Loaded double-metal hydrogenation catalyst, and preparation method and application thereof

A hydrogenation catalyst and bimetallic technology, which is applied in the field of supported bimetallic hydrogenation catalyst and its preparation and application, can solve the problems of complex preparation process, difficulty in industrial application, poor controllability and repeatability, etc., and achieve improvement Hydrodesulfurization performance, good industrial application prospects, guaranteed full utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of a supported bimetallic hydrogenation catalyst, the preparation method comprising the following steps:

[0037] (1) Under the conditions of crystallization, will contain water-soluble Group VIII metal salt, urea, water and γ-Al 2 o 3 The mixture of base carriers is placed in a closed container for crystallization, and the Al contained in it 2 o 3 , the weight ratio of water to alumina in the mixture is ≥1;

[0038] (2) Using the solution containing the VIB group metal salt as the impregnating liquid, impregnating the solid obtained from the crystallization in step (1), followed by drying and roasting in sequence.

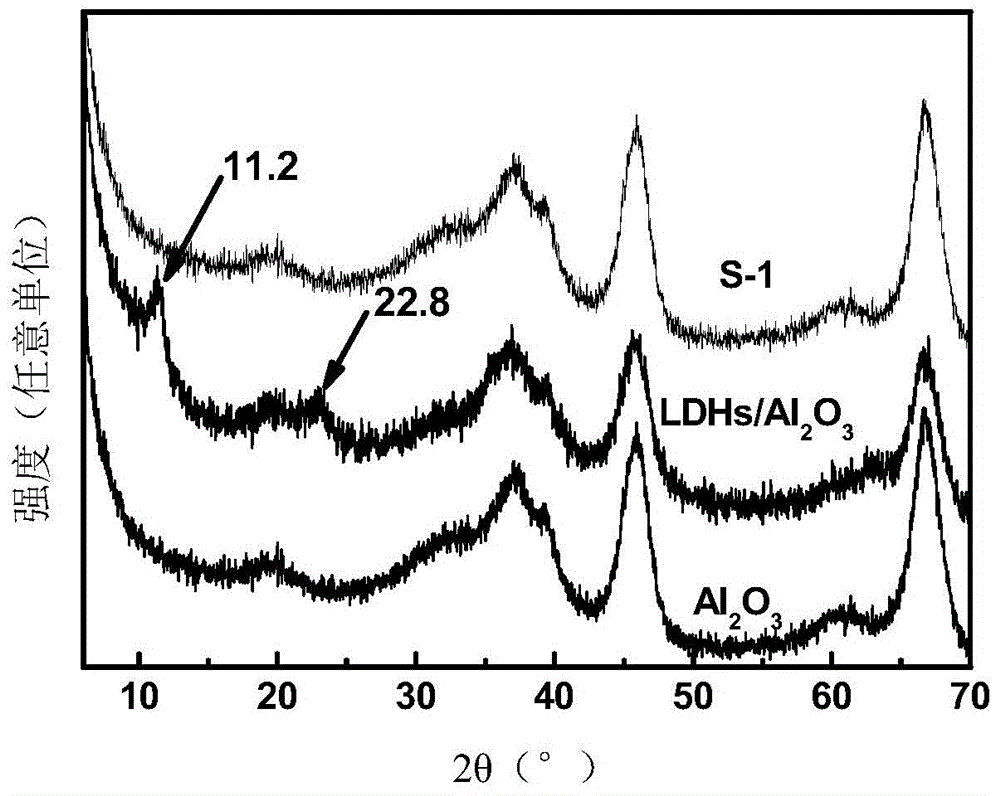

[0039] The essence of the method of the present invention is to first support Group VIII metals through simple, controllable, and low-cost in-situ synthetic hydrotalcite technology, and then introduce Group VIB metals by conventional impregnation methods to obtain a supported bimetallic hydrogenation catalyst ...

Embodiment 1

[0061] (1) Prepare 50 mL of a solution containing 0.2 mol / L nickel nitrate and 0.6 mol / L urea; weigh 10 g of γ-Al with a diameter of 2-5 mm 2 o 3 The particles were poured into the above solution to obtain a mixture, the pH of which was 7.5; the mixture was transferred to an autoclave, and placed in an oven for crystallization at 80° C. for 12 hours;

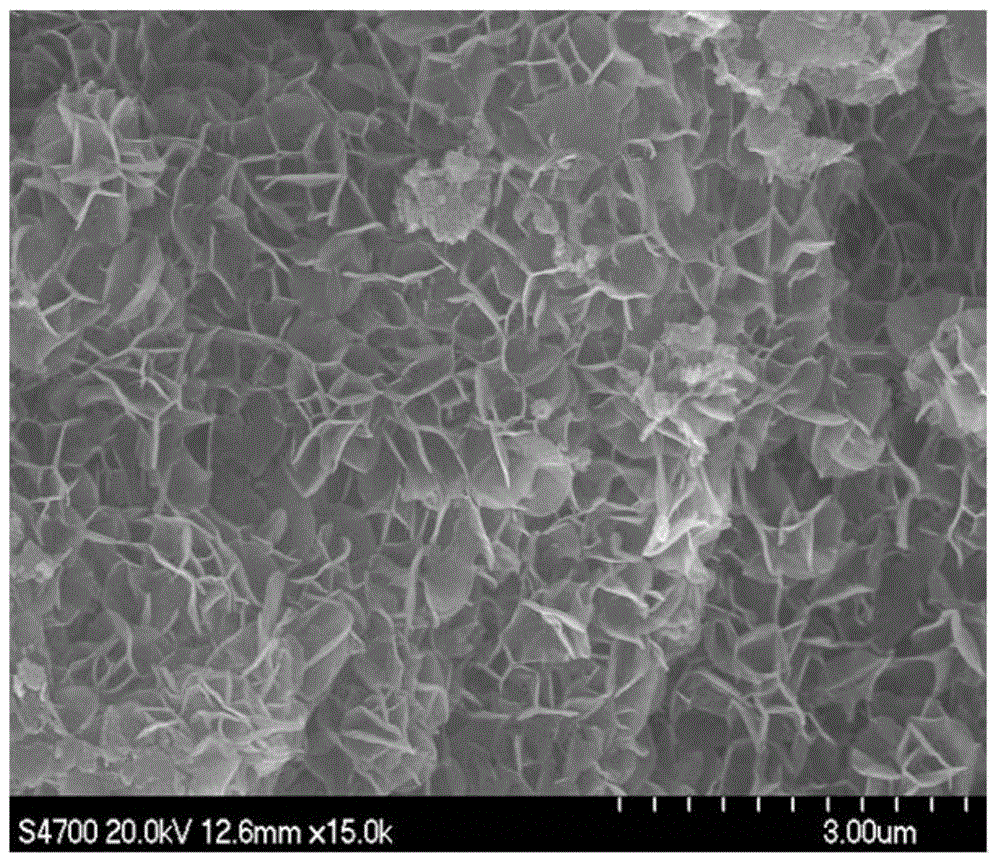

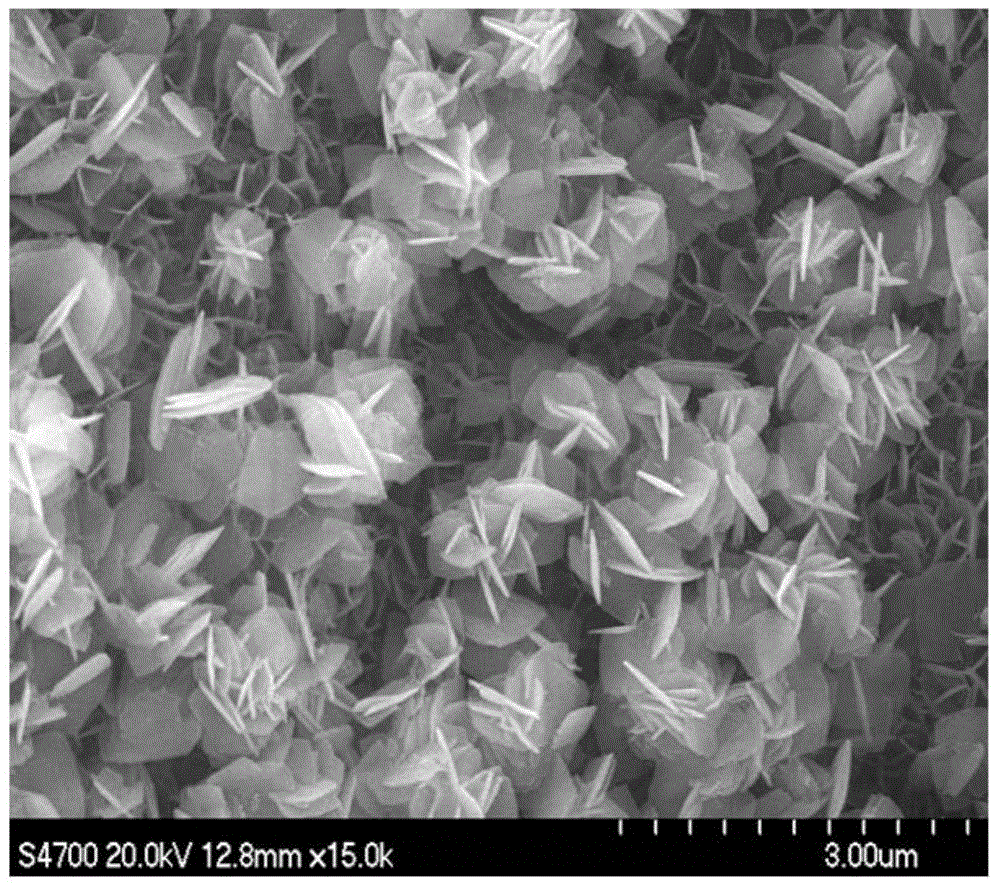

[0062] (2) Filter the material obtained after the crystallization in step (1), wash the solid with water, put it in an oven and dry it at 100°C for 5 hours to obtain NiAl-CO 3 2- -LDHs / γ-Al 2 o 3 Composite material; the NiAl-CO 3 2- -LDHs / γ-Al 2 o 3 SEM images of composite materials figure 1 shown;

[0063] (3) Prepare a sodium molybdate solution containing 6.0 g of sodium molybdate and about 10 mL, and add it dropwise to the NiAl-CO obtained in step (1). 3 2- -LDHs / γ-Al 2 o 3 Soak it in water, dry it at room temperature, then dry it at 100°C for 5h, and bake it at 500°C for 4 hours to get NiMo / γ-Al 2 o 3 Catalyst...

Embodiment 2

[0075] (1) Prepare 50 mL of a solution containing 0.2 mol / L cobalt nitrate and 1.0 mol / L urea, and weigh 15 g of γ-Al with a diameter of 2-5 mm 2 o 3 The particles were poured into the above solution to obtain a mixture, the pH of which was 7.5; the mixture was transferred to an autoclave, and placed in an oven for crystallization at 80°C for 24 hours;

[0076] (2) Filter the material obtained after the crystallization in step (1), wash the solid with water, and dry it in an oven at 100°C for 6 hours to obtain CoAl-CO 3 2--LDHs / γ-Al 2 o 3 Composite material; the CoAl-CO 3 2- -LDHs / γ-Al 2 o 3 The SEM image of the composite material and figure 1 resemblance;

[0077] (3) Prepare an ammonium molybdate solution containing 4.4g of ammonium molybdate and about 15mL, and add it dropwise to the above-mentioned CoAl-CO 3 2- -LDHs / γ-Al 2 o 3 Soak it in water, dry it at room temperature, then dry it at 100°C for 5 hours, and bake it at 400°C for 5 hours to get CoMo / γ-Al 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com