Pressing mold for manufacturing amplitude/multi-polar oriented whole permanent magnetic ring

A technology for pressing molds and permanent magnetic rings, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., and can solve problems such as complex magnetic structure, inconvenient installation, single-orientation orientation or multi-pole orientation magnetic field, etc. Achieve the effect of simplifying the magnetic conduction structure, convenient installation and excellent magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

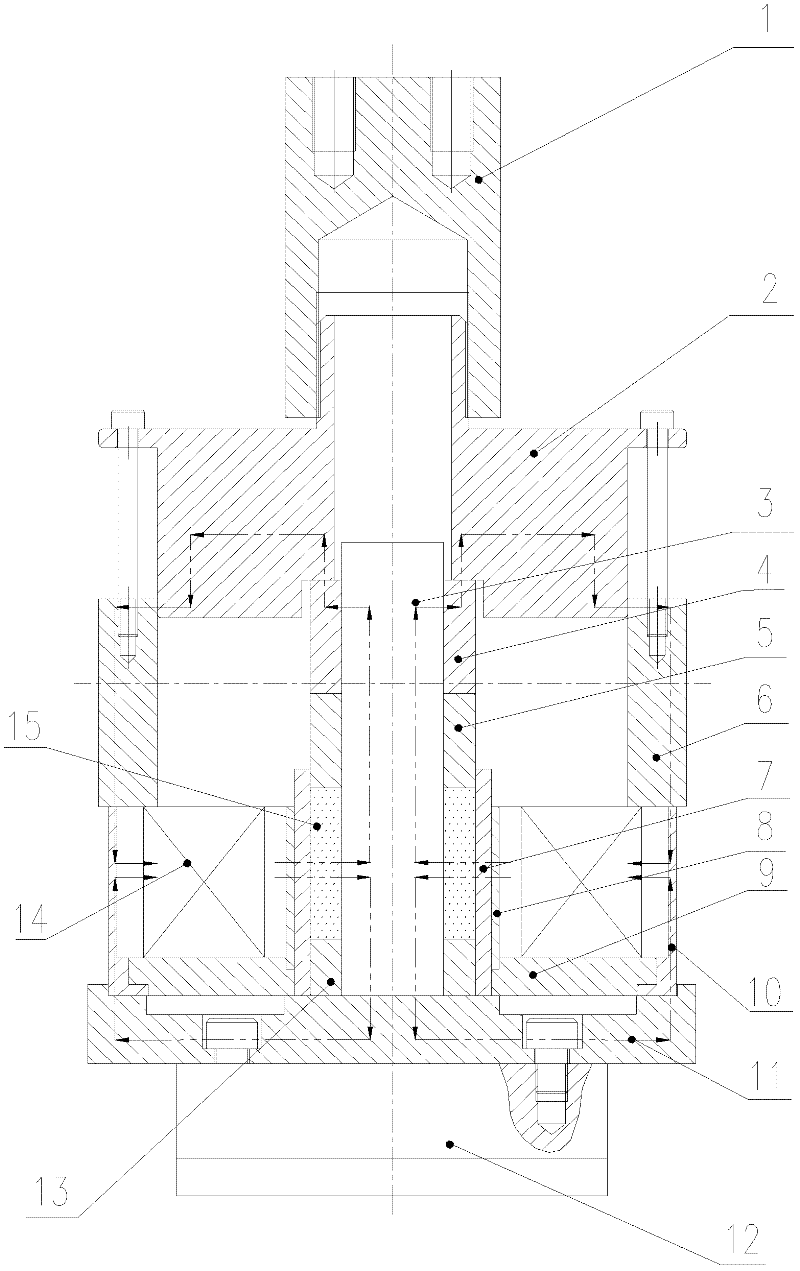

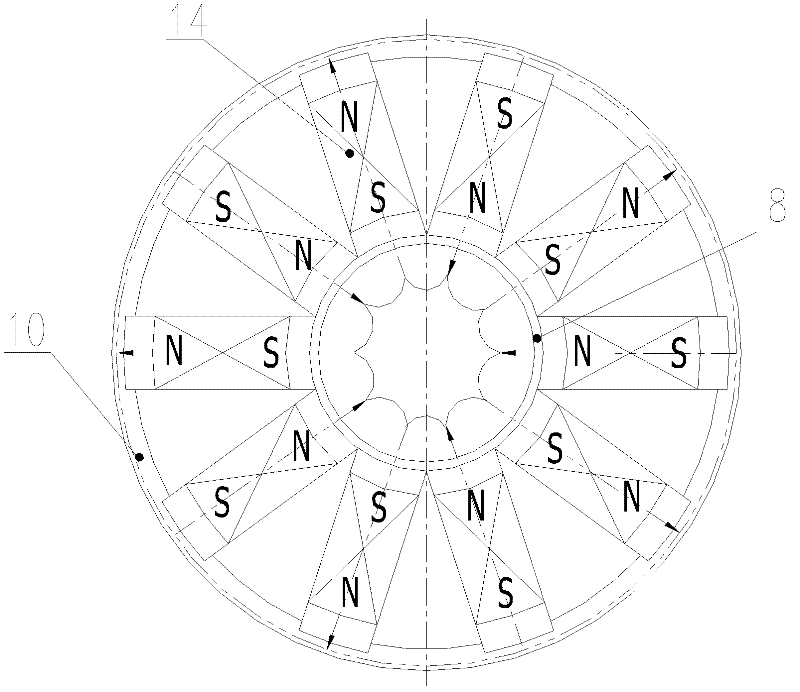

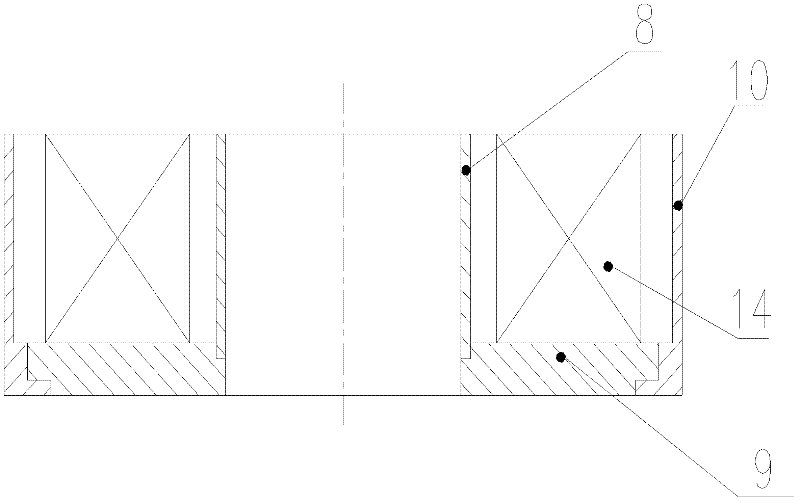

[0030] see figure 1 , figure 2 and image 3 , the pressing mold of the radial or multi-pole oriented integral permanent magnet ring according to the present invention includes a pressing part and a part for generating a radial or multi-polar oriented magnetic field. There is enough clearance between the pressing upper ram 2 and the core rod 3, the magnetically permeable upper die 4 and the non-magnetically permeable upper die 5, which is convenient for adjustment when installing the mould. There are through holes around the upper end of the pressing upper head 2, and the bolts are fixed to press the upper sleeve 6. Through the through holes, the pressing upper pressing head 2 is covered with an upper sleeve 6, and the pressing upper pressing head 2 can be opposite to the upper sleeve. 6 moves up and down to ensure that during the pressing process, the pressing upper sleeve 6 and the pressing upper head 2 are always in contact. The upper end surface of the female mold 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com