Layered perovskite nanosheet, preparation method thereof, preferred orientation type layered perovskite ceramic material and preparation method of preferred orientation type layered perovskite ceramic material

A technology of perovskite type, ceramic material, applied in layered perovskite type nanosheet, its preparation, layered perovskite type ceramic material and its preparation field, can solve problems such as complex preparation process, achieve improved orientation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing layered perovskite nanosheets, comprising the following steps:

[0041] a), titanium source, bismuth source, iron source, calcium source and cobalt source are dissolved in a solvent to obtain a mixed solution;

[0042] b), the mixed solution is mixed with lye to obtain a suspoemulsion;

[0043] c), the suspoemulsion is crystallized to obtain a general formula of Bi 7-x Ca x Fe 3-y co y Ti 3 o 21 layered perovskite nanosheets;

[0044] Wherein, 0

[0045] In the preparation method of layered perovskite nanosheets provided by the present invention, firstly, titanium source, bismuth source, iron source, calcium source and cobalt source are dissolved in a solvent. In an embodiment provided by the present invention, the titanium source is tetrabutyl titanate; the bismuth source is one of bismuth nitrate, bismuth chloride, hydrates of bismuth nitrate and hydrates of bismuth chloride or multiple; the iron sourc...

Embodiment 1

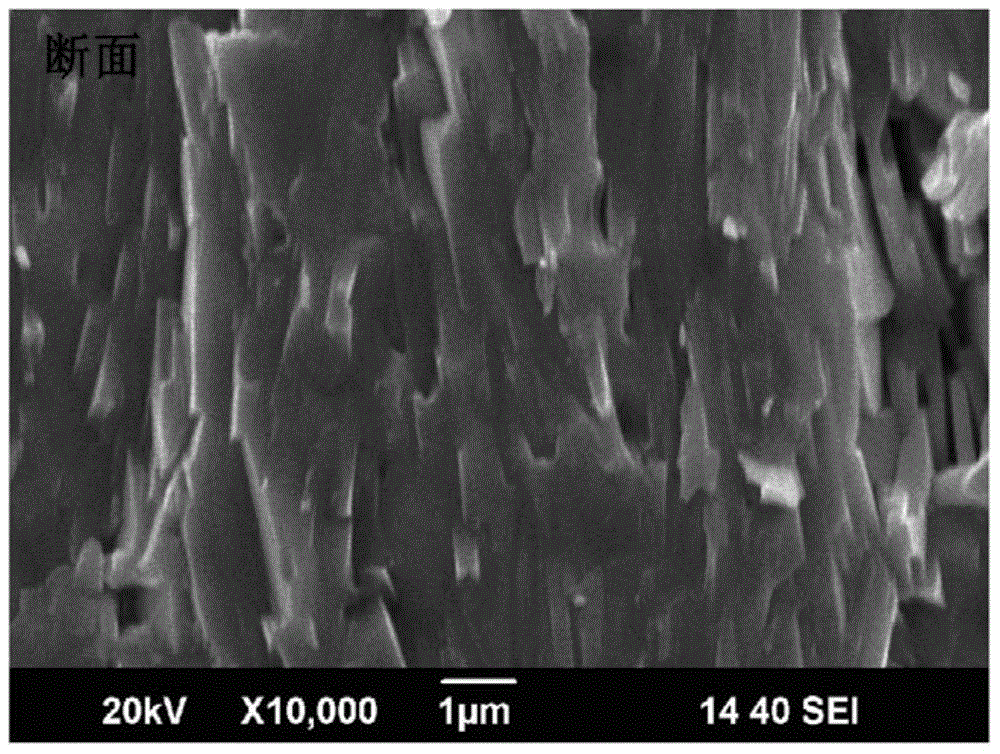

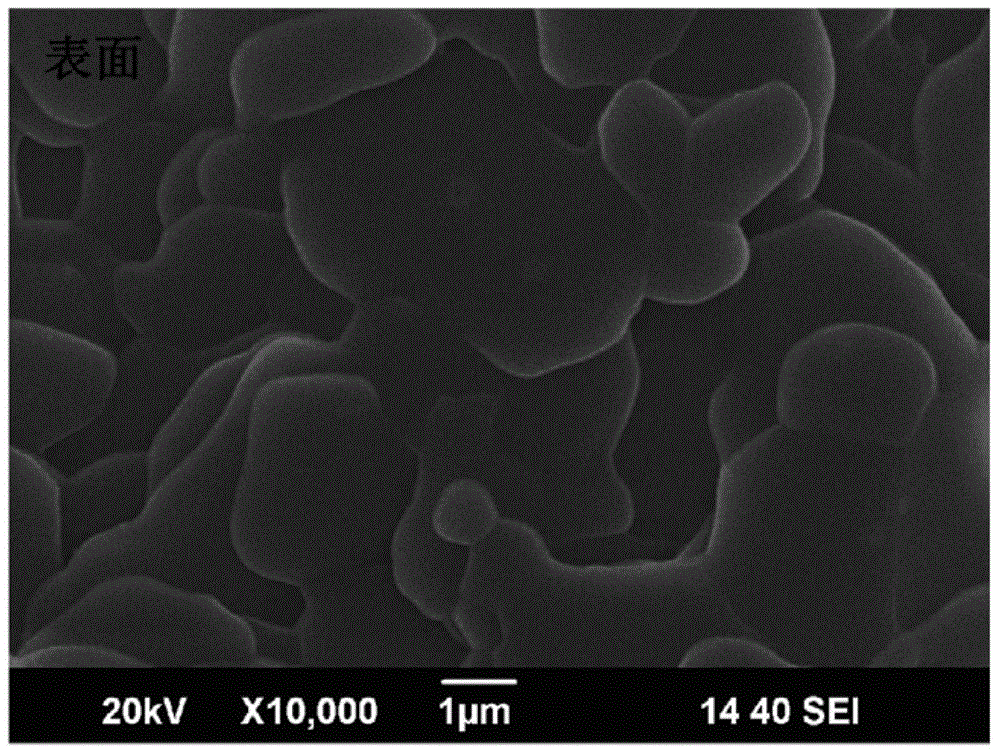

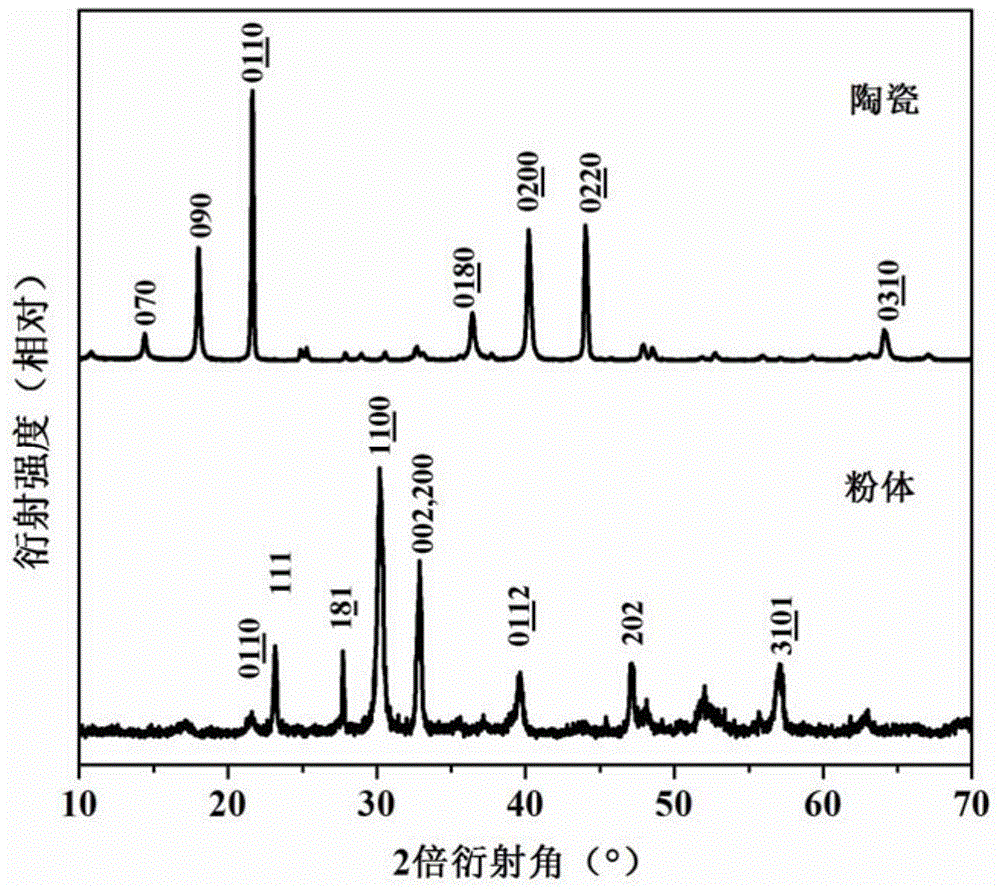

[0079] Weigh 1.503g tetrabutyl titanate, 4.927g bismuth nitrate pentahydrate, 0.035g calcium nitrate tetrahydrate, 1.189g ferric nitrate nonahydrate, and 0.428g cobalt nitrate hexahydrate, dissolve in 10mL of nitric acid with a concentration of 4M, and stir magnetically to form Homogenous mixed solution of metal ions. The metal ion mixed solution was added dropwise at a rate of 0.005 mL / s into 60 mL of 2M sodium hydroxide solution to form a uniform suspension. The suspension was transferred to a polytetrafluoroethylene liner with a volume of 100 mL, and then sealed in a stainless steel reaction kettle. Place it at 200°C for 48 hours, cool down to room temperature naturally, and then go through centrifugation, washing, and drying in sequence to obtain the general formula Bi 6.9 Ca 0.1 Fe 2 CoTi 3 o 21 nanosheet powder.

[0080] Take 0.35g of the above-mentioned powder, press it under an axial pressure of 10Mpa for 60s, and press it into a biscuit disc with a diameter of 1...

Embodiment 2

[0087] Weigh 1.390g tetrabutyl titanate, 4.556g bismuth nitrate pentahydrate, 0.032g calcium nitrate tetrahydrate, 1.237g ferric nitrate nonahydrate, and 0.297g cobalt nitrate hexahydrate, dissolve in 10mL of nitric acid with a concentration of 4M, and stir magnetically to form Homogenous mixed solution of metal ions. The metal ion mixed solution was added dropwise at a rate of 0.01 mL / s into 60 mL of 2M sodium hydroxide solution to form a uniform suspension. The suspension was transferred to a polytetrafluoroethylene liner with a volume of 100 mL, and then sealed in a stainless steel reaction kettle. Place it at 200°C for 48 hours, cool down to room temperature naturally, and then go through centrifugation, washing, and drying in sequence to obtain the general formula Bi 6.9 Ca 0.1 Fe 2.25 co 0.75 Ti 3 o 21 nanosheet powder.

[0088] Take 0.35g of the above-mentioned powder, press it under an axial pressure of 10Mpa for 120s, and press it into a biscuit disc with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com