Patents

Literature

267 results about "X-Ray Fluorescence Spectroscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

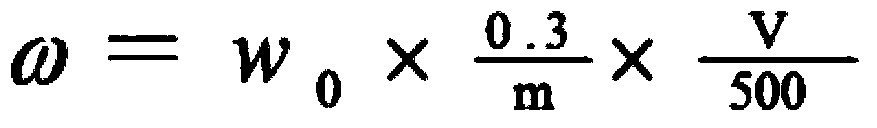

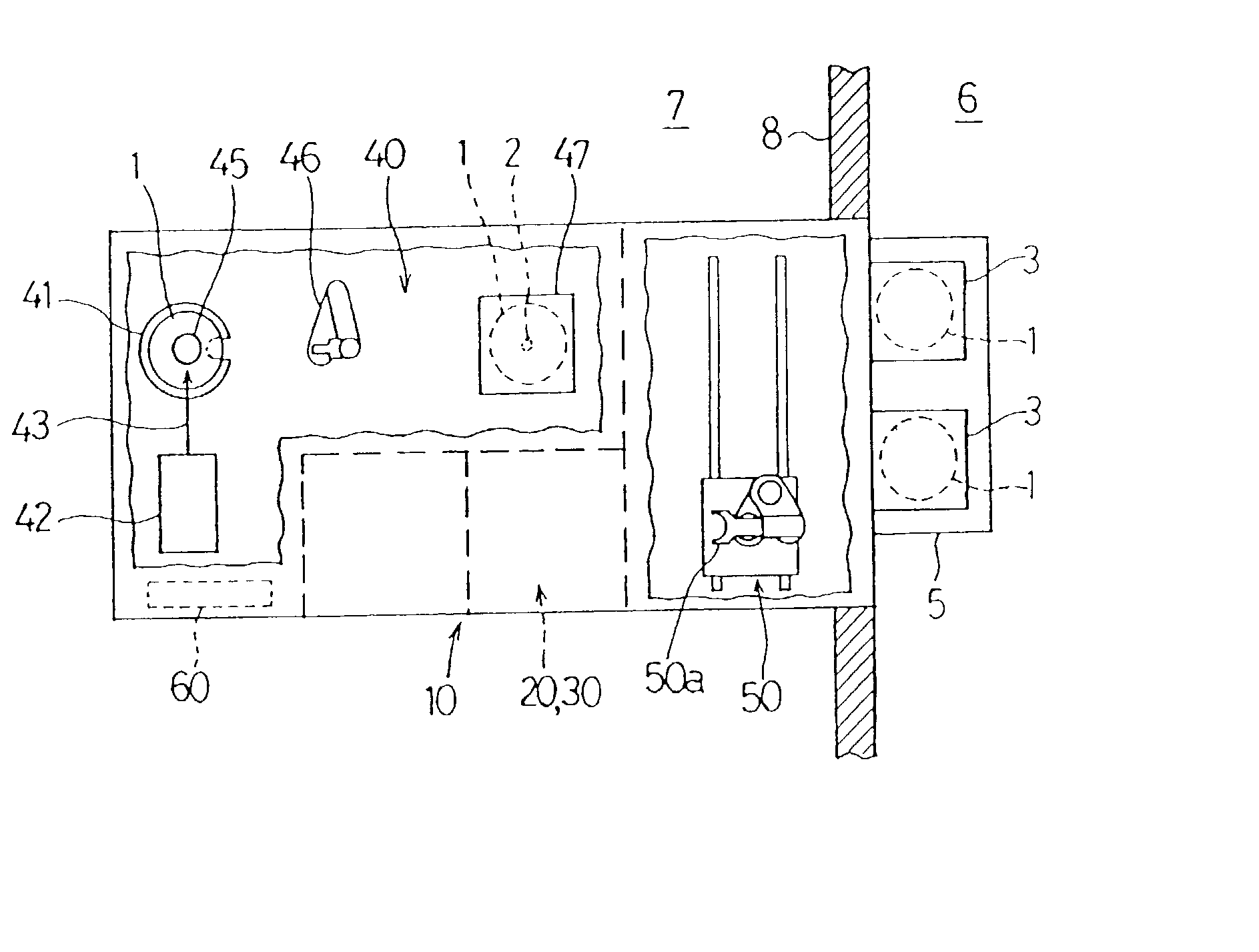

X-ray fluorescence spectrometric system and a program for use therein

InactiveUS20030043963A1Easy to operateLiquid surface applicatorsX-ray spectral distribution measurementFluorescence spectrometryPre treatment

An X-ray fluorescence spectrometric system includes a sample pre-treatment apparatus 10 for retaining on a surface of a substrate a substance to be measured that is found on the surface of the substrate, after such substance has been dissolved and subsequently dried, an X-ray fluorescence spectrometer 40, and a transport apparatus 50 for transporting the substrate from the sample pre-treatment apparatus towards the X-ray fluorescence spectrometer, which system as a whole is easy to operate. This spectrometric system also includes a control apparatus 50 for controlling the sample pre-treatment apparatus 10, the X-ray fluorescence spectrometer 40 and the transport apparatus 50 in a totalized fashion.

Owner:RIGAKU CORP

Iron alloy fusing sample preparation method for X-ray fluorescence spectrum analysis

InactiveCN101832891AReduce sample preparation timeAnalytical results are reliableMaterial analysis using wave/particle radiationPreparing sample for investigationX-rayFerrosilicon

The invention relates to an iron alloy fusing sample preparation method for X-ray fluorescence spectrum analysis, belonging to the technical field of materialization detection and aiming to solve the problem that fusing a film production alloy sample can erode a platinum crucible. The method comprises the steps of building up wall of the platinum crucible, preparing an oxidizing agent, pre-oxidizing an iron alloy sample and fusing and preparing sample from the iron alloy sample. The invention provides the fusing sample preparation method suitable for various iron alloys such as ferromanganese, silicomanganese, calcium silicon, ferrosilicon, ferromolybdenum, ferrotitanium, cymrite, ferrochrome, ferrocolumbium, ferrovanadium, silicon silicomanganese and the like. By adopting the method, a glass fusing piece can be manufactured without eroding the valuable platinum crucible, the sample can be completely oxidized in the sample preparation process, the sample preparation time is short, the prepared glass fusing piece is uniform and perfect, and the mineral effect and the granularity effect can be completely eliminated. The invention has safe and reliable method, simple and convenient operation and good repeatability, is suitable for various iron alloy samples and widens the application range of the fluorescence analysis.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

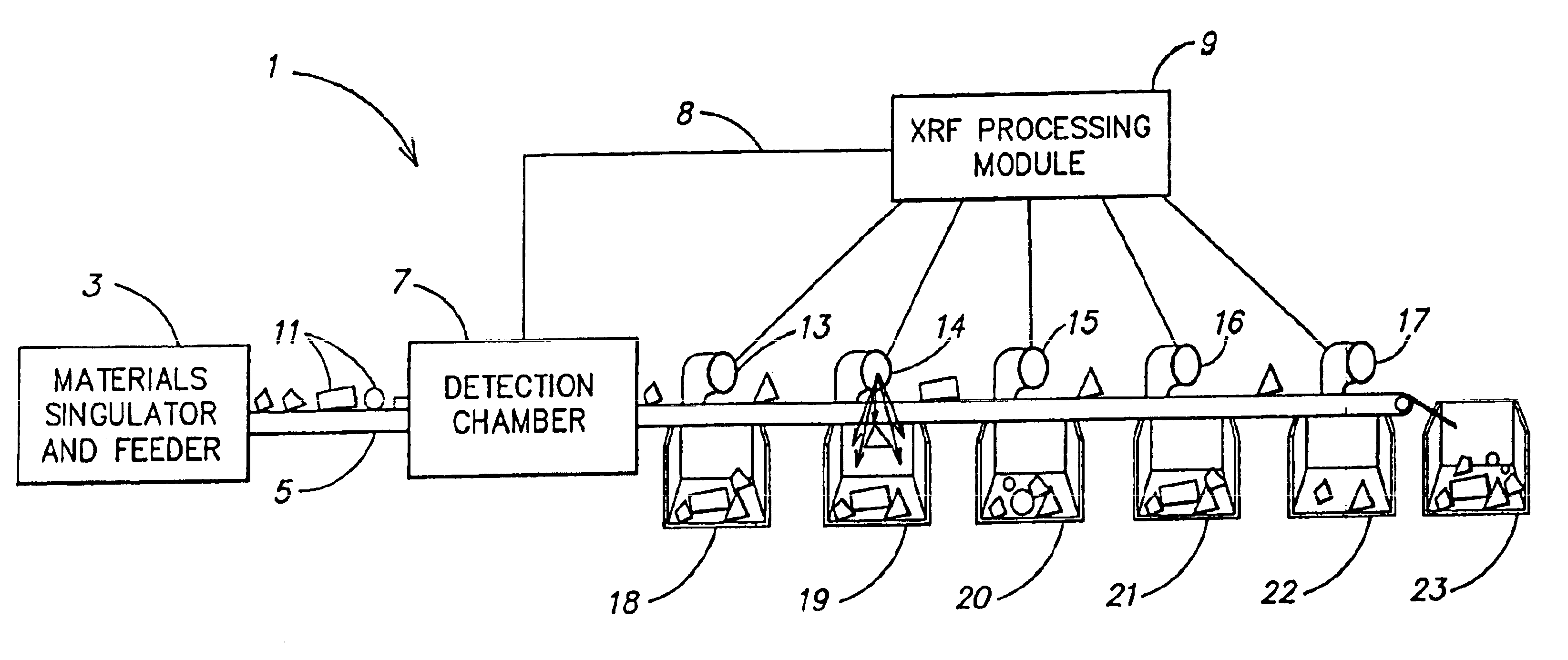

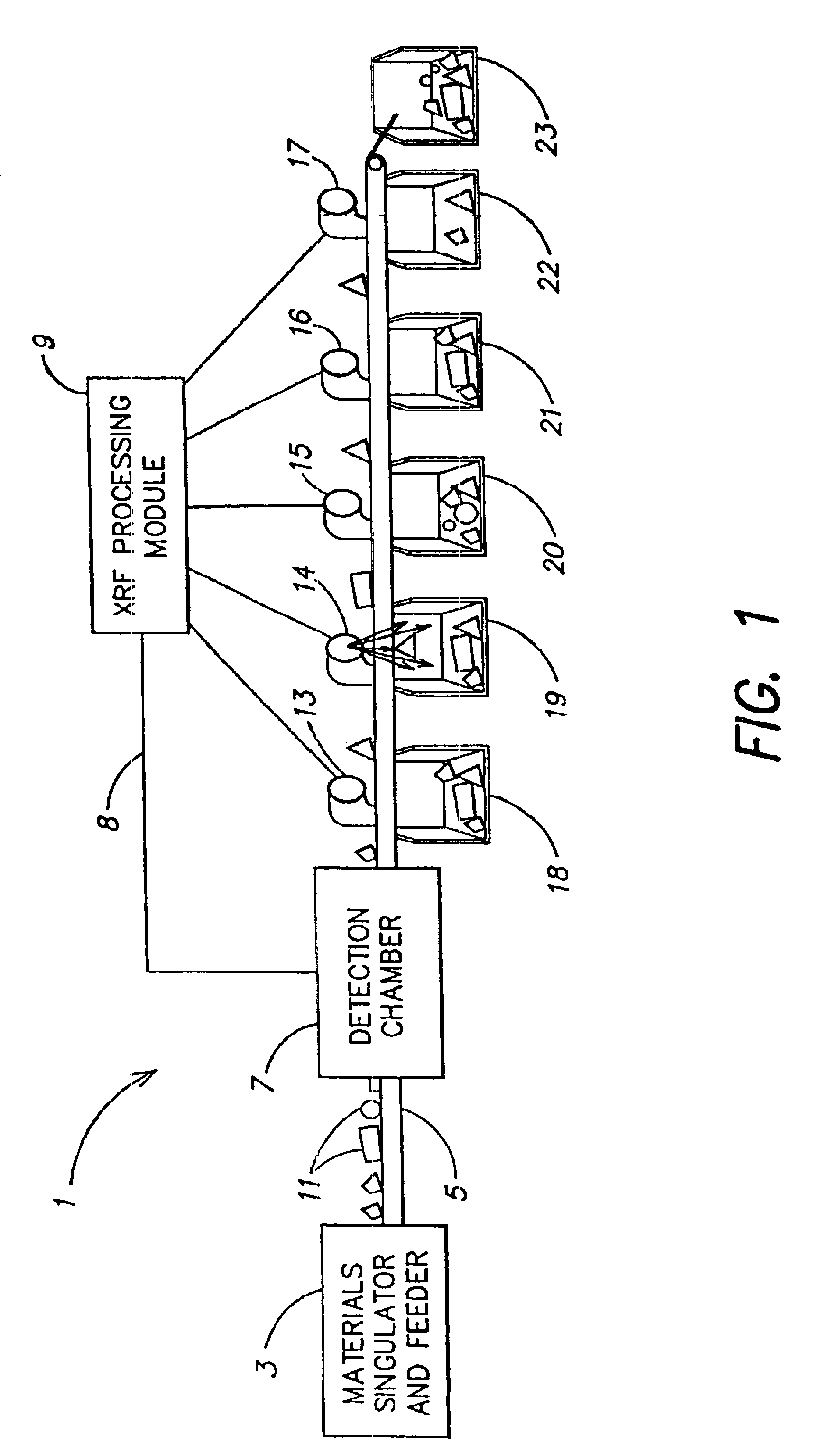

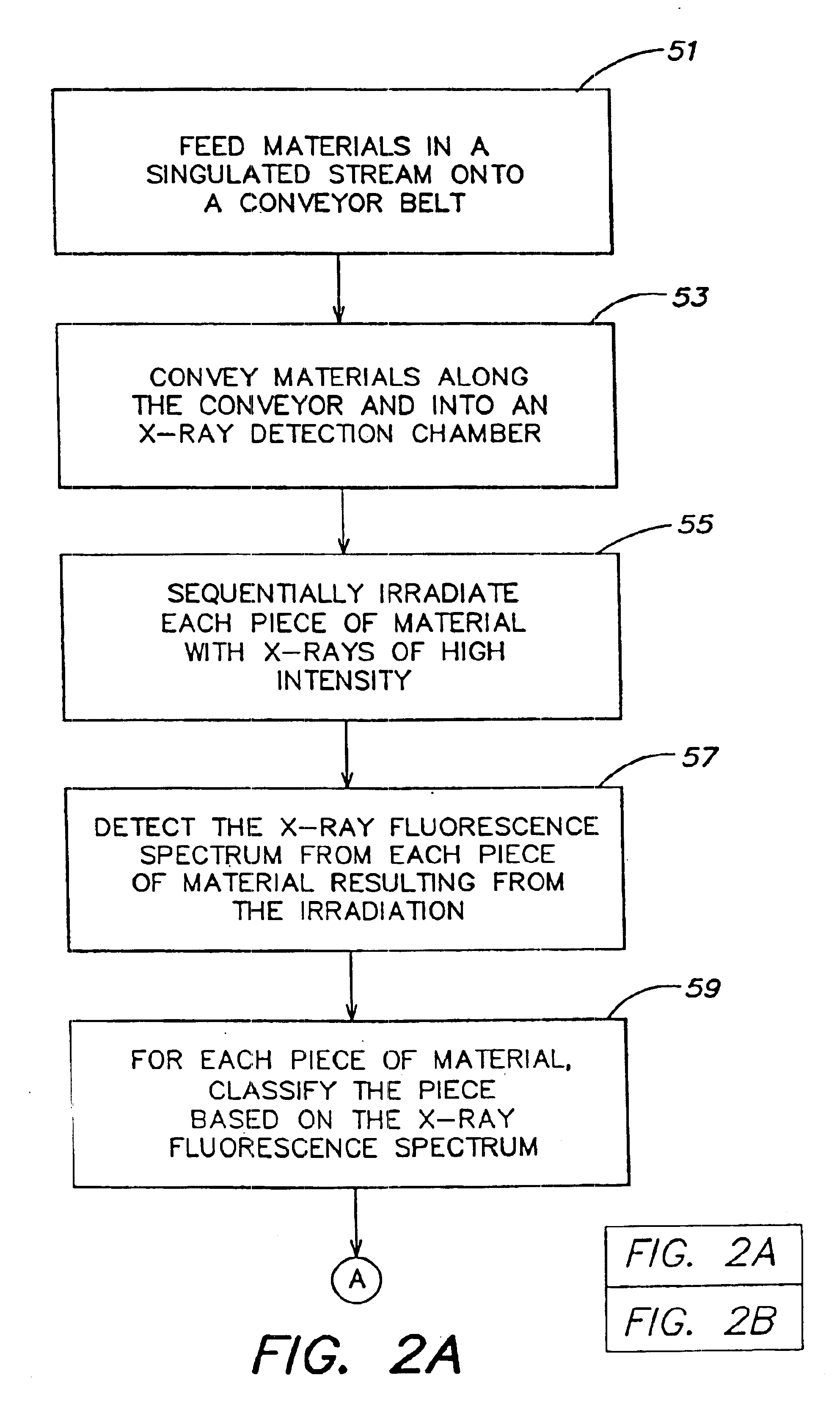

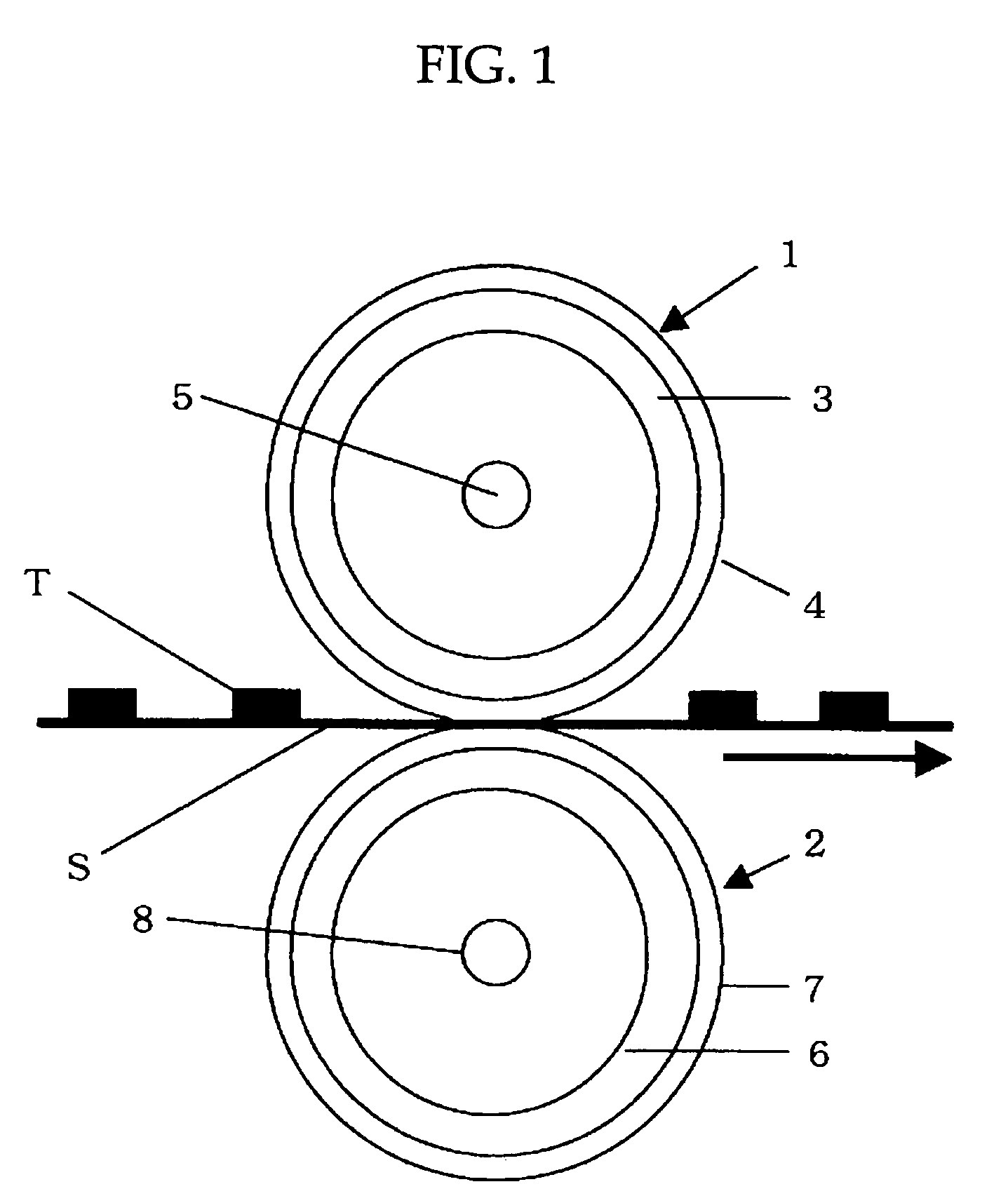

High speed materials sorting using x-ray fluorescence

InactiveUS6888917B2Accuracy of compromisedSpeed of compromisedX-ray spectral distribution measurementUsing wave/particle radiation meansSpectral patternSoft x ray

A system and process for classifying a piece of material of unknown composition at high speeds, where the system connected to a power supply. The piece is irradiated with first x-rays from an x-ray source, causing the piece to fluoresce x-rays. The fluoresced x-rays are detected with an x-ray detector, and the piece of material is classified from the detected fluoresced x-rays. Detecting and classifying may be cumulatively performed in less than one second. An x-ray fluorescence spectrum of the piece of material may be determined from the detected fluoresced x-rays, and the detection of the fluoresced x-rays may be conditioned such that accurate determination of the x-ray fluorescence spectrum is not significantly compromised, slowed or complicated by extraneous x-rays. The piece of material may be classified by recognizing the spectral pattern of the determined x-ray fluorescence spectrum. The piece of material may be flattened prior to irradiation and detection. The x-ray source may irradiate the first x-rays at a high intensity, and the x-ray source may be an x-ray tube.

Owner:SPECSTREETCARET

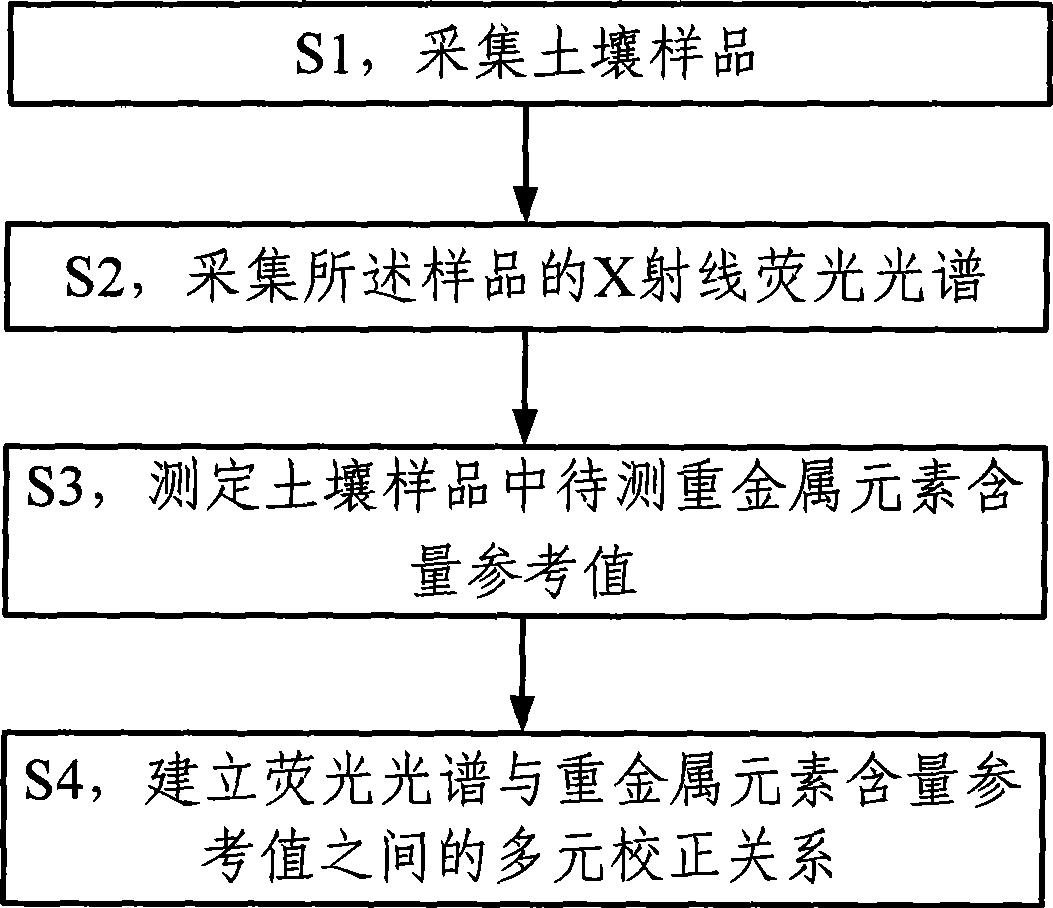

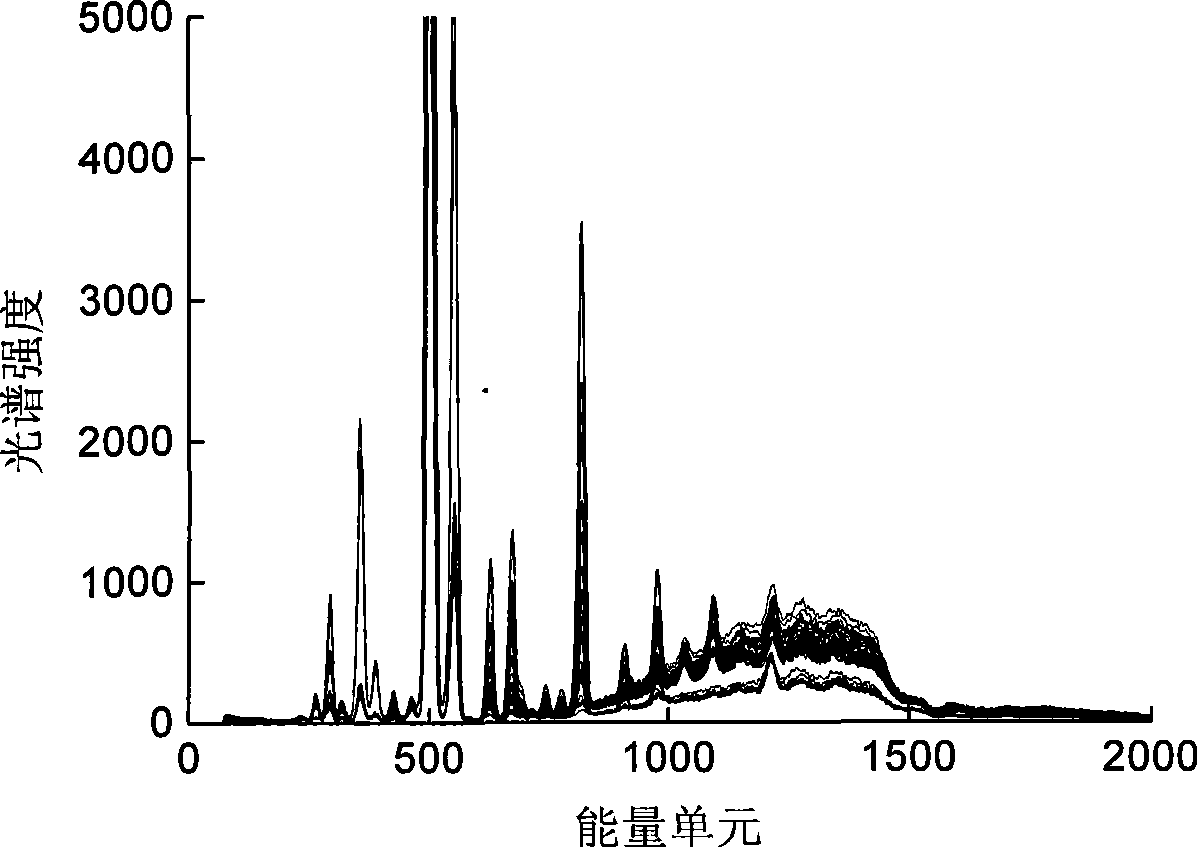

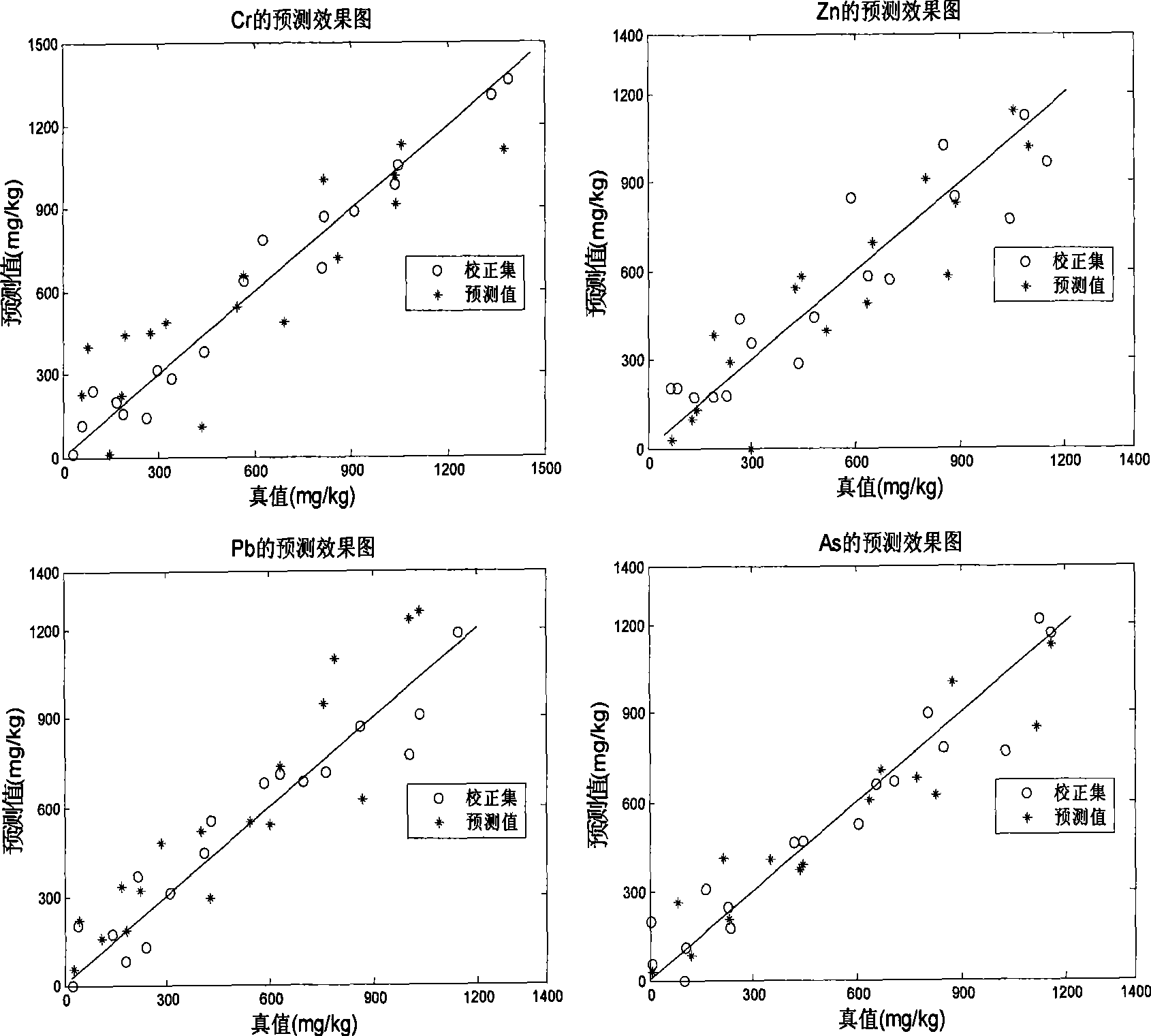

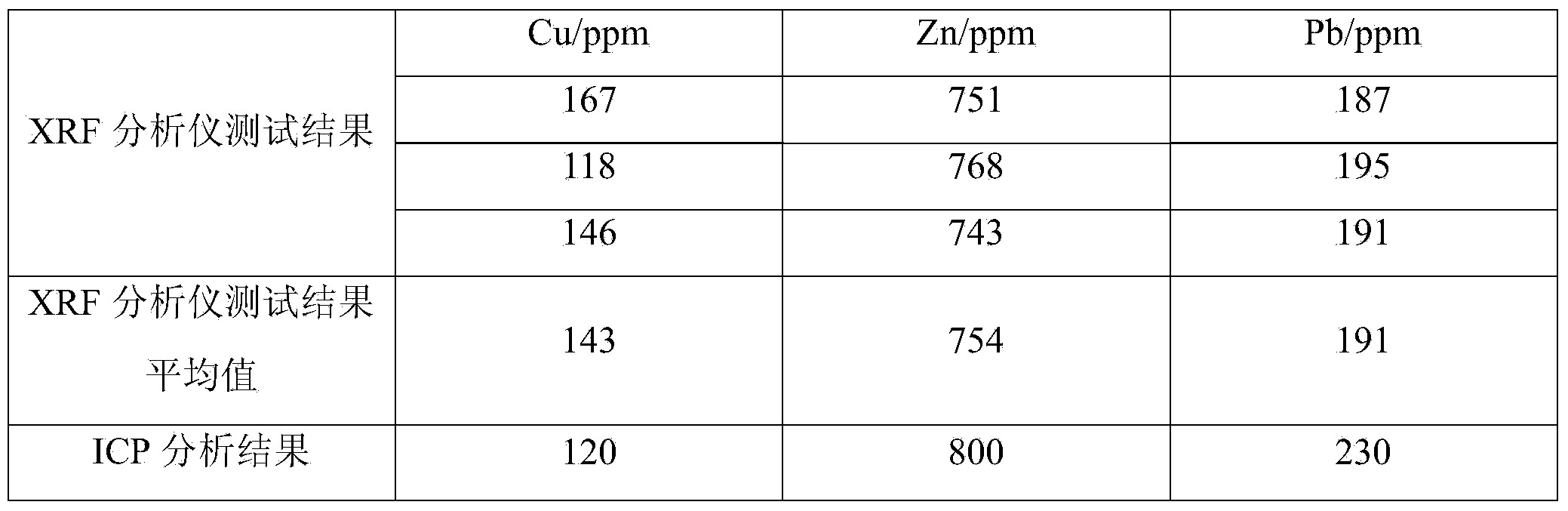

Modeling method of soil heavy metal content detection model and application thereof

InactiveCN101520421AUniversalFast NDTMaterial analysis using wave/particle radiationComplex mathematical operationsModel methodSoil heavy metals

The invention discloses a modeling method of a soil heavy metal content detection model and the application thereof. The modeling method includes the steps of collecting a soil sample, collecting the X-ray fluorescence spectrum of the sample, measuring the reference value of heavy metal element content to be measured in the soil sample, and establishing the correcting relation between the X-ray fluorescence spectrum and the reference value of heavy metal element content. The method can simultaneously perform rapid nondestructive examination to various heavy metal element contents of soil, has wide range of application and high universality and provides a technological base for the on-site detection of farmland soil heavy metal pollution.

Owner:北京农产品质量检测与农田环境监测技术研究中心

Toner for electrophotography, and image fixing process, image forming process, image forming apparatus and process cartridge using the same

InactiveUS7217485B2Sufficient electroconductivityImprove charging effectElectrographic process apparatusDevelopersX-rayImage formation

A toner for electrophotography contains a binder resin, a charge control agent, and a colorant. The colorant is a black iron oxide compound containing 10 to 45% by weight of titanium component calculated in terms of Ti atom in relation to Fe atom when measured by wavelength dispersive X-ray fluorescence spectrometry. Peaks at Bragg angle 2θ of the toner to CuKα X-ray are peak A at 32.9 degrees ±0.3 degrees and peak B at 35.5 degrees ±0.3 degrees, and X ray intensity ratio between peaks A and B (A / B) is in the range of 0.3 to 2.0 at a scan speed of 0.5 to 4 degrees / min.

Owner:RICOH KK

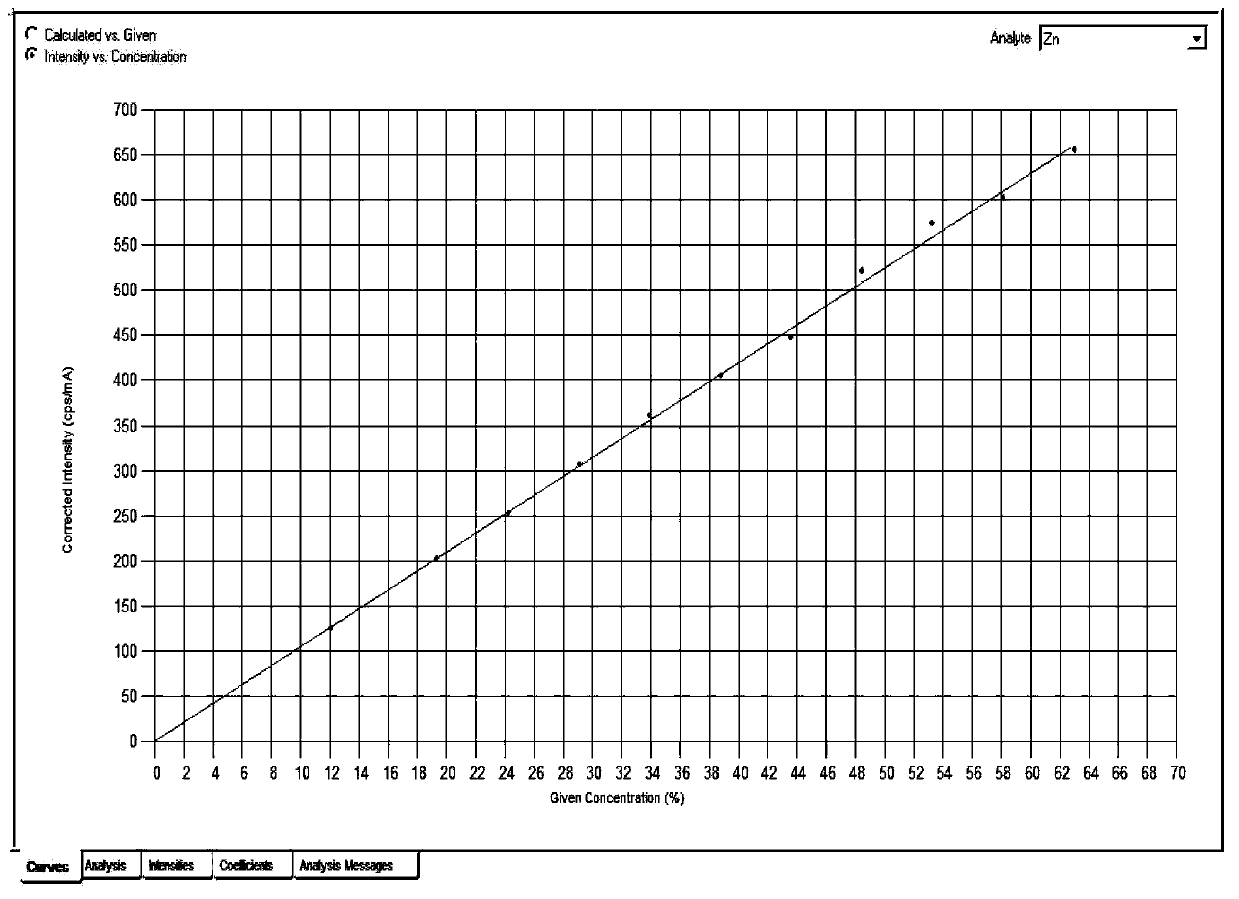

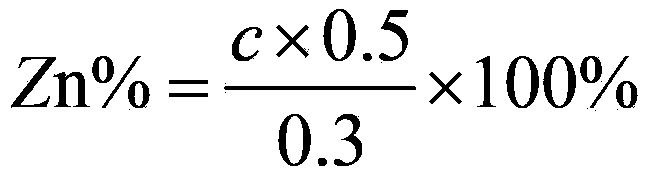

Method for determining content of zinc in zinc concentrate through energy-dispersive X-ray fluorescence spectrometry

ActiveCN103364426AEliminate unevennessElimination of physico-chemical effectsMaterial analysis using wave/particle radiationX-rayFluorescence spectrometer

The invention discloses a method for determining the content of zinc in the zinc concentrate through energy-dispersive X-ray fluorescence spectrometry. The method comprises the following steps: 1, preparing a plurality of zinc-iron working liquids, converting the mass concentrations of Zn in the operating liquids to Zn mass percentage concentrations, detecting the Zn mass percentage concentrations with an energy-dispersive X-ray fluorescence spectrometer as a detector, recording the fluorescence intensity during each time injection of a sample, and making a working curve; and 2, processing the zinc concentrate as a sample to prepare a sample solution, injecting the sample solution under detection conditions for making the working curve, recording the fluorescence intensity displayed on the detector, reading out the Zn mass percentage concentration corresponded to the fluorescence intensity according to the determined working curve, and calculating according to a specific formula to obtain the mass percentage concentration of simple substance zinc in the sample. The method utilizes a solution process to eliminate or basically eliminate the matrix effect, so the zinc content can be accurately determined; and the method has the advantages of simple operation, short detection period, good detection result accuracy and high precision.

Owner:广西出入境检验检疫局危险品检测技术中心

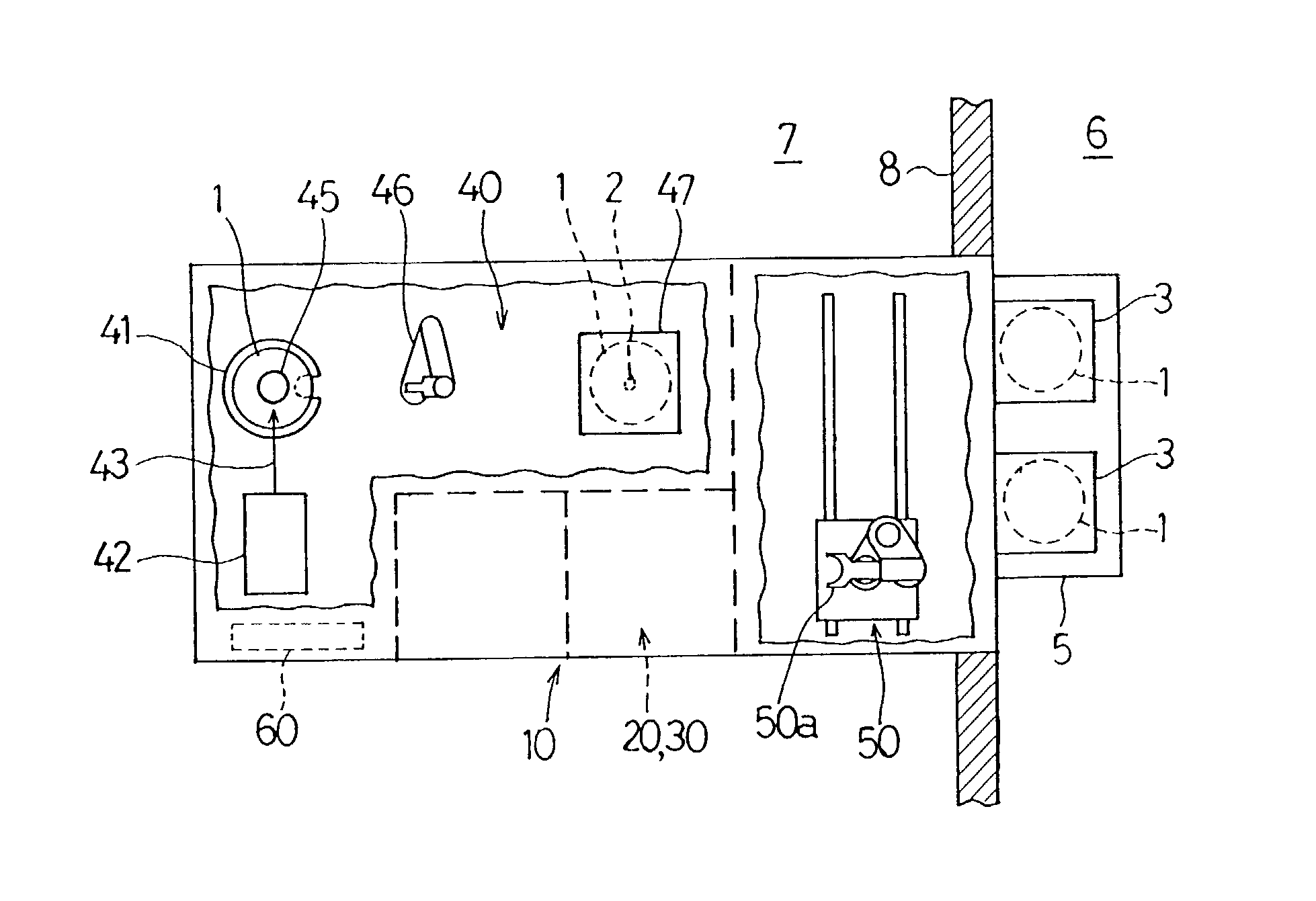

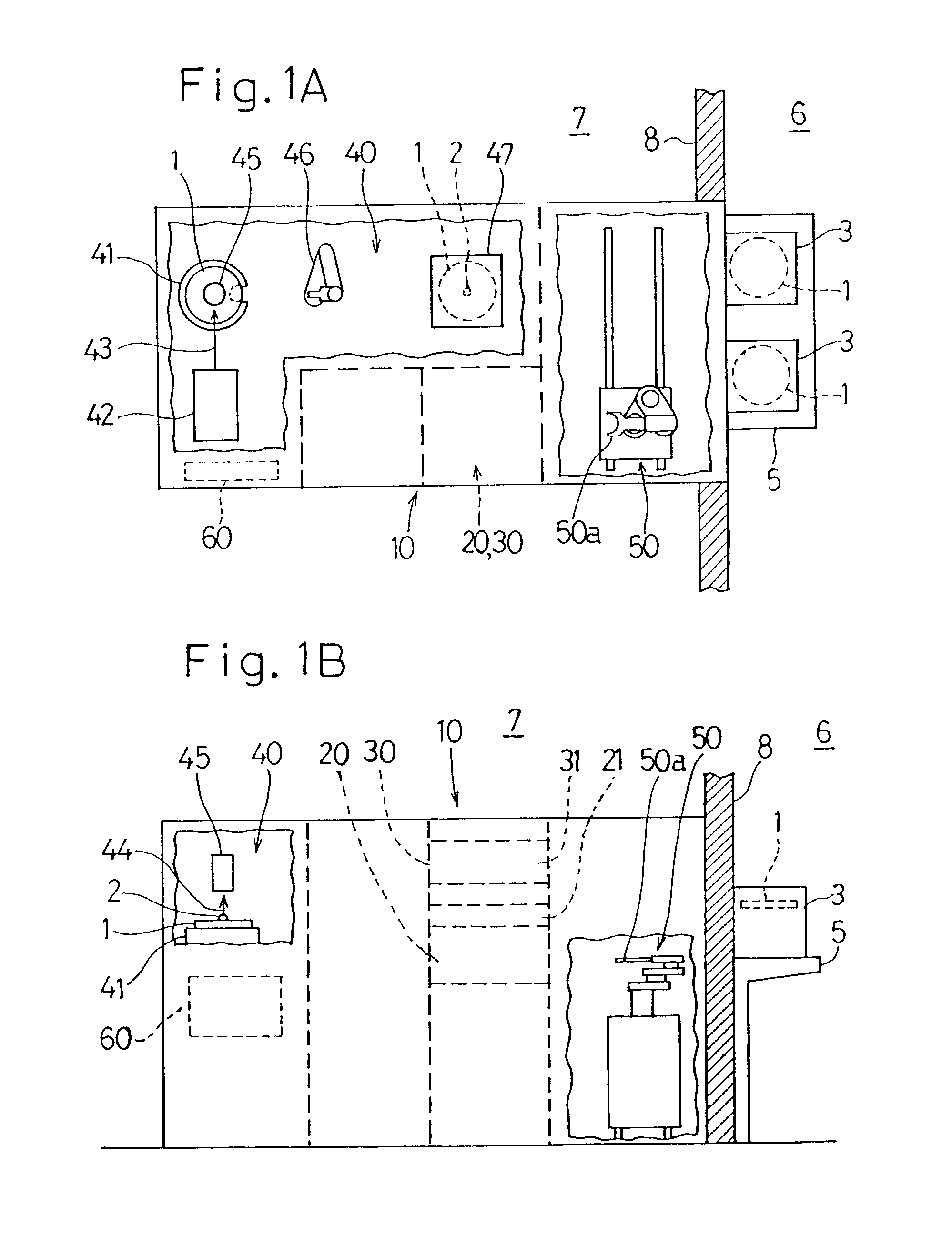

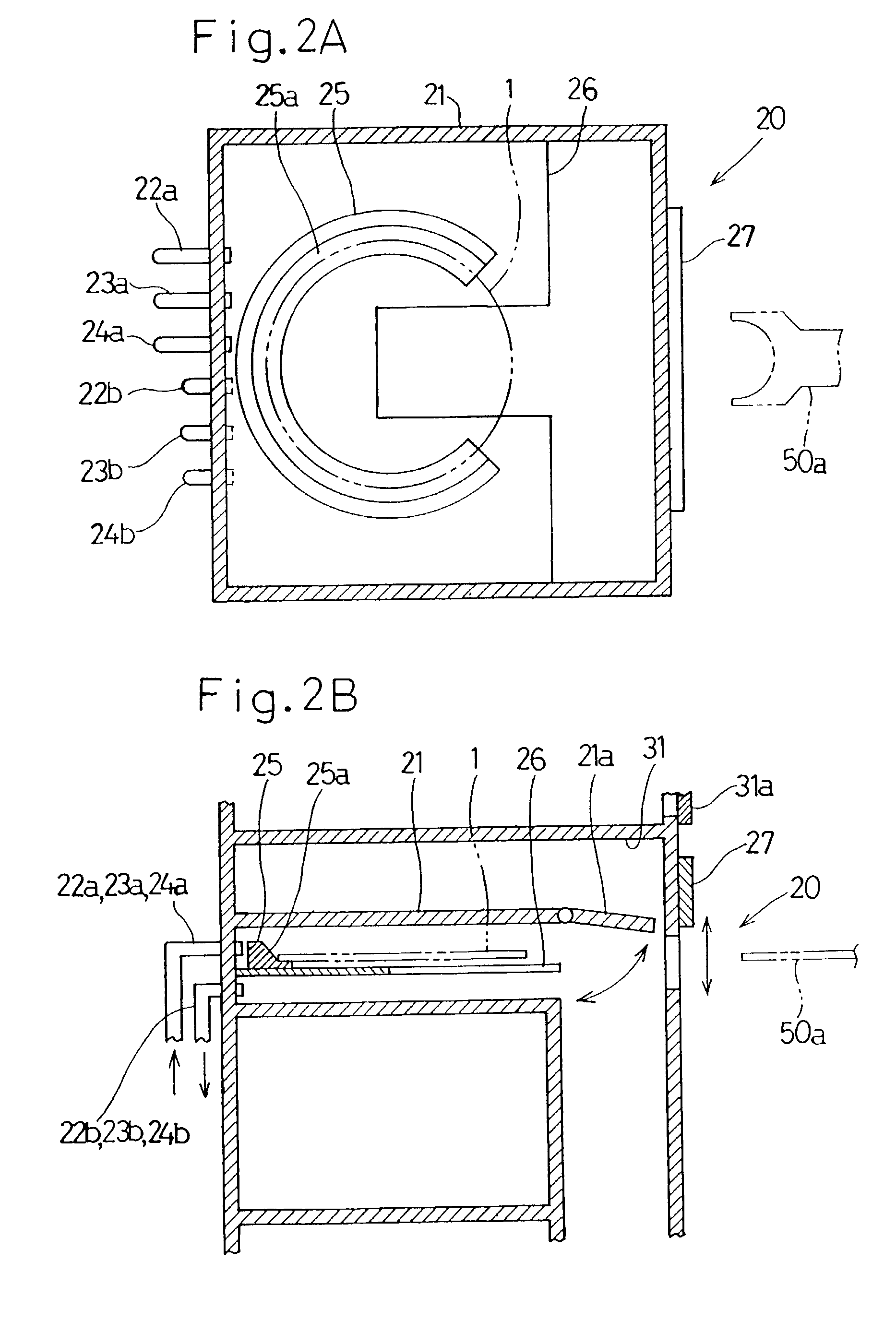

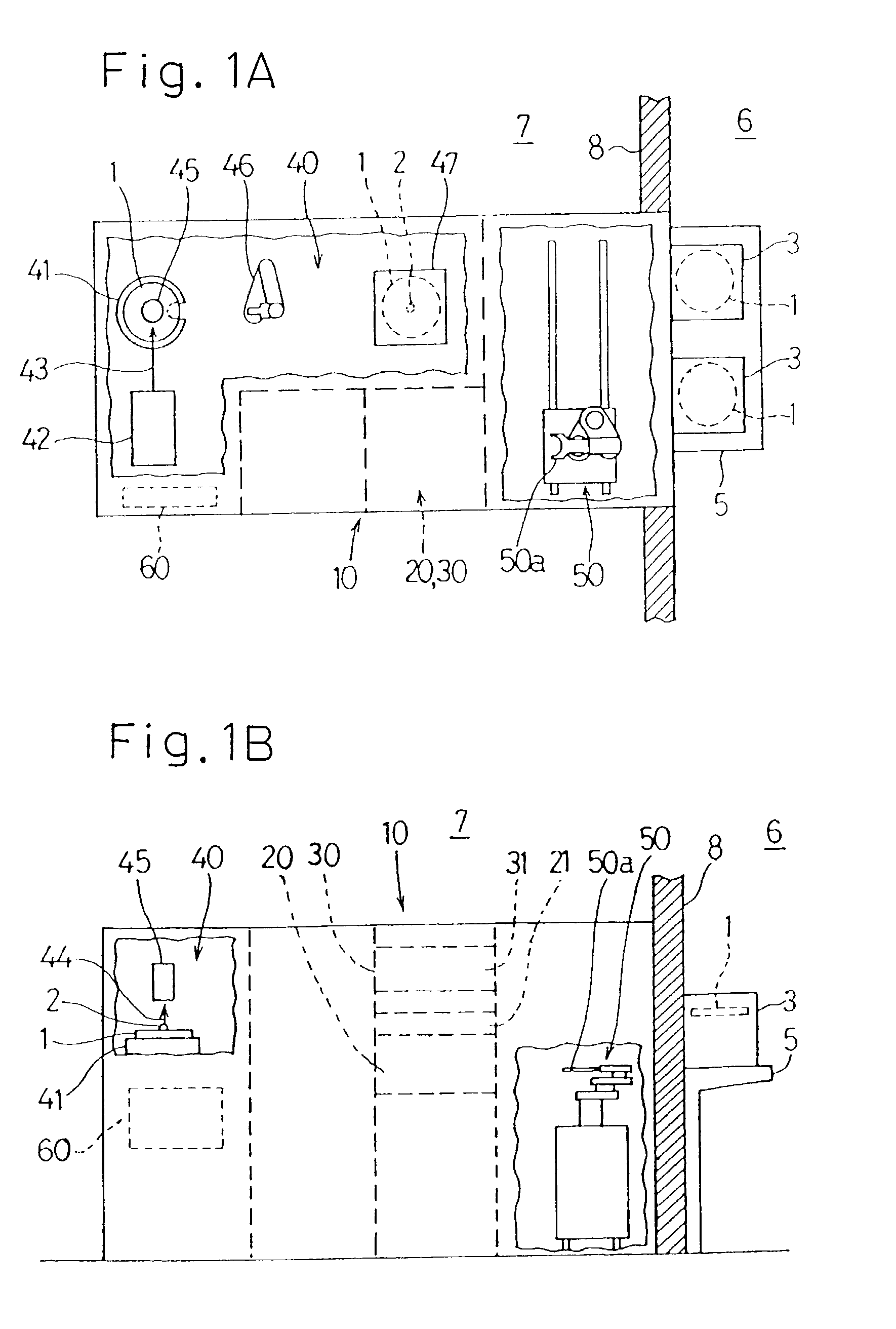

Sample preprocessing system for a fluorescent X-ray analysis and X-ray fluorescence spectrometric system using the same

InactiveUS20030053589A1Extended service lifeLiquid surface applicatorsMaterial analysis using wave/particle radiationReactive gasFluorescence spectrometry

A sample preprocessing system for a fluorescent X-ray analysis includes a sample preprocessing apparatus for retaining on a surface of a substrate a substance to be measured that is found on the surface of the substrate, after such substance has been dissolved and subsequently dried, a transport apparatus for transporting the substrate, and a control apparatus for controlling the sample preprocessing apparatus and the transport apparatus. The control apparatus 60 after having confirmed that the pressure difference between inside and outside of the apparatus 10 (20, 30) and the concentration of the reactive gas within the apparatus are within a predetermined range causes automatically opening and closing shutters 21a, 27 and 31a to thereby avoid a possible corrosion of the apparatuses positioned outside the sample preprocessing apparatus while increasing the service lifetime thereof.

Owner:RIGAKU CORP

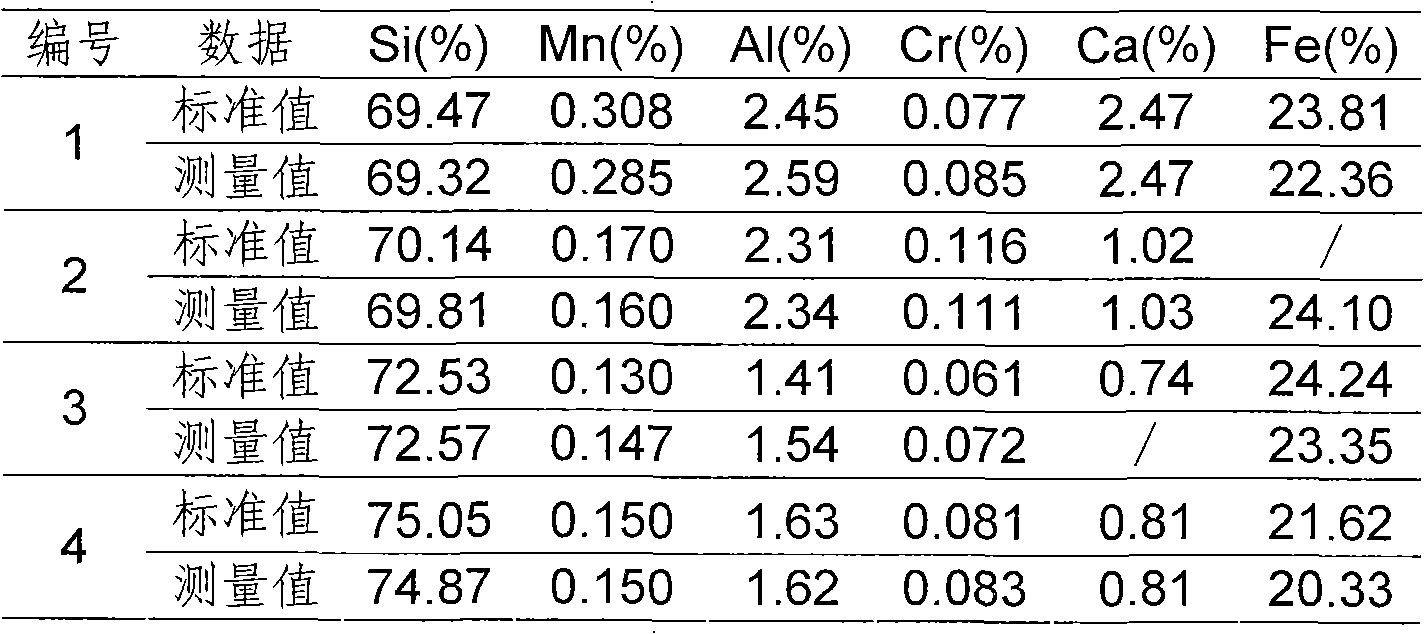

X-ray fluorescence spectrum quantitative analysis method based on LM-BP neural network

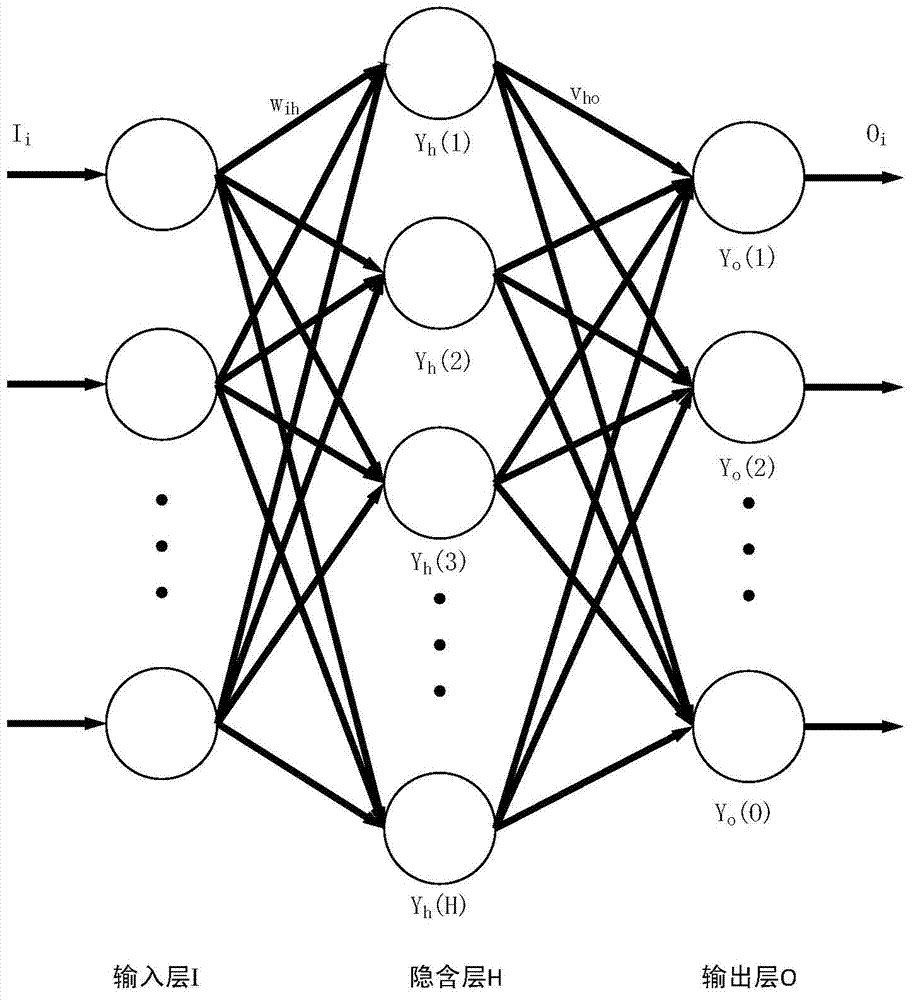

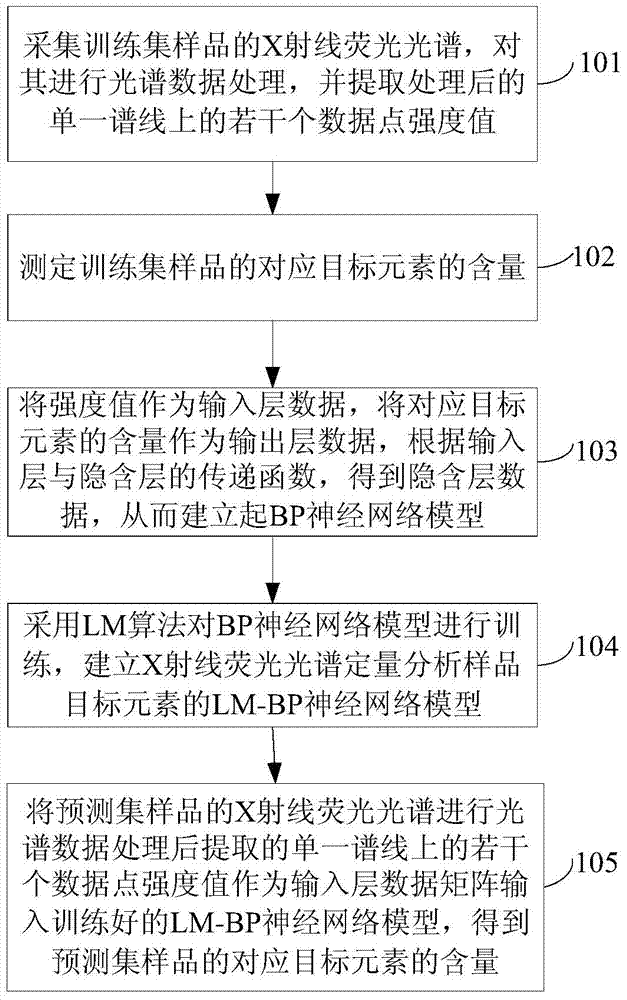

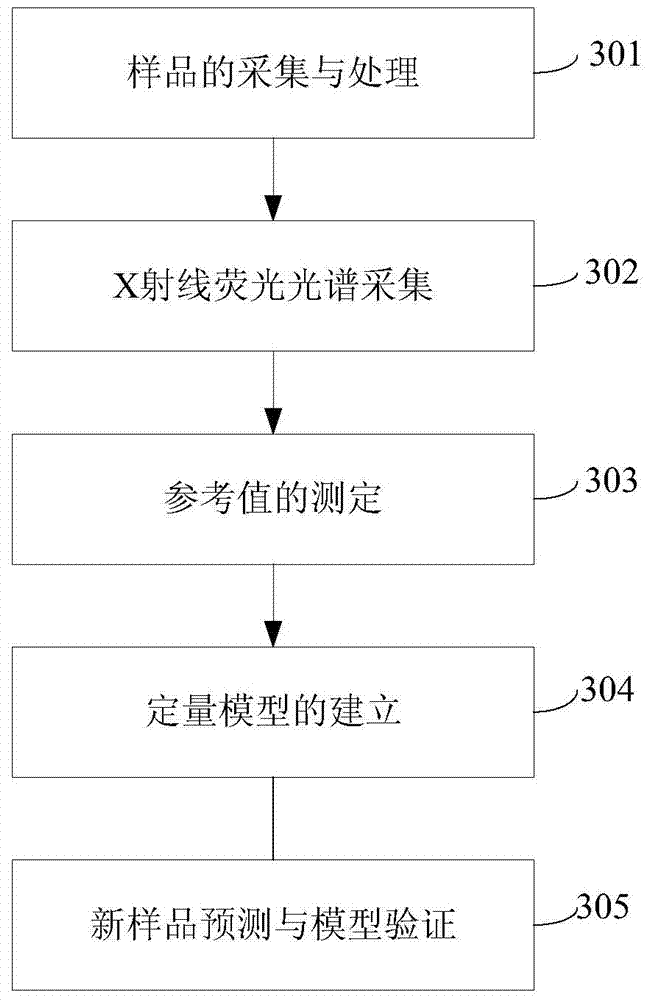

InactiveCN103792246ARapid determinationAccurate measurementMaterial analysis using wave/particle radiationNeural learning methodsNetwork modelData treatment

The invention provides an X-ray fluorescence spectrum quantitative analysis method based on an LM-BP neural network. The method comprises the following steps: acquiring an X-ray fluorescence spectrum of a training set sample, performing spectrum data treatment, and extracting intensity values of a plurality of data points in a single spectral line after the treatment; measuring the content of corresponding target elements of the training set sample; with the intensity values as input layer data and the content of the corresponding target elements as output layer data, acquiring hidden layer data according to a transfer function of an input layer and a hidden layer so as to build a BP neural network model; training the BP neural network model by an LM algorithm; and acquiring the content of the corresponding target element of a prediction set sample by virtue of the trained LM-BP neural network model. The method can be used for performing quantitative analysis on elements by virtue of the X-ray fluorescence spectrum based on the LM-BP neural network.

Owner:BEIJING RES CENT FOR AGRI STANDARDS & TESTING

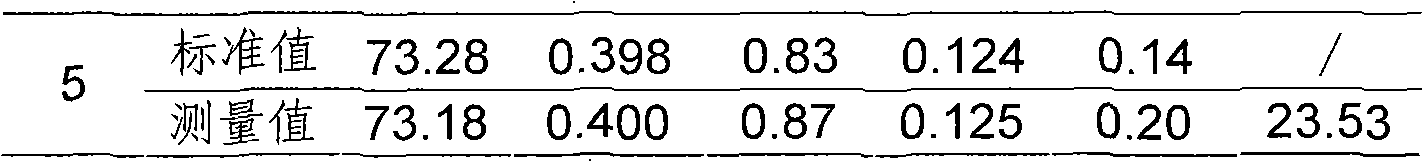

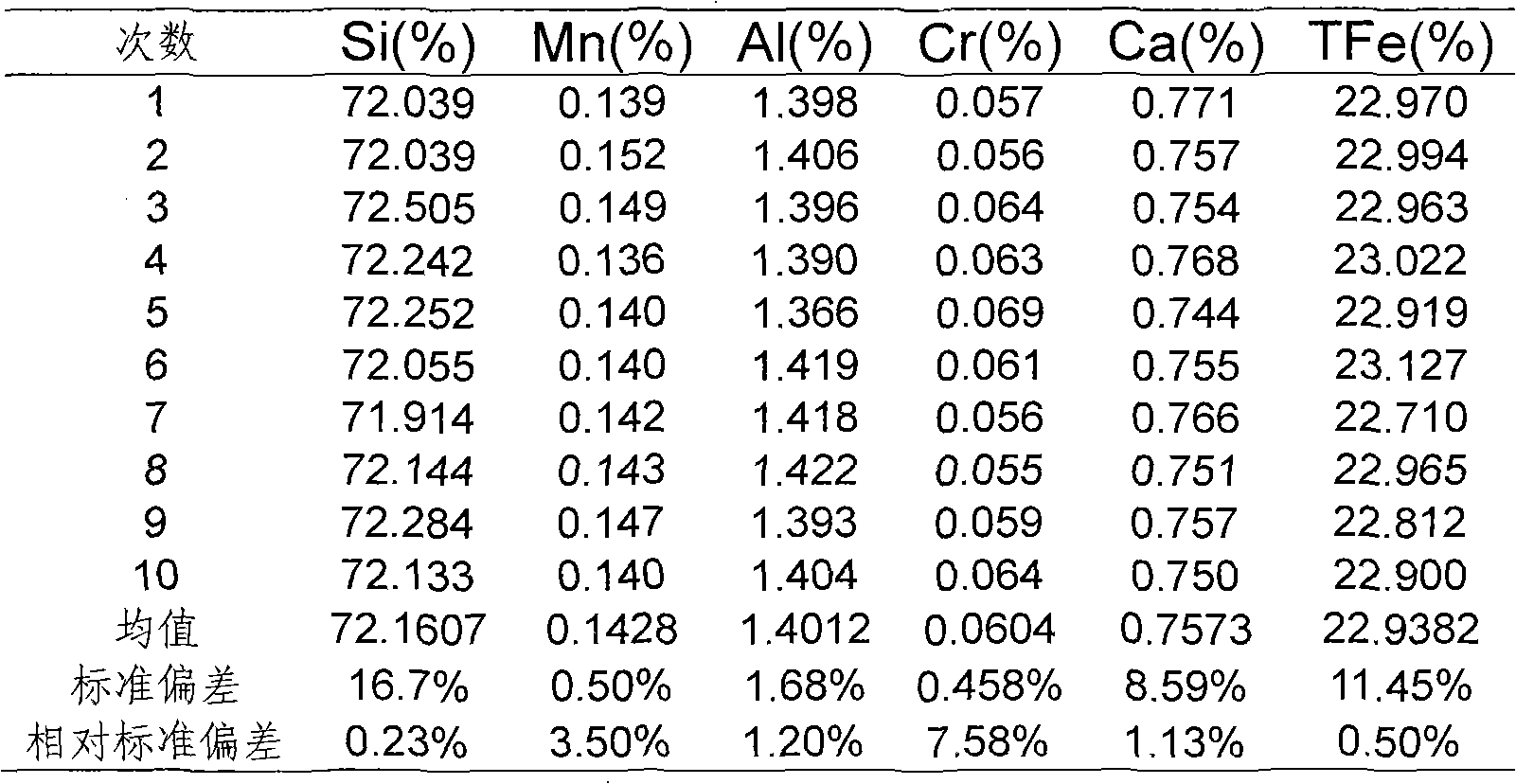

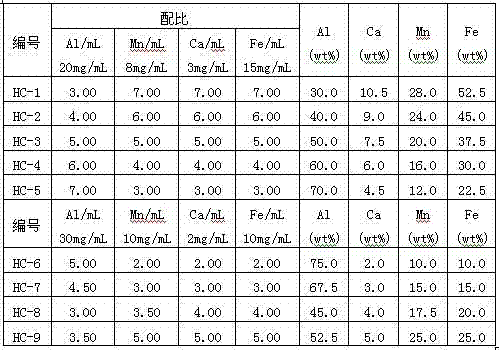

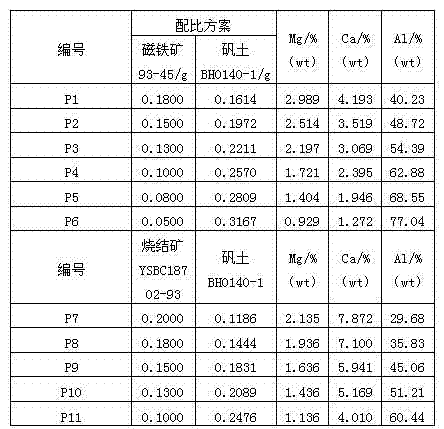

X-ray fluorescence spectroscopy analysis fusion sample preparation method of aluminum, manganese, calcium and iron alloy

InactiveCN102607934AEliminate sources of errorImprove analytical accuracyMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceManganese

The invention discloses an X-ray fluorescence spectroscopy analysis fusion sample preparation method of an aluminum, manganese, calcium and iron alloy, which comprises the steps of: firstly, coating a uniform protection wall layer in a platinum crucible by using lithium tetraborate, then placing an aluminum, manganese, calcium and iron sample, an oxidizing agent, a lithium borate solvent and a releasing agent into the platinum crucible in which the protection wall is coated, uniformly mixing, and then pre-oxidizing the aluminum, manganese, calcium and iron sample; and finally, melting the pre-oxidized aluminum, manganese, calcium and iron sample, and cooling to obtain an aluminum, manganese, calcium and iron sample glass fuse piece, wherein the aluminum, manganese, calcium and iron sample is a detection sample or calibration sample of the aluminum, manganese, calcium and iron alloy, and the sample glass fuse piece is a detection sample glass fuse piece or calibration sample glass fuse piece of the aluminum, manganese, calcium and iron alloy. On the premise of no corrosion to the valuable platinum crucible, the glass fuse piece can be prepared, and the prepared sample is excellent and uniform, thus the mineral effect and the grain size effect are completely eliminated.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Method for determining element of aluminum fluoride using X ray fluorescence spectrophotometry

InactiveCN101059456AAccurate measurementRapid determinationMaterial analysis using wave/particle radiationAluminum fluorideSoft x ray

The invention relates to a method for using X-ray fluorescence spectrum method to measure the components of aluminum fluoride, characterized in that the test process comprises that a, fusing a standard sample and a sample borate mixture solvent into a glass sample at 980-1000Deg. C, b, using X-ray fluorescence spectrum method to measure the fluorescence strength of standard sample to make a correct curvature, c, using a X-ray fluorescence spectrometer to measure the strength and the component contents of the sample. The invention can accurately and quickly measure the component contents of aluminum fluoride, to improve measurement accuracy, meet the demands of aluminum fluoride industry and user, improve working efficiency and save test cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Sintered polycrystalline yttrium aluminum garnet and use thereof in optical devices

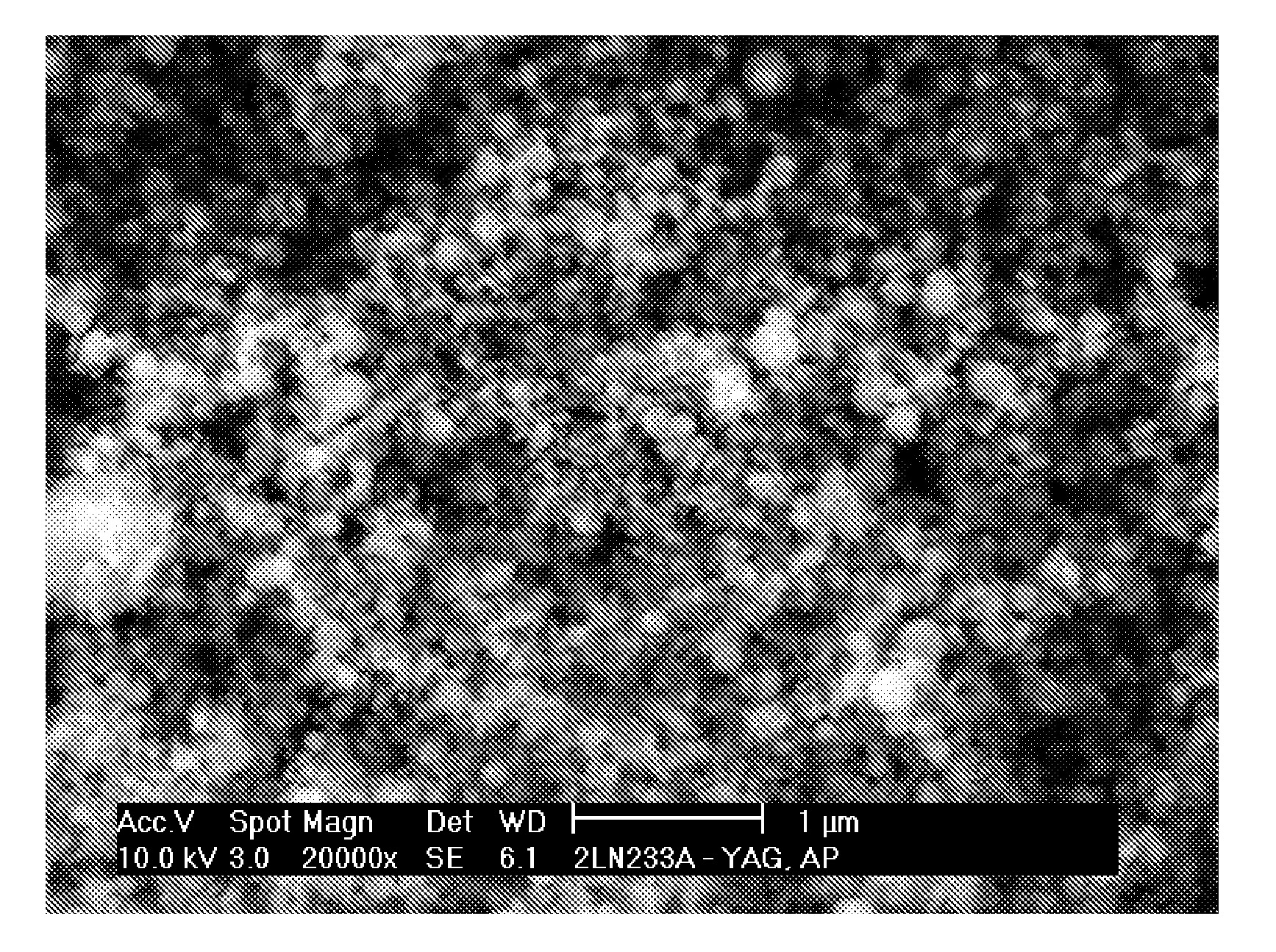

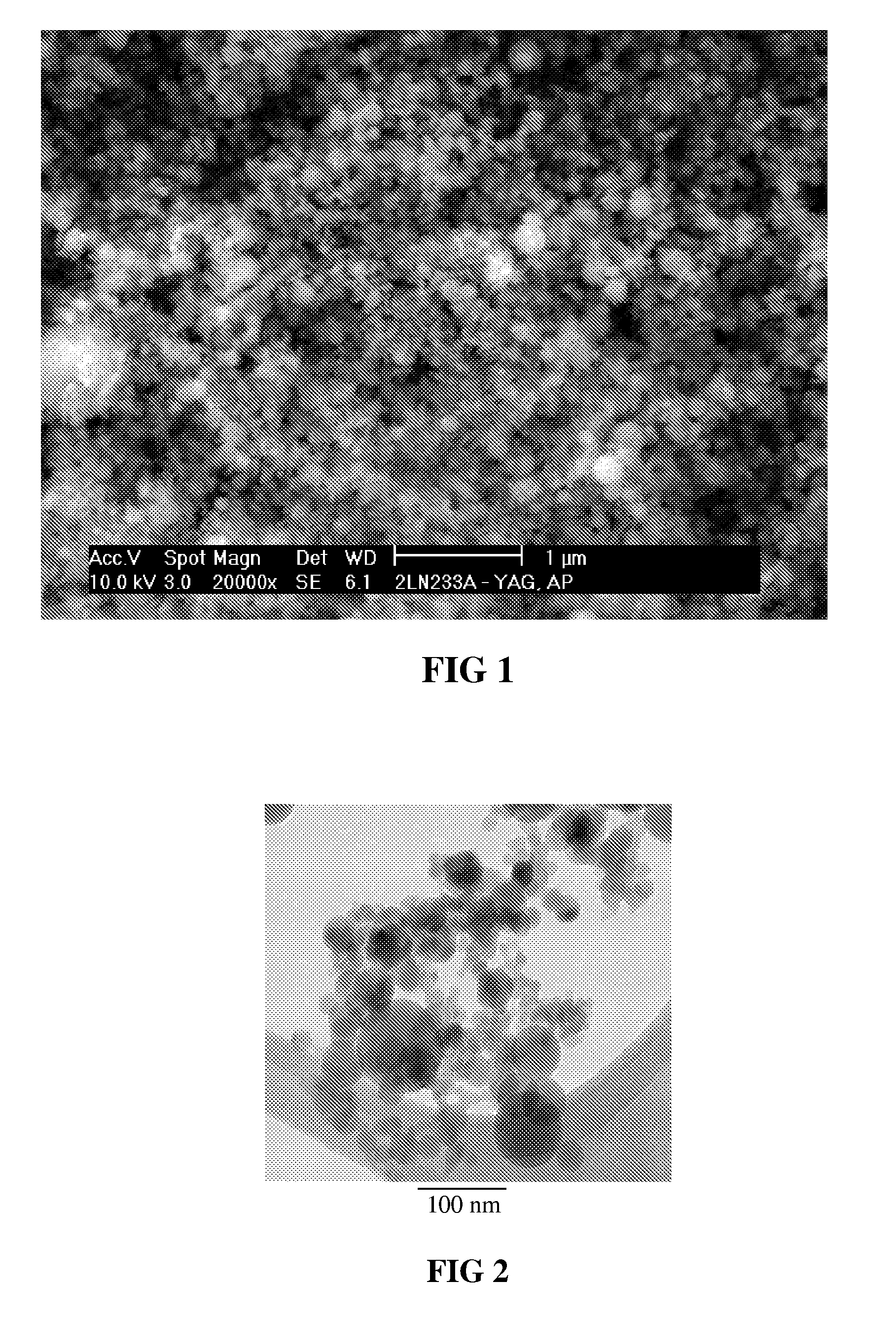

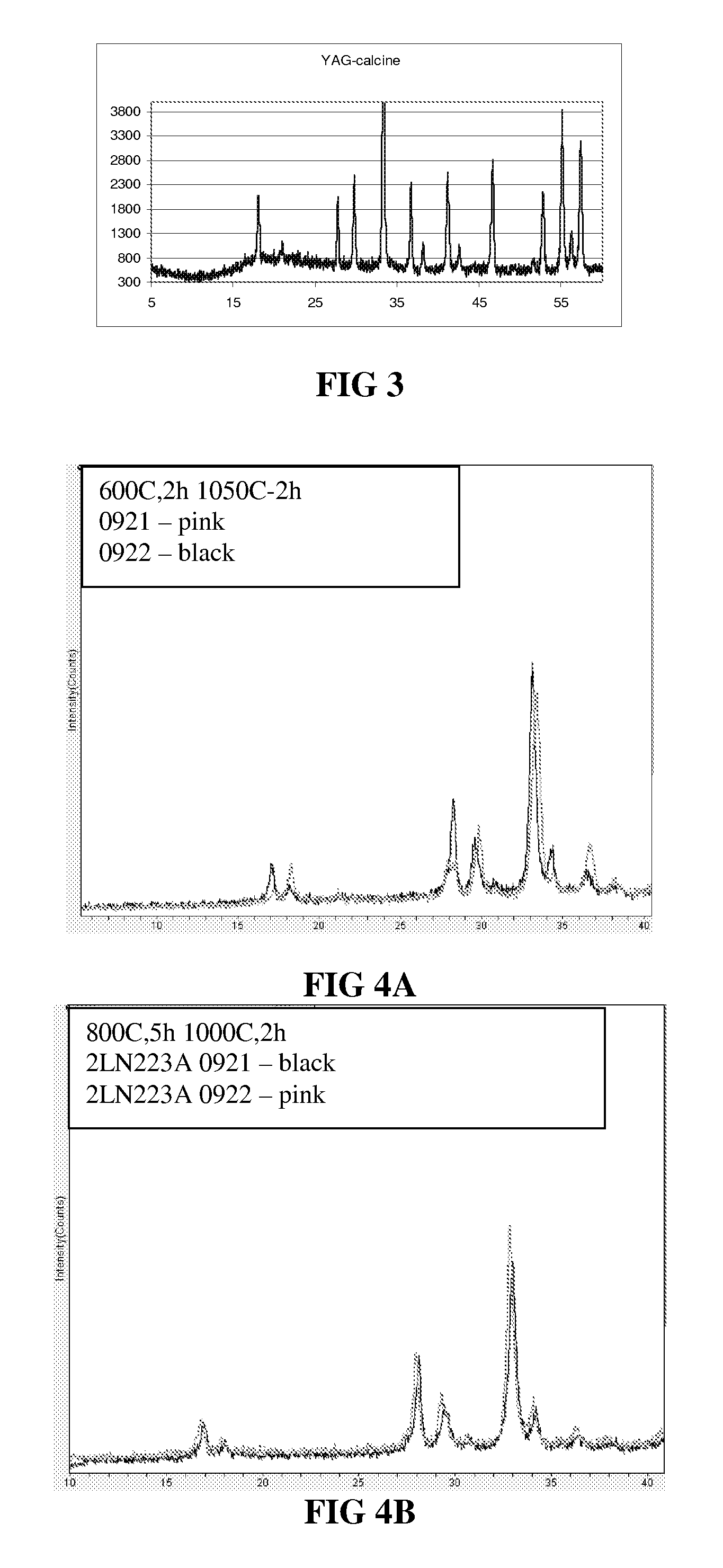

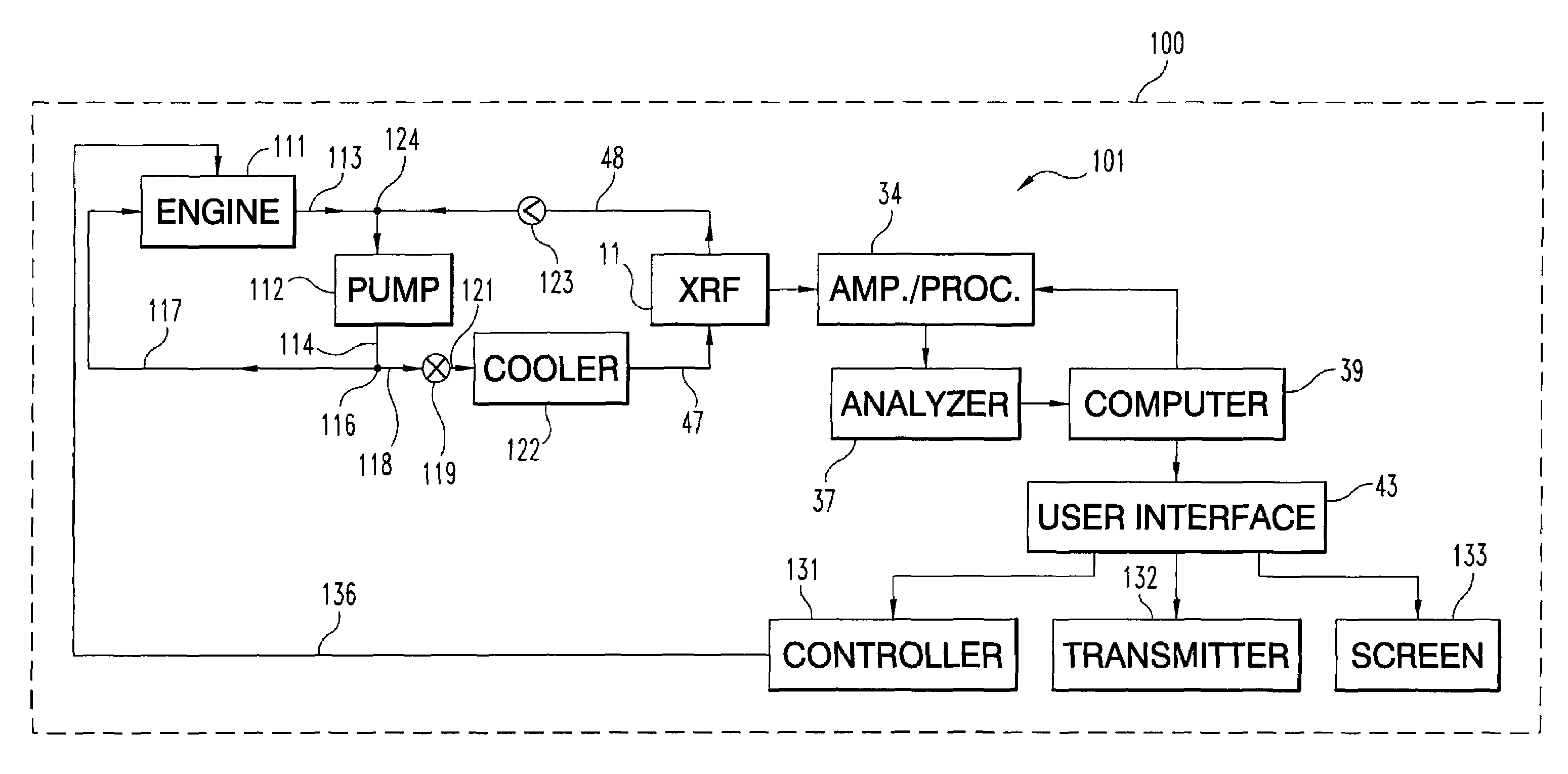

InactiveUS20100048378A1Improve the level ofControl loadMaterial nanotechnologyRare earth metal compoundsCelsius DegreeYttrium

A transparent yttrium aluminum garnet precursor composition is provided that includes a plurality of calcined particles of yttrium aluminum oxide having a mean particle domain size of between 10 and 200 nanometers and a predominant hexagonal crystal structure. High levels of YAG transparency are obtained for large YAG articles through control of the aluminum:yttrium atomic ratio to 1:06±0.001 and limiting impurity loadings to less than 100 ppm. The composition is calcined at a temperature between 700° Celsius and 900° Celsius to remove organic additives to yield a predominant metastable hexagonal phase yttrium aluminum oxide nanoparticulate having an atomic ratio of aluminum: yttrium of 1:0.6±0.001. With dispersion in an organic binder and a translucent YAG article is formed having a transmittance at a wavelength of 1064 nanometers of greater than 75%. The translucent YAG article is characterized by an average domain size of less than 1 micron and having a density of at least 99% and inclusions present at less than 2 surface area percent. The ability of a batch of yttrium aluminum oxide nanoparticles to serve as a transparent YAG precursor includes collecting an X-ray fluorescence spectrum from a plurality of aluminum oxide nanoparticles having a predominant crystal structure other than garnet to yield an A1:Y raw integrated peak intensity ratio. The nanoparticles are sintered to yield a predominant garnet phase and a secondary phase and optionally isostatic pressing during sintering. By using only precursor nanoparticles with a standard deviation of ±0.003 in the peak ratio exceptionally high transparency YAG is reproducibly produced.

Owner:NANOCEROX

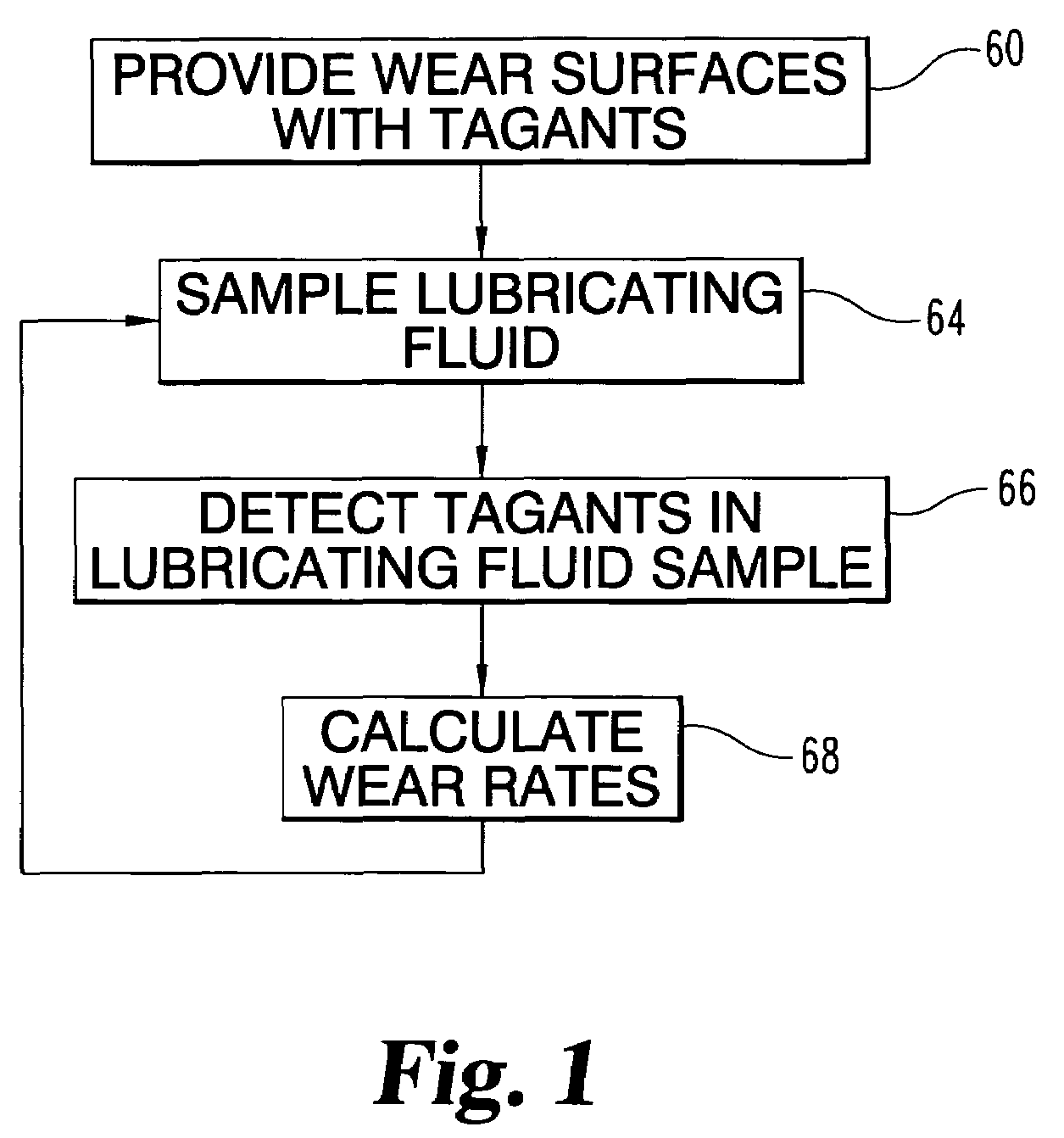

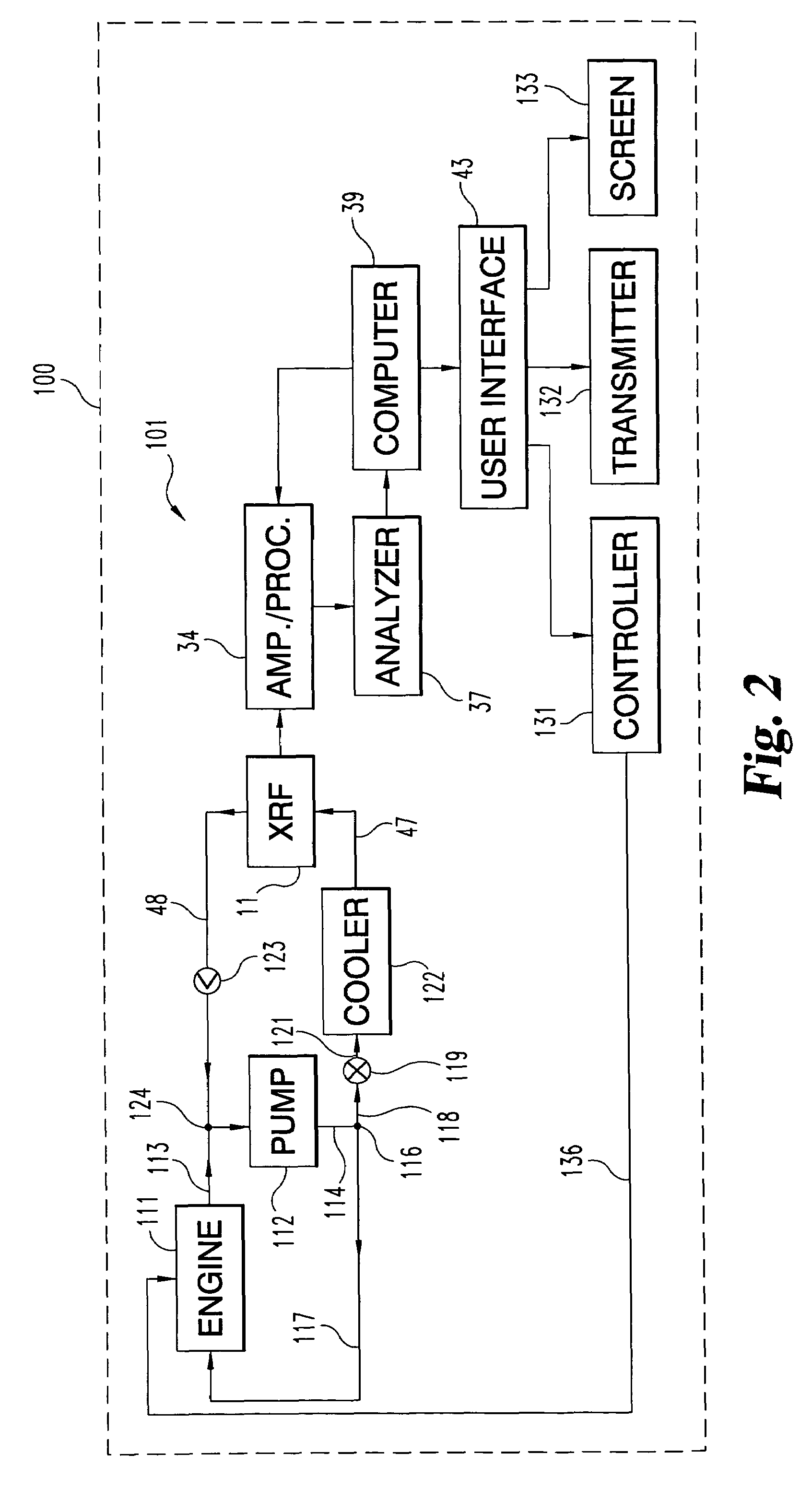

Component specific machine wear determination with x-ray fluorescence spectrometry

InactiveUS7184515B2Material analysis using wave/particle radiationX-ray spectral distribution measurementMachine partsFluorescence spectrometry

X-ray fluorescence analysis is used to determine wear of machine parts on a component-specific basis. The individual wetted wear surfaces of the machine are provided with a signature tagant composition, and as the components wear, the amounts of each tagant in the lubricating fluid are determined by the x-ray fluorescence analysis. An analysis system tracks the amounts of the tagants in the lubricating fluid, and with information of the signature tagant composition of each wear surface, calculates wear rate information for each of the wear surfaces. This component-specific wear information is then used in scheduling maintenance and predicting failures of the machine.

Owner:BATTELLE MEMORIAL INST

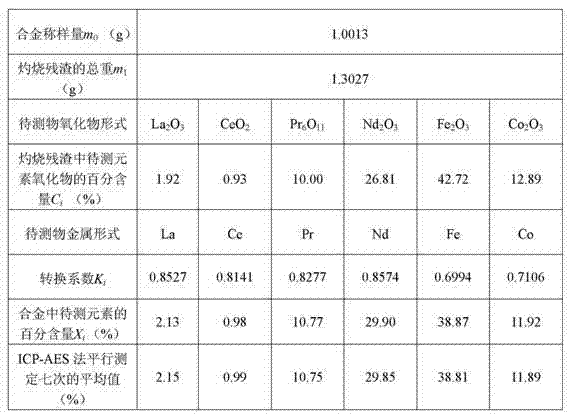

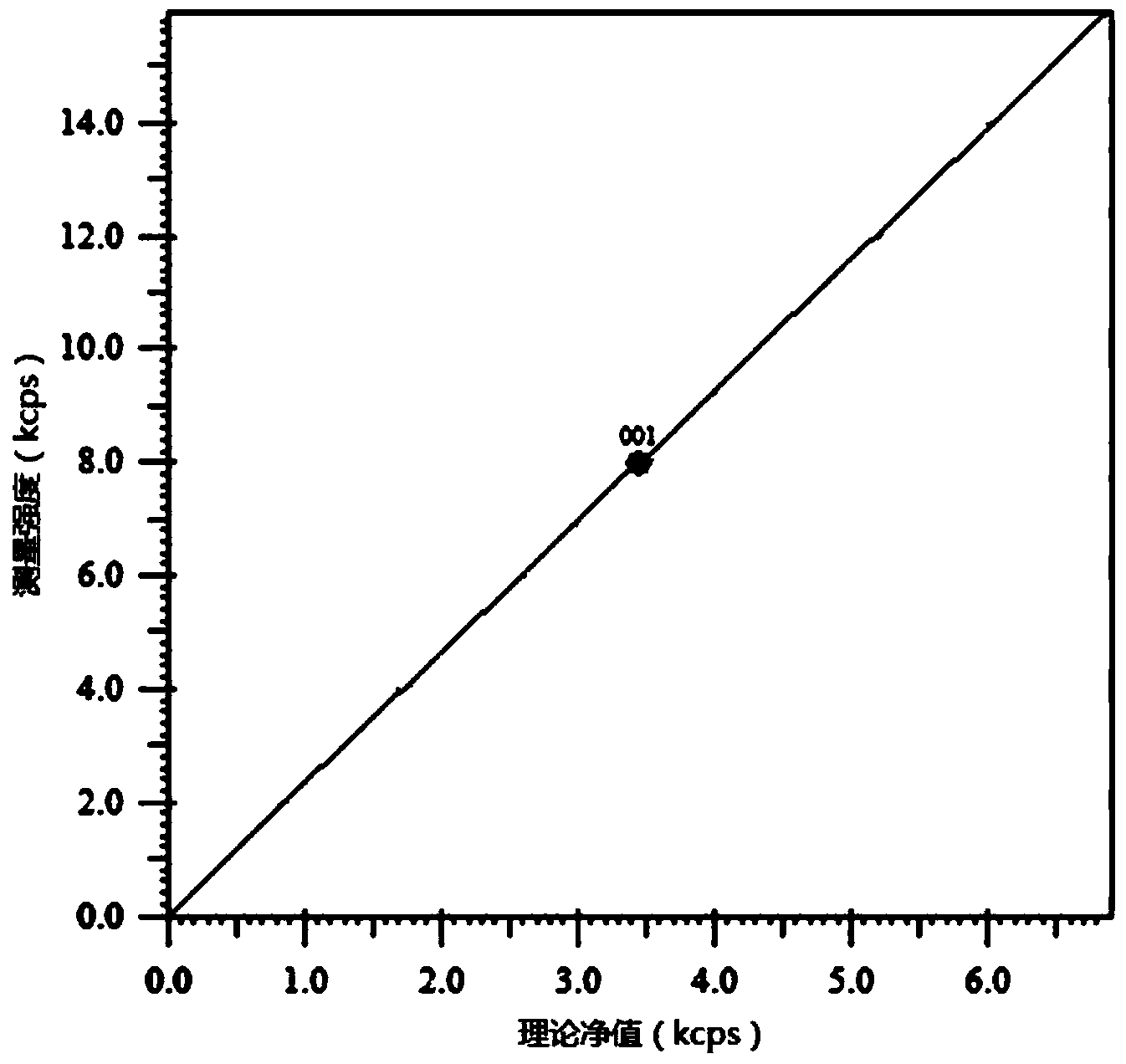

Metal alloy XRF spectrometry utilizing new sample preparation technology

InactiveCN102207475AHigh melting pointSolve the problem that cannot be detected by X-ray fluorescence spectroscopyMaterial analysis using wave/particle radiationPreparing sample for investigationCarbonizationAcid dissolution

The invention provides a metal alloy XRF spectrometry utilizing a new sample preparation technology. The technology comprises the following steps: 1) acid dissolution: dissolving a metal alloy with inorganic acid; 2) precipitation: adjusting the above dissolved sample solution to be alkaline to precipitate elements to be measured, and filtering the precipitation with ashless filter paper; 3) calcination: placing the filtered filter residues together with the filter paper in a porcelain crucible calcined to a constant weight, conversing the filter residues into metal oxides through steps of drying, carbonization, ashing, calcination, etc, and calculating a weight of calcined filter residues; 4) sheet melting: preparing the above calcined filter residues into a sample sheet by a fusion sample preparation method for detection by an XRF spectrometer, and obtaining contents of elements to be measured in the metal alloy through conversion of obtained data. The invention enables the XRF spectrometry to be applied to detections of some special metal alloys which have a high melting point, a high hardness and is easily oxidized.

Owner:INSPECTION & QUARANTINE TECH CENT OF XIAMEN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

X-ray fluorescent spectrum fundamental parameter method utilizing virtually synthesized standard sample

InactiveCN104111263ASolve the problem of no standard samplesFast analysisMaterial analysis using wave/particle radiationLower limitSoft x ray

The invention relates to an X-ray fluorescent spectrum fundamental parameter method utilizing a virtually synthesized standard sample, belonging to the technical field of X-ray fluorescent spectrum detection. A standard sample is integrated with the fundamental parameter method; appropriate working conditions are selected; the comprehensive application such as effective overlap and correction of spectral lines, background deduction and the like is carried out, so that pure strength values of all elements can be obtained; subsequently a standard sample is virtually synthesized, so that a fundamental parameter method curve manufactured by the virtually synthesized standard sample is established; finally a user can establish a general working curve of the same substrate material by using a few standard samples, so that the accurate detection of components of alloys of the same substrate can be achieved; the fundamental parameter method has a wide analysis range and is not limited by an upper limit and a lower limit of the standard sample; a great quantity of standard samples are not required to be purchased, so that the fundamental parameter method has great economic benefits. The X-ray fluorescent spectrum fundamental parameter method is also applicable to detection of the novel material and capable of meeting detection of novel materials which are developed by research institutions of colleges and universities and the like, and solves the problem of no standard sample of the novel material. The method is wide in application prospect in detection field of X-ray fluorescence spectrophotometers.

Owner:DALIAN UNIV OF TECH +4

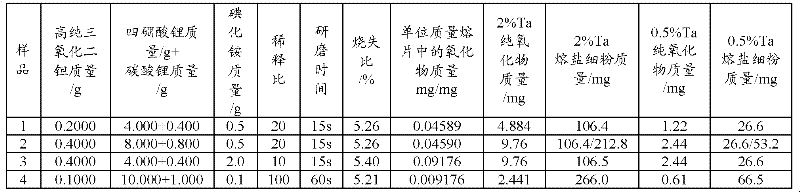

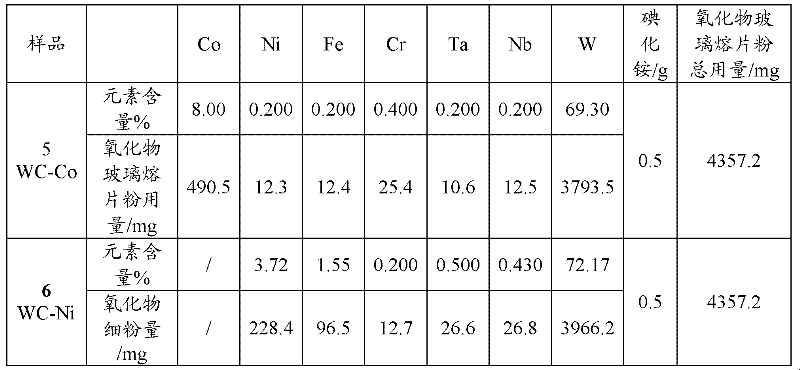

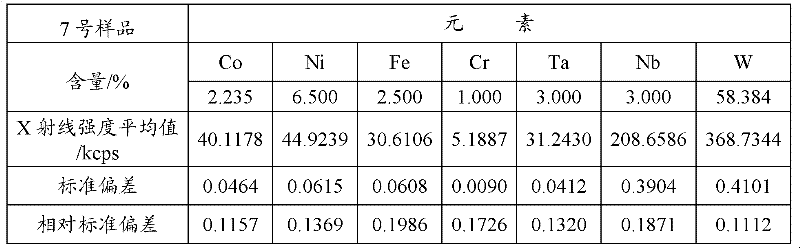

Method for preparing standard sample for testing content of hard-alloy components and method for testing content of hard-alloy components

ActiveCN102539207AEasy to prepareQuick and easy to manufactureMaterial analysis using wave/particle radiationPreparing sample for investigationSoft x rayX-ray

The invention discloses a method for preparing a standard sample for testing the content of hard-alloy components by adopting the X-ray fluorescence spectrometry and a method for testing the content of hard-alloy components by adopting the X-ray fluorescence spectrometry. The method for preparing the standard sample comprises the following steps: preparing a variety of high-purity single oxide glass fuse pieces under the same condition of preparing glass fuse pieces of the sample under test; grinding the high-purity single oxide glass fuse pieces into powder and filling the powder into bottles respectively; weighting the powder of the high-purity single oxide glass fuse pieces, which comprises a variety of elements under test in the sample under test, to prepare the standard sample, wherein the range of the content of a variety of elements of the standard sample covers the range of the content of a variety of elements of the sample under test; and finally preparing the glass fuse pieces of the standard sample according to the method. A working curve is made by using the glass fuse pieces of the standard sample, and then the content of a variety of elements of the hard alloy sample under test are tested by adopting the X-ray fluorescence spectrometry. Due to the adoption of the standard sample prepared by using the method of the invention, the limit to the detection method of the hard alloy, which is caused by the standard sample, can be eliminated, the accuracy of the result can be improved, and the application range of the X-ray fluorescence spectrometry can be expanded.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

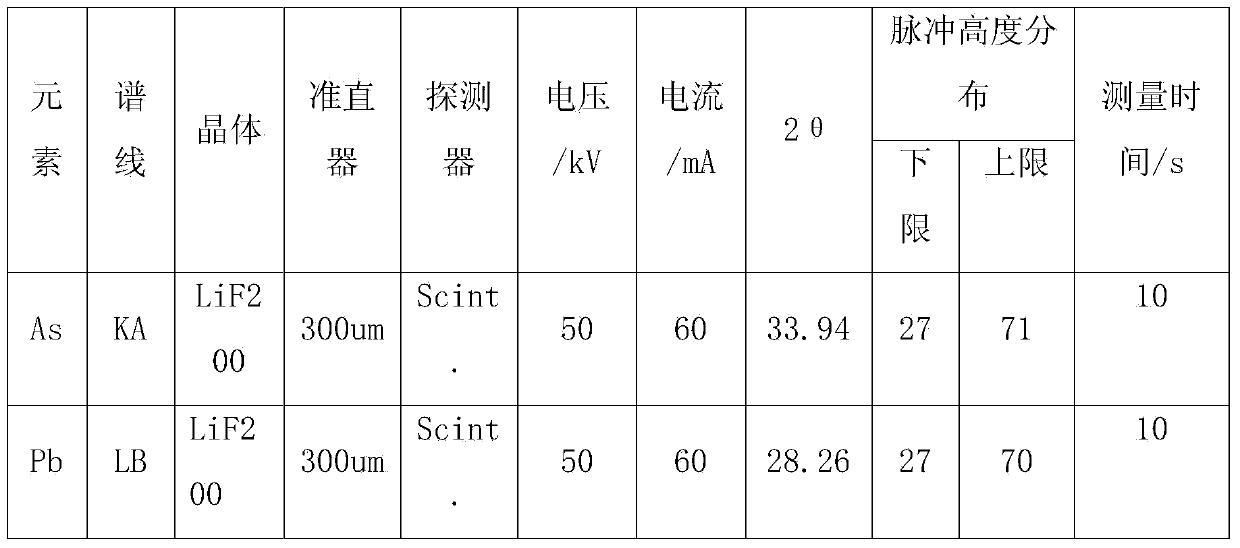

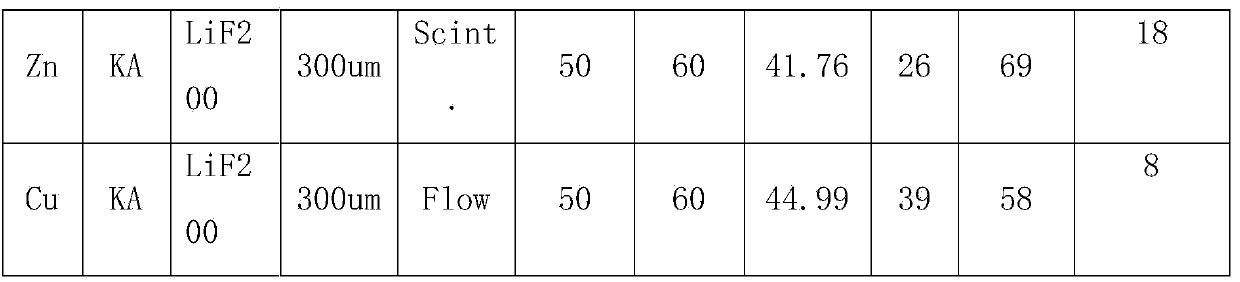

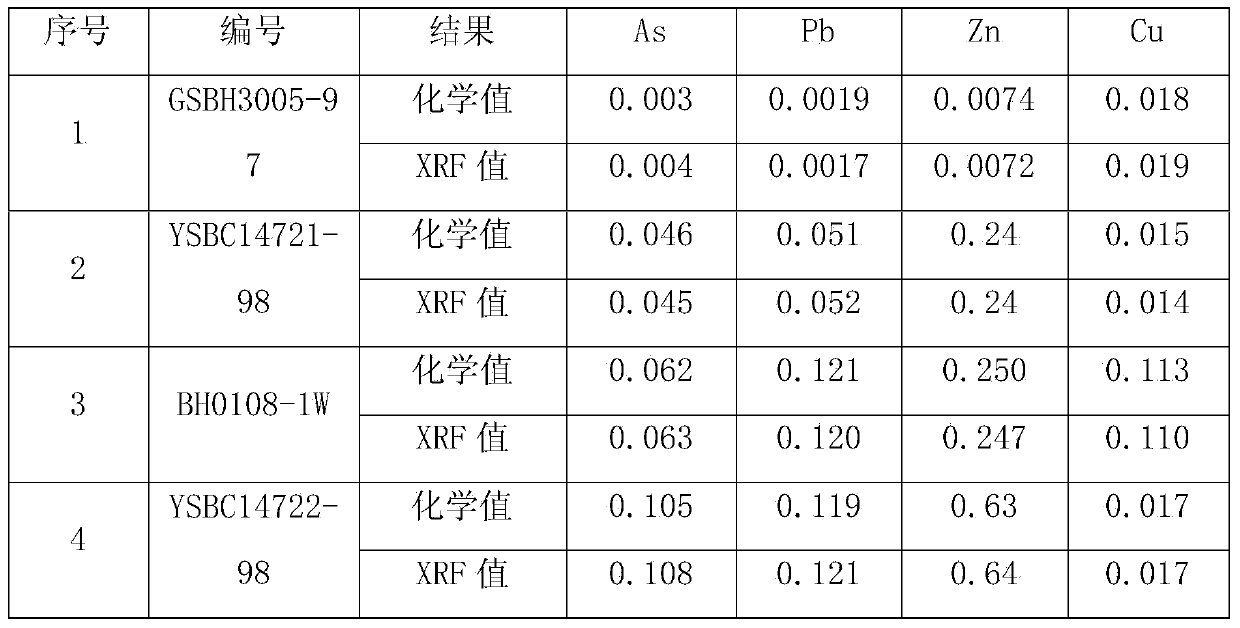

Method for determining the content of harmful elements in iron ore by using X-ray fluorescent spectrometry

InactiveCN103743769AReduce absorption-enhancement effectEvenly distributedMaterial analysis using wave/particle radiationX-rayCu element

The invention relates to a method for determining the content of harmful elements in iron ore by using X-ray fluorescent spectrometry. The method comprises the following steps: firstly, selecting an iron ore standard sample and a standard substance to prepare a series of standard samples, and then transferring the standard samples, an oxidant and a release agent to a platinum yellow crucible after mixing; preparing a glass sheet after melting at high temperature, so as to obtain a calibration sample; measuring the strength of As, Pb, Zn and Cu elements in the calibration sample by using an X-ray fluorescence spectrophotometer, and making a calibration curve; putting a test sample fabricated by the same fabrication method as the calibration sample into the X-ray fluorescence spectrophotometer; and making a calibration curve of an X-ray fluorescent spectrometry by using the calibration sample for measuring, so as to obtain the content of As, Pb, Zn and Cu elements in the sample. Thus, the content of main elements of SiO2, CaO, MgO, Al2O3, TiO2, P and the like is measured when the content of As, Pb, Zn and Cu in the iron ore is measured.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

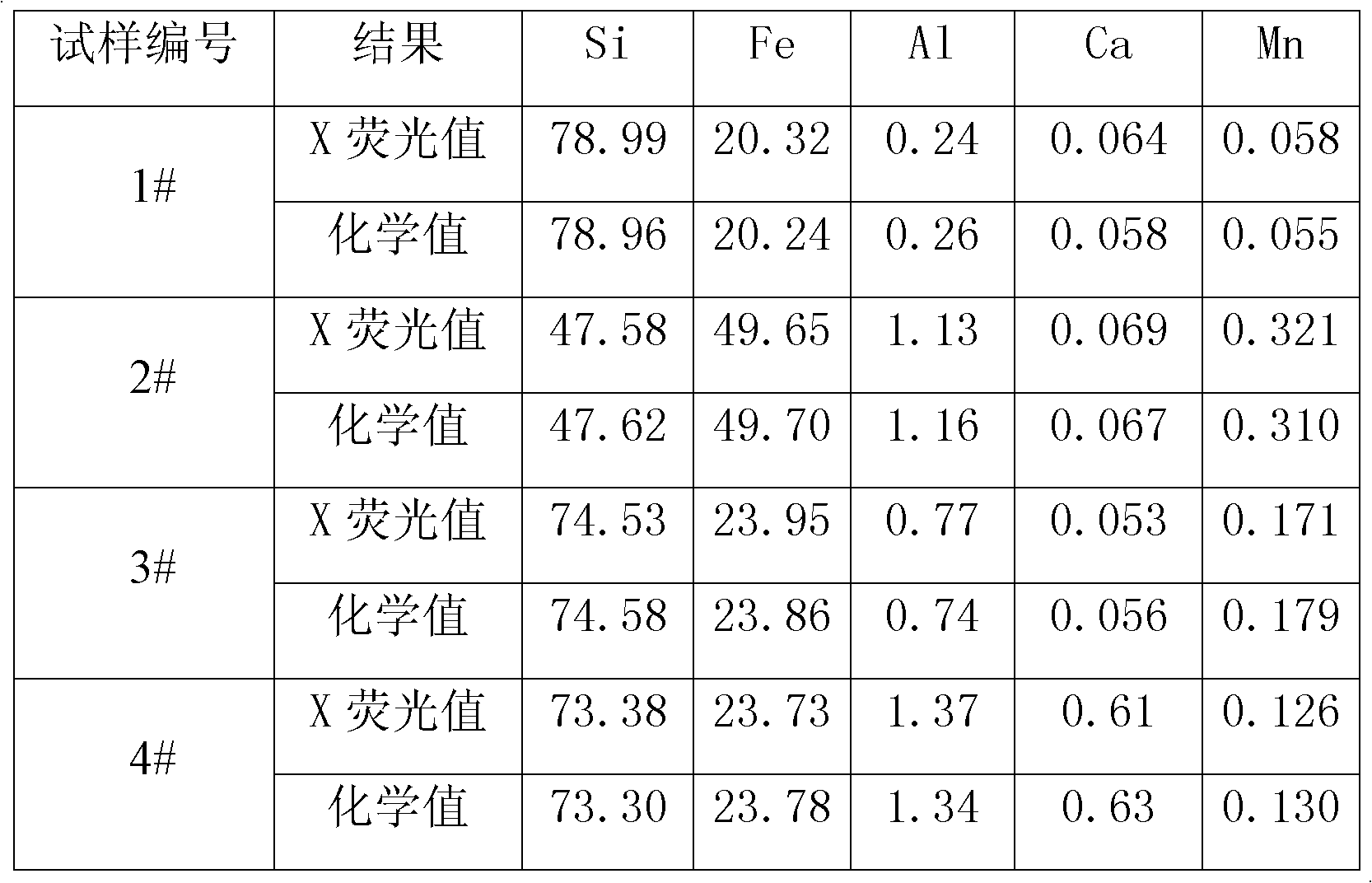

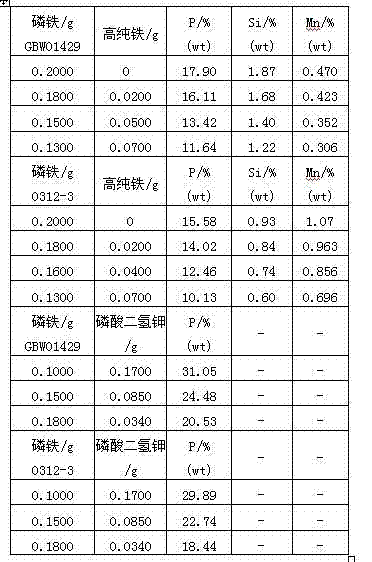

Method for analyzing ferrosilicon alloy components for X-ray fluorescence spectrum analysis

InactiveCN102156142AShort preparation timeEvenly distributedMaterial analysis using wave/particle radiationPreparing sample for investigationTest sampleX-ray

The invention discloses a method for analyzing ferrosilicon alloy components for X-ray fluorescence spectrum analysis. A method for preparing a sample comprises the following steps of: selecting a proper oxidant; adding a flux into a platinum crucible, putting the platinum crucible in a high temperature furnace, and melting the flux at high temperature to manufacture a wall built-up flux crucible with the basement of flux; mixing a ferrosilicon alloy test sample, the flux and the oxidant, pouring the mixture into the flux crucible, and covering a certain amount of mixed flux; and putting the flux crucible filled with the ferrosilicon alloy test sample, the flux, the oxidant and the mixed flux into the high temperature furnace, preliminarily oxidizing at low temperature, shifting into a high temperature zone, and melting at high temperature to prepare the ferrosilicon alloy test sample glass sample for the X-ray fluorescence spectrum analysis. In the technical scheme, elements are uniformly distributed in the prepared glass sample, and the glass sample has no particle effect and can be preserved for a long time; moreover, the operation method is simple and safe, the preparation time of the sample is short, and primary and secondary quantity elements in the ferrosilicon alloy are rapidly and accurately measured.

Owner:MAANSHAN IRON & STEEL CO LTD

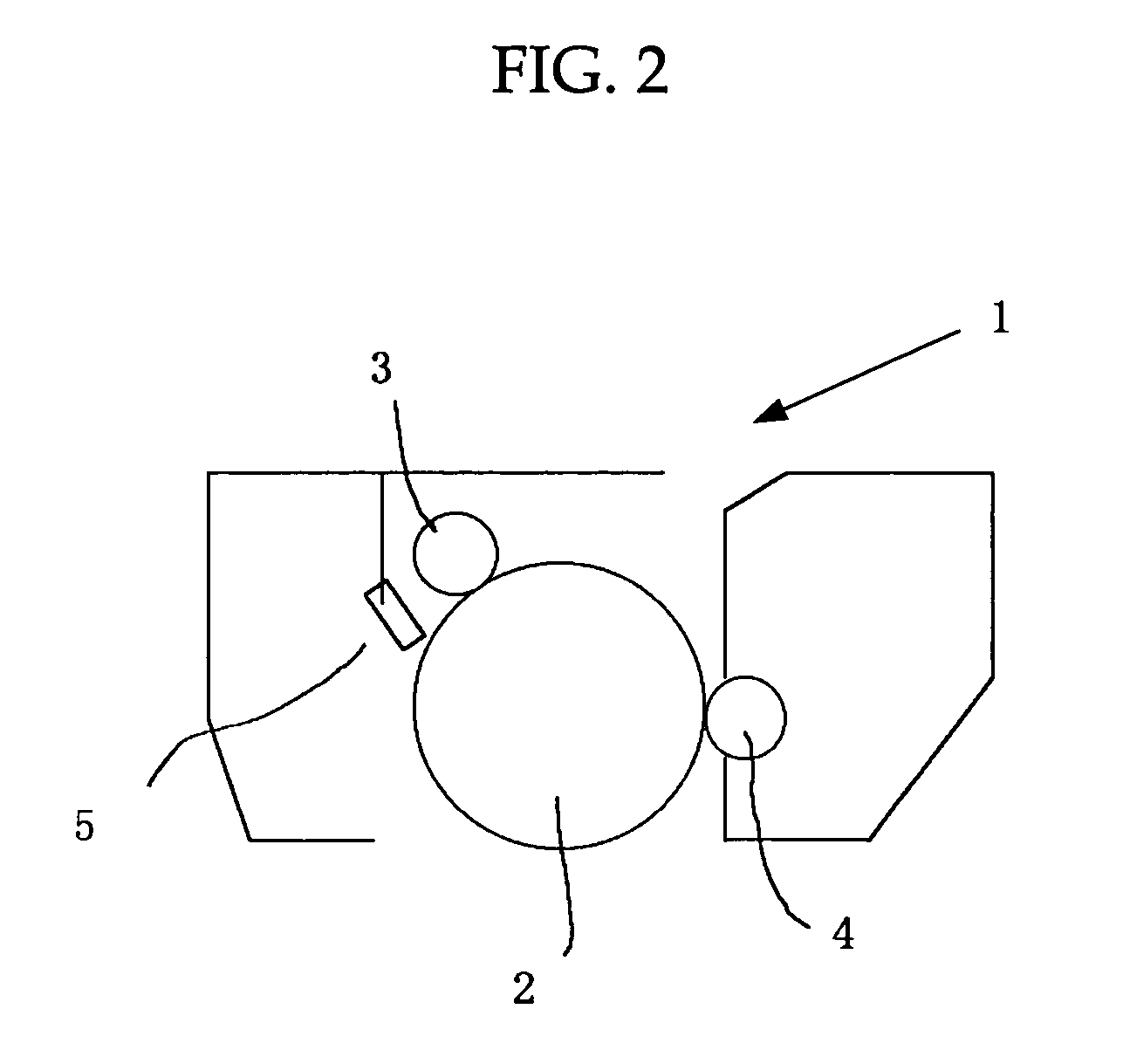

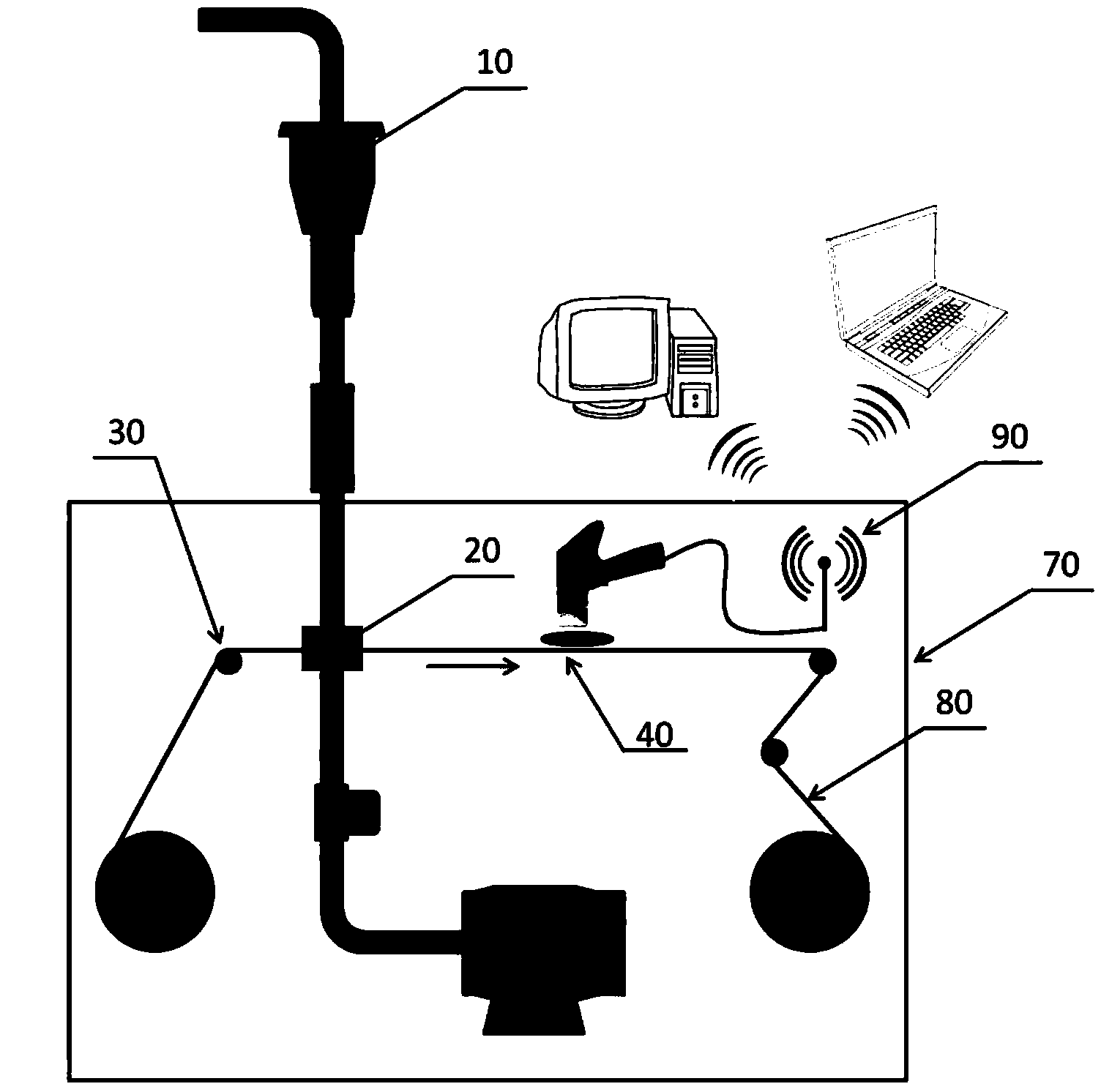

On-line detection device and method for heavy metal content in flue gas

InactiveCN103822934AAvoid the tediousness of testingEasy to storeMaterial analysis using wave/particle radiationPreparing sample for investigationMethod testEngineering

The invention discloses an on-line detection device and method for heavy metal content in a flue gas, and the device comprises a gas sampler 10, a belt type active filter membrane 80, a filter membrane transport unit 30, an XRF (X-ray fluorescence) detector 40, a wireless communication unit 90 and a control unit; the whole device has the advantages of being simple and ingenious in structure, and easy to popularize; according to the detection method, an X-ray fluorescence spectroscopy method is used for qualitative and quantitative analysis of harmful elements in the flue gas, a burdensome chemical method test is avoided, work efficiency is improved, at the same time the test precision reaches ppm level; by design of the belt type active filter membrane, a simple method for solving the difficult transfer problem between the sampler collection and the detector is provided, and by design of materials of the belt type active filter membrane, enrichment and detection of multiple-state heavy metals can be achieved, and the detection is timely, and high in efficiency.

Owner:CENT SOUTH UNIV

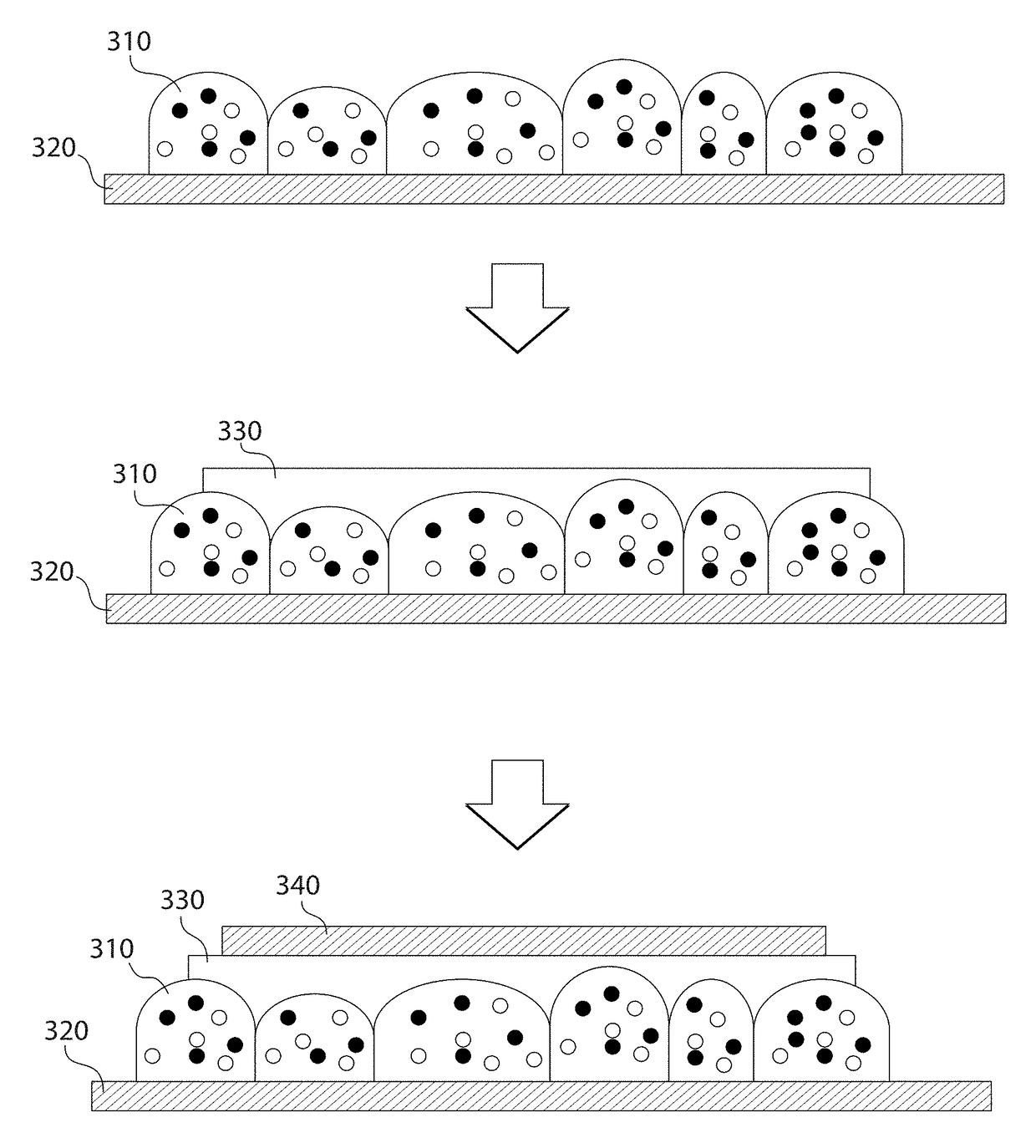

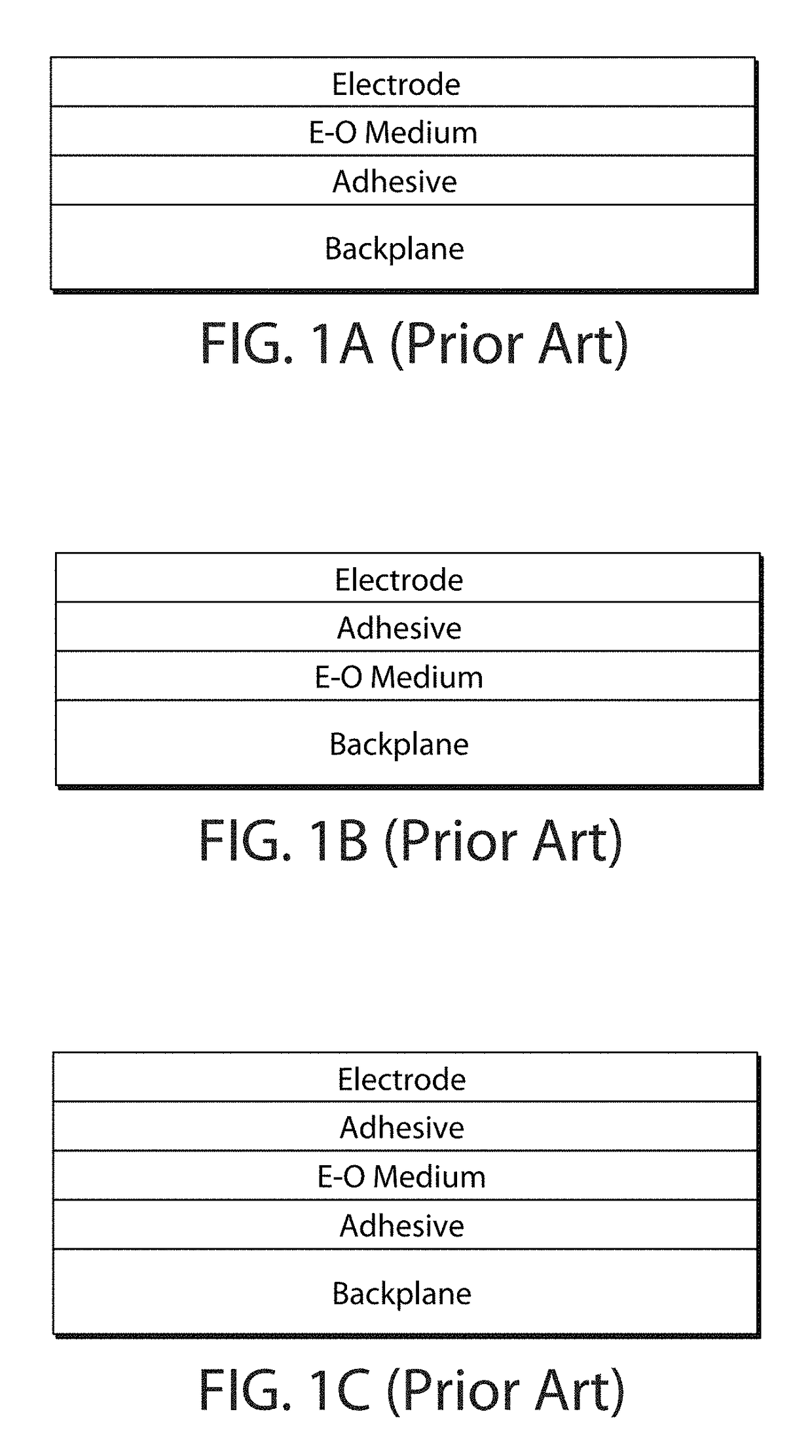

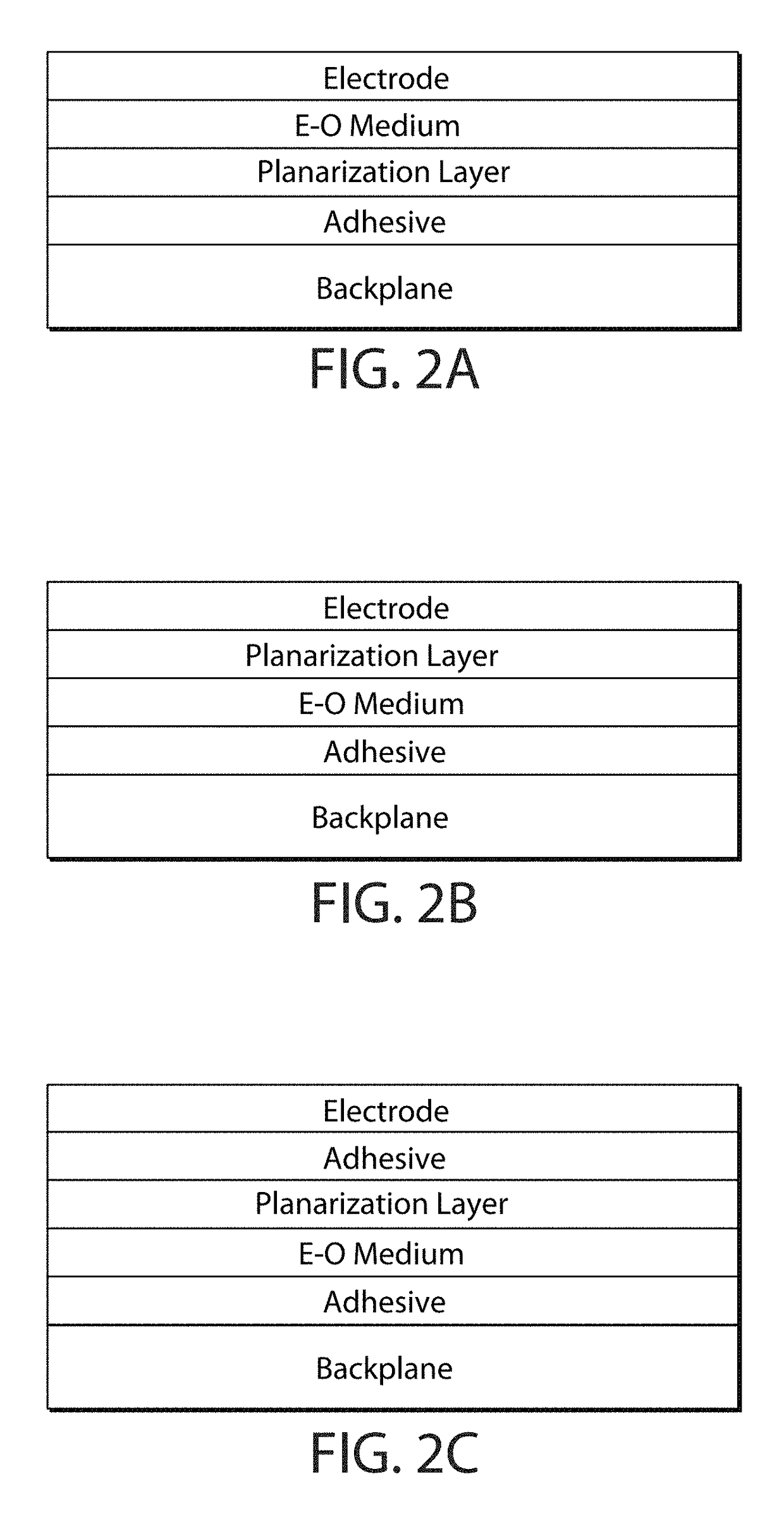

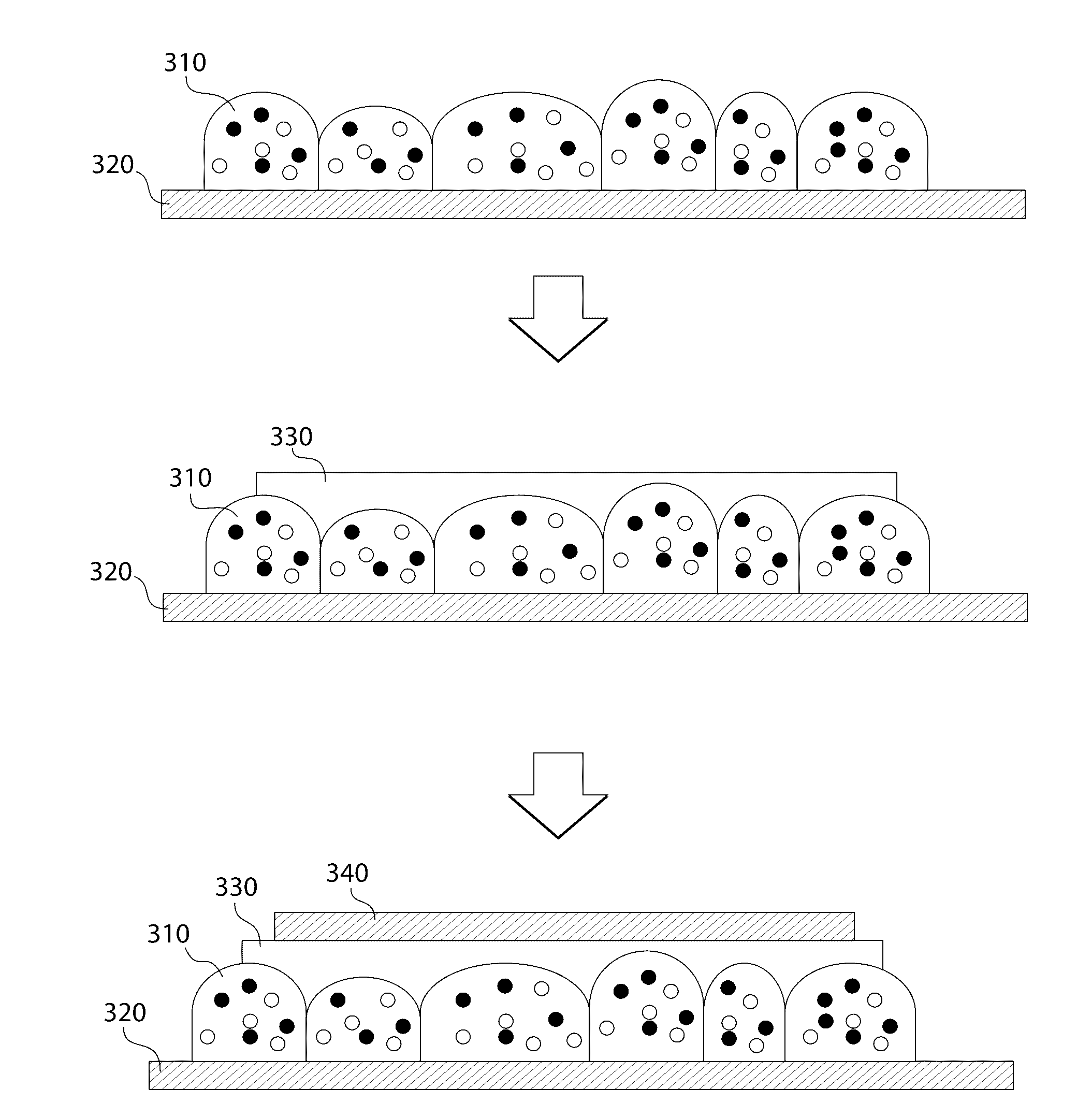

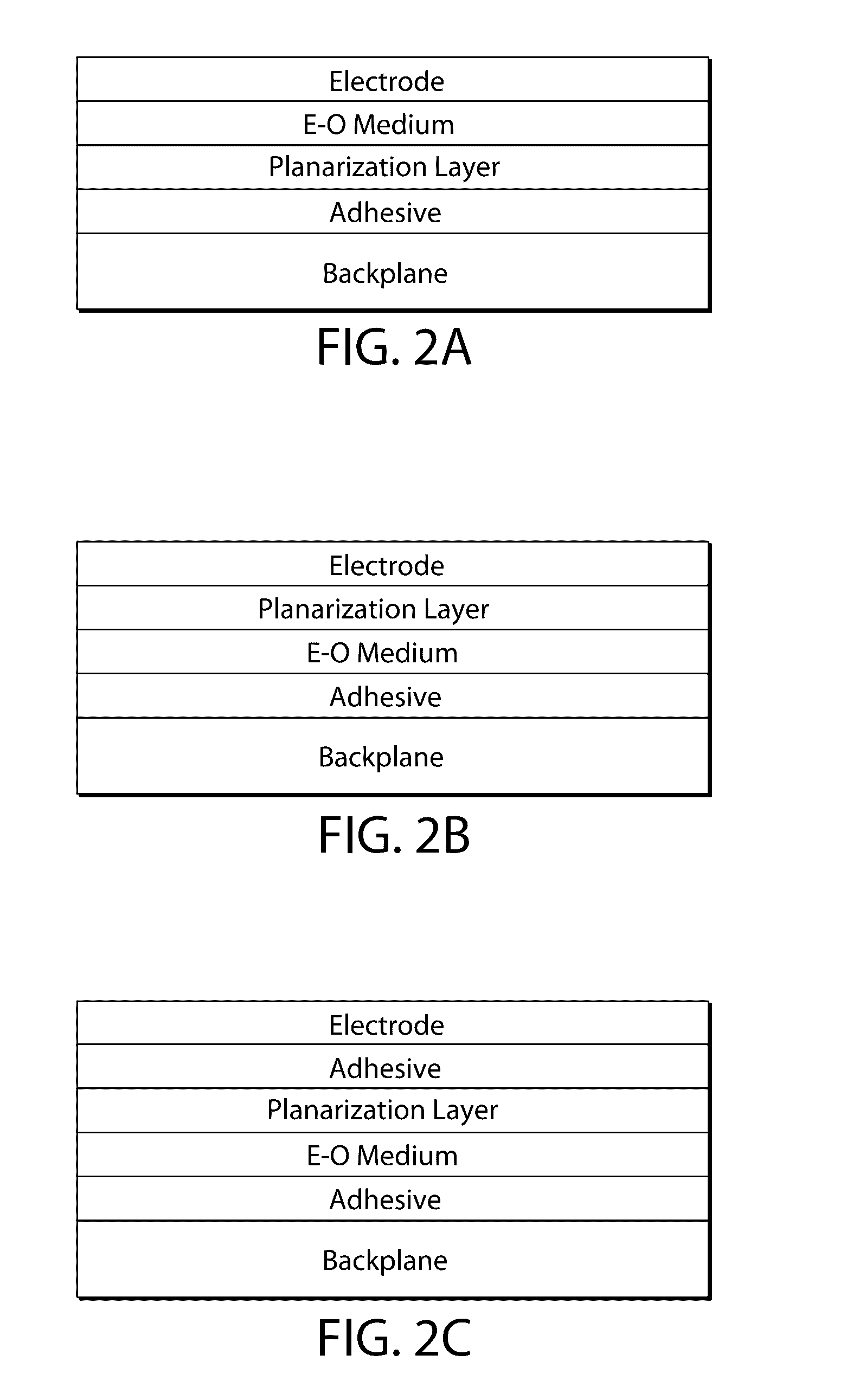

Polymer formulations for use with electro-optic media

ActiveUS9777201B2Improve adhesionExcellent characteristicsMaterial analysis using wave/particle radiationPolyureas/polyurethane adhesivesMetal oxide nanoparticlesRefractive index

Polymer formulations including urethane acrylates, adhesion promoters, and conductive monomers. By selecting suitable conductive monomers, it is possible to achieve formulations having a volume resistivity from 106 to 1010 Ohm·cm after being conditioned for one week at 25° C. and 50% relative humidity. Such formulations are suitable for incorporation into electro-optic materials, such as electro-optic displays or variable transmission films, e.g., for architectural applications. In other embodiments, the formulations additionally include metal oxide nanoparticles to alter the refractive index and / or conductivity. The addition of certain metal nanoparticles additionally facilitates non-destructive measurement of layer thickness using X-ray fluorescence spectroscopy.

Owner:E INK CORPORATION

Method for detecting content of carborundum impurities by applying X-ray fluorescent spectrometry

ActiveCN101718720AReduce workloadImprove accuracyMaterial analysis using wave/particle radiationSoft x rayTest sample

The invention relates to a method for detecting the content of carborundum impurities by applying an X-ray fluorescent spectrometry, comprising the following steps of: firstly, preparing a test sample wafer; secondly, preparing a standard sample wafer: (1) purifying a sample of carborundum; (2) purifying the carborundum to prepare puried carborundum; and (3) artificially preparing a standard sample and finally pressing the standard sample into a standard carborundum sample wafer; thirdly, establishing a working curve of the X-ray fluorescent spectrometry by the standard sample wafer; and fourthly, placing the prepared test sample wafer in an X-ray fluorescent spectrograph, measuring the sample wafer by the established working curve and automatically calculating the contents of various elements in the sample. By adopting the method, the workload for preparing standard series can be greatly reduced and the accuracy and the speed for preparation can be improved, thereby avoiding the defects of the traditional method for detecting the carborundum. The method is concise and rapid, meets the requirement of trade development, has great generalization and application values, and can be widely suitable for testing various samples by the X-ray fluorescent spectrum.

Owner:CHEM MINERALS & METALLIC MATERIALS INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Polymer formulations for use with electro-optic media

ActiveUS20170022403A1Improve adhesionExcellent characteristicsMaterial analysis using wave/particle radiationPolyureas/polyurethane adhesivesMetal oxide nanoparticlesRefractive index

Polymer formulations including urethane acrylates, adhesion promoters, and conductive monomers. By selecting suitable conductive monomers, it is possible to achieve formulations having a volume resistivity from 106 to 1010 Ohm·cm after being conditioned for one week at 25° C. and 50% relative humidity. Such formulations are suitable for incorporation into electro-optic materials, such as electro-optic displays or variable transmission films, e.g., for architectural applications. In other embodiments, the formulations additionally include metal oxide nanoparticles to alter the refractive index and / or conductivity. The addition of certain metal nanoparticles additionally facilitates non-destructive measurement of layer thickness using X-ray fluorescence spectroscopy.

Owner:E INK CORPORATION

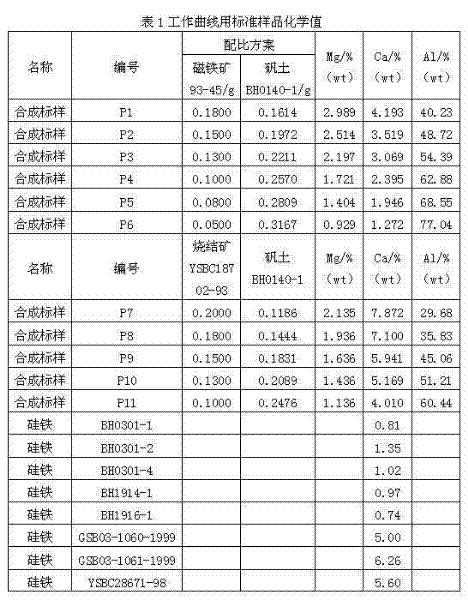

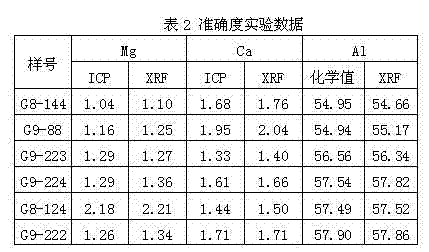

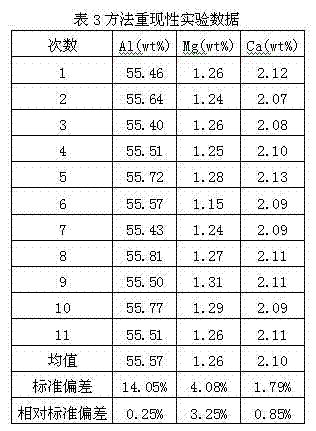

Melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis

InactiveCN102331364AAccelerationAccuracyMaterial analysis using wave/particle radiationPreparing sample for investigationGranularityLithium carbonate

The invention discloses a melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis. The melted sampling method is characterized by comprising the following steps of: hanging a layer of uniform lithium tetraborate protective wall in a platinum crucible; putting an aluminum magnesium calcium iron sample, lithium carbonate and potassium iodide into the platinum crucible in which the protective wall is hung, mixing uniformly, and covering a layer of lithium tetraborate; pre-oxidizing the aluminum magnesium calcium iron sample; and melting the oxidized aluminum magnesium calcium iron sample, and cooling to obtain a glass fuse piece of the aluminum magnesium calcium iron alloy. By the method, the sampling time is short, the manufactured glass fuse piece is uniform and perfect, and the specification of a mineral effect and a granularity effect can be eliminated completely. The glass fuse piece can be used for the X-ray fluorescence spectrum analysis, the obtained analytic result is accurate and reliable, and the requirements of modern enterprises on quick and accurate detection of analytic data are met. The method is safe, reliable, easy to operate and high in repeatability, and the application range of an X-ray fluorescence spectrum method is broadened.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

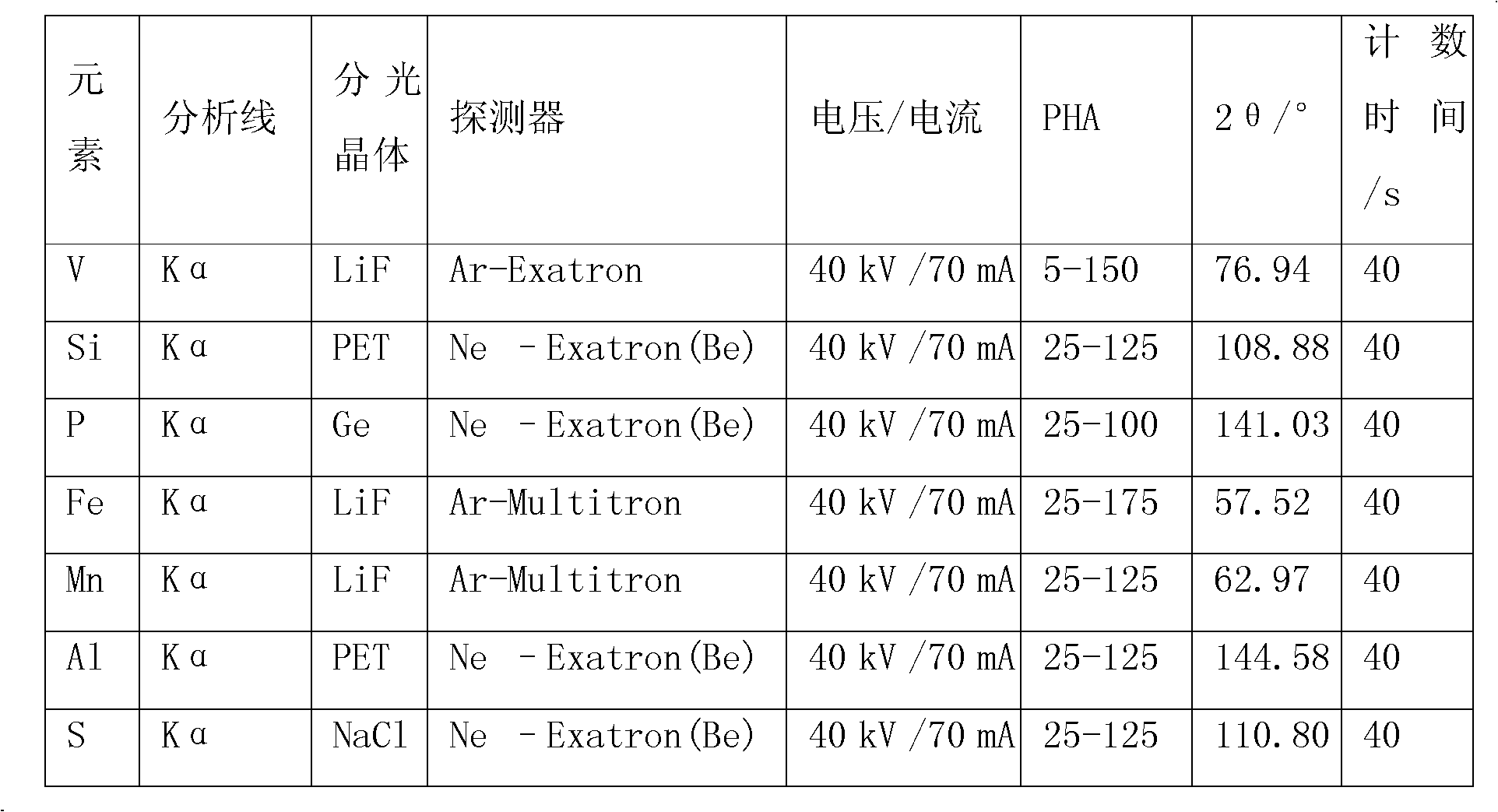

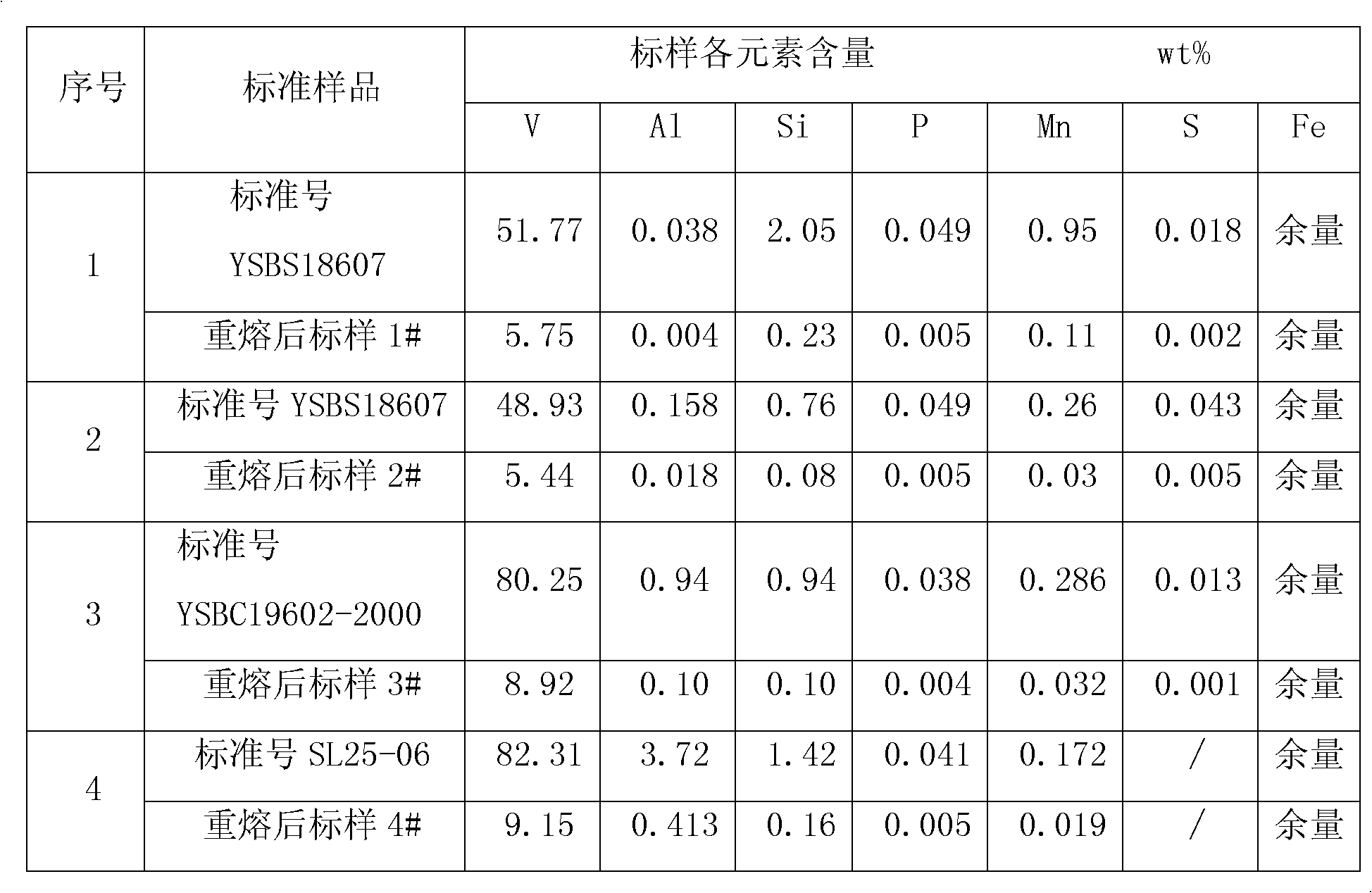

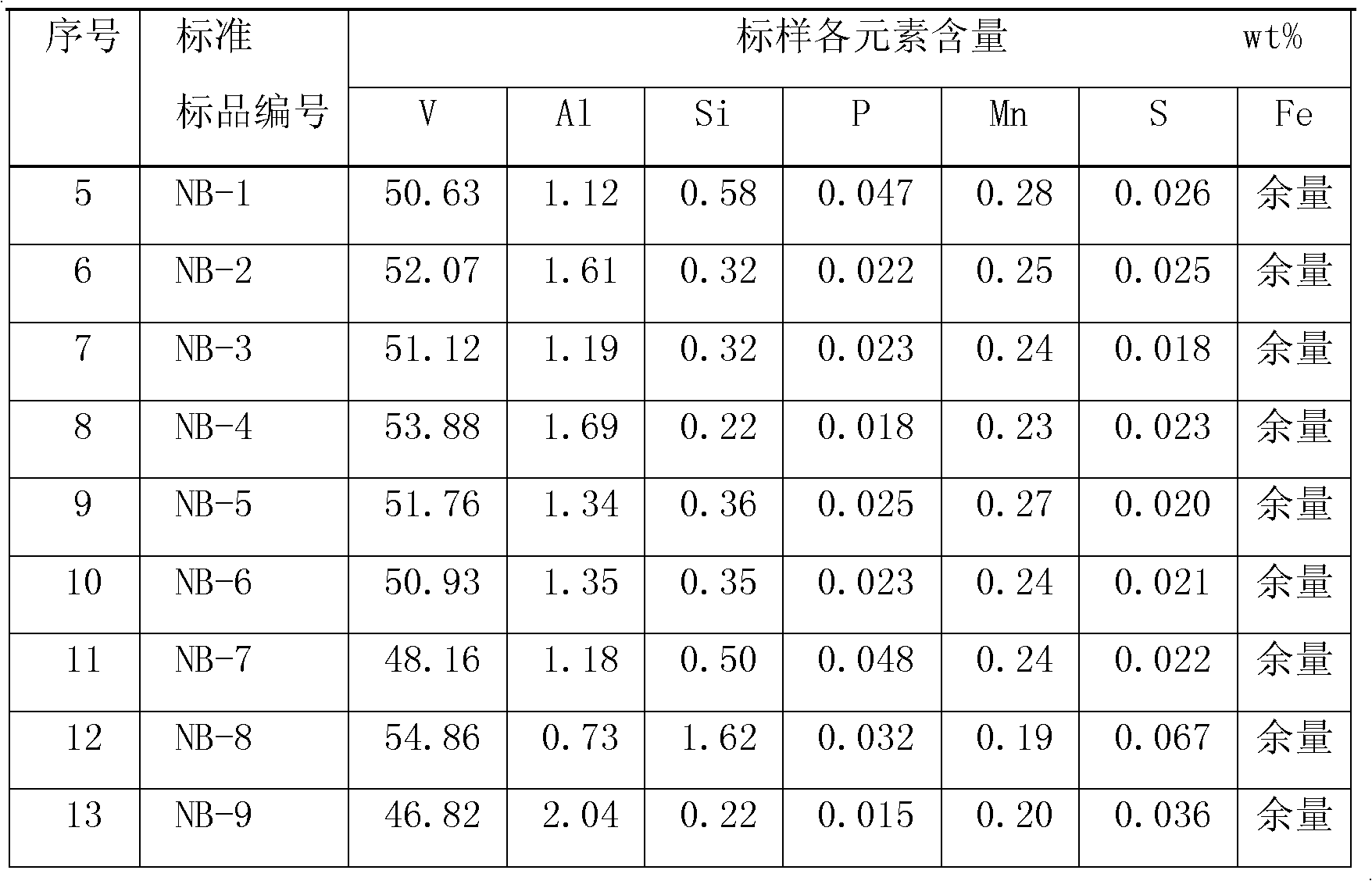

Method for analyzing vanadium iron ingredients by melt smelting sampling-X-ray fluorescence spectrum process

InactiveCN102253068AHigh speedImprove efficiencyMaterial analysis using wave/particle radiationPreparing sample for investigationAdditive ingredientSpectrograph

The invention belongs to the technical field of the detection of vanadium iron, and particularly relates to a method for analyzing vanadium iron ingredients by a melt smelting sampling-X-ray fluorescence spectrum process. The method comprises the following steps of: (1) in a low-content calibration standard sample, mixing a vanadiumiron guide sample and pure iron powder, smelting under vacuum, casting for forming, measuring by using an X-ray fluorescence spectrograph, measuring the strength of a high-content calibration standard sample on the X-ray fluorescence spectrograph, crushing, analyzing a constant value by a wet process, and establishing a standard curve for each calibration standard sample, wherein the high-content calibration standard sample is a vanadium iron sample with different ingredient content gradients; and (2) taking a vanadium iron melt in a smelting electric furnace, casting to form blocks, polishing, measuring by using the X-ray fluorescence spectrograph, and calculating the content of each element in vanadium iron according to the standard curve drawn in the step (1). By the method, analytical information can be fed back within 10 minutes, so the method has the characteristics of high speed, high efficiency, low cost, safety and environment friendliness, and is suitable for quick and on-spot analysis of a ferroalloy smelting furnace.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

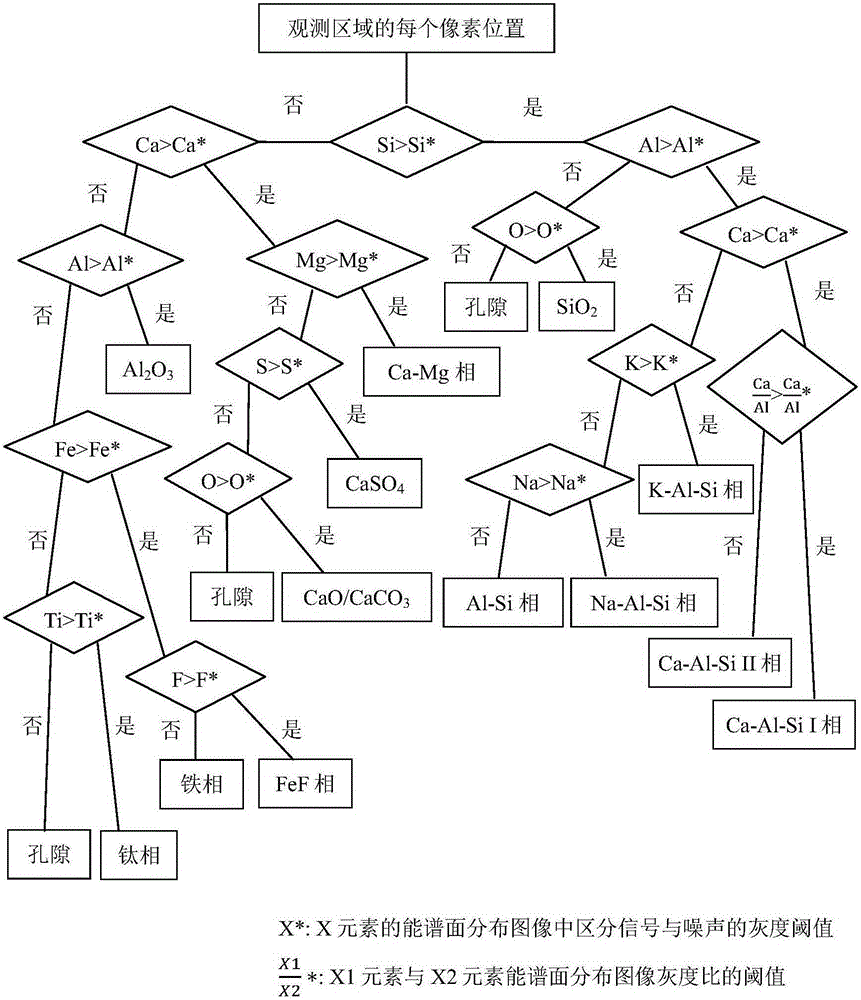

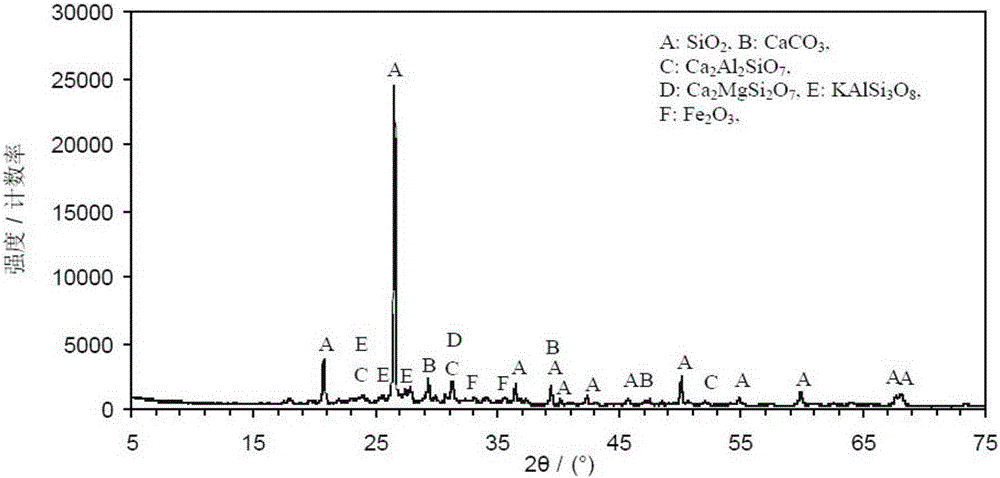

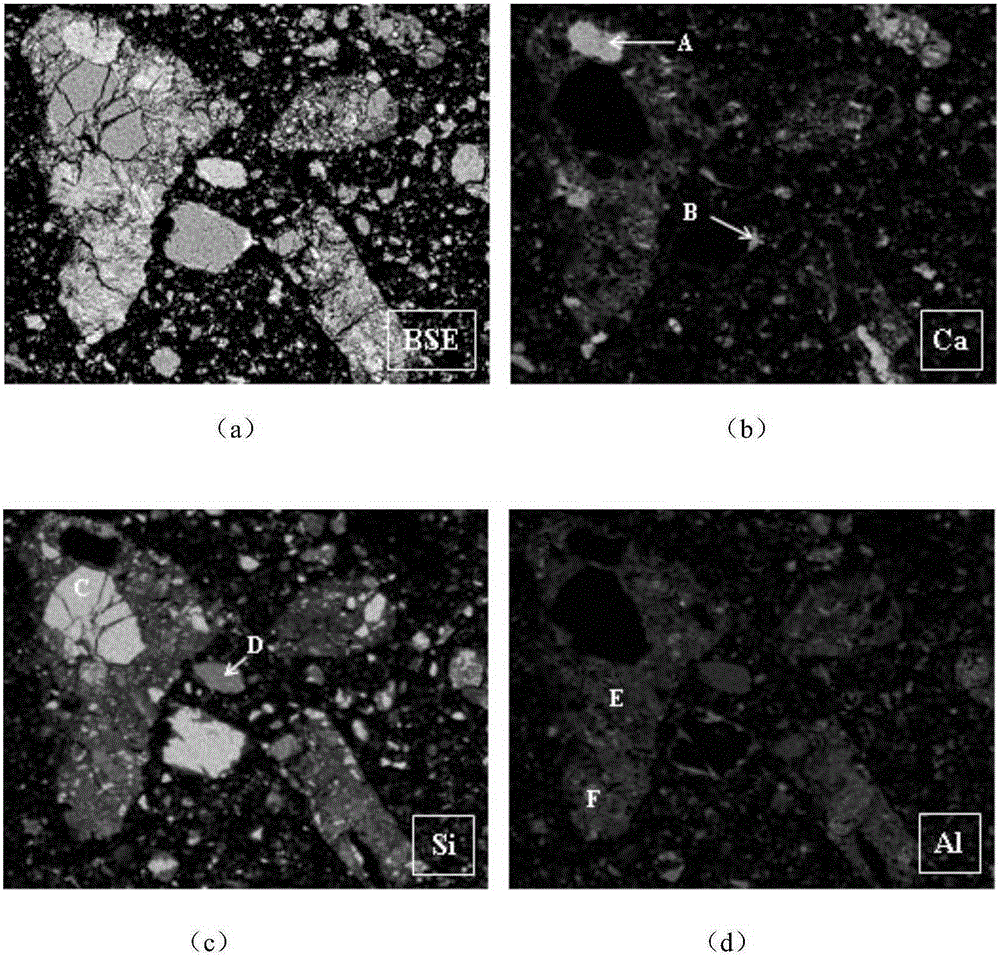

Coal gangue phase analysis method based on energy dispersion X-ray spectrum

ActiveCN105181717AThe spatial distribution is clearly presentedPredictive reactivityMaterial analysis using wave/particle radiationFluorescenceX-ray

The invention relates to a coal gangue phase analysis method based on an energy dispersion X-ray spectrum. The method includes the specific steps of firstly, analyzing the chemical composition of coal gangue through chemical analysis or X-ray spectrofluorimetry; secondly, analyzing the mineral composition of coal gangue through X-ray diffraction; thirdly, determining types of elements where energy spectrum face distribution images need to be collected; fourthly, shooting backscattered electron images and element energy spectrum face distribution images of coal gangue, and analyzing and observing composition of main phases through energy spectrum points; fifthly, designing a phase analysis method, comprehensively processing the energy spectrum distribution images of all the elements in the same area, removing noise in the analysis result, and obtaining split phase pseudocolor images and the phase analysis result of coal gangue. The phase analysis method can be used for type analysis, volume percentage content calculation and space distribution observation in coal gangue and activated coal gangue. The method is effective for both the crystalline state phase and the amorphous state phase, and is sensitive to the low-content phase.

Owner:TONGJI UNIV

Preparation method of ferroalloy calibration samples for X-ray fluorescence spectrum analysis

InactiveCN102818722ASolving No Standard SamplesSolve the problem of insufficient standard samplesMaterial analysis using wave/particle radiationPreparing sample for investigationX-rayAlloy

The invention discloses a preparation method of ferroalloy calibration samples for X-ray fluorescence spectrum analysis. The preparation method is characterized in that firstly, high-pure metal and / or standard reagents are weighed according to the alloy proportioning, then, the high-pure metal and / or standard reagents are dissolved into solution by solvents, next, the solution is quantificationally transferred into a platinum yellow crucible and is melted after being mixed with lithium borate, oxidants and release agents, the cooling is carried out, and a ferroalloy calibration sample glass fuse piece is obtained. The method has the advantages that the ferroalloy calibration samples to be measured are compounded by reference or standard substances with similar element composition and content range, and the problem of no ferroalloy standard sample to be measured or standard sample insufficiency is solved. The ferroalloy calibration sample glass fuse piece obtained by the method is used for the X-ray fluorescence spectrum analysis, the result is accurate and reliable, and the application range of an X-ray fluorescence spectrum analysis method is expanded.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

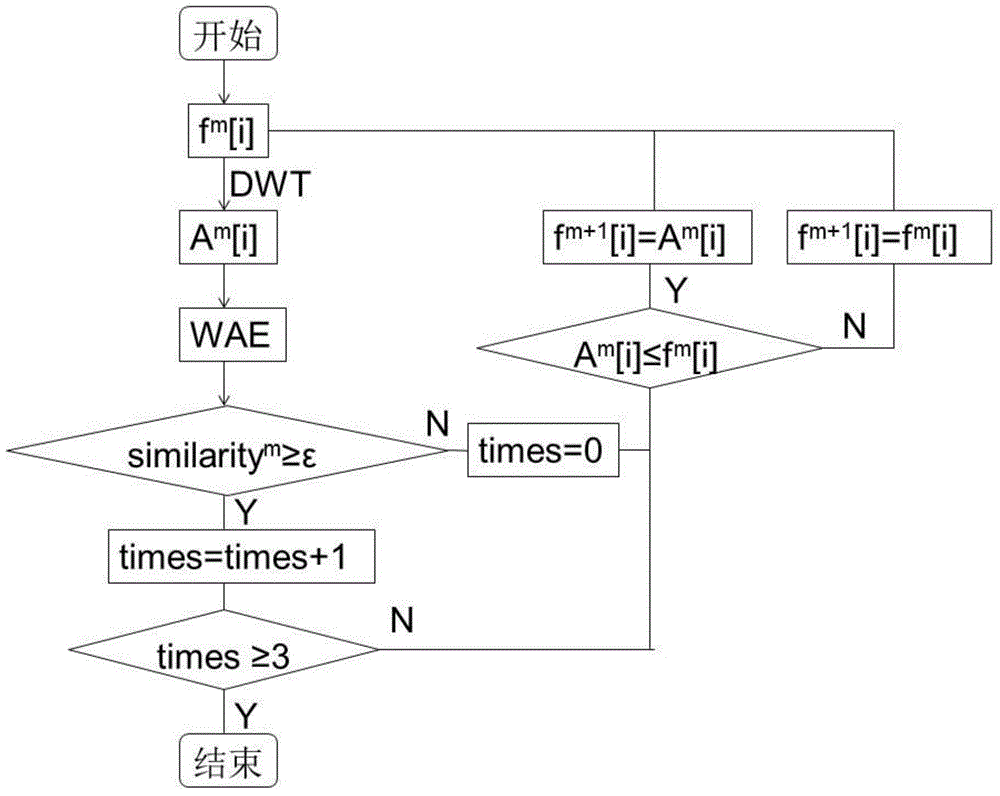

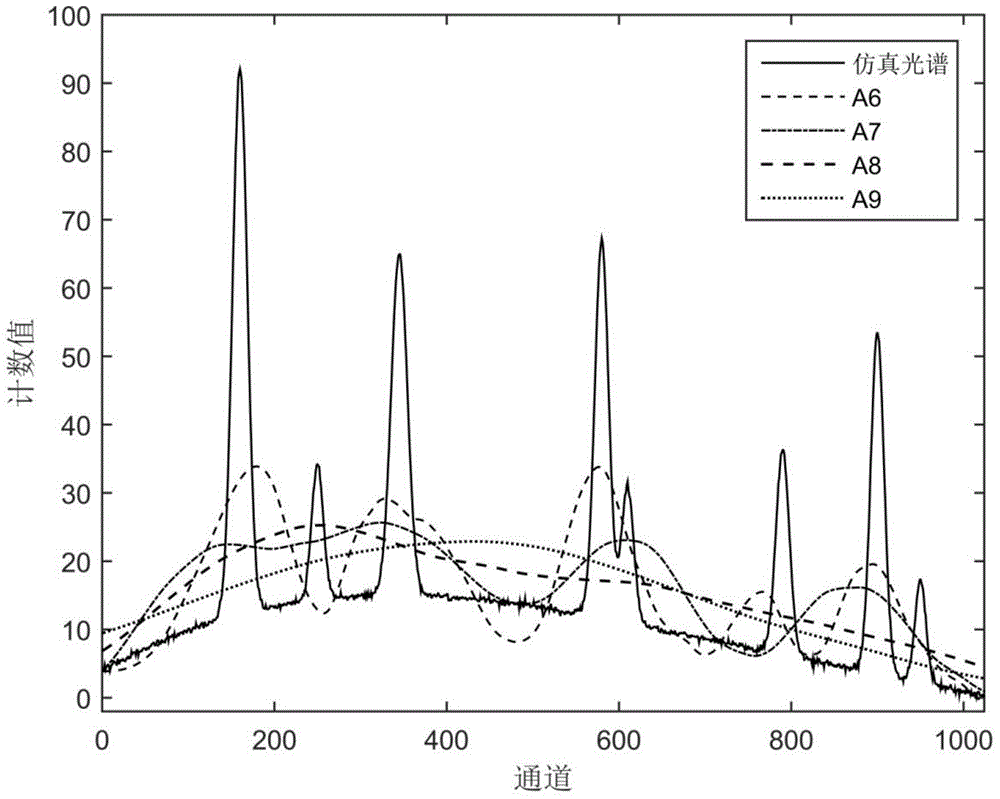

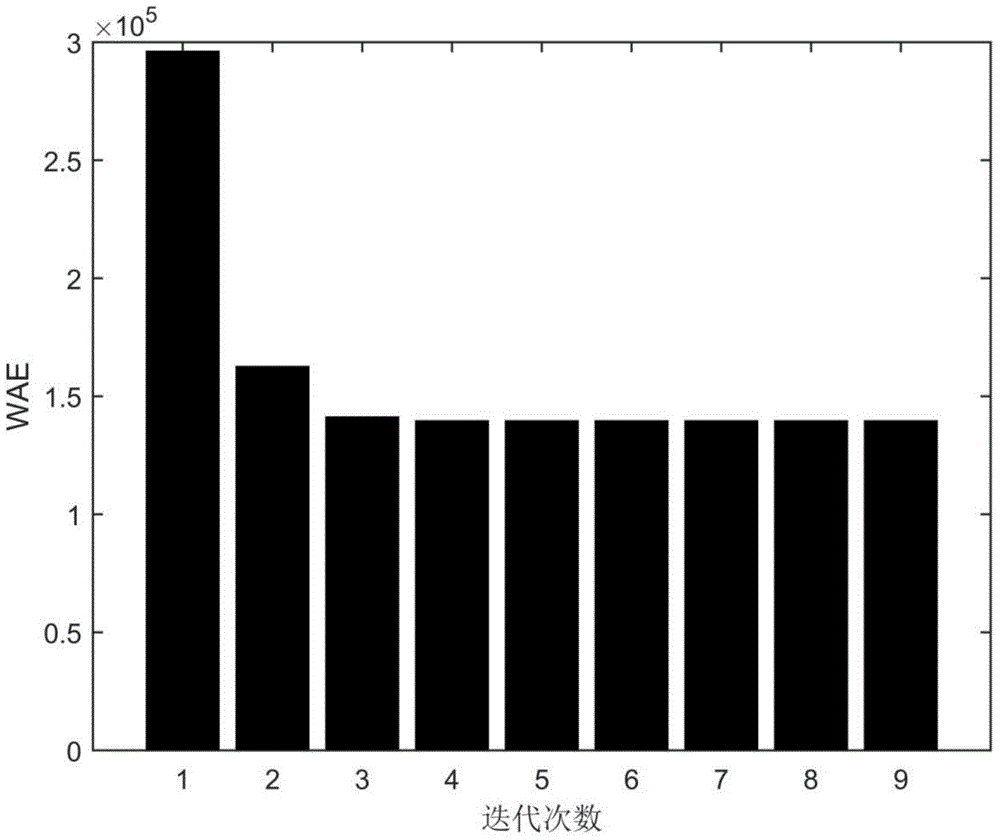

Method of X-ray fluorescence spectrum background rejection

InactiveCN104931518AReduce the impactEliminate the effects ofMaterial analysis using wave/particle radiationSoft x rayWavelet approximation

The invention discloses a method of X-ray fluorescence spectrum background rejection. Iterative wavelet transform is used to analyze the X-ray fluorescence spectrum, which overcomes the defect that spectrum distortion is easily caused when traditional wavelet transform is used to reject the spectrum background. When the characteristic peak and the frequency band of the background coincide, the method provided by the invention can still effectively extract the pure characteristic peak. The concept of wavelet approximation energy is presented in the invention and is used to evaluate the distribution situation of the background energy at a low frequency band. Compared with wavelet energy, the wavelet approximation energy can be used for more directly and accurately evaluating the spectrum background at a low frequency band. According to the method, wavelet entropy is used to select an optimal wavelet basis; after dilation and translation, the optimal wavelet basis can better match the whole or partial spectrum, and the spectrum sparsity after wavelet transform can be increased, and the operational efficiency is improved.

Owner:SOUTHEAST UNIV

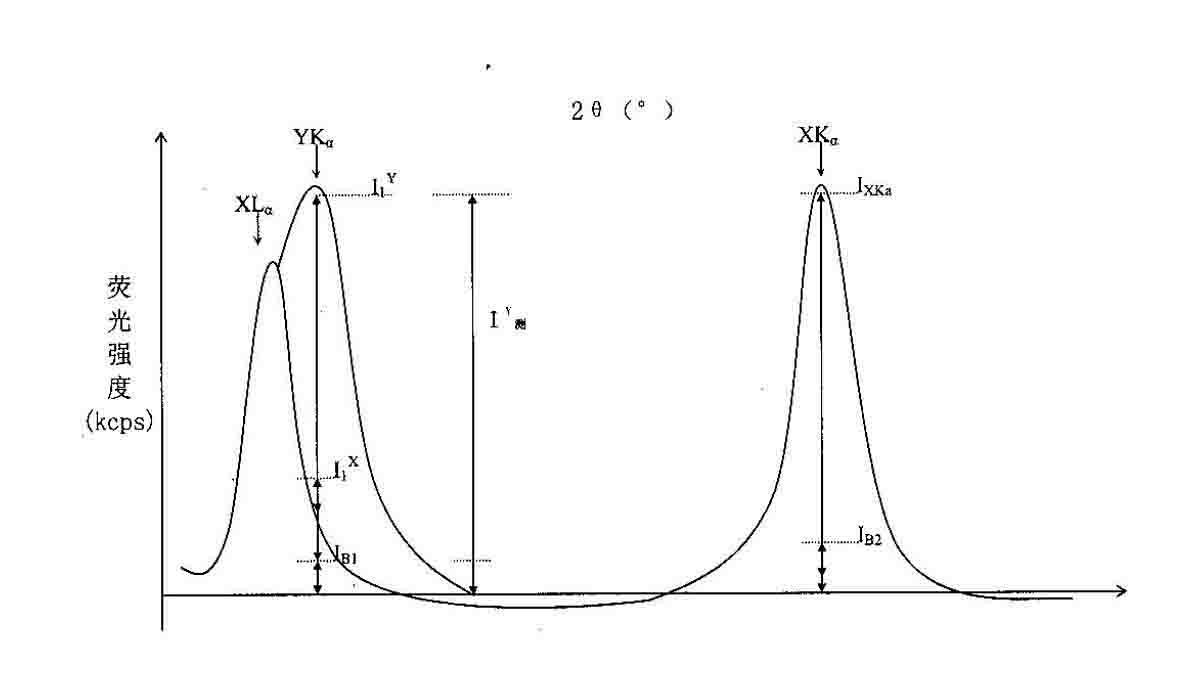

Method for correcting overlap of X ray fluorescent spectroscopy spectral lines

InactiveCN102128851AReduce usageSimplified Overlap Intensity Correction MethodMaterial analysis using wave/particle radiationX-raySpectroscopy

The invention discloses a method for correcting overlap of X ray fluorescent spectroscopy spectral lines. The method comprises the following steps of: (1) overlapping a YKa spectral line of a Y element with an XLa spectral line of an X element, wherein the real intensity I1<Y> of the YKa spectral line of the Y element is equal to I<Y> measured-I1<X>; (2) selecting a standard sample which contains the Y element and does not contain the X element and establishing a calibration curve according to the percentage composition Wi of the Y element and the measured real total fluorescent intensity Ii of the Y element, wherein a calibration curve formula is that: Wi=a*Ii+bY, and the element sensitivity M=1 / a; (3) with respect to of the standard sample which contains the Y element and does not contain the X element, calculating the XLa overlap fluorescent intensity I1<X>=K*IXKA=M*C at the YKa, wherein a spectral line overlap correction coefficient K=I<Y> measured-M*c / IXKA; and (4) measuring the fluorescent intensity of the corrected spectral line of the Y element, wherein the fluorescent intensity is real intensity I1<Y>=I<Y> measured-K*IXKA. The method has the advantages of lowering production test cost and simplifying a spectral line overlap intensity correction method.

Owner:SHENYANG AIRCRAFT CORP

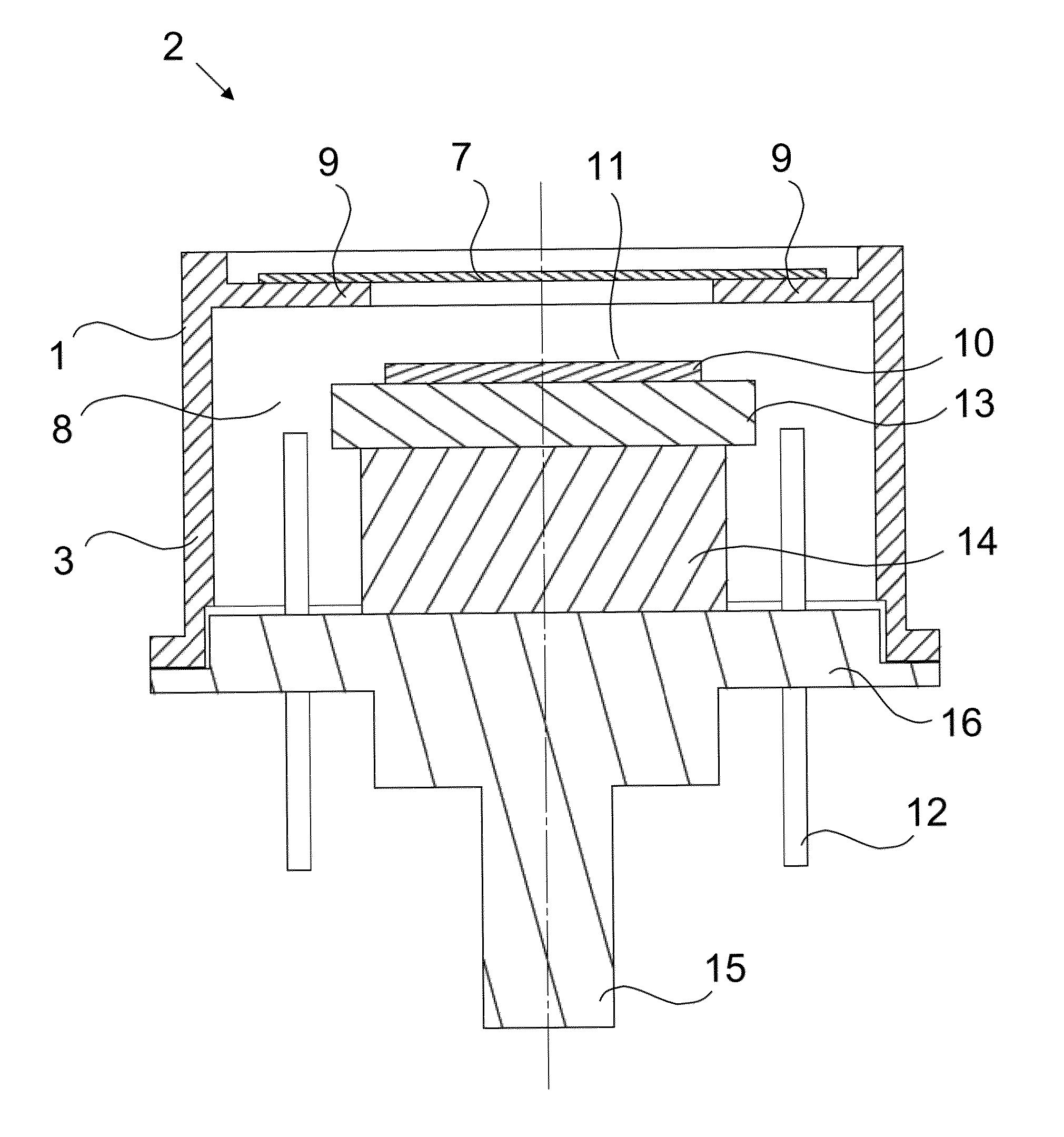

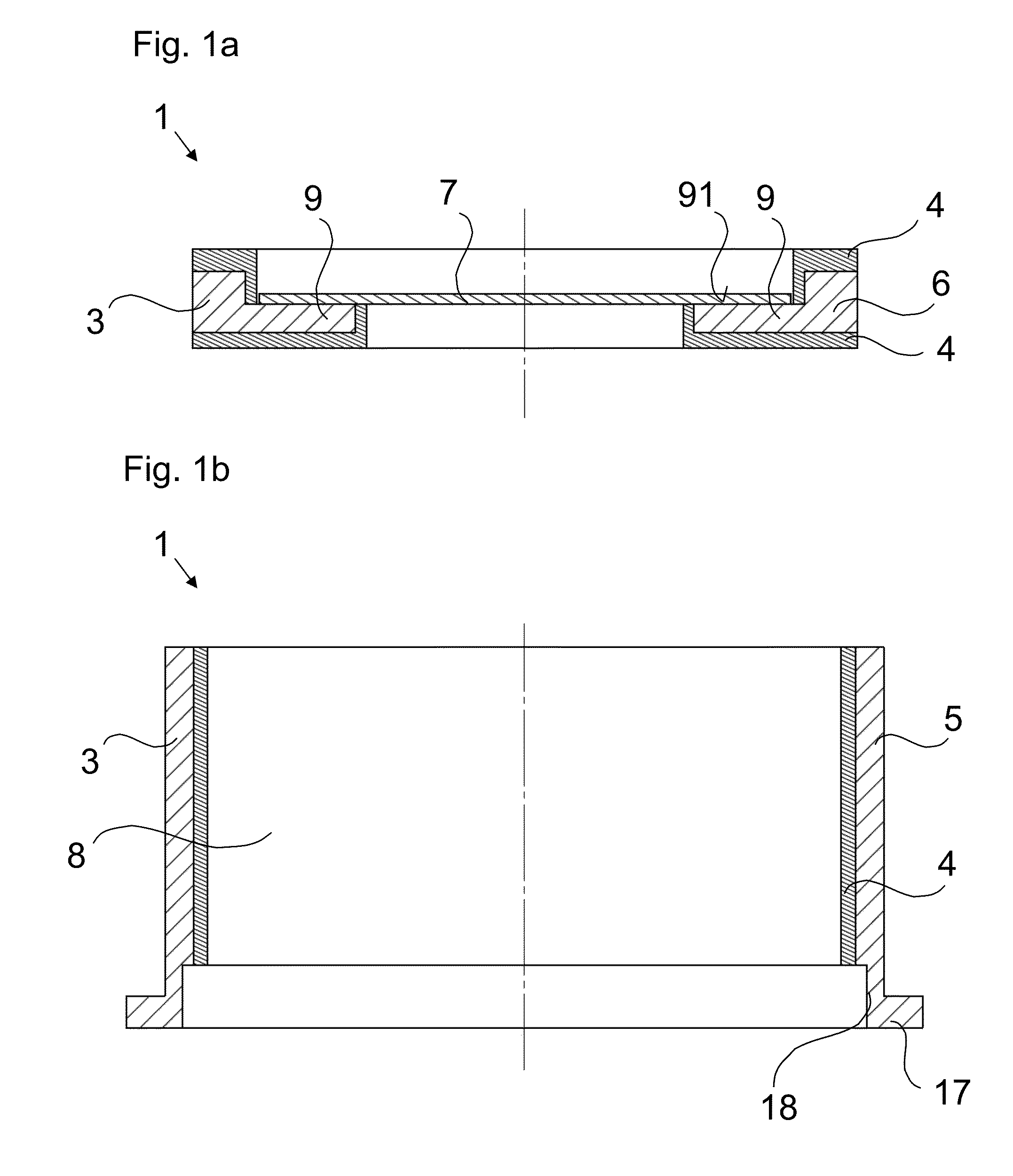

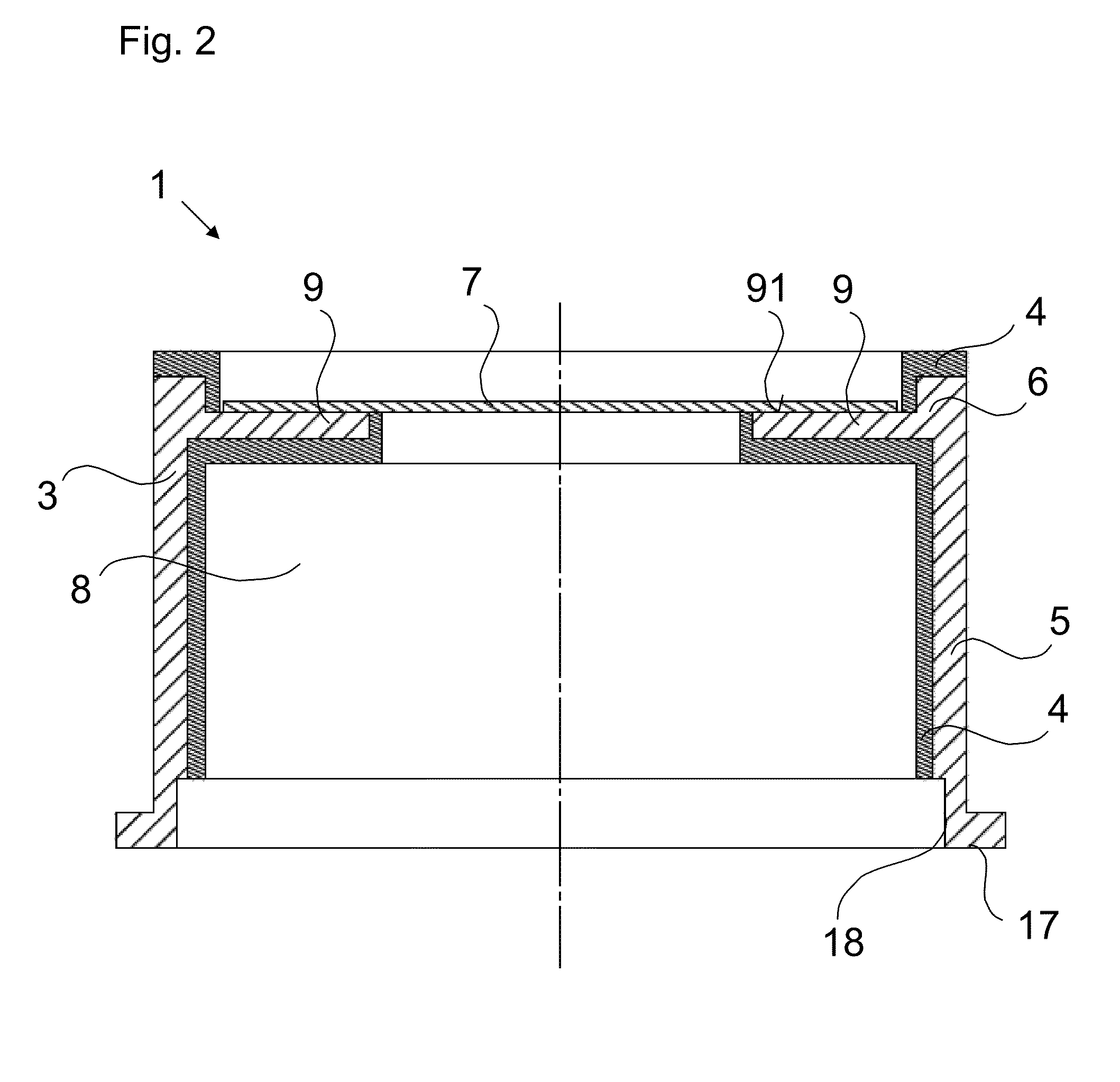

Device for a radiation detector and radiation detector with the device

ActiveUS8835857B2Inhibition is effectiveLow efficiencyX-ray spectral distribution measurementGlass dosimetersPhysicsX-ray fluorescence

A device for a radiation detector includes a main body, which includes a material G and is at least partially provided with a coating. The coating has at least a first layer with a material A1. The material G of the main body can be excited by a primary radiation impinging on the coating, so that an x-ray fluorescence radiation is produced with an x-ray fluorescence spectrum, which has a maximum MG at an energy EG. Furthermore, at an energy E1, the material A1 has an absorption edge. In this case, the material A1 is chosen such that the relationships E1<EG and EG−E1≦̸4 keV apply. Also specified is a radiation detector, which has the device and a detector element, which is suitable for the detection of the primary radiation.

Owner:KETEK

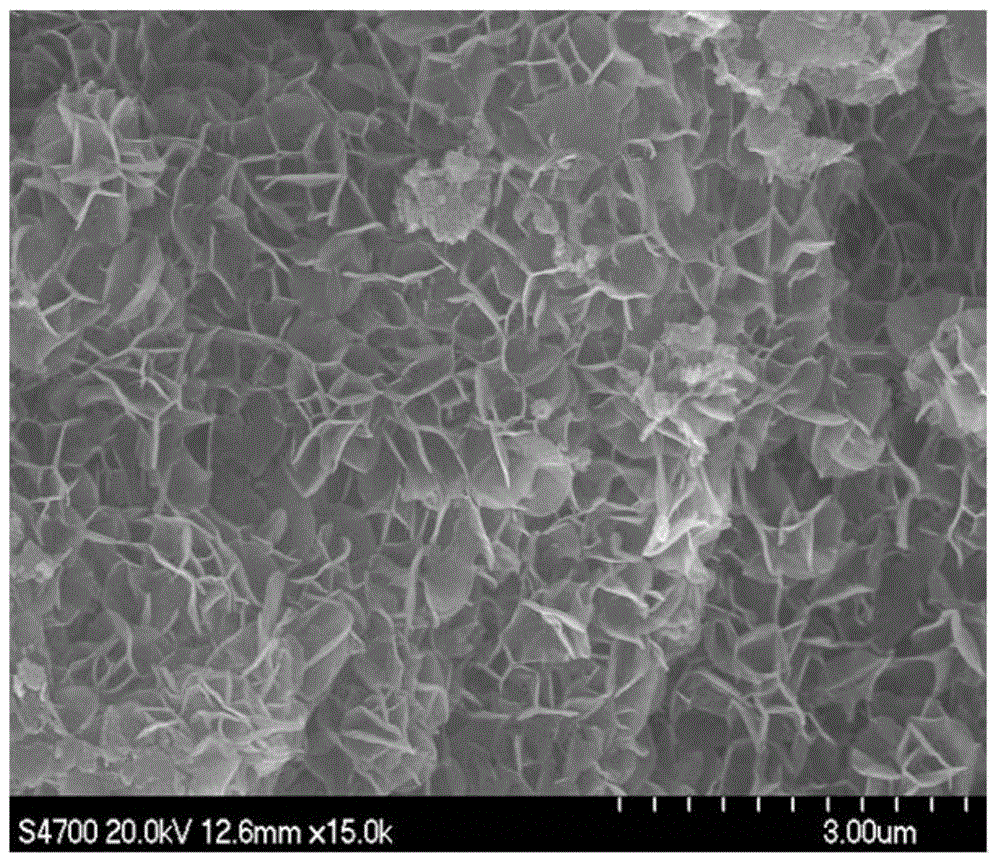

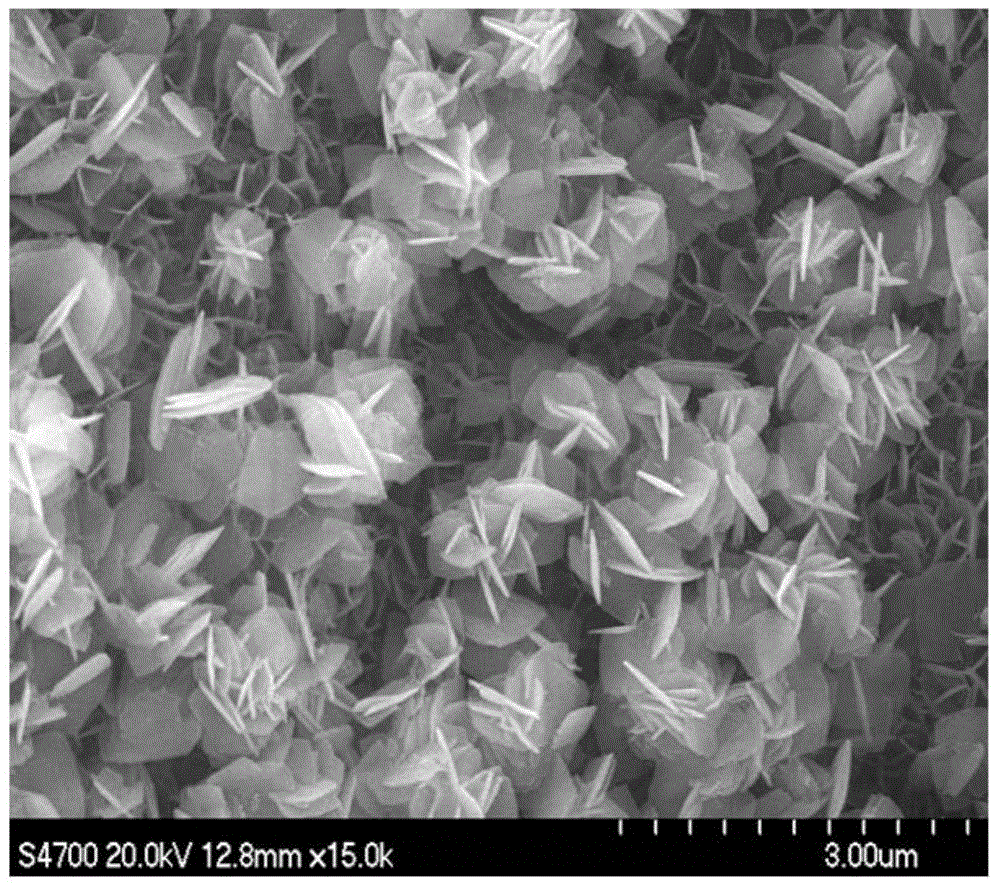

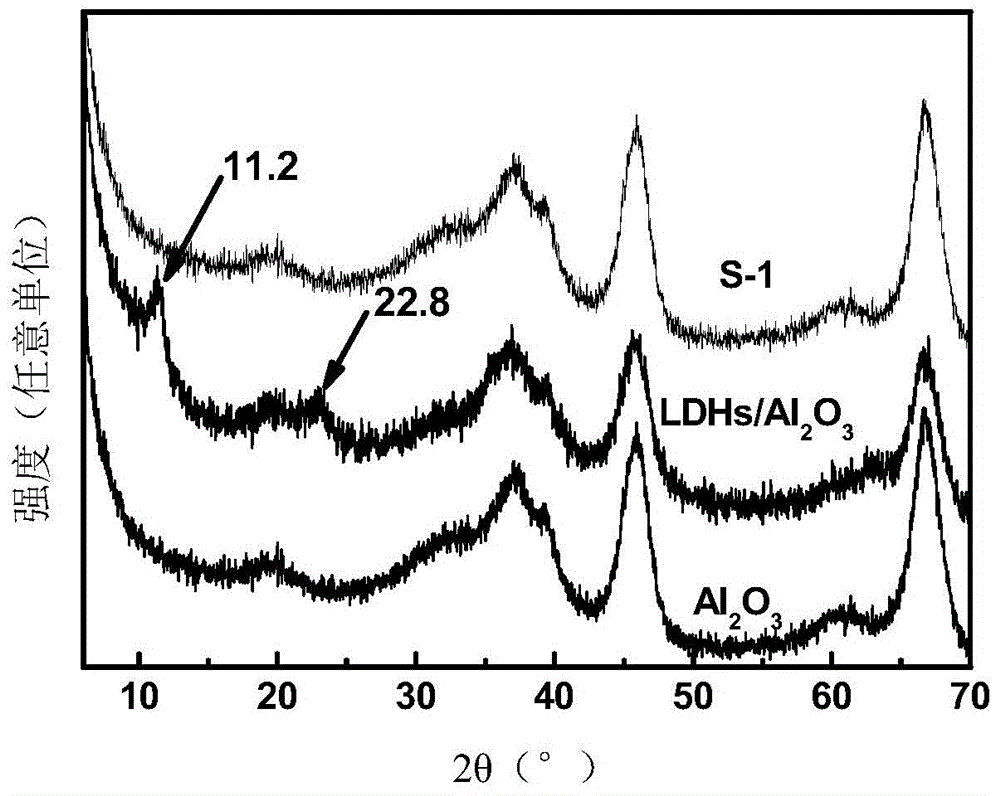

Loaded double-metal hydrogenation catalyst, and preparation method and application thereof

ActiveCN105521792AEvenly distributedFully loadedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFluorescenceHydrodesulfurization

The invention provides a loaded double-metal hydrogenation catalyst, and a preparation method and application thereof. The catalyst comprises a gamma-Al2O3-contained carrier and active metal components loaded on the gamma-Al2O3-contained carrier, wherein the active metal components comprise a group-VIB metal component and a group-VIII metal component which have the following characteristics: through the analysis of an X-ray photoelectron spectroscopy, the mol ratio of the group-VIB metal atom to the Al atom on the surface of the catalyst is measured to be 0.11 to 0.25, and the mol ratio of the group-VIII metal atom to the Al atom on the surface of the catalyst is measured to be 0.01 to 0.10; and through the analysis of an X-ray fluorescence spectroscopy, the mol ratio of the group-VIII metal atom to the group-VIB metal atom in the catalyst is measured to be 0.2 to 1. The loaded double-metal hydrogenation catalyst prepared by using the method provided by the invention has good dispersibility, active-centre accessibility and structural stability, significantly improves hydrodesulphurization property of the catalyst, and has good industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

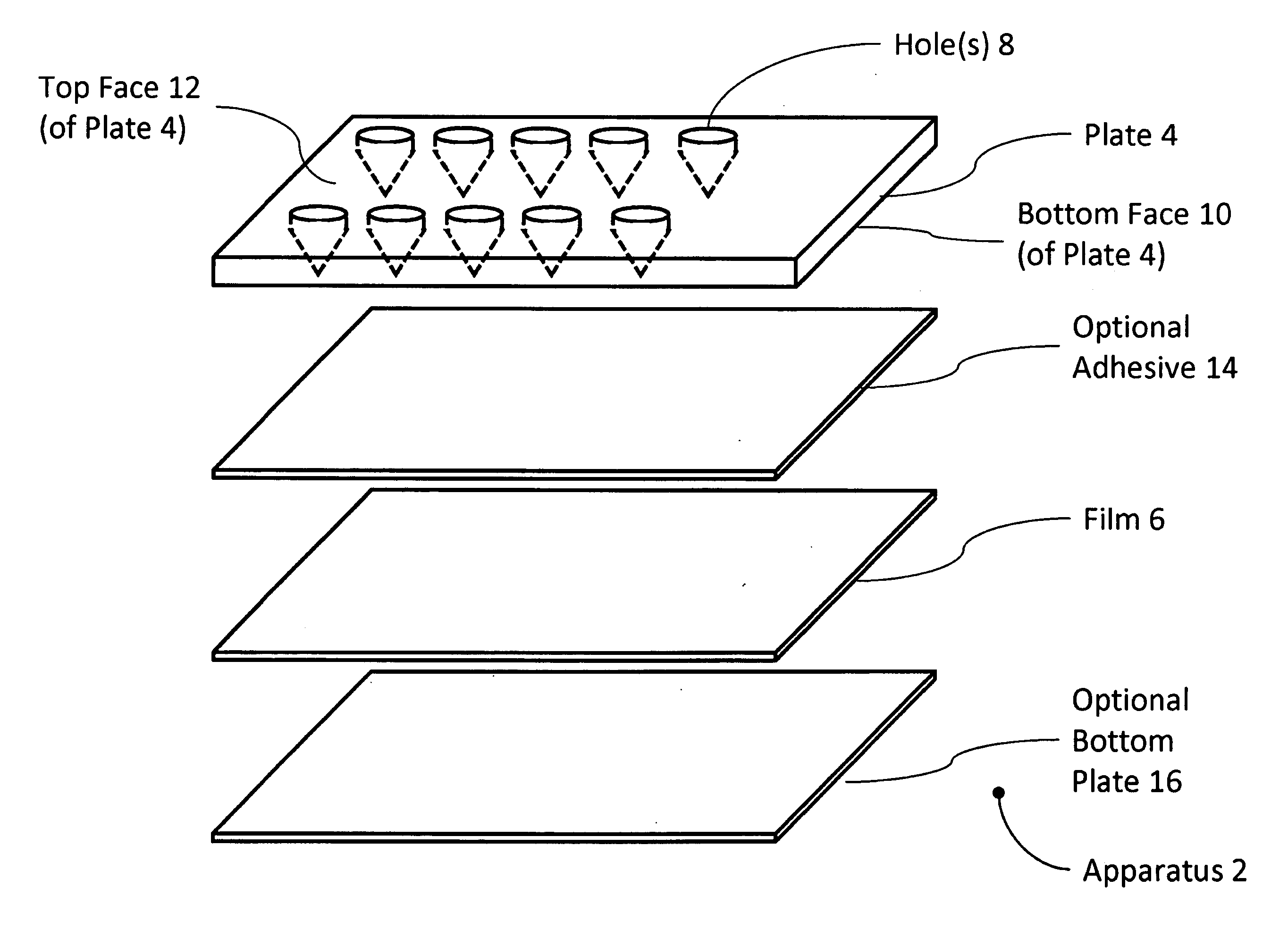

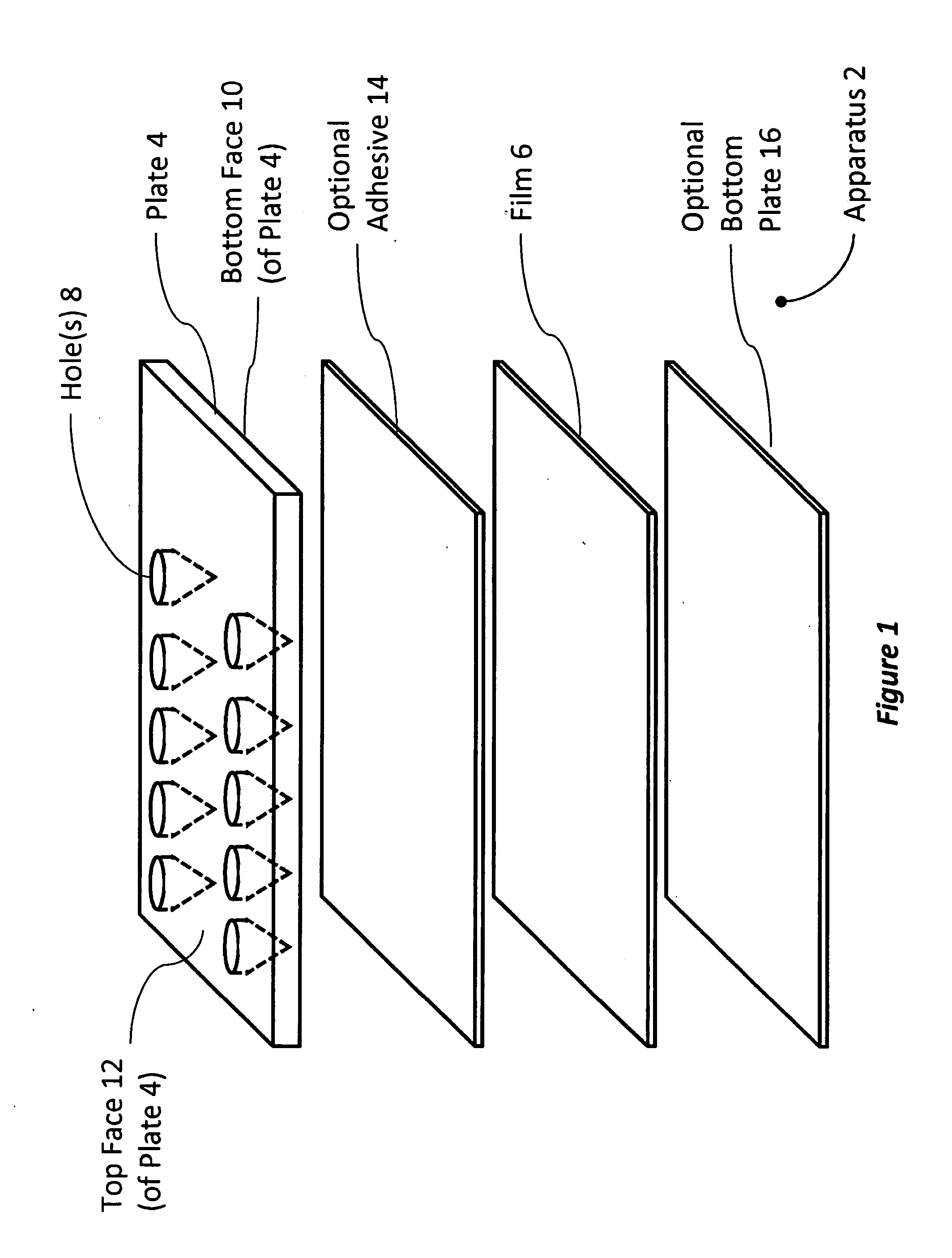

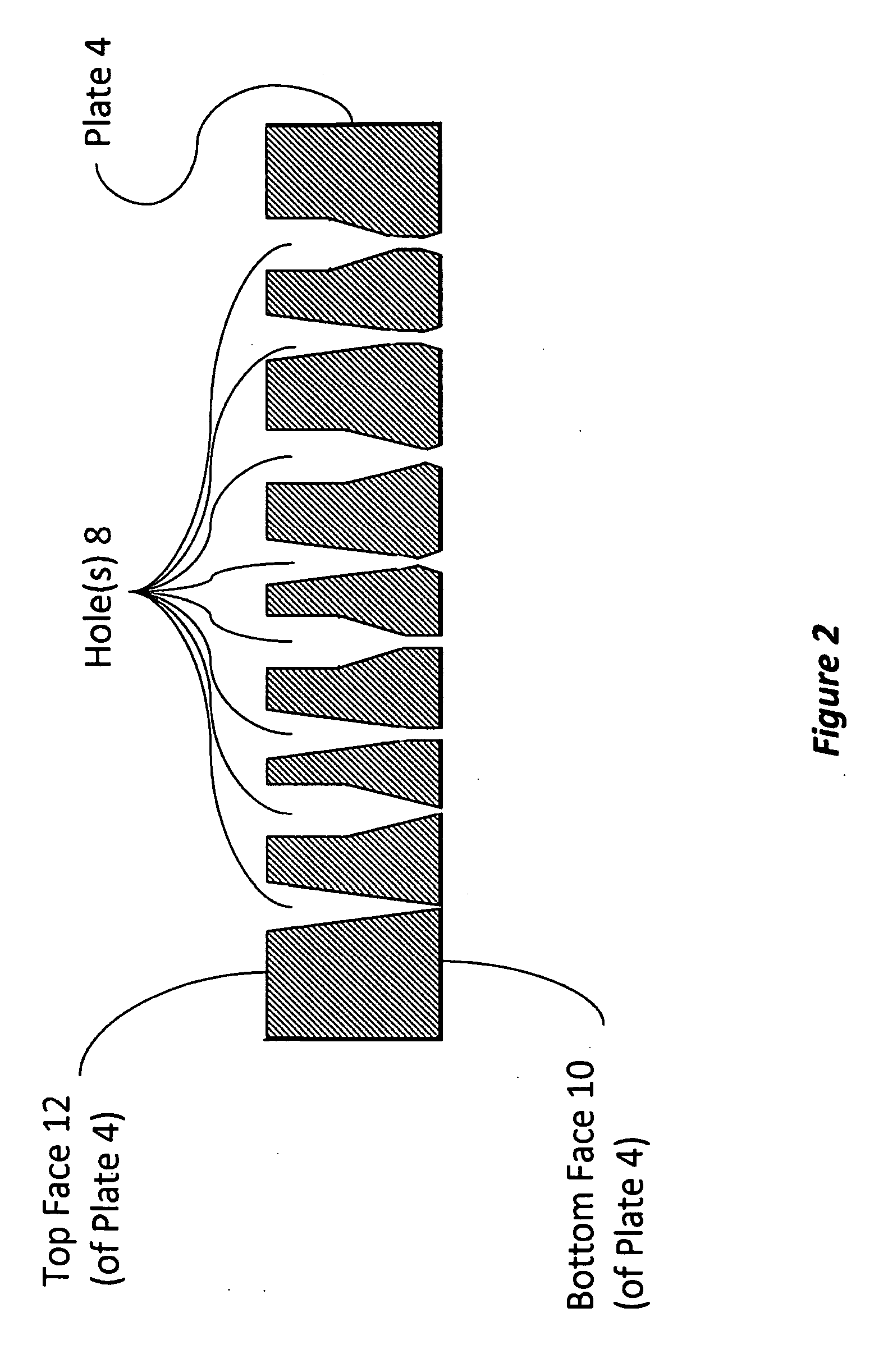

Well Plate

ActiveUS20090046832A1Material analysis using wave/particle radiationX-ray spectral distribution measurementRh elementPlatinum

The present invention includes an apparatus for preparing samples for measurement by x-ray fluorescence spectrometry. The apparatus comprises a plate having one or more holes passing through the plate. The holes are covered by a film on one side of the plate. The holes are less than 500 micrometers across in one dimension where the film covers the holes. The film is translucent to x-rays. The present invention also includes an apparatus for preparing samples for measurement by x-ray fluorescence spectrometry. The apparatus comprises a plate having one or more holes passing through the plate. The holes are covered on one side of the plate by a detachable cover forming a water-tight seal against the plate. The cover is substantially free of the elements osmium, yttrium, iridium, phosphorus, zirconium, platinum, gold, niobium, mercury, thallium, molybdenum, sulfur, lead, bismuth, technetium, ruthenium, chlorine, rhodium, palladium, argon, silver, and thorium. The holes are less than about 500 micrometers across in one dimension where the cover covers the holes. The present invention also includes a method for preparing samples for measurement by x-ray fluorescence spectrometry. The method comprises providing a solution of with less than 10 micromolar solute and a volume of between about 2 microliters and about 2 milliliters. The solution is concentrated and analyzed using x-ray fluorescence spectrometry.

Owner:ICAGEN LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com