Composite anode active material and preparation method thereof, anode and battery

A technology for positive active materials and active materials, which is applied in the field of composite positive active materials and their preparation, positive electrodes and batteries, can solve the problems of loss of electrochemical activity, insufficient preparation process, and non-uniform dispersion, etc., to achieve lithium supplementation Uniform distribution, excellent lithium supplementation effect, good effect of lithium deintercalation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

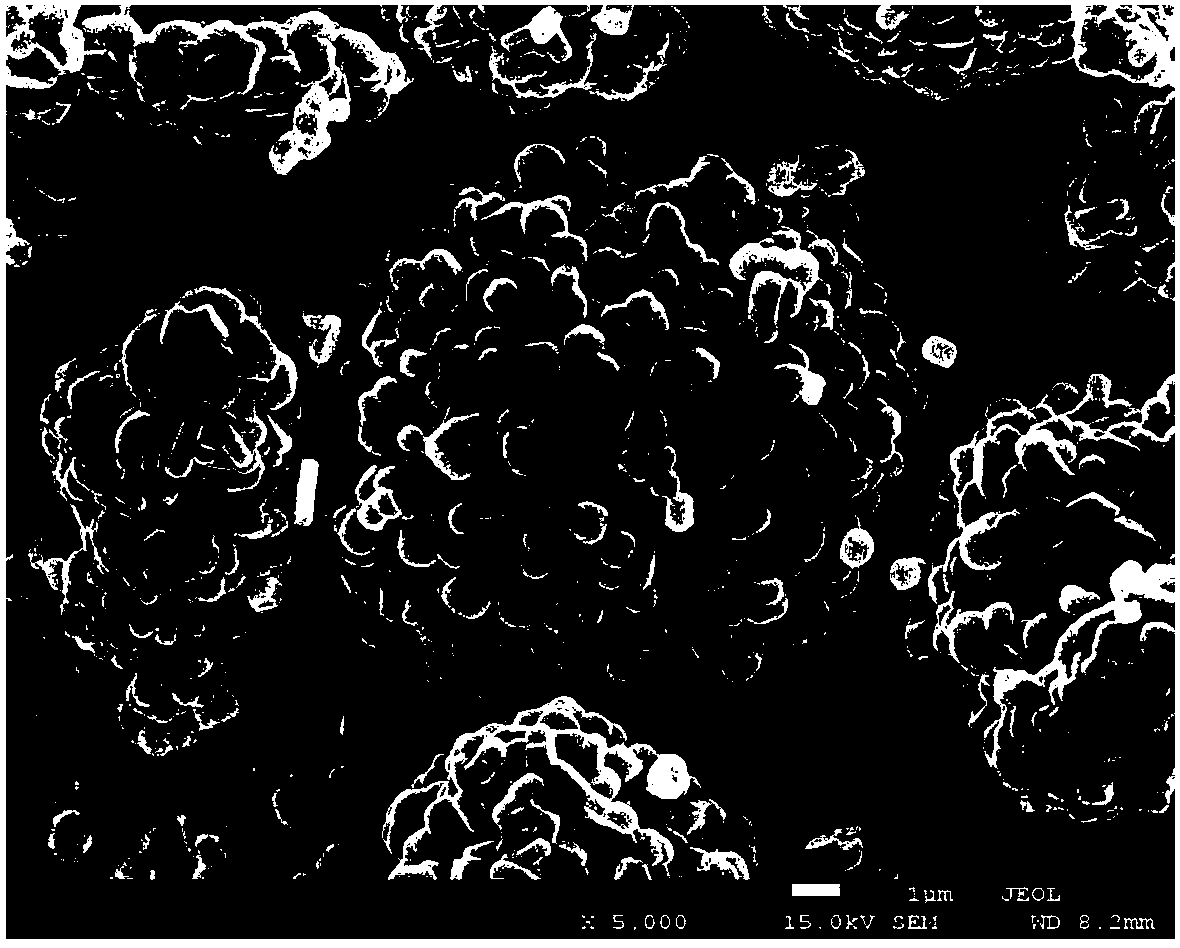

[0034] A second aspect of the present invention provides a method for preparing a composite positive electrode active material, the method comprising:

[0035](1) In the first aqueous solvent, in the presence of a complexing agent and a precipitating agent, the water-soluble salt forming the positive electrode active material other than the lithium salt is subjected to coprecipitation treatment to obtain a core precursor;

[0036] (2) The core precursor is subjected to surface hydroxylation treatment;

[0037] (3) In the second aqueous solvent, heat-treat the product of the surface hydroxylation treatment, silicon source and water-soluble salt containing M element;

[0038] (4) performing solid-liquid separation on the heat-treated product, drying and roasting the obtained solid phase to obtain a composite positive electrode active material with a core-shell structure;

[0039] Wherein, water-soluble lithium salt is introduced during the heat treatment of step (3) and / or in t...

Embodiment 1

[0088] This example is used to illustrate the composite cathode active material of the present invention and its preparation method.

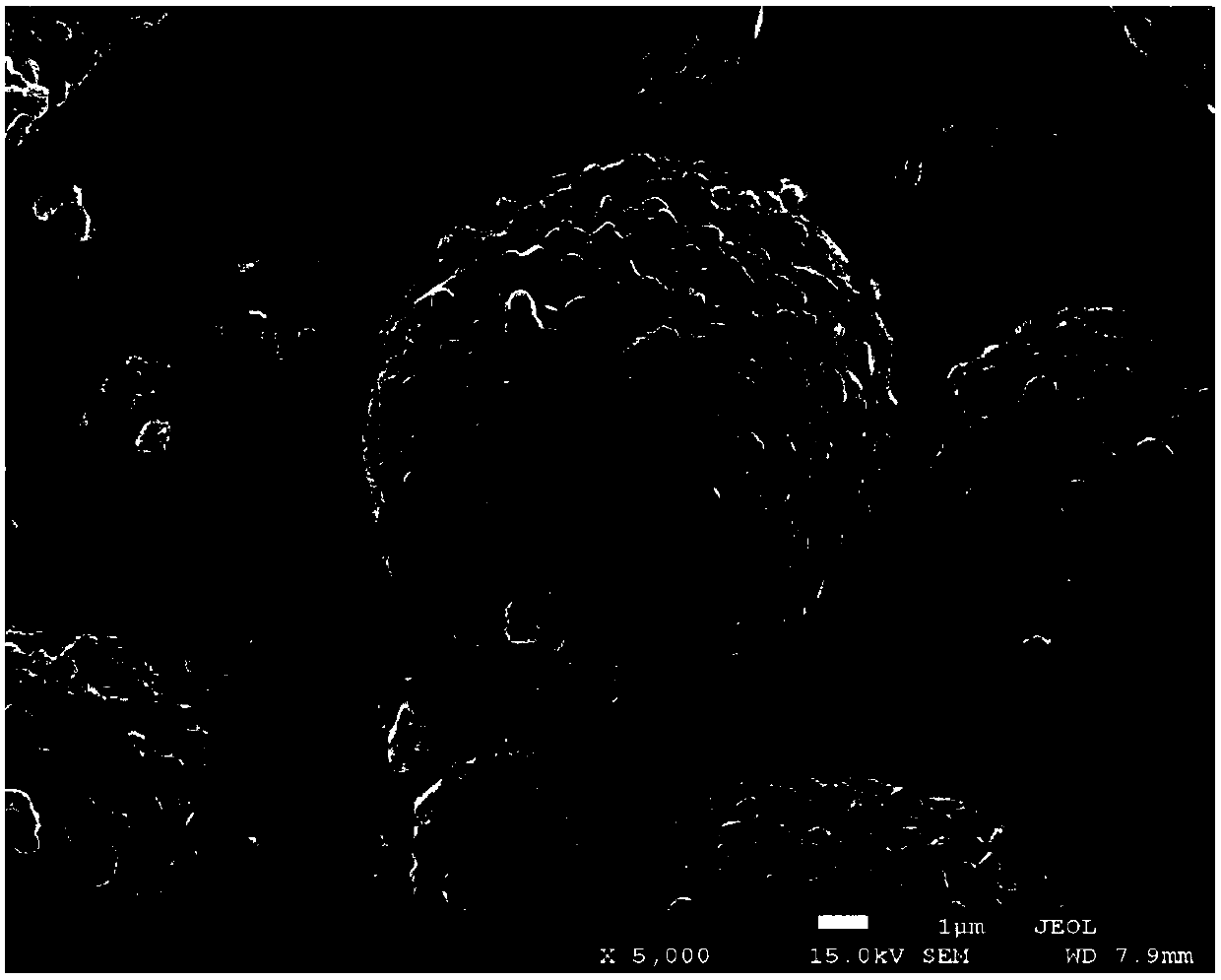

[0089] (1) 50mmol of nickel nitrate and 50mmol of cobalt nitrate are dissolved in 100g of water, then 5g of ammonia water (concentration is 10% by weight) is added and sodium hydroxide is added to adjust the pH to 11, to carry out co-precipitation reaction at 30°C for 24h, and filter to obtain Core Prebody ( figure 1 As can be seen from the SEM image shown, the particle size of the core precursor is about 10 μm);

[0090] (2) immerse the core precursor in 10% by weight hydrogen peroxide at 25° C. for 30 minutes, and then obtain the core precursor treated with surface hydroxylation;

[0091] (3) Add 10 g of the surface hydroxylated core precursor to a mixed solvent of 100 g of ethanol and water (the weight ratio of methanol and water is 2:1), and reflux for 30 min, and then dropwise add 7.5 g of orthosilicic acid Ethanol solution of ethyl este...

Embodiment 2

[0095] This example is used to illustrate the composite cathode active material of the present invention and its preparation method.

[0096] According to the method described in embodiment 1, the difference is:

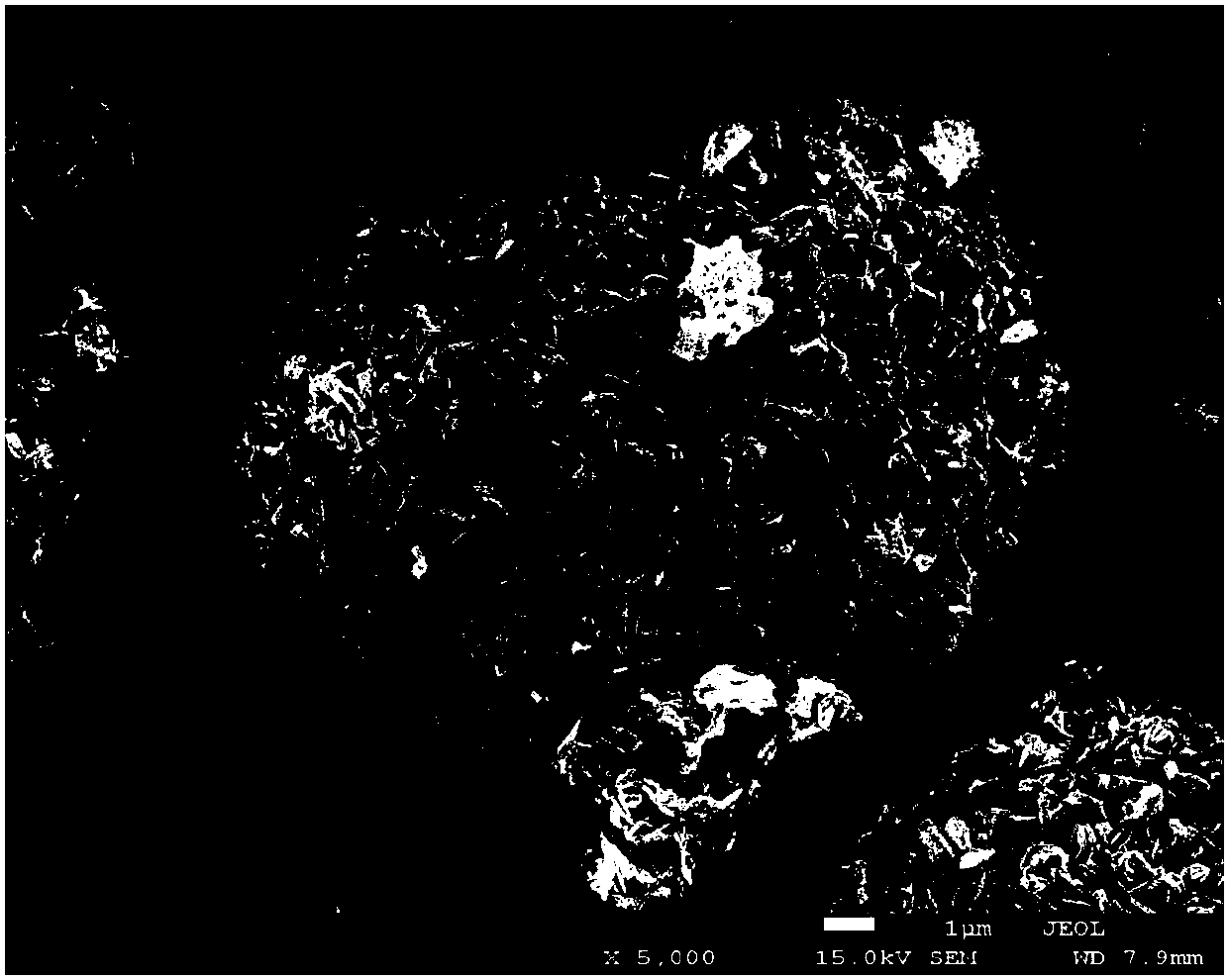

[0097] In step (3), the core precursor of this surface hydroxylation treatment of 10g, the ethanol solution of 7.5g orthosilicate ethyl (concentration of orthosilicate is 30% by weight), the aqueous solution of 195g ferrous nitrate (nitrite nitrate Iron concentration is 1% by weight) and lithium nitrate aqueous solution (lithium nitrate concentration is 10% by weight) of 50g joins in the airtight autoclave, and the mixed solvent of the ethanol and water that adds 100g (the weight ratio of methyl alcohol and water is 2 : 1), then stirred and reacted at 150°C for 5h, filtered and dried to obtain a solid phase;

[0098] In step (4), the amount of lithium nitrate aqueous solution is 40g;

[0099] Finally, a composite positive electrode active material is obtained. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com