Method for reparative regeneration of lithium cobalt oxide anode material in waste batteries

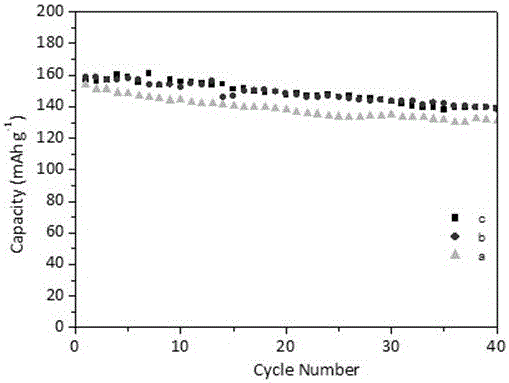

A technology for positive electrode materials and waste batteries, which is applied in the field of lithium cobalt oxide positive electrode material repair and regeneration, can solve the problems of high equipment investment requirements, high environmental protection pressure, high cost, etc., to improve charge and discharge stability and cycle performance, improve separation degree, The effect of preventing aluminum foil from breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

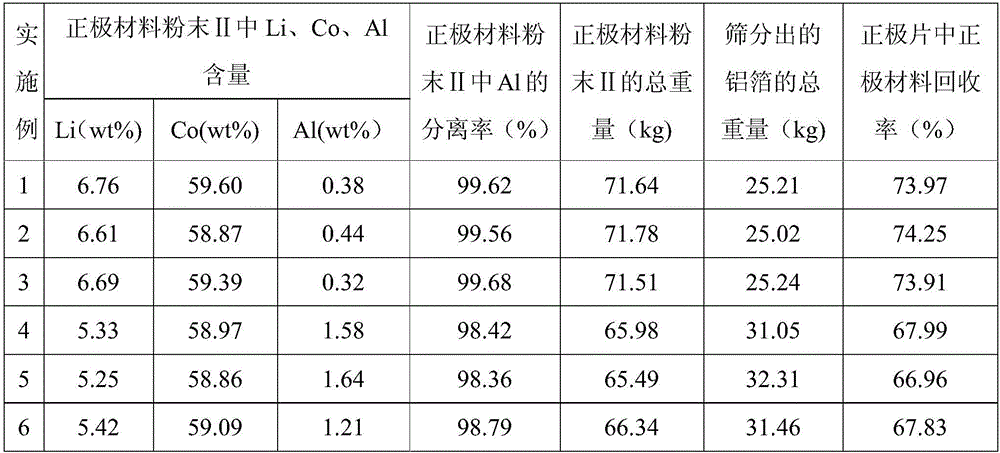

Embodiment 1

[0029] Step 1, clean the surface of the used lithium-ion battery, discharge the battery in a sodium chloride solution, and classify it according to the positive electrode material specifications lithium cobaltate, nickel-cobalt-manganese ternary material, lithium manganate, lithium iron phosphate, etc. Sorting lithium cobalt oxide batteries;

[0030] Step 2, cleanly disassemble the lithium cobalt oxide battery classified above, and sort out the positive electrode, electrolyte, negative electrode, and shell. The specific operation is to first cut the battery, take out the battery, and then put the battery positive Classification of poles and diaphragms;

[0031] Step 3, take 100Kg of the above-mentioned sorted positive pole pieces and spread them on the high-temperature resistant mesh belt with a thickness of 5cm, and control the mesh belt to vibrate continuously at a frequency of 50Hz through the mesh belt vibrator. The vibration motor of the vibrator adopts a frequency conver...

Embodiment 2

[0039] Step 1, clean the surface of the used lithium-ion battery, discharge the battery in a sodium chloride solution, and classify it according to the positive electrode material specifications lithium cobaltate, nickel-cobalt-manganese ternary material, lithium manganate, lithium iron phosphate, etc. Sorting lithium cobalt oxide batteries;

[0040] Step 2, cleanly disassemble the lithium cobalt oxide battery classified above, and sort out the positive electrode, electrolyte, negative electrode, and shell. The specific operation is to first cut the battery, take out the battery, and then put the battery positive Classification of poles and diaphragms;

[0041] Step 3, take 100Kg of the above-mentioned sorted positive pole piece and spread it on the high temperature resistant mesh belt with a thickness of 1cm, and control the mesh belt to vibrate continuously at a frequency of 5Hz through the mesh belt vibrator. 0.75Kw, the motor operating frequency is 5Hz; at the same time, ...

Embodiment 3

[0049] Step 1, clean the surface of the used lithium-ion battery, discharge the battery in a sodium chloride solution, and classify it according to the positive electrode material specifications lithium cobaltate, nickel-cobalt-manganese ternary material, lithium manganate, lithium iron phosphate, etc. Sorting lithium cobalt oxide batteries;

[0050] Step 2, cleanly disassemble the lithium cobalt oxide battery classified above, and sort out the positive electrode, electrolyte, negative electrode, and shell. The specific operation is to first cut the battery, take out the battery, and then put the battery positive Classification of poles and diaphragms;

[0051] Step 3, take 100Kg of the above-mentioned sorted positive pole piece and spread it on the high-temperature resistant mesh belt with a thickness of 3cm, and control the mesh belt to vibrate continuously at a frequency of 25Hz through the mesh belt vibrator. The vibration motor of the vibrator adopts a frequency conversio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com