LiBH4-silver/silver halide compound fast-ion conductor and preparation method thereof

An ionic conductor and silver halide technology, applied in electrochemical generators, electrical components, circuits, etc., can solve the problems of low-temperature conductivity and high-temperature computer rate, and limit the application of solid electrolytes, and achieve excellent low-temperature conductivity and low cost. Low, the effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 LiBH 4 - Preparation of Ag Composite Hydride Fast Ion Conductor

[0018] In the isolation of air (H 2 O2 4 Put it into a stainless steel ball tank equipped with stainless steel balls at a molar ratio of 10:1 with Ag; use planetary wheel ball mill mechanical ball milling method, under the protection of high-purity (99.9999%) inert gas, to obtain LiBH 4 -Ag composite particles. The mass of the sample in the spherical tank is 1g, the volume of the spherical tank is 200ml, the weight ratio of the ball to the sample is 40:1, the revolution speed is set to 400rpm, and the ball milling time is 2 hours.

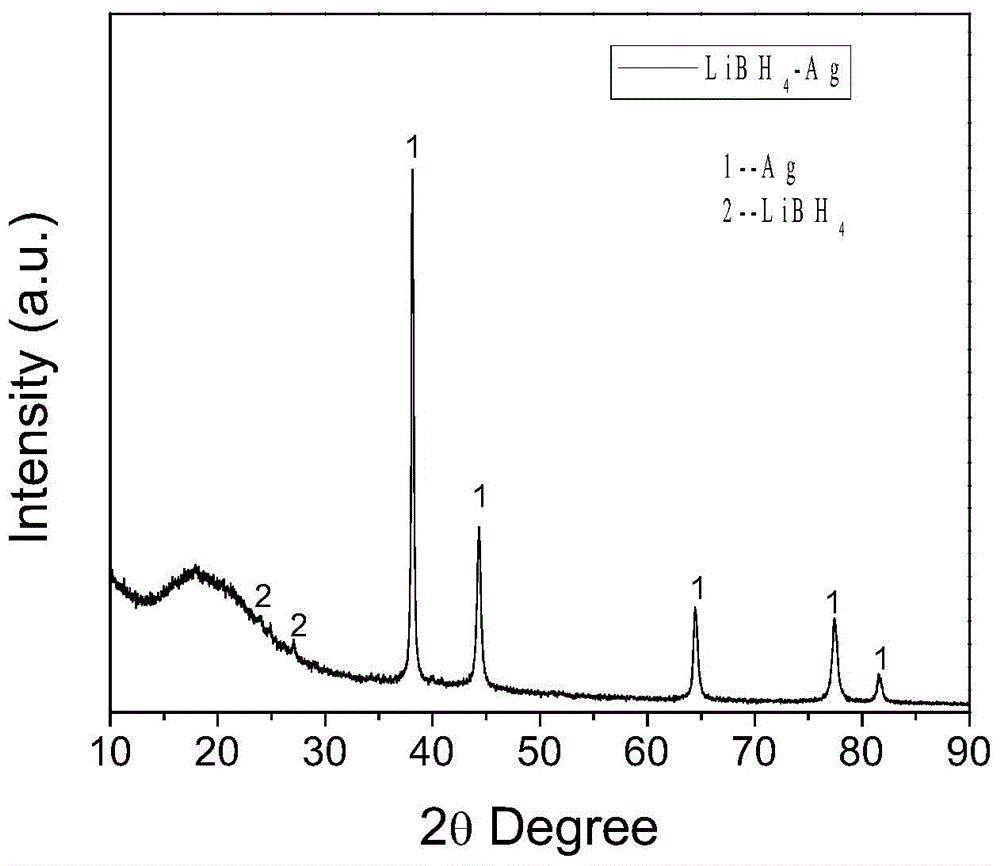

[0019] Take out part of LiBH 4 -Ag composite particles are used for X-ray diffraction (XRD) experiments, the sample cell is covered by a specific polymer film, and is sealed with a vacuum grease to prevent the action of water and oxygen in the air on the sample. The target material of the X-ray source used is a Cu target, the tube voltage is 40kV, and the tube cu...

Embodiment 2

[0022] In the isolation of air (H 2 O2 4 Mix it with AgI at a molar ratio of 10:1, put it into a stainless steel ball tank equipped with stainless steel balls; adopt a planetary wheel ball mill mechanical ball milling method, under the protection of high-purity (99.9999%) inert gas, Get LiBH 4 - AgI complex particles. The mass of the sample in the spherical tank is 1g, the volume of the spherical tank is 200ml, the weight ratio of the ball to the sample is 40:1, the revolution speed is set to 400rpm, and the ball milling time is 2 hours.

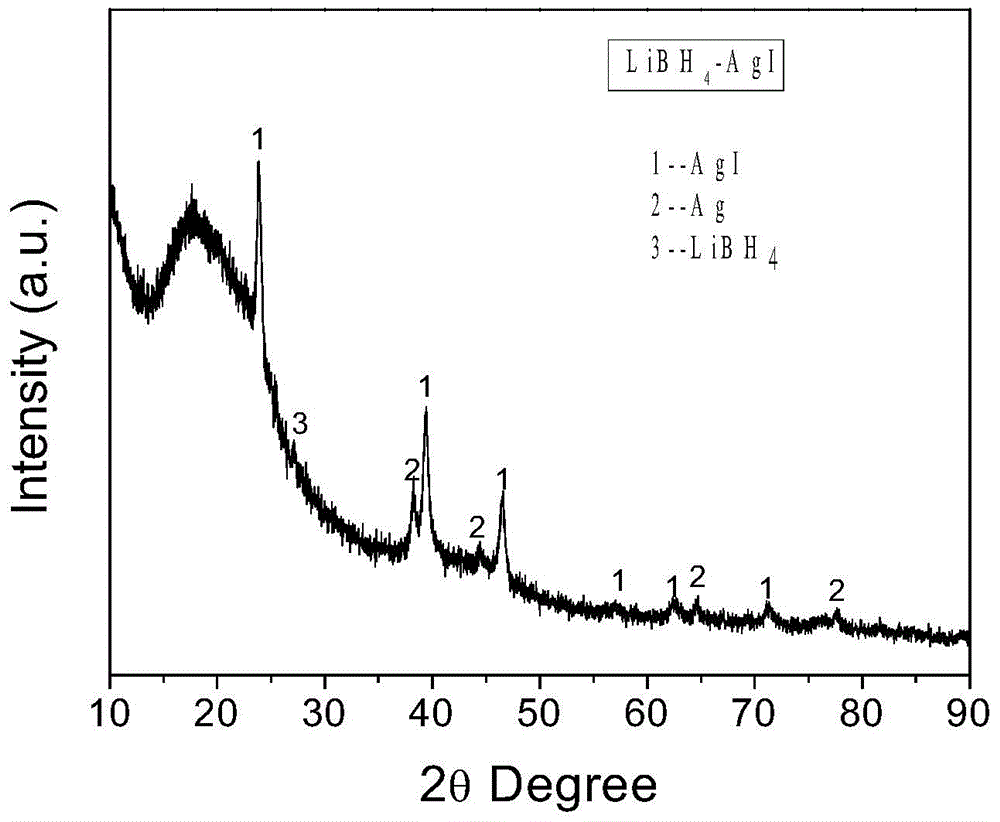

[0023] Take out part of LiBH 4 -AgI composite particles are used for X-ray diffraction (XRD) experiments. The sample cell is covered by a specific polymer film, and is sealed with vacuum grease to prevent the effect of water and oxygen in the air on the sample. The target material of the X-ray source used is a Cu target, the tube voltage is 40kV, and the tube current is 40mA. The resulting XRD spectrum is as image 3 shown.

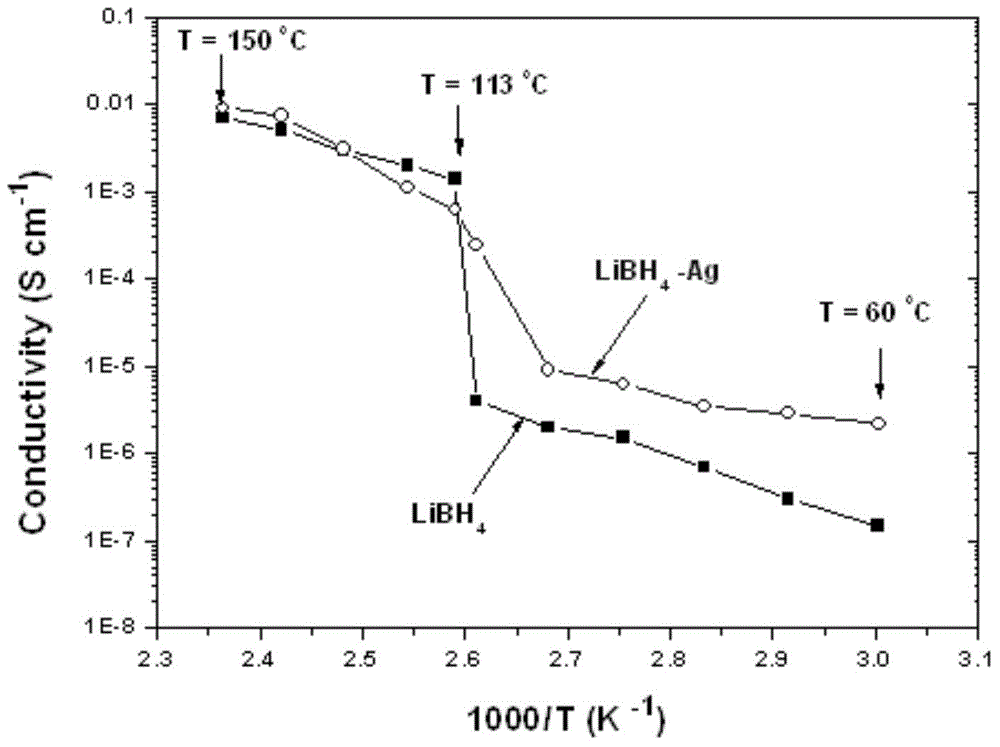

[0024] Th...

Embodiment 3

[0025] Example 3 LiBH 4 - Preparation of AgF Composite Hydride Fast Ion Conductor

[0026] LiBH 4 -AgF composite hydride fast ion conductor is isolated from air (H 2 O2 4 and AgF into a stainless steel spherical tank with stainless steel grinding balls; using a planetary wheel ball mill mechanical ball milling method, under the protection of high-purity (99.9999%) argon, LiBH 4 -AgF mixed evenly. Since the samples are easy to react with oxygen and water, all sample manipulations are carried out in a glove box filled with high-purity argon, and the oxygen and water contents in the glove box are lower than 1ppm. The mass of the sample in the spherical tank is 1g, the volume of the spherical tank is 200ml, the weight ratio of the ball to the sample is 60:1, the revolution speed is set to 600rpm, and the ball milling time is 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com