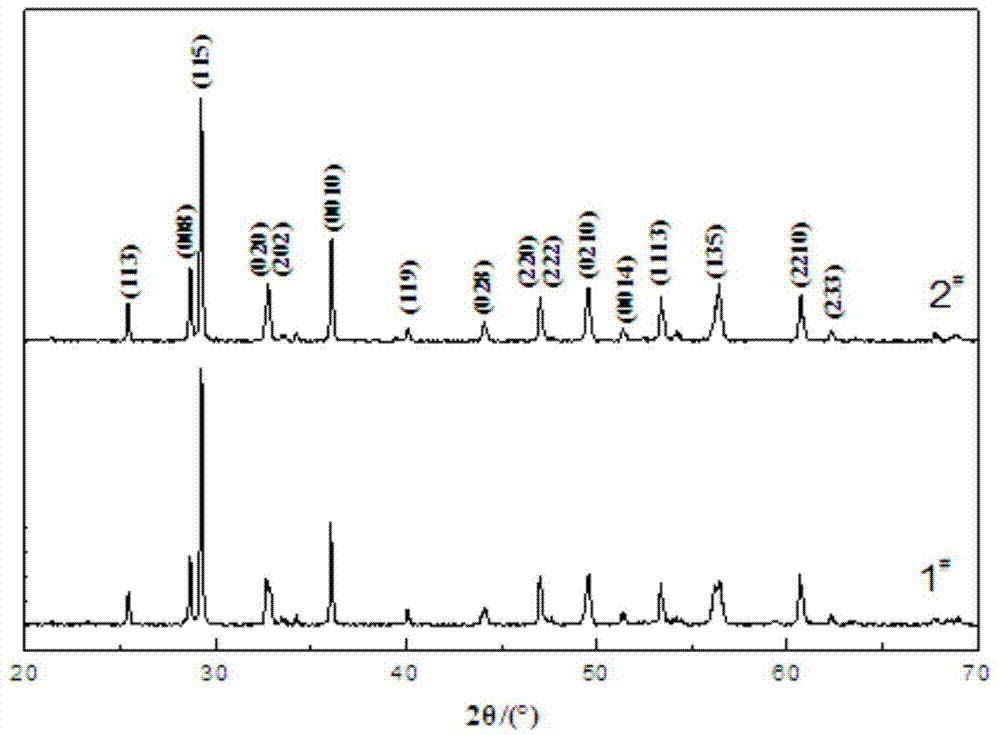

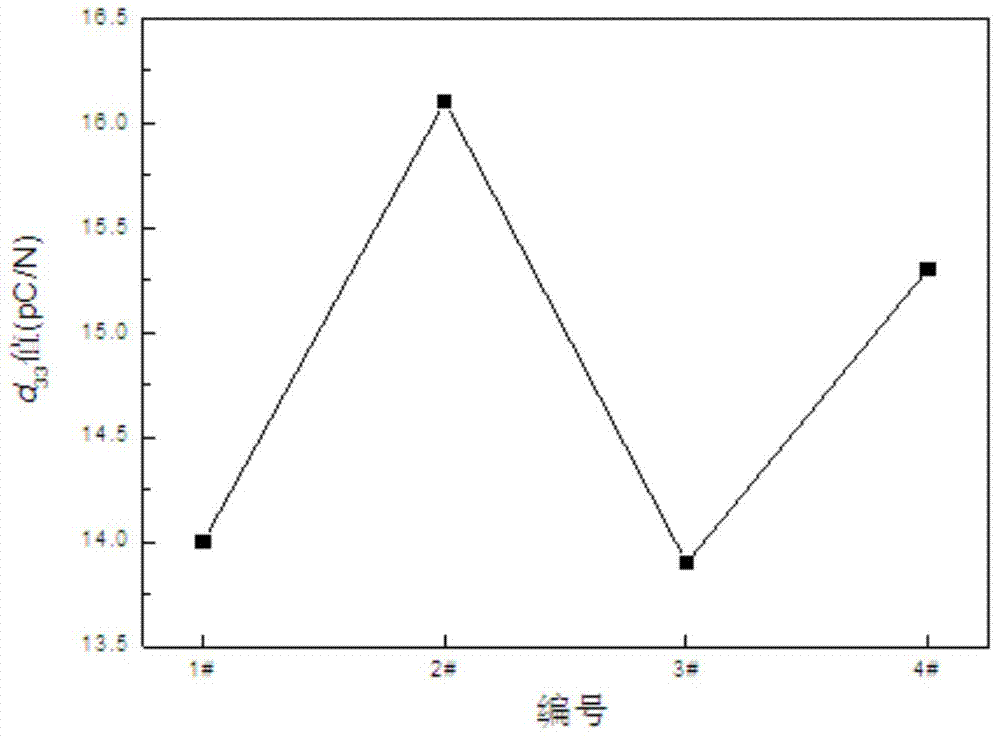

Lithium, cerium, tungsten (Li, Ce, W) co-doped bismuth calcium niobate (CBN)-based piezoelectric ceramic material and preparation method thereof

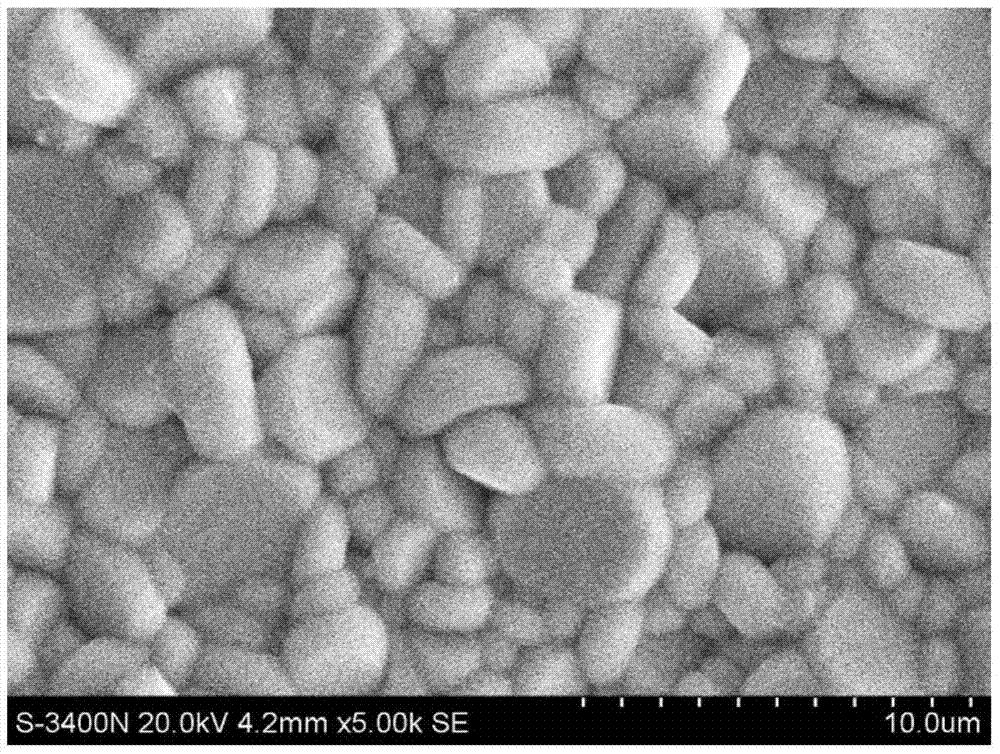

A bismuth-calcium niobate-based, bismuth-calcium niobate technology, applied in the field of materials science and engineering, to achieve the effects of improving piezoelectric performance, uniform crystal grains, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of bismuth niobate calcium-based ceramic powder

[0037] According to the general formula Ca 0.92 (Li, Ce) 0.04 Bi 2 Nb 1.99 W 0.01 O 9 (X=0.08, Y=0.01) for weighing and batching, with absolute ethanol as the dispersion medium, the raw materials and absolute ethanol are mixed in a mass ratio of 1:1.5, placed in a polyurethane ball mill, and ball milled with a planetary ball mill for 12h , the rotating speed is 400rpm, bake under the baking lamp for 2h, and then continuously heat up to 850℃ in the programmed temperature box furnace, and keep the temperature for 2h to obtain the calcium bismuth niobate-based ceramic powder;

[0038] (2) Secondary ball milling

[0039] The above-mentioned calcium bismuth niobate-based ceramic powder and dispersion medium absolute ethanol were mixed at a mass ratio of 1:1.5, placed in a polyurethane ball mill, and milled with a planetary ball mill for 12 hours at a rotational speed of 400 rpm, and baked under a drying la...

Embodiment 2

[0047] According to the general formula Ca 0.92 (Li, Ce) 0.04 Bi 2 Nb 1.96 W 0.04 O 9 (X=0.08, Y=0.04) for weighing and batching, with absolute ethanol as the dispersion medium, the raw materials and absolute ethanol are mixed at a ratio of 1:1.5, placed in a polyurethane ball mill, and ball milled with a planetary ball mill for 12h, The rotating speed is 400 rpm, and it is baked under a baking lamp for 2 hours, and then continuously heated to 850° C. in a programmed temperature-controlled box furnace, and kept for 2 hours to obtain a calcium bismuth niobate-based ceramic powder;

[0048] (2) Secondary ball milling

[0049] The above-mentioned calcium bismuth niobate-based ceramic powder and dispersion medium absolute ethanol were mixed at a mass ratio of 1:1.5, placed in a polyurethane ball mill, and milled with a planetary ball mill for 12 hours at a rotational speed of 400 rpm, and baked under a drying lamp for 2 hours. to dry;

[0050] (3) Granulation and tableting ...

Embodiment 3

[0057] (1) Preparation of bismuth niobate calcium-based ceramic powder

[0058] According to the general formula Ca 0.92 (Li, Ce) 0.04 Bi 2 Nb 1.97 W 0.03 O 9 (X=0.08, Y=0.03) for weighing and batching, with absolute ethanol as the dispersion medium, the raw materials and absolute ethanol are mixed at a mass ratio of 1:1.5, placed in a polyurethane ball mill, and ball milled with a planetary ball mill for 12h , the rotating speed is 400rpm, bake under the baking lamp for 2h, and then continuously heat up to 850°C in a programmed temperature-controlled box furnace, and keep the temperature for 2h to obtain the calcium bismuth niobate-based ceramic powder;

[0059] (2) Secondary ball milling

[0060] The above-mentioned calcium bismuth niobate-based ceramic powder and dispersion medium absolute ethanol were mixed at a mass ratio of 1:1.5, placed in a polyurethane ball mill, and milled with a planetary ball mill for 12 hours at a rotational speed of 400 rpm, and baked under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com