Optimization process method for preparing high-coercivity permanent magnet by adding heavy rare earth hydroxide into neodymium iron boron

A technology with high coercive force and processing method, which is applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the limited range of sintered NdFeB coercive force improvement and the magnetic orientation arrangement of difficult magnetic powder , affect the performance of magnets and other issues, to achieve the effect of improving local coercive force, high hydrogenation saturation, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

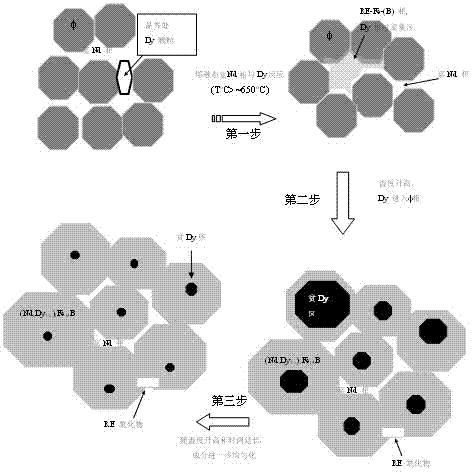

[0075] Example 1: Place the heavy rare earth Dy in a vacuum furnace and pass through hydrogen, the hydrogen pressure is 8bar, heated to 450 ° C, and cooled naturally to obtain the hydride of Dy, and the hydrogenation of Dy is carried out under the protective atmosphere of nitrogen, argon or helium Put the particles into cyclohexane for ball milling to obtain 3-7 μm micropowders, and then move them into an oxygen-free glove box under the protective atmosphere of nitrogen, argon or helium to dry. Under the protective atmosphere of nitrogen, argon or helium, mix the Nd16Fe76B8 hydrogen explosion micropowder with the average particle size of 10μm and the hydride micropowder of heavy rare earth Dy. The atomic percentage of the hydride micropowder of heavy rare earth Dy in the mixed micropowder is 3at.%. , the mixed micropowder after powder mixing is sealed in a rubber mold, and it is magnetized by a small frequency alternating reverse magnetic field pulse and isostatically pressed a...

Embodiment 2

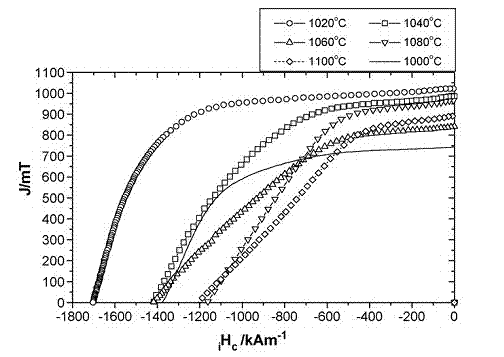

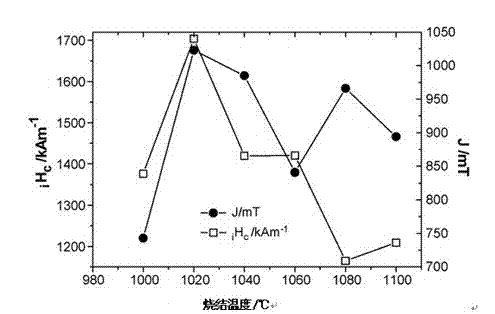

[0077] Example 2: The heavy rare earth Dy was placed in a hydrogen environment of 8 bar, heated to 450° C. in a vacuum furnace, and cooled naturally to obtain Dy hydride. Put the crude heavy rare earth Dy hydride particles into cyclohexane for ball milling to obtain 3-7 μm micropowder, then move it into a glove box for drying, and pass in argon gas to prevent oxidation. Under the protective atmosphere of argon, the ball-milled Nd13.5Fe79.75B6.75 hydrogen explosion micropowder is mixed with the hydride micropowder of heavy rare earth Dy, and the hydride micropowder of heavy rare earth Dy accounts for 0 at.% of the mixed micropowder respectively , 1 at.%, 2 at.%, 3 at.%, 4 at.%, it is best to make the heavy rare earth hydride fine powder accounts for the atomic percentage of the mixed fine powder is 1at% ~ 3at%, the mixed fine powder after the mixed powder Enclosed in a rubber mold, magnetized by a small frequency alternating reverse magnetic field pulse and isostatically presse...

Embodiment 3

[0079] Example 3: The heavy rare earth Tb was placed in a hydrogen environment of 8 bar, heated to 450° C. in a vacuum furnace, and cooled naturally to obtain a hydride of Tb. Put the crude Tb hydride particles into cyclohexane for ball milling to obtain 3-7 μm micropowder, then move it into a glove box for drying, and pass through argon gas to prevent oxidation. Under the protective atmosphere of argon, the ball-milled Nd13.5Fe79.75B6.75 hydrogen explosion micropowder is mixed with the hydride micropowder of heavy rare earth Tb, and the atomic percentage of the hydride micropowder of heavy rare earth Tb in the mixed micropowder is (a): 0 at.%; (b):1 at.%; (c):2 at.%; (d):3 at.%; (e):4 at.% , seal the mixed fine powder into rubber In the mold, it adopts small-frequency alternating reverse magnetic field pulse magnetization and isostatic pressing at room temperature. The magnetic field strength is 4.5T and the pressure is 1200kgcm -2 , to get about 50% of the density of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com