Fe-Co-Mo-P-C series amorphous alloy electrocatalyst as well as preparation method and application thereof

A fe-co-mo-p-c, amorphous alloy technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low current density, high overpotential and poor stability of electrocatalysts, and achieve good electrocatalytic activity , low cost, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (2) Preparation of master alloy ingot

[0034] According to the predetermined ratio, the processed Fe, Co, Mo metal elements and C powder, P powder are mixed and proportioned, the raw materials are placed in a vacuum electric arc furnace, and argon gas with a purity of 99.99% is introduced after vacuuming, and the arc is passed through Smelting turns the raw materials into master alloy ingots. In order to ensure the uniformity of the alloy composition, the master alloy is repeatedly smelted in the furnace for more than 4 times, and the ferrophosphorus and carbon powder are smelted as slowly as possible during each smelting process to prevent the volatilization of raw materials due to excessive temperature.

[0035] (3) High vacuum belt

[0036] Put the master alloy ingot into the vacuum induction furnace for secondary smelting. After vacuuming, argon gas with a purity of 99.99% is introduced to adjust the injection pressure. By slowly increasing the induction current, ...

Embodiment

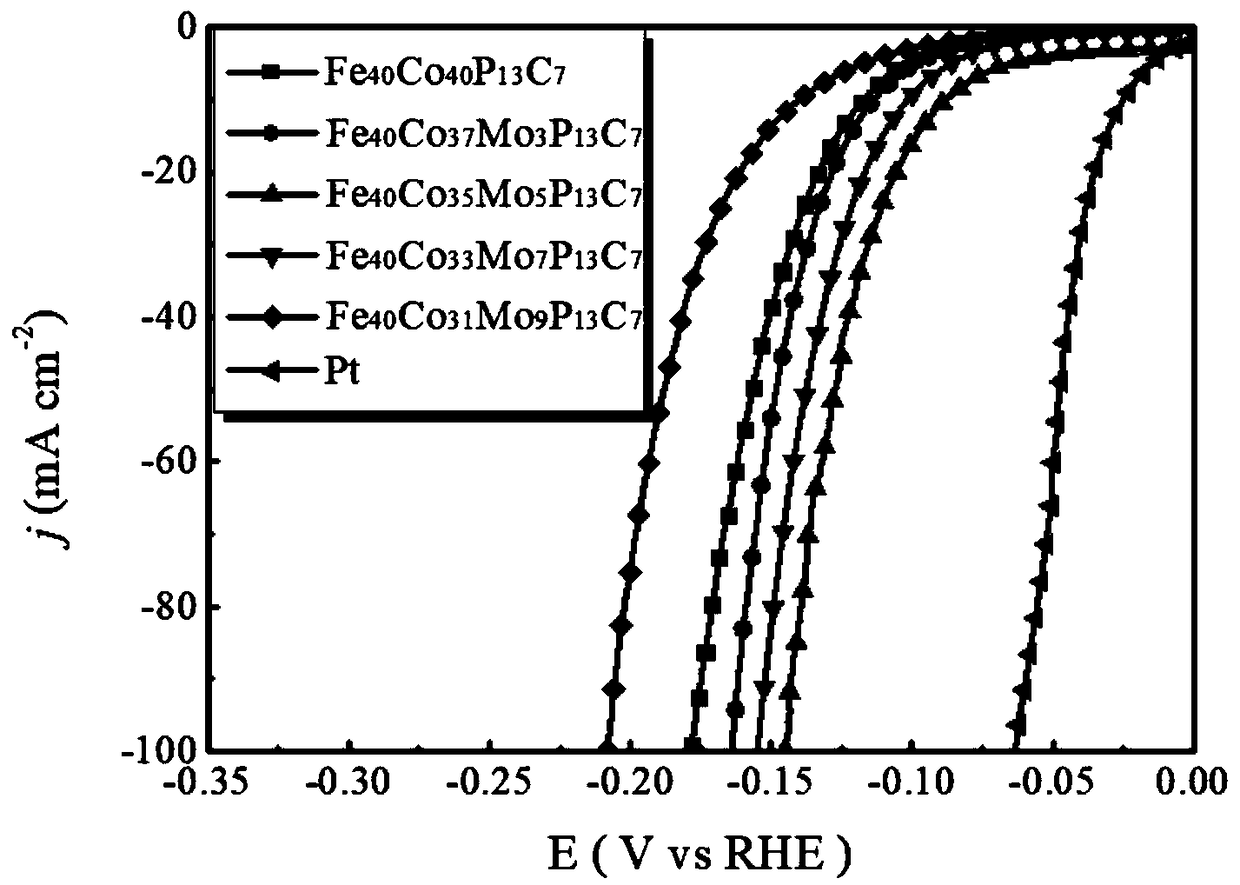

[0038] In this example, a series of Fe-Co-Mo-P-C amorphous alloy strips with different components were prepared according to the above process, and the following characterizations and tests were carried out:

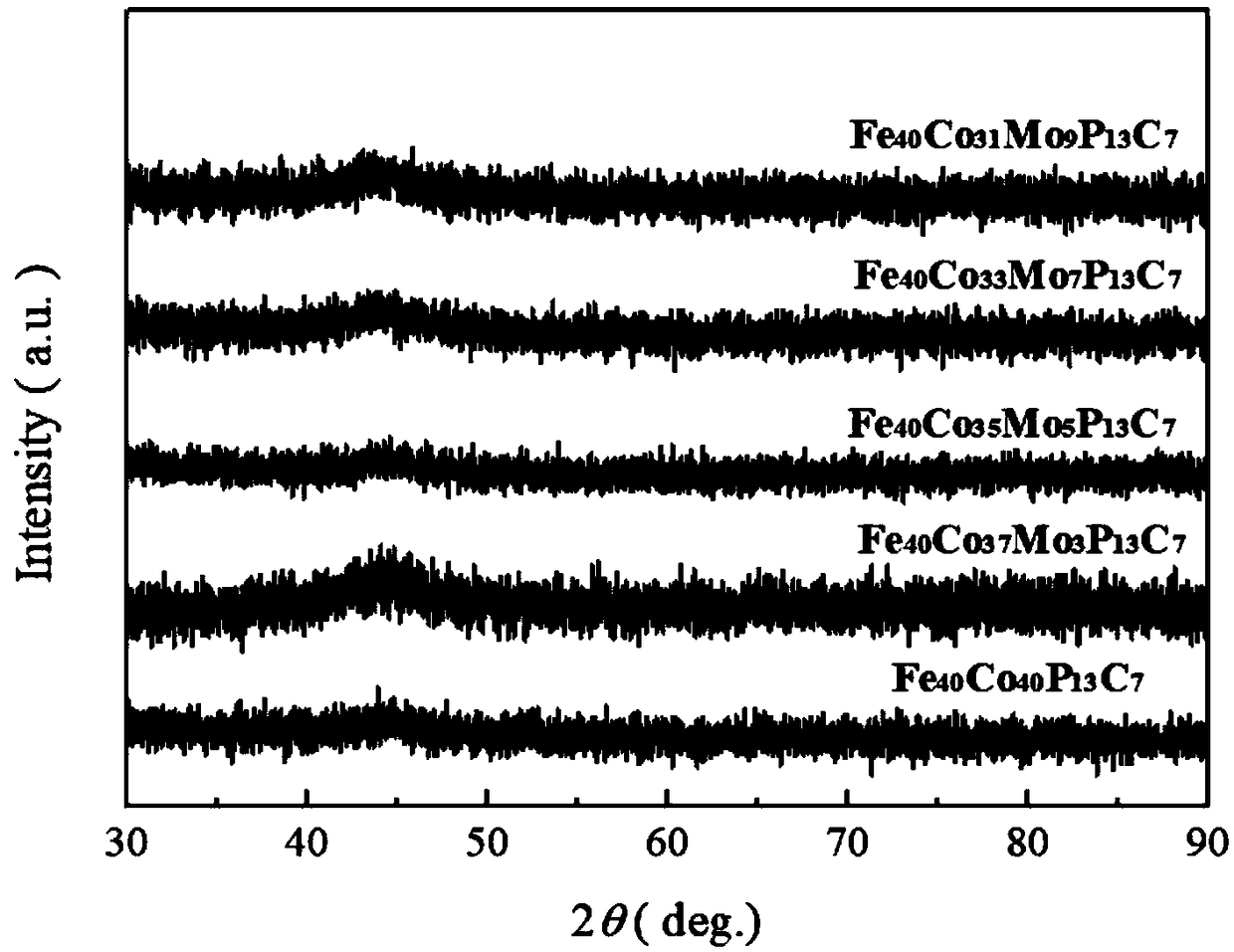

[0039] 1. Put the obtained amorphous alloy strip into an X-ray diffractometer, analyze its crystal structure, and obtain an XRD spectrum. figure 1 It is the X-ray diffraction spectrum of some components Fe-Co-Mo-P-C series amorphous alloy strips obtained in this example. It can be seen from the figure that there is only a single wide and diffuse wide band on the XRD line of the amorphous alloy. No diffraction peaks corresponding to crystals are observed, which is a typical feature of amorphous alloys, and it can be preliminarily concluded that these alloy strips are amorphous structures.

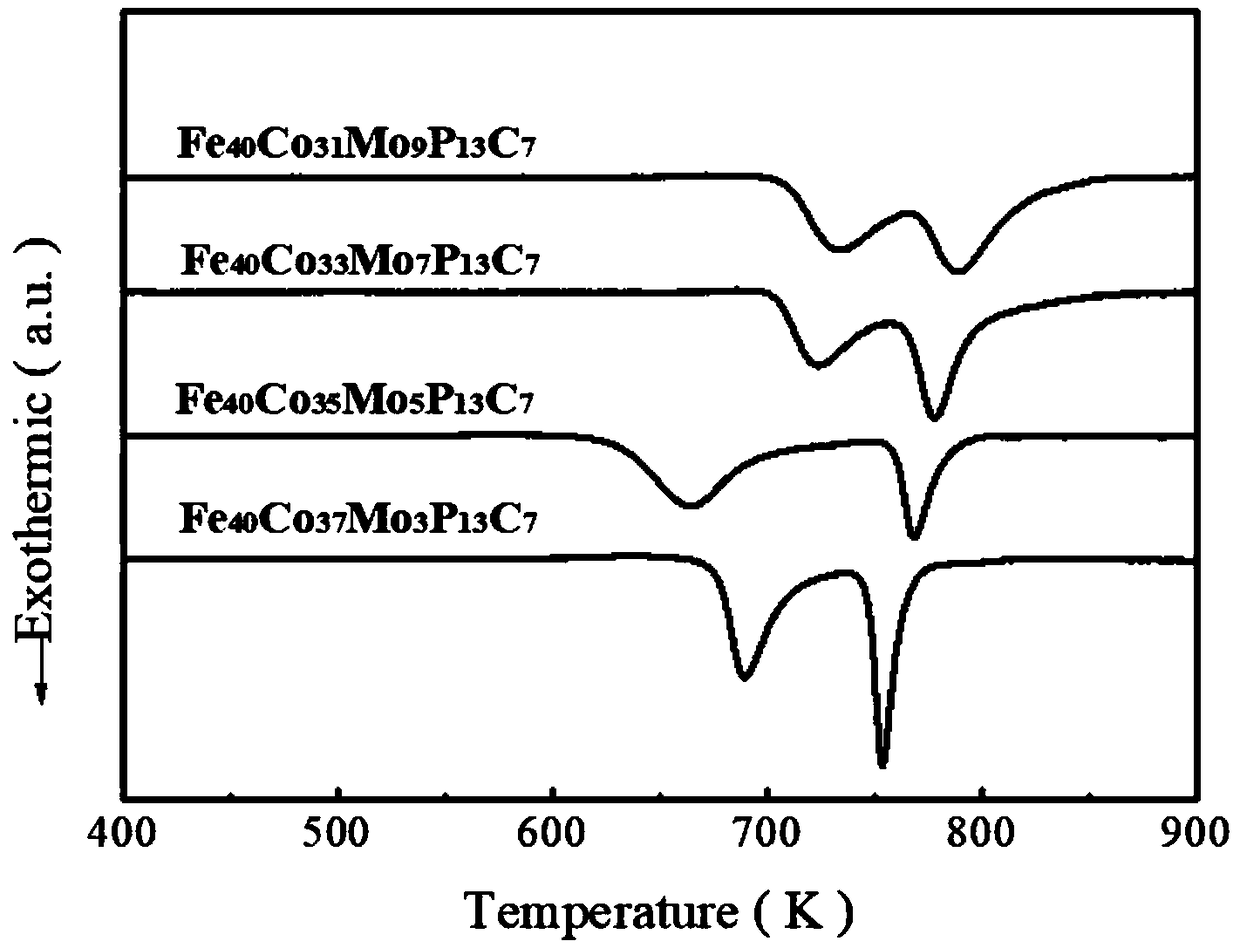

[0040]2. Put the obtained amorphous alloy strip into a DSC apparatus, analyze the thermal stability of the material by differential scanning calorimetry, and obtain its DSC curve. fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com