A high magnification spherical lithium iron phosphate carbon composite positive electrode material and a preparation method thereof

A technology of lithium iron phosphate and positive electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of low conductivity of materials, insufficient cracking reaction of organic gases, and unfavorable uniform coating of carbon and other problems, to achieve the effect of improving electrical conductivity, fine grain size and good crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

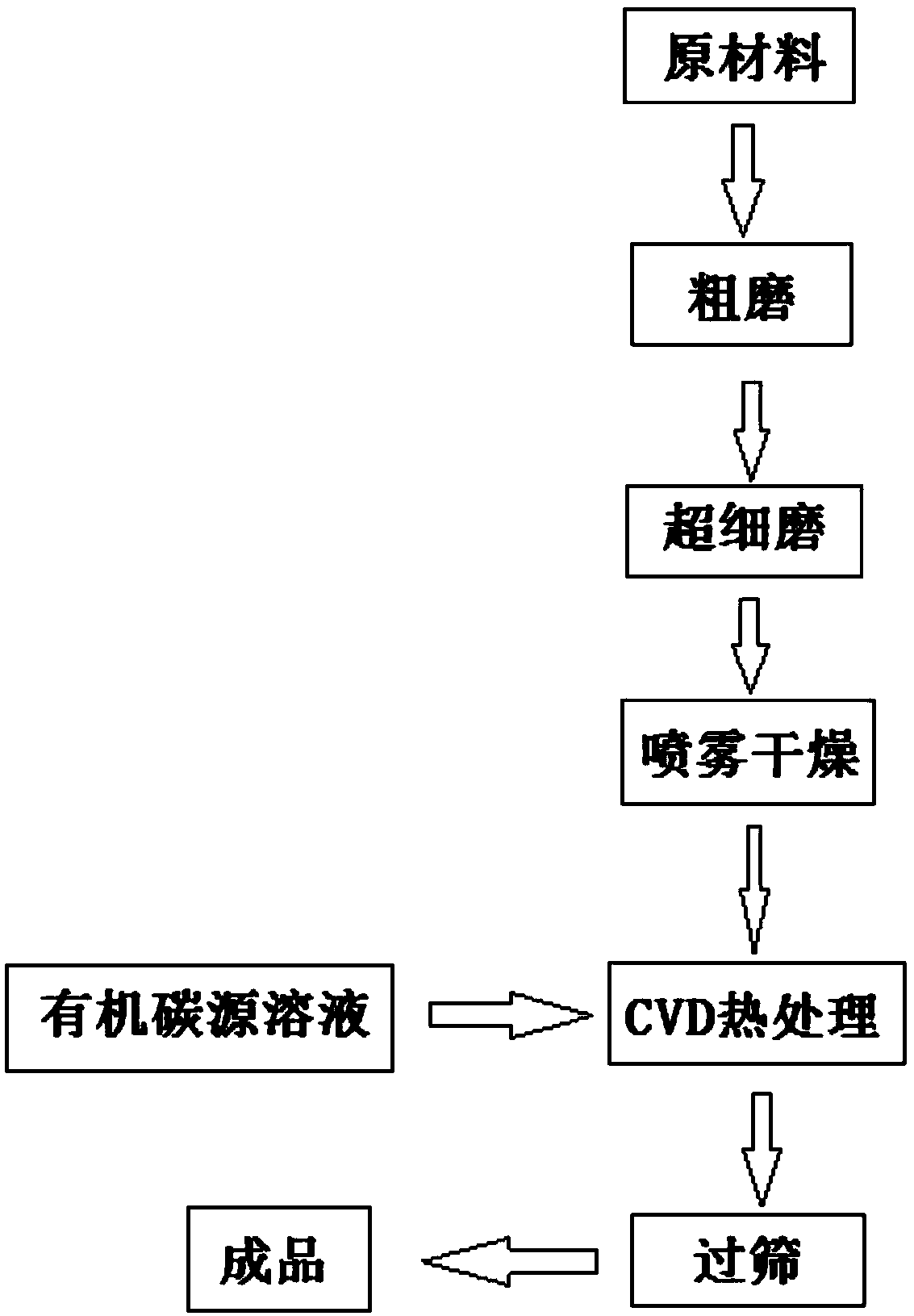

Method used

Image

Examples

Embodiment 1

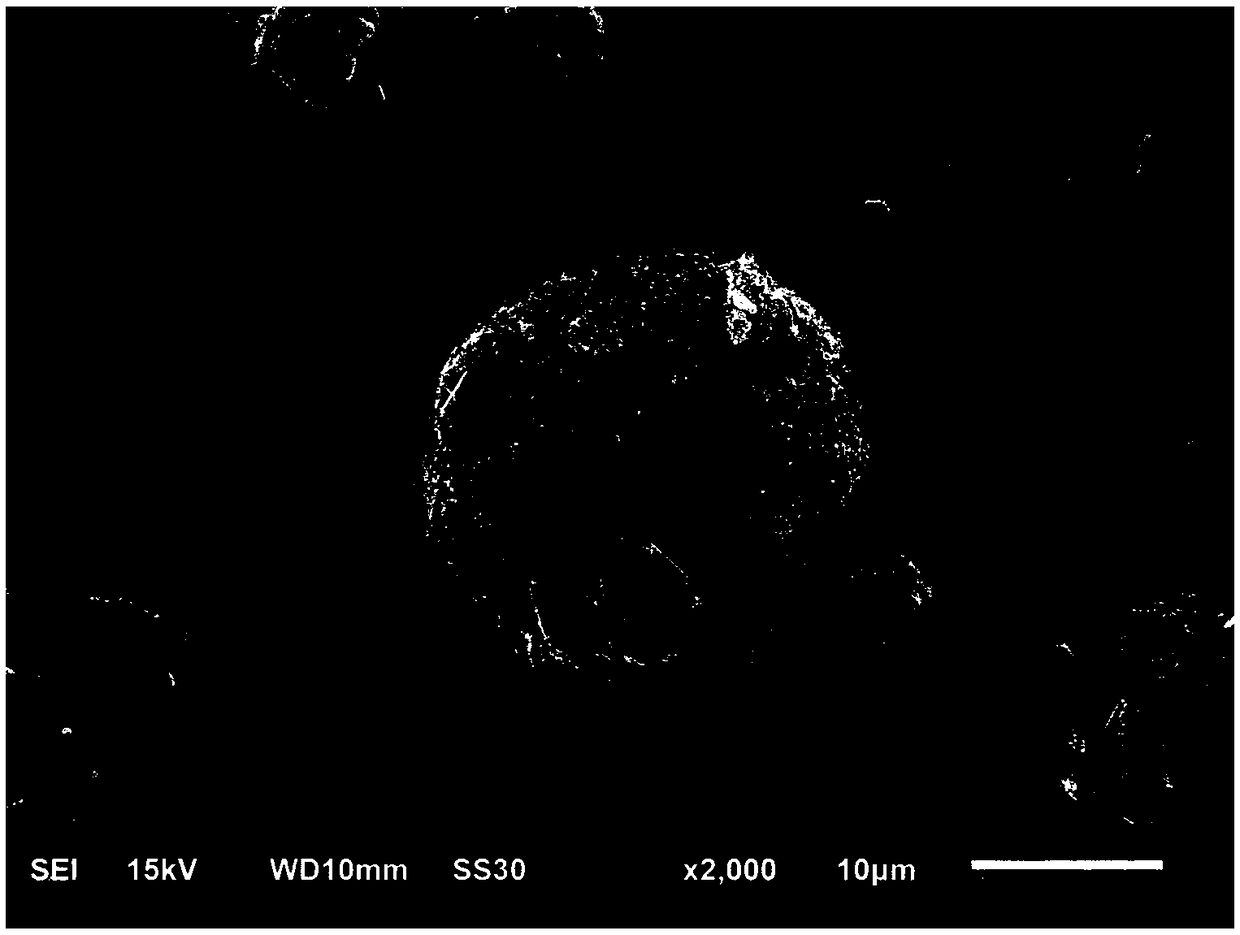

[0096] (1) Ferric phosphate, lithium source, carbon source A, dispersant, and metal oxide additives are proportioned according to the proportion: the lithium source is lithium hydroxide, and the quality of Li in lithium hydroxide accounts for 7.2% of the iron phosphate mass ratio; carbon source A adopts glucose, accounting for 8% of the mass ratio of iron phosphate; the metal oxide additive adopts titanium dioxide, accounting for 1.2% of the mass ratio of iron phosphate; the dispersant adopts PEG6000, accounting for 0.5% of the mass ratio of iron phosphate; after adding pure water for rough grinding for 1.0h, the obtained Slurry A: Slurry A is ultrafinely ground for 6 hours to obtain slurry B with a particle size D50 of 50-100 nm, and the solid content of the slurry is controlled to 40%, and then the slurry B is spray-dried to obtain a lithium iron phosphate precursor Powder, the particle size is 1μm~6μm;

[0097] (2) Place the lithium iron phosphate precursor powder in a nitr...

Embodiment 2

[0099](1) Ferric phosphate, lithium source, carbon source A, dispersant, and metal oxide additives are batched according to the formula: the lithium source is lithium carbonate, and the Li element in lithium carbonate accounts for 7.5% of the iron phosphate mass ratio; carbon source A adopts starch , accounting for 10% of the mass ratio of iron phosphate; the additive is Al2O3, accounting for 1.6% of the mass ratio of iron phosphate; the dispersant is PEG2000, accounting for 1.5% of the mass ratio of iron phosphate; after adding pure water for rough grinding for 1.0h, the slurry A is obtained ; Ultrafine milling of slurry A for 4 hours to obtain slurry B with a particle size D50 of 50-300 nm, control the solid content to 45%, and then spray-dry slurry B to obtain a lithium iron phosphate precursor with a particle size of 1 μm to 6 μm body powder;

[0100] (2) Place the lithium iron phosphate precursor powder in a helium atmosphere rotary furnace for heat treatment gradient tem...

Embodiment 3

[0102] (1) Ferric phosphate, lithium source, carbon source A, dispersant, and metal oxide additives are formulated according to the formula: the lithium source is lithium acetate, and the Li element in lithium acetate accounts for 8.0% of the mass ratio of iron phosphate; carbon source A uses fiber element, accounting for 12.5% of the mass ratio of ferric phosphate; the additive is magnesium oxide, accounting for 5.0% of the mass ratio of ferric phosphate; the dispersant is PEG4000, accounting for 0.8% of the mass ratio of ferric phosphate; after adding pure water for rough grinding for 1.0h, slurry A is obtained; Ultrafine milling of slurry A for 5 hours to obtain slurry B with a particle size D50 of 50-400 nm, control the solid content to 35%, and then spray-dry slurry B to obtain a lithium iron phosphate precursor with a particle size of 1 μm to 10 μm Powder;

[0103] (2) Place the lithium iron phosphate precursor powder in an argon atmosphere rotary furnace for heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com