Preparation method of carbon nano-Li2FeSiO4 composite cathode material

A composite positive electrode material, lithium ferrous silicate technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of inability to achieve carbon coating and limit the performance of lithium ferrous silicate, so as to improve the electrical conductivity and electrical conductivity. Chemical activity, good cycle performance and rate performance, and the effect of improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

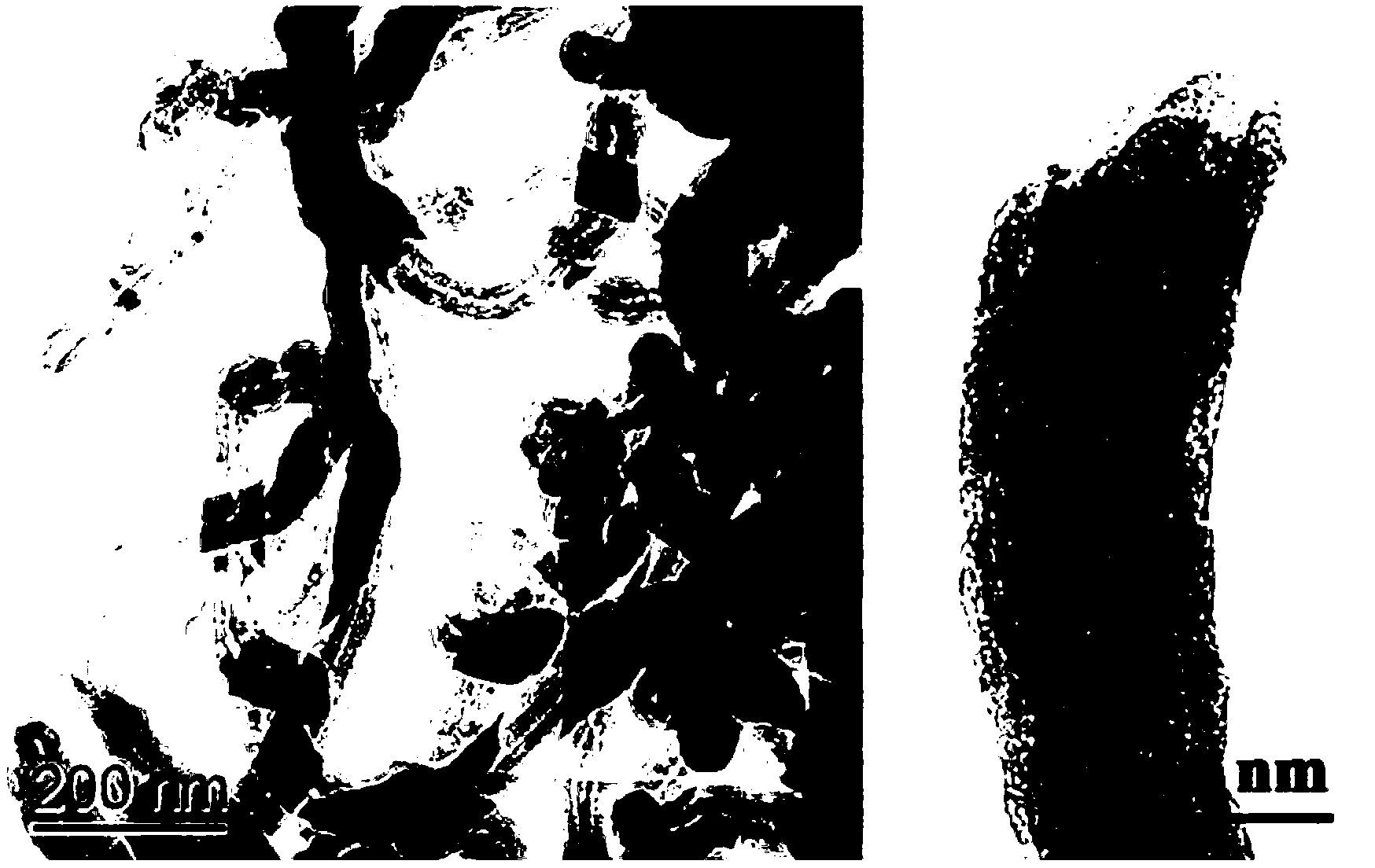

[0019] Example 1. Commercialized multi-walled carbon nanotubes are ultrasonically dispersed in concentrated nitric acid, refluxed for 6 hours in an oil bath at 140°C, fully washed with distilled water until the filtrate is neutral, and dried in an oven at 80°C to obtain acidified multi-walled carbon nanotubes. Multi-walled carbon nanotubes of different qualities were added to a mixed solution of 160mL ethanol and 16mL deionized water, and dispersed evenly by ultrasonication for one hour, and 1.28gTEOS and 2mL ammonia water were added under magnetic stirring, and the stirring was continued for 24 hours. Finally, multi-walled carbon nanotube silica composites with different loads were obtained, figure 1 It shows the morphology of the composite material with a silica content of 56wt%, and the amorphous silica is uniformly loaded on the surface of the multi-walled carbon nanotubes, and its thickness is 10-12nm.

Embodiment 2

[0020] Embodiment 2. Be that the multi-walled carbon nanotube silicon dioxide composite material of 76wt% is silicon source with silicon dioxide content, ferrous oxalate and lithium acetate are respectively iron source and lithium source, press iron, silicon, lithium element molar ratio Dissolve in 20mL ethanol at a ratio of 1:1:2, disperse evenly by ultrasonication for one hour, and stir in an oil bath at 60°C until the ethanol is completely volatilized. The obtained solid was ground evenly in an agate mortar, pressed into tablets, heated to 650°C at 5°C / min under an argon atmosphere, kept for 10h, and cooled naturally to obtain a multi-walled carbon nanotube-lithium ferrous silicate composite material.

Embodiment 3

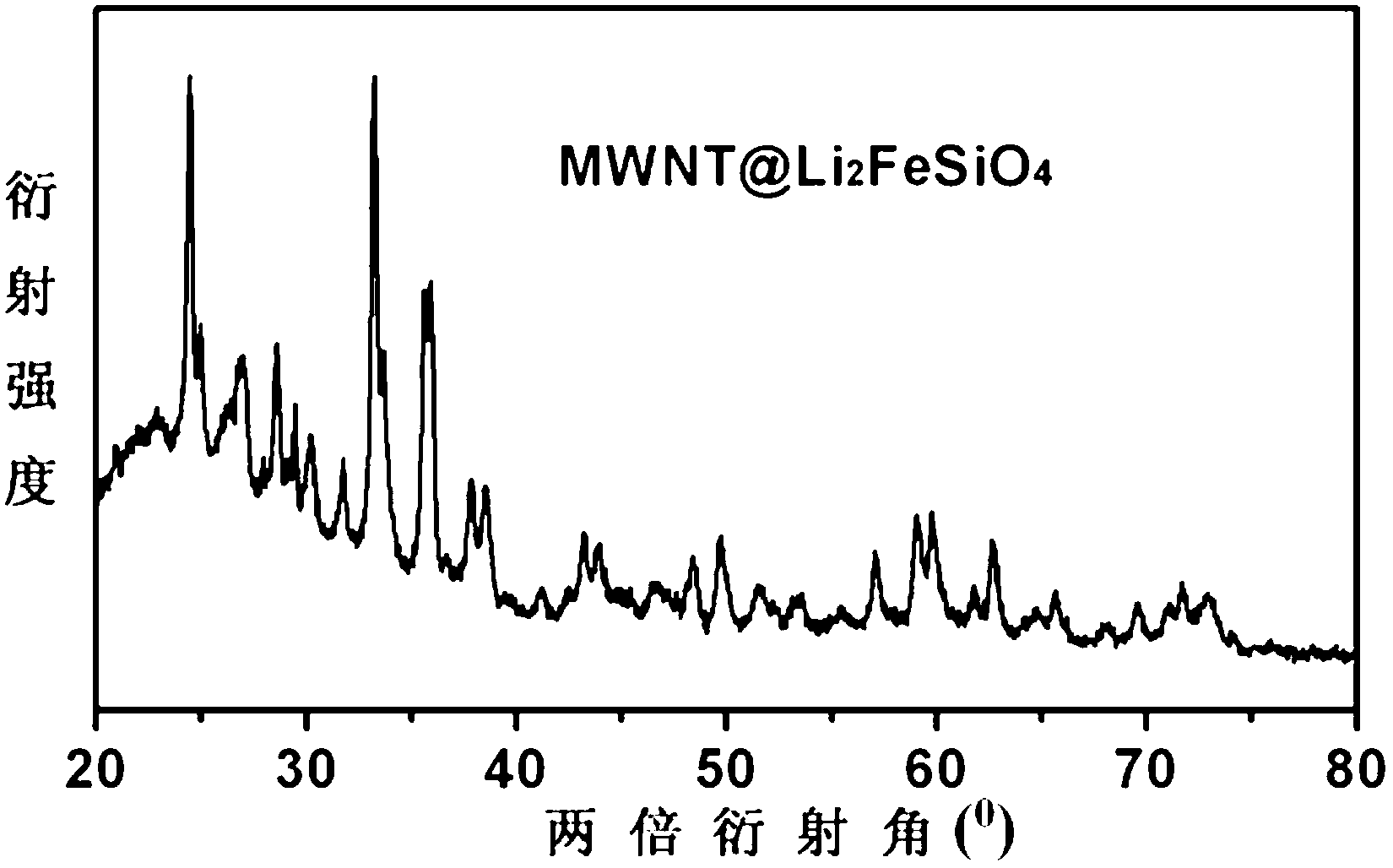

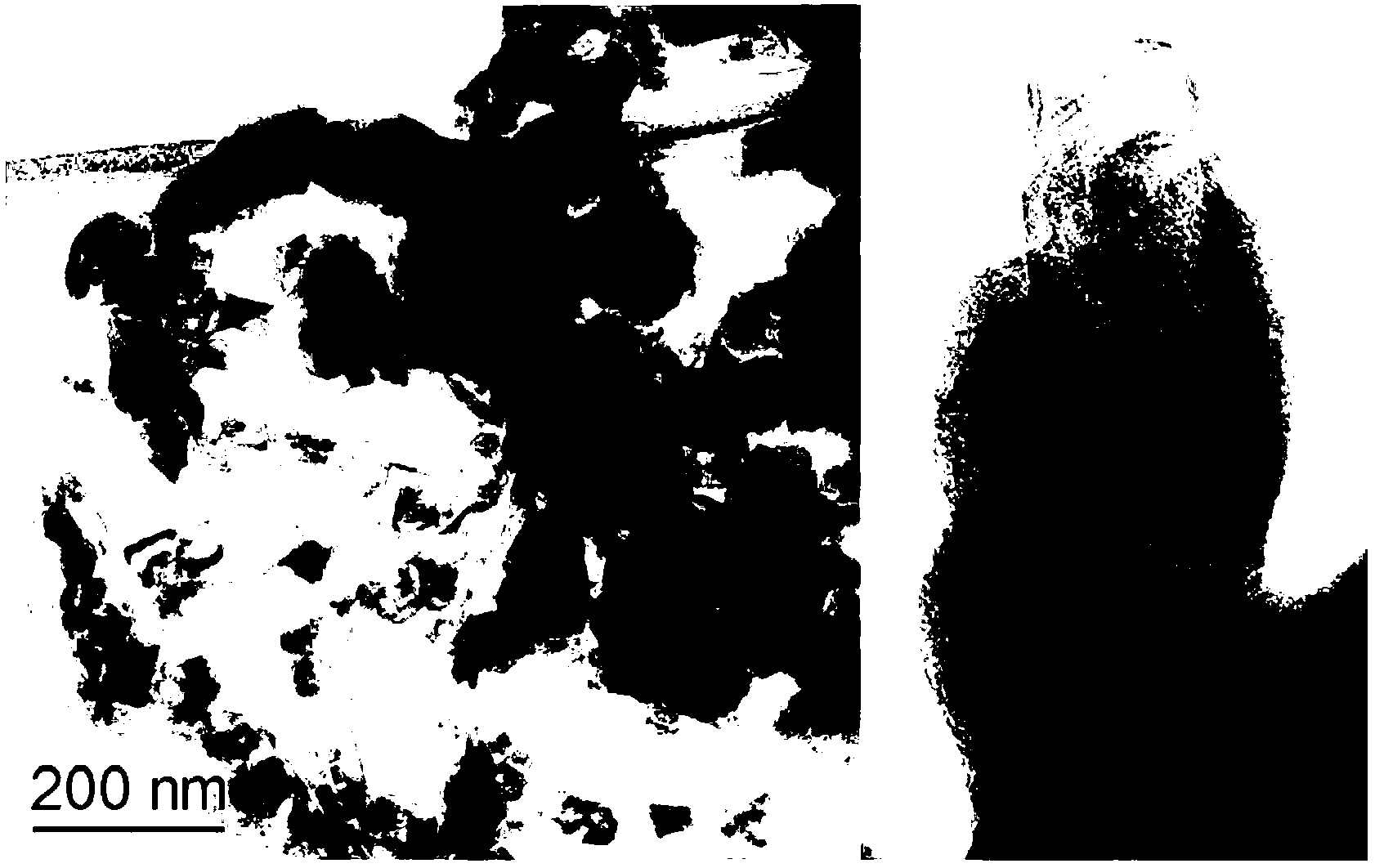

[0021] Embodiment 3. Be that the multi-walled carbon nanotube silicon dioxide composite material of 56wt% is silicon source with silicon dioxide content, ferrous oxalate and lithium acetate are respectively iron source and lithium source, press iron, silicon, lithium element molar ratio Dissolve in 20mL ethanol at a ratio of 1:1:2, disperse evenly by ultrasonication for one hour, and stir in an oil bath at 60°C until the ethanol is completely volatilized. Grind the obtained solid in an agate mortar evenly, press it into tablets, heat it up to 600°C at 5°C / min in an argon atmosphere, keep it warm for 5h, and obtain the multi-walled carbon nanotube-ferrous silicate with core-shell structure after natural cooling lithium composites. MWNT 2 FeSiO 4 The XRD pattern of the composite material is as figure 2 As shown, the lithium ferrous silicate is a monoclinic structure, and the space group is P2 1 / n, at 26 o The nearby peaks are the diffraction peaks of multi-walled carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com