Iron alloy fusing sample preparation method for X-ray fluorescence spectrum analysis

A technique of fluorescence spectroscopy and fusion sample preparation, which is applied in the field of analysis and detection, can solve the problems of increasing the complexity and difficulty of high-temperature melting samples, the inability to effectively oxidize samples into glass sheets, and the higher requirements of the sample preparation process, so as to achieve accurate analysis results Reliable, eliminate mineral effects, method safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

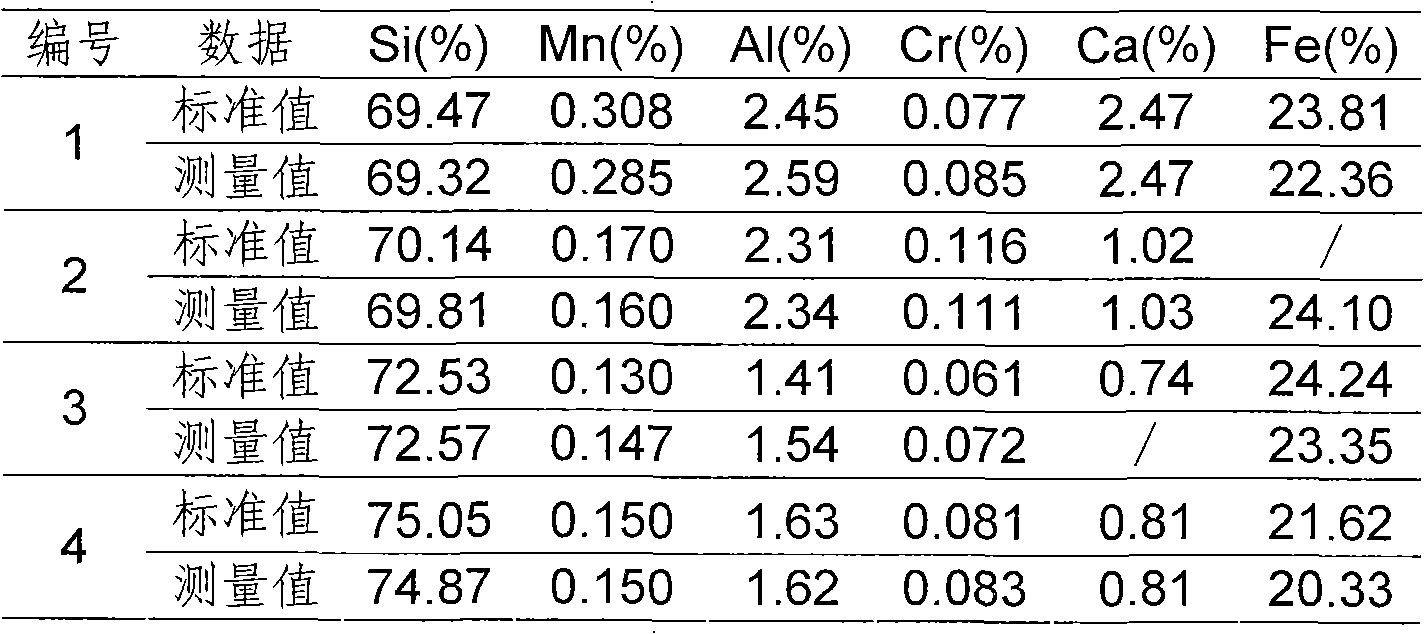

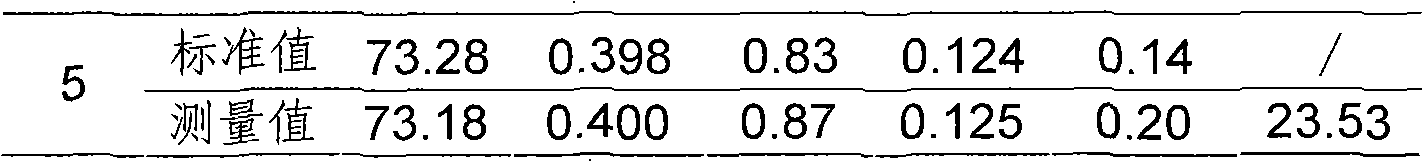

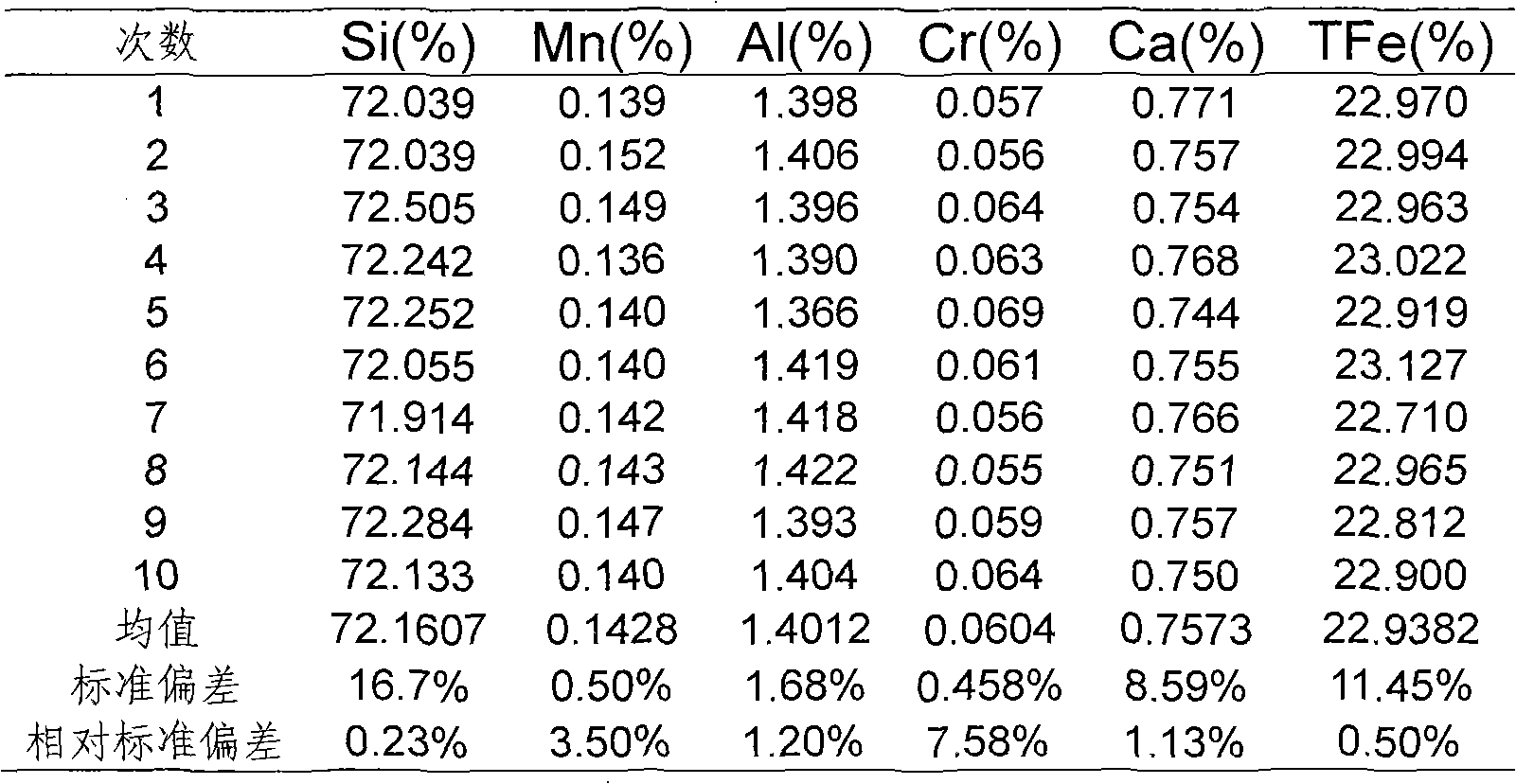

[0018] Embodiment 1, taking ferrosilicon as an example to illustrate the method involved in the present invention:

[0019] Silicon in the ferrosilicon alloy is the 14th element of the fourth main group, which is an amphoteric substance, weakly reducing, and relatively difficult to oxidize. Taking ferrosilicon as an example can illustrate the versatility of this method, that is, the applicability of the present invention to general ferroalloy samples Strong characteristics.

[0020] 1. The preparation of ferrosilicon glass frit is completed by the following steps

[0021] 1. Weigh 8.0000g of lithium tetraborate in a platinum crucible, melt it at 1000℃, slowly rotate the crucible after taking it out, and hang a layer of uniform protective wall in the platinum crucible; (the current specifications of the platinum crucible for general melting sample preparation are The bottom diameter is 34 mm, and the height is about 25 mm. It can meet the requirements with 8.0000g.)

[0022] 2. Weigh ...

Embodiment 2

[0037] The second embodiment takes ferromanganese as an example to illustrate the method involved in the present invention:

[0038] 1. The preparation of ferromanganese glass frit is completed by the following steps

[0039] 1. Weigh 8.0000g lithium tetraborate in a platinum crucible, melt it at 1030℃, slowly rotate the crucible after taking it out, and hang a uniform protective wall in the platinum crucible;

[0040] 2. Weigh 0.2000g ferromanganese sample and weigh Li 2 CO 3 , Na 2 CO 3 And KNO 3 0.5000g each, weigh 1.0000g67%Li 2 B 4 O 7 And 33% LiBO 3 Put the mixed flux in the platinum crucible and mix well;

[0041] 3. Add 5g (20 drops) of 300g / L ammonium iodide release agent;

[0042] 4. Put the crucible in the muffle furnace at 810℃ for pre-oxidation. In this process, preheat the crucible at the door of the furnace for 1 min, and then slowly move the crucible into the furnace for pre-oxidation for 20 min. The sample after oxidation should be Flowable liquid without black particl...

Embodiment 3

[0054] In the third embodiment, silico-manganese alloy is taken as an example to illustrate the method involved in the present invention:

[0055] 1. The preparation of silico-manganese alloy glass frit is completed by the following steps

[0056] 1. Weigh 8.0000g of lithium tetraborate in a platinum crucible, melt it at 1050℃, slowly rotate the crucible after taking it out, and hang a uniform protective wall in the platinum crucible;

[0057] 2. Weigh 0.2000g silico-manganese alloy sample and weigh Li 2 CO 3 , Na 2 CO 3 And KNO 3 0.5000g each, weigh out 1.0000g 67% Li 2 B 4 O 7 And 33% LiBO 3 Put the mixed flux in the platinum crucible and mix well;

[0058] 3. Add 4.5g (18 drops) 300g / L of ammonium iodide release agent;

[0059] 4. Put the crucible into the muffle furnace at 790℃ for pre-oxidation. In this process, preheat the crucible at the door of the furnace for 1.5 minutes, and then slowly move the crucible into the furnace for pre-oxidation for 18 minutes. The sample after oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com