High-corrosion-resistance multi-hard-magnetic-principal-phase Ce permanent magnet and preparation method thereof

A permanent magnet, multi-hard magnetic technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

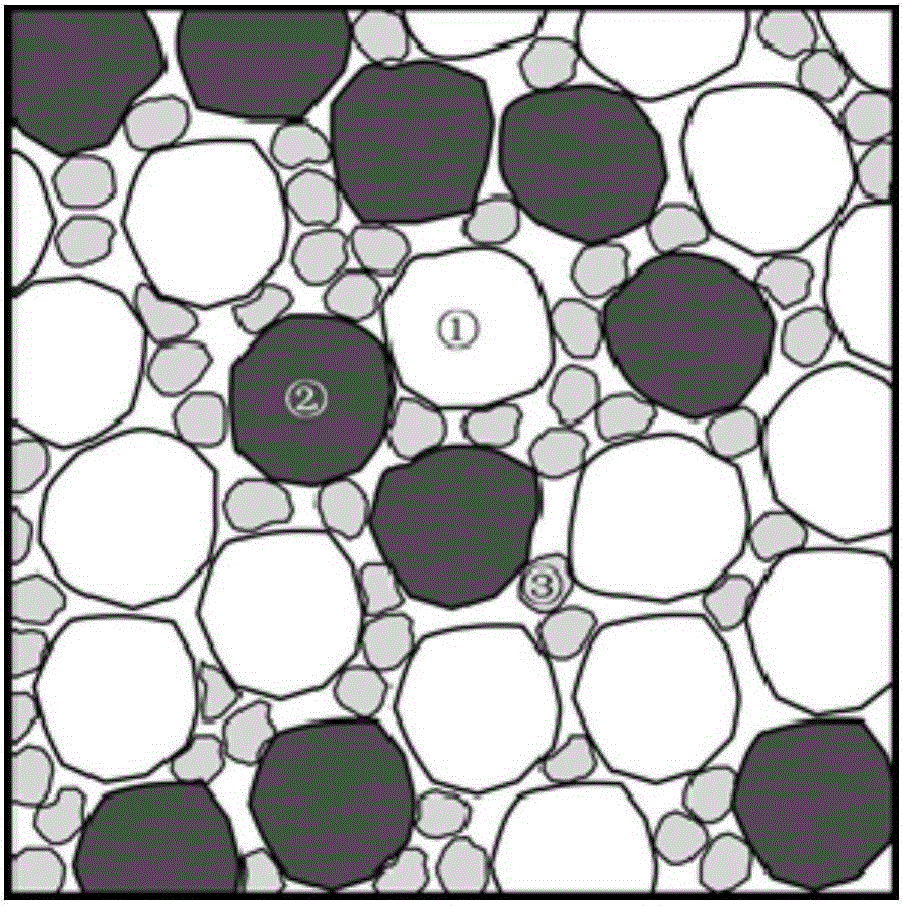

[0074] The invention provides a high corrosion resistance, multi-main phase Ce permanent magnet preparation method, according to the performance requirements of the multi-hard magnetic main phase Ce-Fe-B permanent magnet alloy, design the main phase with different k values (anisotropy constants) Alloy, so as to determine the phase structure composition of Ce-Fe-B permanent magnets with different multi-hard magnetic main phases, such as multi-phase permanent magnets composed of Ce-Fe-B and Nd-Fe-B, Pr-Fe-B, Dy-Fe-B Hard magnetic main phase structure, or multiple hard magnetic main phases composed of (Pr, Ce)-Fe-B and Nd-Fe-B, (Pr, Dy)-Fe-B, (Ho, Gd)-Fe-B Structure; in the final magnet, Ce is the rare earth element with the most content in terms of mass percentage, and 0% to 75% of the total rare earth content is replaced by one or both of La, Nd, Pr, Dy, Ho, Gd, Er One or more mixed rare earth substitutes. The method comprises the following process steps:

[0075] (1) A var...

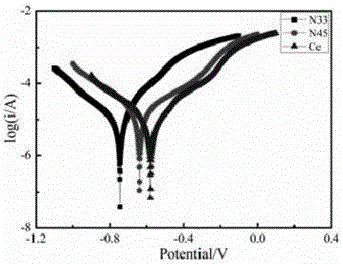

Embodiment 1

[0089] Embodiment 1-is Ce-Fe-B / Nd-Fe-B / Dy-Fe-B three hard magnetic main phase structure

[0090] Design composition (Ce 0.5 Nd 0.45 PR 0.05 ) 29 Fe 68.1 B 0.9 tm 2 (TM = Ga, Co, Cu, Nb).

[0091] (1) According to the alloy mass percentage composition Ce 29 Fe 68.15 B 0.85 tm 2 ,Nd 28.5 Fe 68.6 B 0.9 tm 2 and Dy 29.1 Fe 68.9 B 1 tm 2 Prepare raw materials separately.

[0092] (2) Melt the prepared raw materials separately. First put the raw materials into the quick-setting crucible of the intermediate frequency induction melting furnace, and when the vacuum degree reaches 10 -2 When the Pa is above, power on and preheat, and wait until the vacuum degree reaches 10 again. -2 When the Pa exceeds Pa, stop vacuuming and fill with high-purity Ar to make the Ar pressure in the furnace reach 0.08MPa for smelting. After all the raw materials are melted, they are refined by electromagnetic stirring, and then the molten steel is cast on a water-cooled copper roller ...

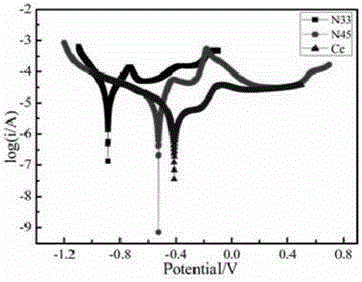

Embodiment 2

[0099] Example 2 - (La, Ce, Nd)-Fe-B / Nd-Fe-B / (Ho, Dy, Pr, Nd)-Fe-B three main phase structure

[0100] Equivalent composition (Ce 0.45 La 0.05 Nd 0.3 PR 0.15 Ho 0.02 Dy 0.03 ) 30 Fe 68.39 B 0.94 tm 0.67 (TM = Ga, Co, Cu, Nb).

[0101] (1) According to mass percentage (La 0.08 Ce 0.75 Nd 0.05 PR 0.12 ) 30 Fe 68.4 B 0.9 tm 0.7 、Nd 30 Fe 68.3 B 1.1 tm 0.6 and (Ho 0.15 Dy 0.25 Nd 0.4 PR 0.2 ) 30 Fe 68.4 B 1 tm 0.6 Prepare raw materials separately.

[0102] (2) Melt the prepared raw materials separately. First put the raw materials into the quick-setting crucible of the intermediate frequency induction melting furnace, and when the vacuum degree reaches 10 -2 When the Pa is above, power on and preheat, and wait until the vacuum degree reaches 10 again. -2 After Pa is above, stop vacuuming and fill high-purity Ar to make the Ar pressure in the furnace reach 0.08Mpa for smelting. After all the raw materials are melted, electromagnetic stirring is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com