Comprehensive recycling method of lithium ion battery anode material

A technology for lithium ion batteries and cathode materials, which is applied in the field of comprehensive recycling of cathode materials in lithium iron phosphate series and ternary series batteries, can solve the problem of recycling ternary batteries alone, no recycling of scrapped batteries, small profit space, and difficulty in forming a scale To avoid the risk of production line shutdown, reduce sorting costs, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

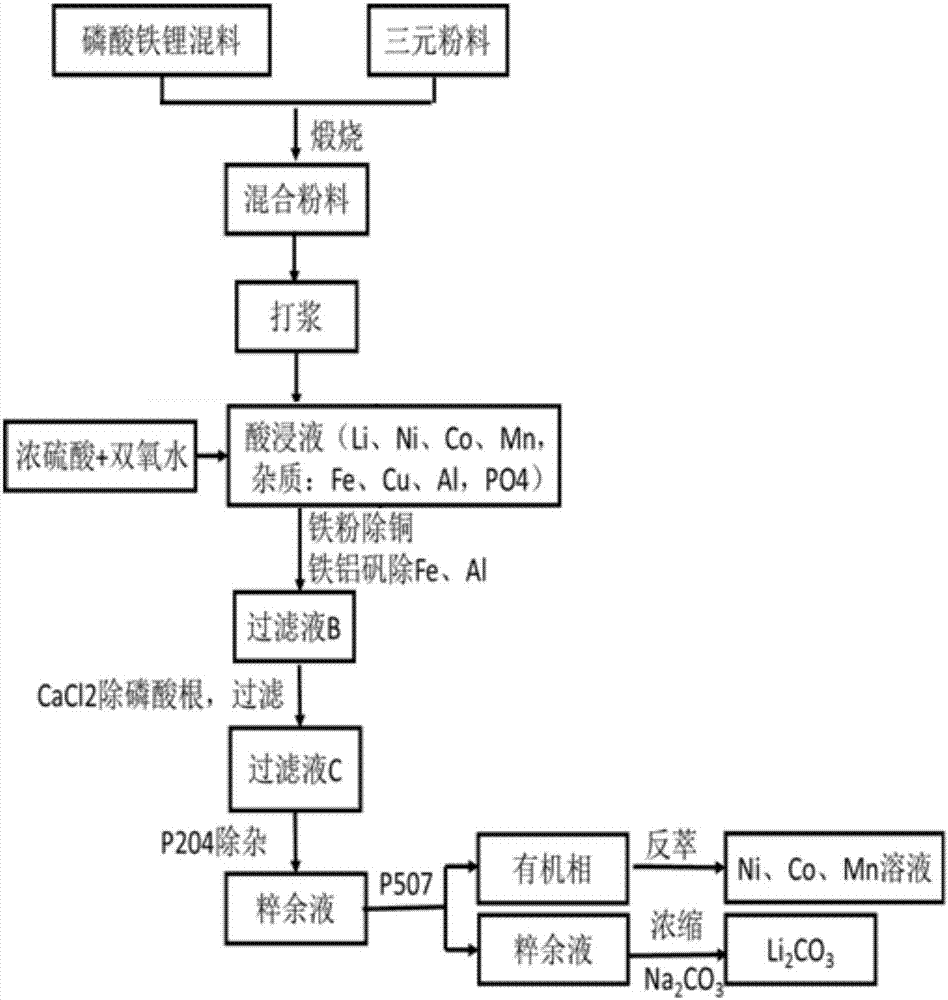

[0027] A kind of comprehensive recovery method of lithium ion battery cathode material, such as figure 1 Shown:

[0028] (1) Take 2kg of the mixed material of lithium iron phosphate and the positive electrode material of the ternary battery, carry out high-temperature pretreatment at 600°C in the air for 6 hours, take it out after natural cooling; oxidize the ferrous iron in the lithium iron phosphate to trivalent Iron, and remove part of the carbon powder in the powder;

[0029] (2) adding the mixed material after high temperature pretreatment into 8L deionized water for beating treatment to obtain a beating liquid;

[0030] (3) Add 24 mol of concentrated sulfuric acid and 6 L of hydrogen peroxide, stir and react at 85° C. for 2 hours, then filter the reactant to remove insoluble matter, and obtain filtrate A;

[0031] (4) After the pH value of filtrate A is adjusted to 1.5-, calculate the add-on of iron powder by Cu content in the test filtrate A, remove the copper element...

Embodiment 2

[0037] (1) Take 2kg of the mixed material of lithium iron phosphate and the positive electrode material of the ternary battery, carry out high-temperature pretreatment at 800°C in the air for 2 hours, take it out after natural cooling; oxidize the ferrous iron in the lithium iron phosphate to trivalent Iron, and remove part of the carbon powder in the powder;

[0038] (2) adding the mixed material after high-temperature pretreatment into 4L deionized water for beating treatment to obtain a beating liquid;

[0039] (3) Add 20 mol of concentrated sulfuric acid and 2 L of hydrogen peroxide, stir and react at 60° C. for 3 hours, then filter the reactant to remove insoluble matter, and obtain filtrate A;

[0040] (4) After the pH value of filtrate A is adjusted to 1.5, the addition of iron powder is calculated by testing the Cu content in filtrate A, and the copper element in filtrate A is removed through filtration, and the removal rate of copper element is about 90%, and then adj...

Embodiment 3

[0046] (1) Take 2kg of the mixed material of lithium iron phosphate and the positive electrode material of the ternary battery, carry out high-temperature pretreatment at 400°C in the air for 10 hours, take it out after natural cooling; oxidize the ferrous iron in the lithium iron phosphate to trivalent Iron, and remove part of the carbon powder in the powder;

[0047] (2) adding the mixed material after high-temperature pretreatment into 20L deionized water for beating treatment to obtain a beating liquid;

[0048] (3) Add 30 mol of concentrated sulfuric acid and 10 L of hydrogen peroxide, stir and react at 95° C. for 0.5 hour, then filter the reactant to remove insoluble matter to obtain filtrate A;

[0049] (4) after the pH value of filtrate A is adjusted to 2, calculate the add-on of iron powder by Cu content in the test filtrate A, remove the copper element in filtrate A through filtration, copper element removal rate is about 90%, then adjust When the pH value reaches 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com