Castable for large steel ladle

A ladle casting, large-scale technology, applied in the field of ladle castables, can solve the problems of a lot of solid waste, high labor intensity, and high resource consumption, and achieve the effects of improving durability, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

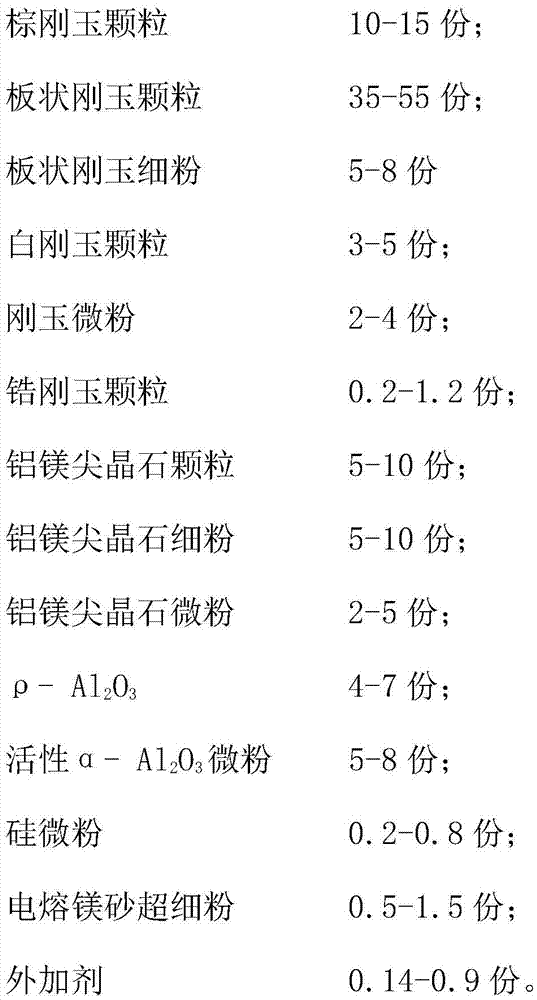

Method used

Image

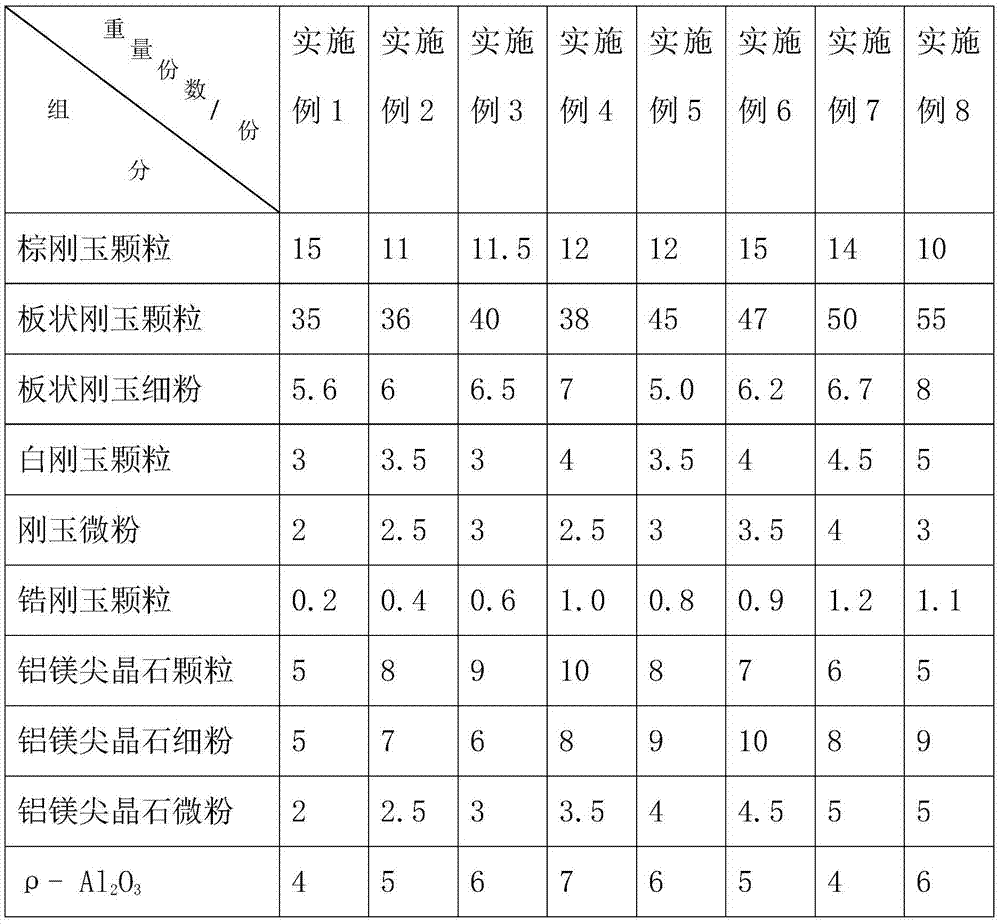

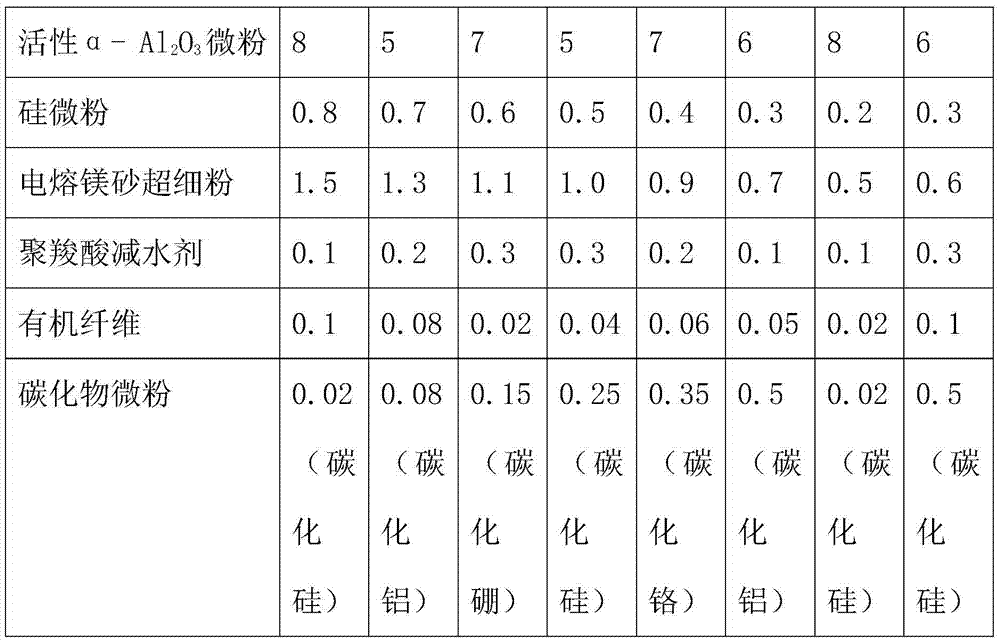

Examples

Embodiment Construction

[0019] In order to better understand the purpose, features, and effects of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

[0020] At first, the technical parameter of each component in the embodiment is described as follows:

[0021] The fine carbide powder is more than one of aluminum carbide, silicon carbide, boron carbide and chromium carbide, and the particle diameter of the carbide fine powder is 2-5 microns.

[0022] The particle size of the brown corundum particles is 20-30 mm, the particle size of the plate-shaped corundum particles is 0-6 mm, the particle size of the plate-shaped corundum fine powder is 0.045 mm, and the particle size of the white corundum particles is diameter of 5-8 mm, the particle size of the corundum powder is 5 microns, and the particle size of the zirconium corundum particles is 0.1-0.5 mm

[0023] Al in the Al-Mg spinel particles, the Al-Mg spinel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com