Anisotropic Z-type hexagonal ferrite and antenna using same

A hexagonal ferrite, anisotropic technology, applied in the direction of antenna, inorganic material magnetic, electrical components, etc., can solve the problem of using frequency limit, reduce antenna bandwidth, low impedance, etc., achieve high cut-off frequency, high dielectric constant , the effect of high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 (Ba 3 Co 2 Fe 24 O 41 )

[0015] The material uses metal oxides and carbonates with purity higher than 99% as raw materials, BaCO 3 , Co 2 O 3 And Fe 2 O 3 According to molecular formula weight ratio, using conventional ceramic technology, pre-sintering temperature 1180~1240℃, sintering temperature 1200~1280℃, adding trace Bi 2 O 3 And MnCO 3 Adjust (addition amount is 0.005~0.01% by weight), the real part of dielectric constant ε'is about 8~18, the real part of complex permeability μ'is about 5~10, in the frequency range of 100MHz~2G The imaginary part ε", μ" that can maintain the dielectric constant and permeability is small, that is, the loss of the Z-type ferrite is small, and the loss tangent angle is generally less than 0.06. Moreover, the present invention can also control the process and formula to make the anisotropic Z-type hexagonal ferrite reach a certain frequency

Embodiment 2

[0016] Example 2 (Using this material to design UHF RFID microstrip antenna)

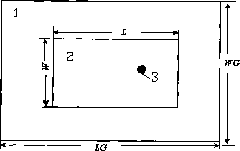

[0017] Using the process and material of Example 1 (anisotropic Z-type hexagonal ferrite ε′=17, μ′=7, tgδ ε =0.01, tgδ μ =0.05) Manufacturing UHF RFID microstrip antenna for magnetic substrate, the antenna structure is as figure 1 with figure 2 As shown in the figure, 1 is the grounding plate, 2 is the rectangular patch, 3 is the feed point, 4 is the anisotropic Z-shaped hexagonal ferrite, and 5 is the feed probe; patch size L=16mm, W= 18mm, the ground plate LG=WG=30mm.

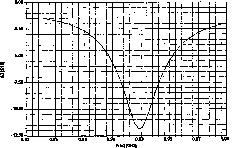

[0018] The resulting antenna S 11 Curve like image 3 (Antenna bandwidth (S 11 <-10dB) is 918MHz~939MHz); the antenna gain is about 1.76dBi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com