Anisotropic rare-earth permanent magnet material and its magnetic powder and magnet mfg. method

An anisotropic and rare earth permanent magnet technology, which is applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of not having calendering anisotropy and not being able to prepare anisotropic calendering magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

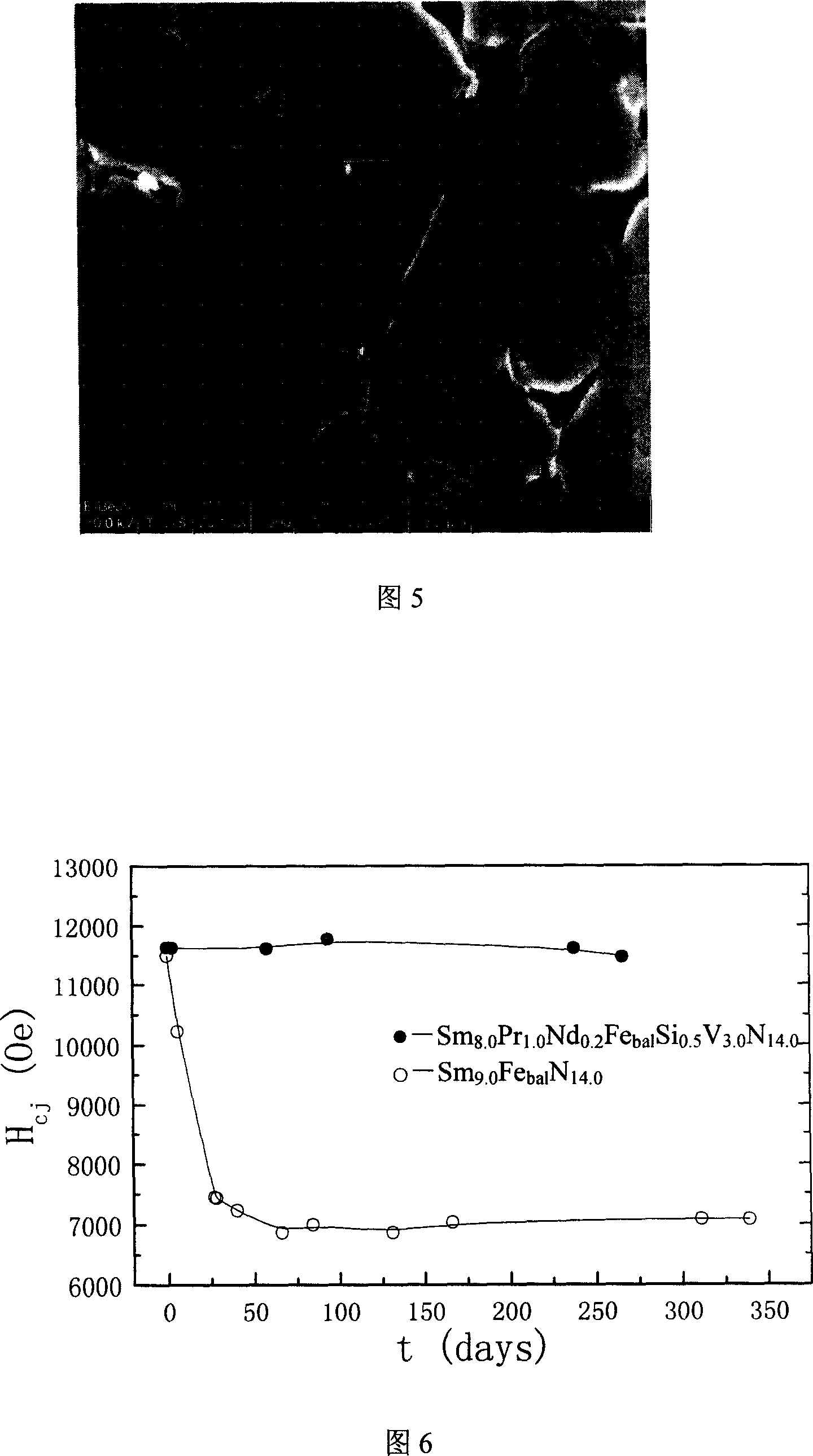

[0071] The composition of Sm, Pr, Fe, Si in the following list 1, the master alloy is prepared by quick-setting sheet technology, and then heat-treated in a nitrogen atmosphere, the treatment temperature is 450°-600°C (because the composition changes, the nitrogen absorption temperature should be adjusted appropriately , to ensure the best gas-solid phase reaction conditions under the corresponding components), and finally use a ball mill to powder, and the average particle size of the magnetic powder is 1.5 μm. The magnetic powder was stored in the atmosphere at room temperature (July 1st to November 1st), and Sm 2 Fe 17 N x The residual magnetic induction intensity of the type magnetic powder does not change much, but the coercive force is significantly attenuated, so the maximum magnetic energy product also changes. It can be seen from the comparison that the Sm-Pr-Fe-Si-N magnetic powder has excellent performance and stability.

[0072] Table 1.Sm 2 Fe 17 N x The res...

Embodiment 2

[0076] Carry out according to the step of embodiment 1 fully, with composition (Sm 1-α PR α ) 9.0 Fe bal Si 1.0 N 14.0 . Prepare magnetic powder, change the value of α, the dependence of permanent magnetic properties and α is shown in Table 2.

[0077] Table 2. Magnetic powder (Sm 1-α PR α ) 9.0 Fe bal Si 1.0 N 14.0 The change of permanent magnetic properties with α (stabilized performance)

[0078] α

Embodiment 3

[0080] Carry out according to the method and step of embodiment 1 fully, but with composition (Sm 0.9 PR 0.1 ) 9.0 Fe bal Si y N 14.0 Prepare magnetic powder, change the value of y, the dependence of permanent magnetic properties and y is shown in Table 3.

[0081] Table 3. (Sm 0.9 PR 0.1 ) 9.0 Fe balSi y N 14.0 Variation of magnetic powder properties with Si content y

[0082] y

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com