Positive electrode active material, positive electrode, battery, and production method for lithium ion secondary battery

A positive electrode active material and secondary battery technology, applied in active material electrodes, electrode manufacturing, secondary batteries, etc., can solve the problem of failing to obtain sufficient discharge capacity, and achieve excellent cycle characteristics and rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

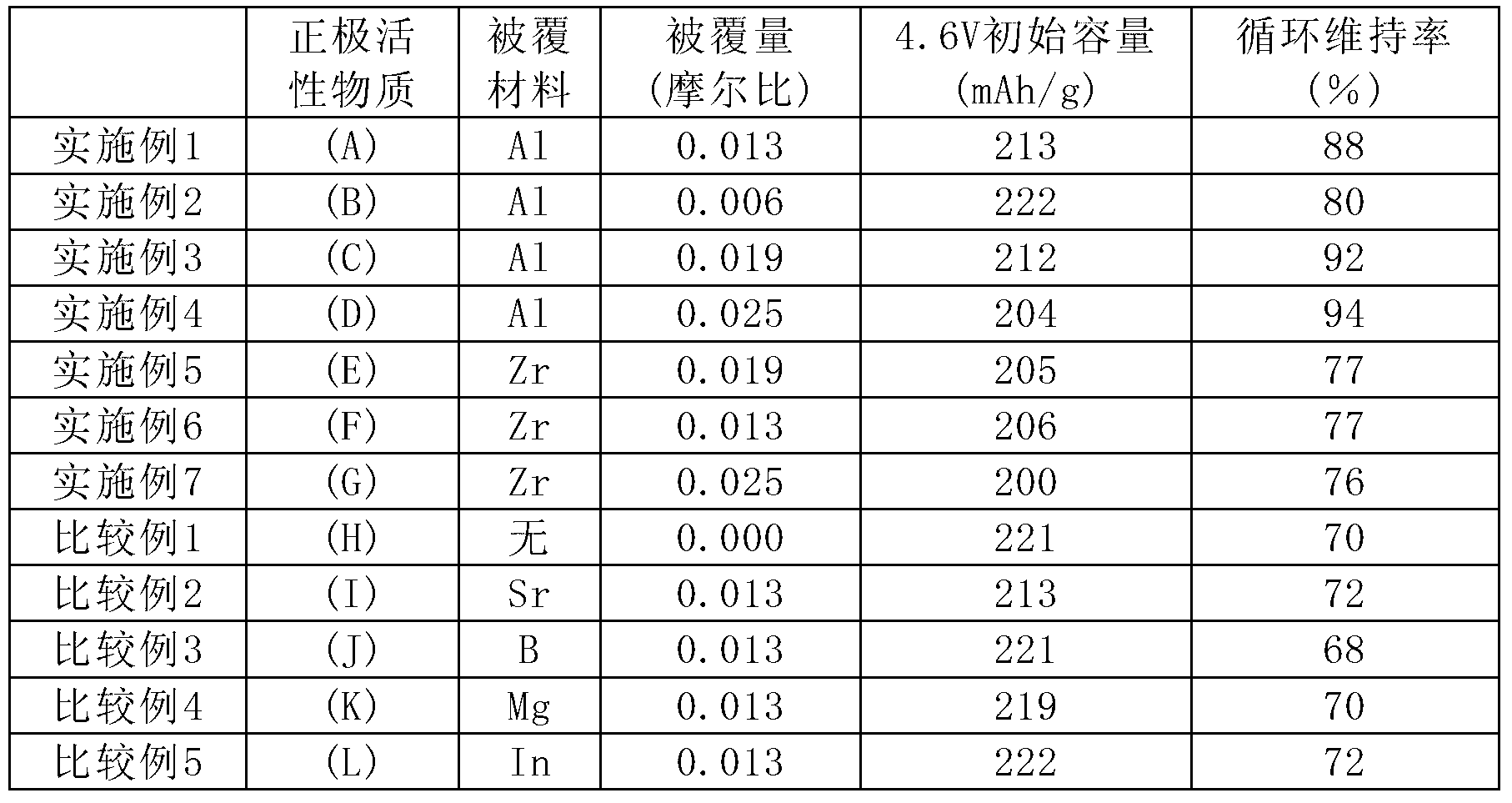

Examples

Embodiment 1

[0118] Al 2 o 3 2.98 g of distilled water was added to 7.02 g of an aqueous basic aluminum lactate solution in terms of 8.5% by mass to obtain an aqueous Al solution (composition (1)).

[0119] 1.0 g of the composition (1) was added by spraying to 10 g of the lithium-containing composite oxide of the example, and brought into contact with the lithium-containing composite oxide of the example and the composition (1) while being mixed. Next, after drying the resulting mixture at 90° C. for 2 hours, it was heated at 450° C. for 8 hours in an oxygen-containing atmosphere to obtain the positive electrode active material (A) of Example 1, which was composed of an oxide of Al element (I) Composition of particles (II) concentrated on the surface of the lithium-containing composite oxide.

[0120] The metal element (coating material) aluminum of the composition (1) contained in the positive electrode active material (A) is relative to the sum of the transition metal elements nickel, ...

Embodiment 2~4

[0122] Except that the amount of the sprayed composition (1) is set to 0.5g, 1.5g, and 2.0g respectively, the operation is carried out in the same manner as in Example 1 to obtain positive electrode active materials (B) to (D), and the positive electrode active material ( B) to (D) consist of particles (II) in which the oxide (I) of the Al element is concentrated on the surface of the lithium-containing composite oxide.

[0123] The metal element (coating material) aluminum of the composition (1) contained in the positive electrode active material (B) to (D) is relative to the sum of the transition metal elements nickel, cobalt, and manganese of the lithium-containing composite oxide of the embodiment in moles The ratio (coating amount) {(the number of moles of Al) / (the total number of moles of Ni, Co, and Mn)} was 0.006, 0.019, and 0.025, respectively. The cross sections of the powders of the obtained positive active materials (B) to (D) were embedded with resin, ground with ...

Embodiment 5

[0125] In zirconium content as ZrO 2 Converted to 20.7% by mass of ammonium zirconium carbonate (chemical formula: (NH 4 ) 2 [Zr(CO 3 ) 2 (OH) 2 ]) 3.03 g of distilled water was added to 6.97 g of the aqueous solution to prepare a Zr aqueous solution (composition (2)).

[0126] Next, 1.5 g of the composition (2) was spray-added to 10 g of the lithium-containing composite oxide of the example being stirred, and the lithium-containing composite oxide of the example and the composition (2) were brought into contact while being mixed. Next, after drying the obtained mixture at 90° C. for 2 hours, it was heated at 450° C. for 5 hours in an oxygen-containing atmosphere to obtain a positive electrode active material (E), which was concentrated from an oxide (I) of the Zr element. Particles (II) constitute the surface of the lithium-containing composite oxide.

[0127] The metal element (coating material) zirconium of the composition (2) contained in the positive electrode activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com