Sample preparation method for carbon fiber tensile property test

A technology of tensile properties and carbon fiber, which is applied in the field of material test sample preparation, can solve the problems of uncontrollable carbon fiber multifilament tension, uneven force of carbon fiber multifilament, long sample preparation and test cycle, etc., to reduce sample preparation time , Improve curing performance and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

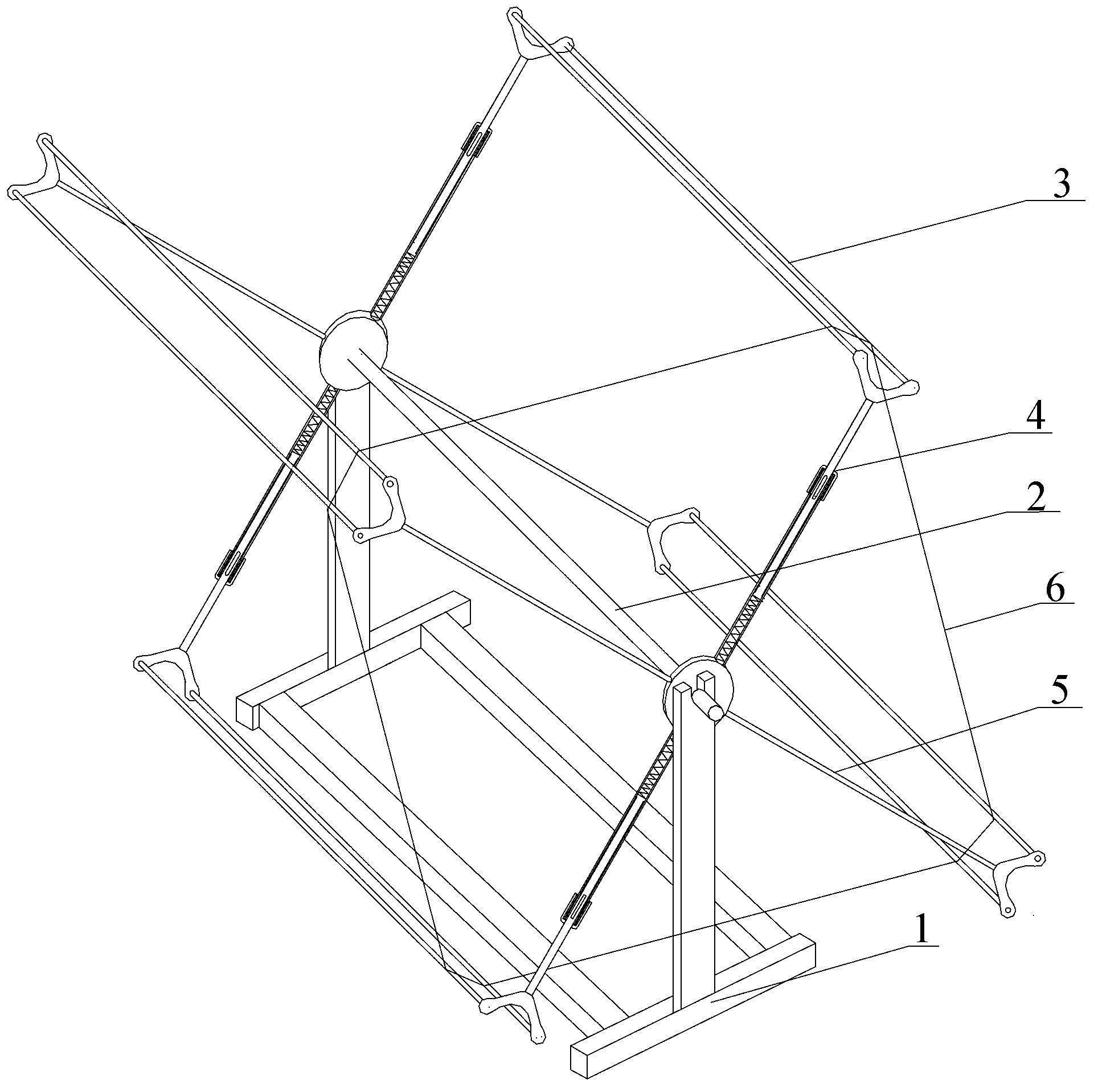

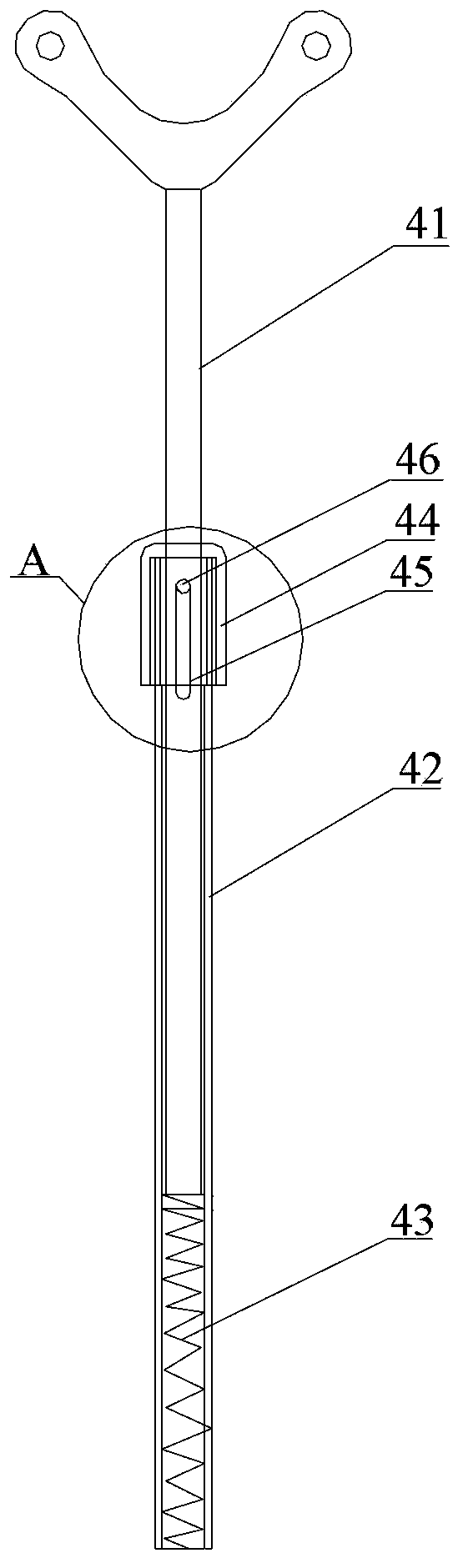

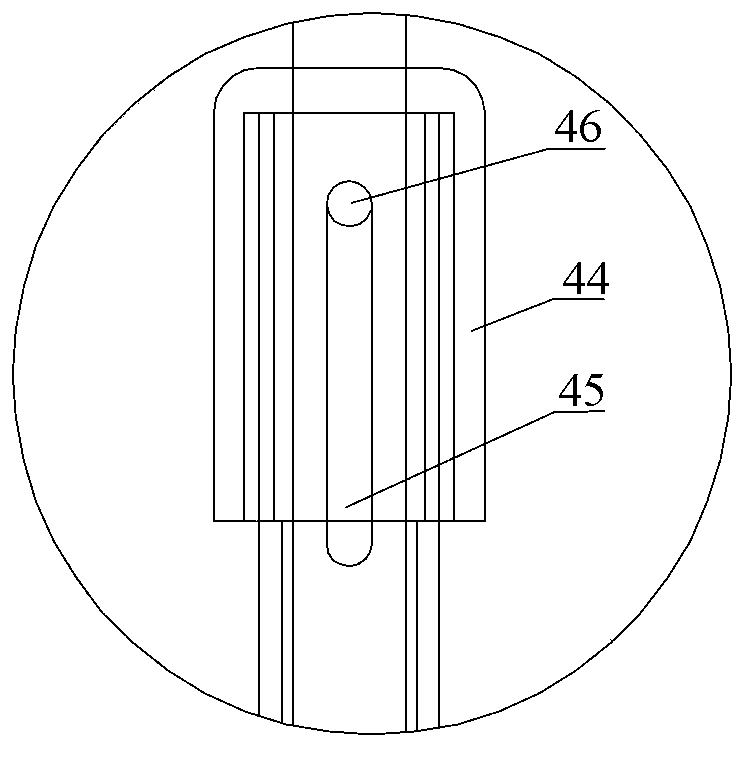

[0030] Such as figure 1 As shown, it is a sample preparation device for carbon fiber tensile performance testing, including: a main body support 1, a central shaft 2, a winding frame 3, and a fixed rod 5 and a telescopic rod 4 for supporting the winding frame 3. The central shaft 2 is installed on On the main body support 1, one end of the fixed rod 5 and the telescopic rod 4 are fixed with the winding frame 3, and the other end is fixed on the central axis 2. Both the fixed rod 5 and the telescopic rod 4 are perpendicular to the central axis 2 . The length of fixed rod 5 is 212mm, and the length of telescopic rod 4 is 212mm ± 25mm, and ± 25mm is adjustable distance. There are four fixed rods 5 and telescopic rods 4, which are arranged on two different axial planes perpendicular to the central axis 2, and two fixed rods 5 and 4 are arranged on each axial plane perpendicular to the central axis 2. Two telescopic rods 4, each fixed rod 5 on a plane perpendicular to the axial d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com