Supported type catalyst, preparation method thereof, application thereof and Fischer-Tropsch synthesis method thereof

A supported catalyst and Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems that the catalyst activity needs to be further improved, and achieve Effects of improved Fischer-Tropsch synthesis performance, high C5+ selectivity, and high CO conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of a supported catalyst, the preparation method comprising the following steps:

[0030]1) impregnating the support with a solution of a compound containing a cobalt metal component;

[0031] 2) reducing and activating the impregnated carrier obtained in step 1);

[0032] 3) impregnating the reductively activated product in step 2) with a solution of a compound containing a precious metal active component in a reducing or inert atmosphere;

[0033] 4) impregnating the carrier with a solution of a compound containing a non-precious metal auxiliary component;

[0034] Wherein, the step 4) is performed in any period before, during, and after step 1), and before, during, and after step 3).

[0035] Preferably, the solution containing the compound of the cobalt metal component in step 1) also contains the compound of the noble metal active component, and the weight ratio of the compound of the noble metal active comp...

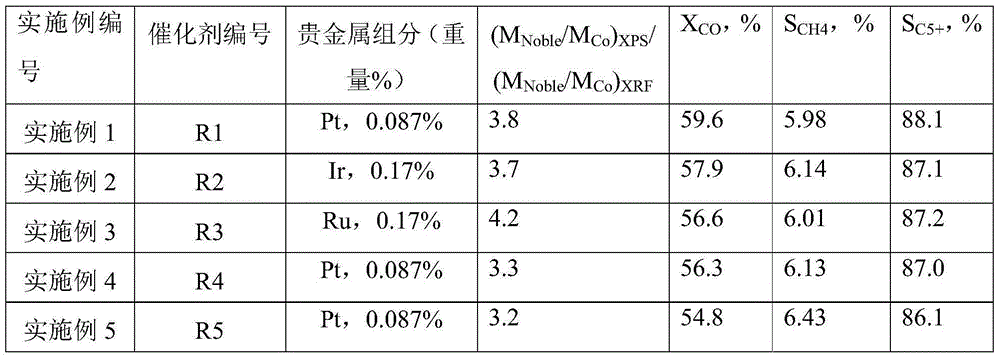

Embodiment 1

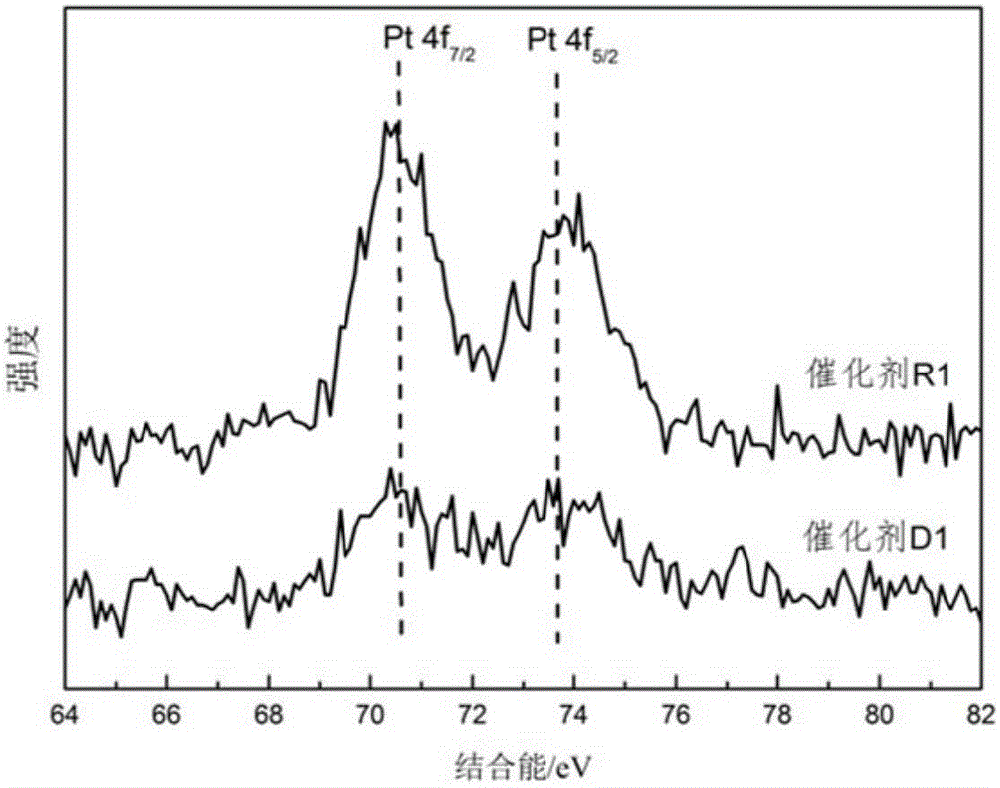

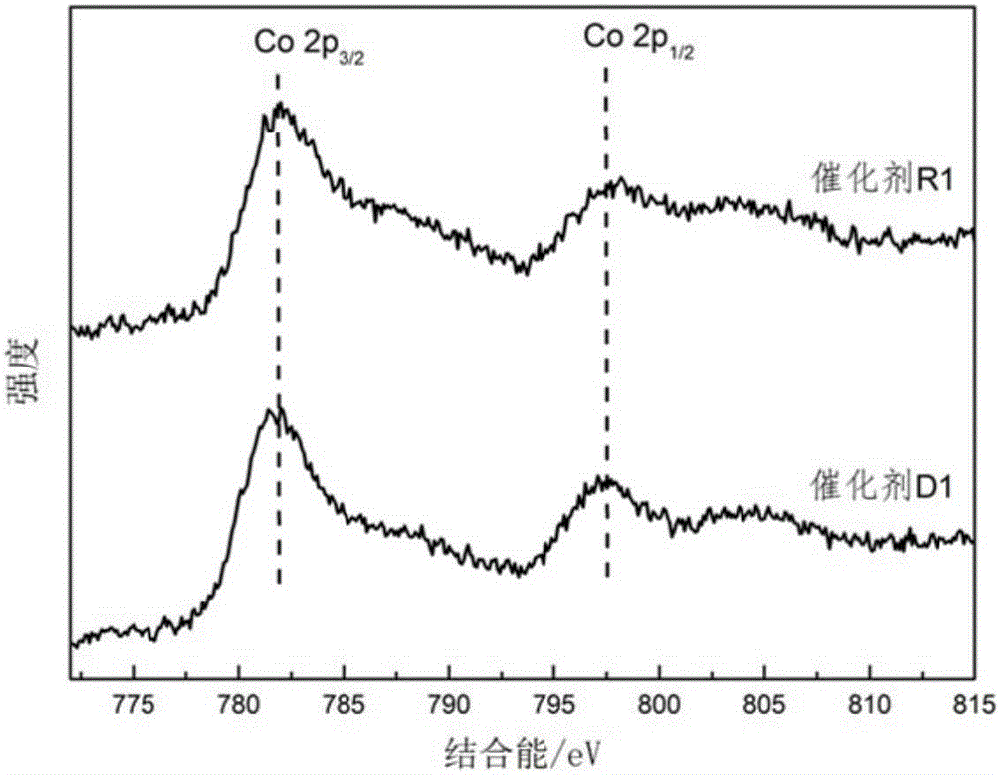

[0062] (1) Catalyst preparation and characterization

[0063] According to the metal salt content required by the equal volume impregnation method, it is formulated into 42.5 ml of cobalt nitrate containing 176 g / L of cobalt, 0.24 g / L of platinum, 10.2 g / L of zirconium, dichlorotetraammine platinum and zirconium oxynitrate dihydrate. dipping solution. Decant the impregnation liquid to 50 g SiO 2 The carrier (Fuji Silicon Co., Japan, with an average particle size of 40-80 microns) was stirred at 20°C for 4 hours, dried at 120°C, calcined at 400°C for 4 hours, reduced by hydrogen at 400°C for 4 hours, and the hydrogen pressure was 0.1 MPa. After reduction, the temperature was lowered to room temperature, and 63.8 ml of a dichlorotetraammine platinum aqueous solution containing 0.63 g / L of platinum was added under a hydrogen atmosphere, allowed to stand for 1 hour, and then dried with hydrogen. Then by O 2 / N 2The mixed gas with a volume ratio of 0.5% was passivated for 0.5 ...

Embodiment 2

[0067] (1) Catalyst preparation and characterization

[0068] According to the metal salt content required by the equal volume impregnation method, 42.5 ml of the impregnation solution containing cobalt 176 g / L, iridium 0.48 g / L, zirconium 10.2 g / L, iridium chloride and zirconium oxynitrate dihydrate was prepared. Decant the impregnation liquid to 50 g SiO 2 The carrier (Qingdao Ocean Chemical Plant, average particle size is 40-80 microns), stirred evenly at 15°C, allowed to stand for 6 hours, dried at 100°C, calcined at 450°C for 2 hours, reduced with hydrogen at 450°C for 2 hours, and the hydrogen pressure was 1 MPa. After reduction, the temperature was lowered to room temperature, and 63.8 ml of an iridium chloride aqueous solution containing 1.26 g / L of iridium was added under a hydrogen atmosphere, allowed to stand for 1 hour, and then blown dry with hydrogen. Then by O 2 / N 2 The mixed gas with a volume ratio of 0.8% was passivated for 2 hours and stored in a desicca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com