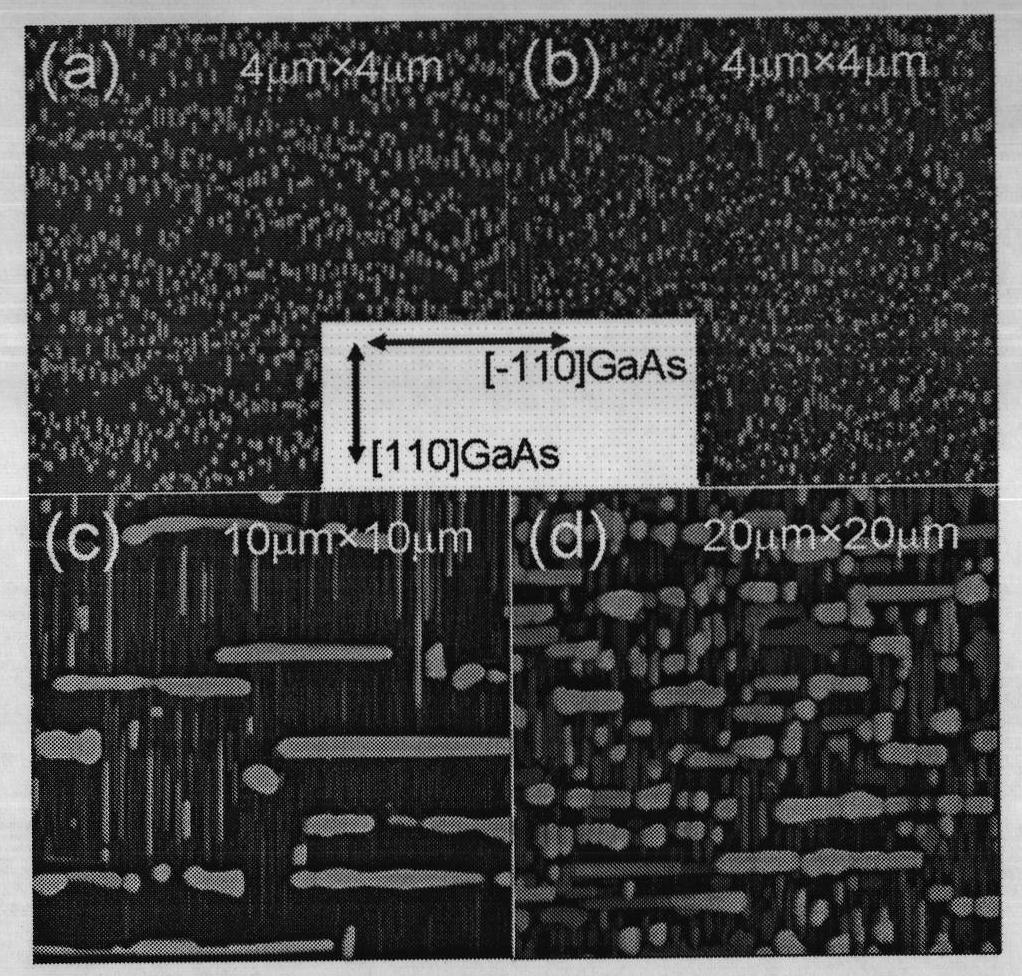

[0025] 2. In the growth chamber, increase the growth temperature to 20°C above the deoxidation temperature of GaAs(001) single crystal, and epitaxially grow a GaAs high-temperature buffer layer with a thickness of 200nm and above to improve the interface quality of heterogeneous growth; at 450-550°C , grow MnAs nanowires, keep As in the g...

Embodiment 1

[0030] 1. First, confirm that the MBE system is equipped with at least high-purity Mn source, Ga source, and As source (purity higher than 99.999%). Complete the growth preparation procedures of the MBE equipment: cut the GaAs(001) single crystal substrate in the ultra-clean room according to the requirements and adhere it to the sample stage with molten In; put the substrate together with the sample stage into the sample entry and exit chamber, The substrate and the sample stage are dehydrated and baked; the substrate and the sample stage are transferred to the buffer chamber, and the substrate and the sample stage are baked to remove organic impurities; the growth chamber is cooled with liquid nitrogen to improve the background Vacuum to 2×10 -10 Torr below.

[0031] 2. Transfer the substrate together with the sample stage to the growth chamber, increase the growth temperature to 20°C above the deoxidation temperature of the GaAs(001) single crystal substrate, and epitaxial...

Embodiment 2

[0035] In step 2, the growth temperature was controlled to 500° C., and the rest of the steps were the same as in Example 1. The morphology of the sample is characterized by figure 1 As shown in (b), the hysteresis loop is as Figure 4 (a) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com