Method for preparing standard sample for testing content of hard-alloy components and method for testing content of hard-alloy components

A technology of cemented carbide and standard samples, which is applied in the field of X-ray fluorescence spectroscopic analysis, can solve the problems of difficult uniformity of high-purity oxides, high operation requirements, and long grinding time, so as to remove the limitation of cemented carbide detection methods and shorten the Process and time, avoiding the effect of cumbersome valuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to one aspect of the present invention, the preparation method of the standard sample for determining the composition of cemented carbide by X-ray fluorescence spectrometry includes the following steps.

[0023] Step 1: Weigh a certain mass of single oxide, add flux according to the dilution ratio of 1:10~1:100, add flux 0.1~1 times the mass of flux and 0.1~2g release agent at the same time, mix well Then put it into a muffle furnace or a high-frequency automatic melting machine, heat it to 700 ° C ~ 1200 ° C for 5 ~ 40 minutes, and then place it to cool and automatically demould to obtain a single oxide glass fusion sheet, and prepare a variety of single oxide glass fusion sheets as required. piece. Preferably, the mixture of a single oxide, a flux, a co-solvent, and a release agent is melted at a temperature of 1150° C. for 25 minutes. If it is heated in a muffle furnace, it needs to be taken out and shaken once during the period; if it is heated in a high-...

Embodiment 1

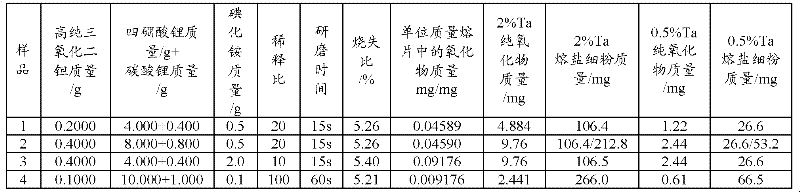

[0039] Preparation of single oxide tantalum trioxide glass fusing powder

[0040] Taking the single oxide tantalum trioxide as an example to illustrate the preparation process and advantages of the single oxide glass frit powder in the standard sample preparation method of the present invention.

[0041] A. Weigh 0.2000g of high-purity tantalum trioxide, add 4.000g of lithium tetraborate at a dilution ratio of 1:20, and add 0.400g of lithium carbonate 0.1 times the mass of lithium tetraborate flux as a flux and 0.5g of lithium tetraborate at the same time. Ammonium iodide was used as a mold release agent, mixed evenly, put into a muffle furnace, heated to 1150°C and melted for 25 minutes, taken out and shaken once during the period, and then left to cool and automatically released from the mold to obtain a tantalum trioxide glass frit. Weigh the tantalum trioxide glass frit, calculate the mass of tantalum trioxide contained in the tantalum trioxide glass frit per unit mass, an...

Embodiment 2

[0050] Preparation of standard samples

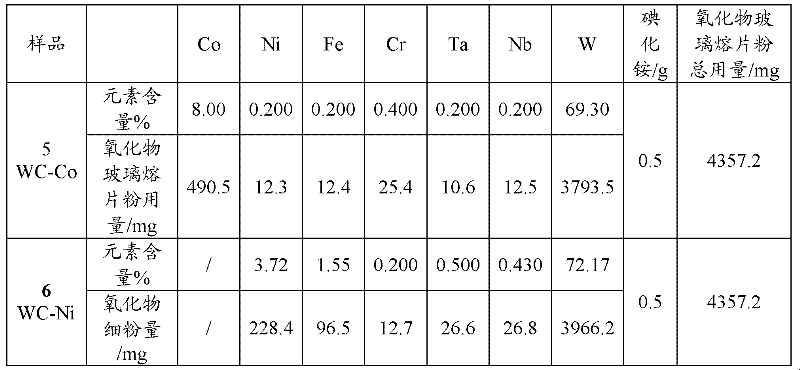

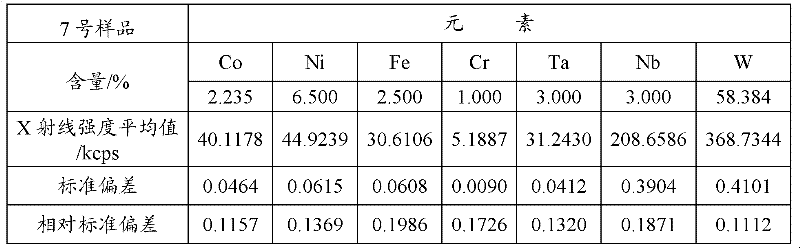

[0051] Prepare two grades of tungsten-based cemented carbide standard samples to illustrate the preparation steps in the standard sample preparation method of the present invention.

[0052] Weigh 0.2000g of a single oxide, add 4.000g of lithium tetraborate at a dilution ratio of 1:20, and simultaneously add 0.400g of lithium carbonate that is 0.1 times the mass of lithium tetraborate flux as a flux and 0.5g of ammonium iodide as a flux. Release agent, mixed evenly, put into muffle furnace, heated to 1150°C and melted for 25 minutes, took out and shaked once during the period, then left to cool and automatically released from the mold to obtain a single oxide glass frit. In this example, cobalt trioxide glass frits, nickel sesquioxide glass frits, ferric oxide glass frits, chromium oxide glass frits, tantalum pentoxide glass frits, pentoxide glass frits, Niobium glass frit, tungsten trioxide glass frit.

[0053] Weigh each of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com