Method for analyzing vanadium iron ingredients by melt smelting sampling-X-ray fluorescence spectrum process

A fluorescence spectroscopy and vanadium-iron alloy technology, which is applied in the field of vanadium-iron alloy detection, can solve the problems that have not been reported in the literature, and achieve the effect of solving mineral effects, cost, safety, environmental protection, and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

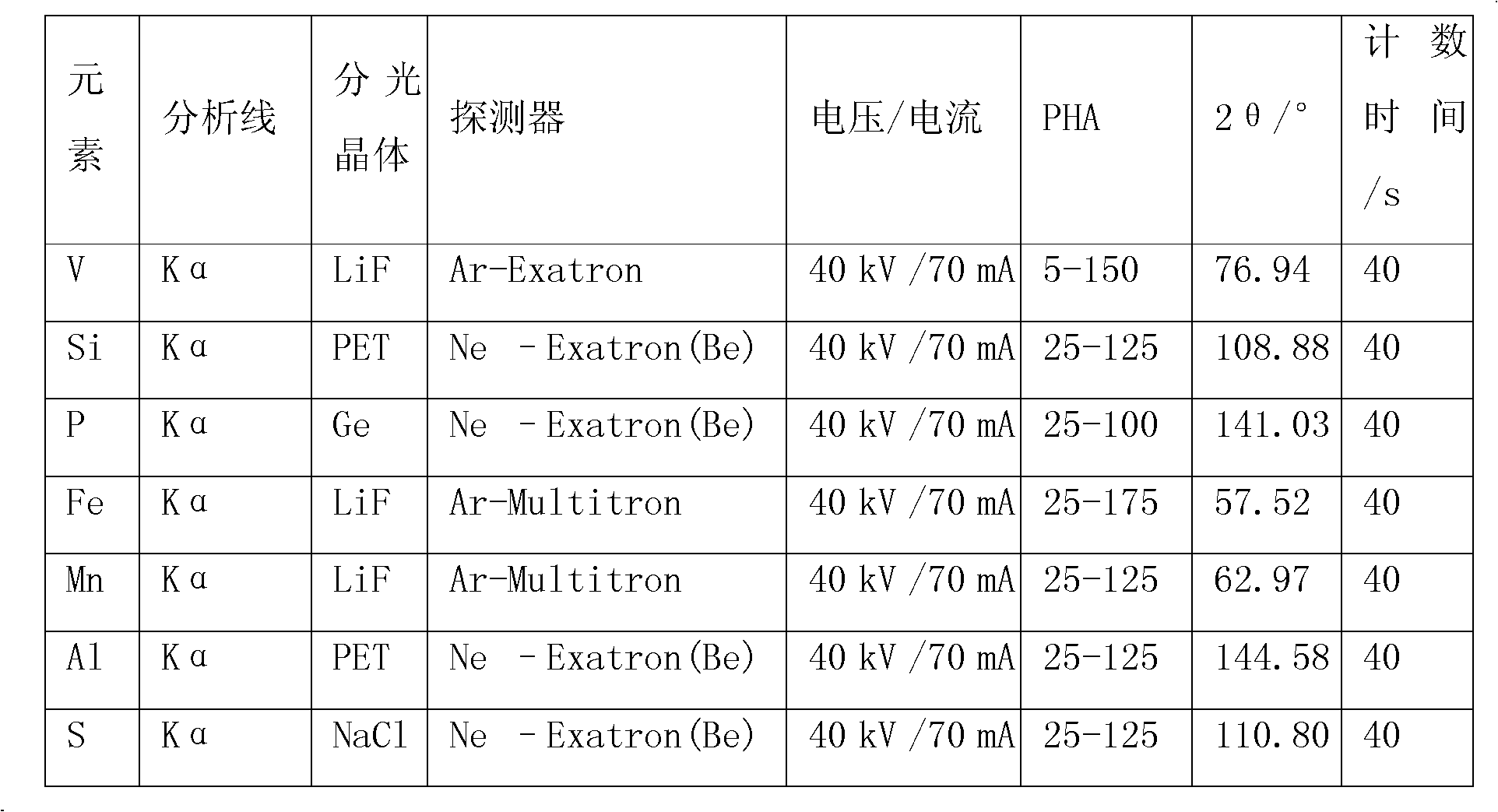

[0024] Example Melt Smelting Sampling-X-ray Fluorescence Spectrometry Analysis and Determination of Ferrovanadium Composition

[0025] (1) Sample preparation method

[0026] Take out the molten ferrovanadium sample from the smelting electric furnace, and quickly cast it into a sample block. It is required that the sample is uniform without delamination, the surface is smooth, and there is no crack damage. The sample is initially polished on the grinding wheel prototype, and then finely polished by the surface grinder. It is required that the polished surface should be smooth, with clear lines, no crossing, no flash, no pores, inclusions and cracks. The sample should not be overheated and cannot be stained. Calibration standard samples and analytical samples should be ground under the same conditions without overheating to prevent sample oxidation.

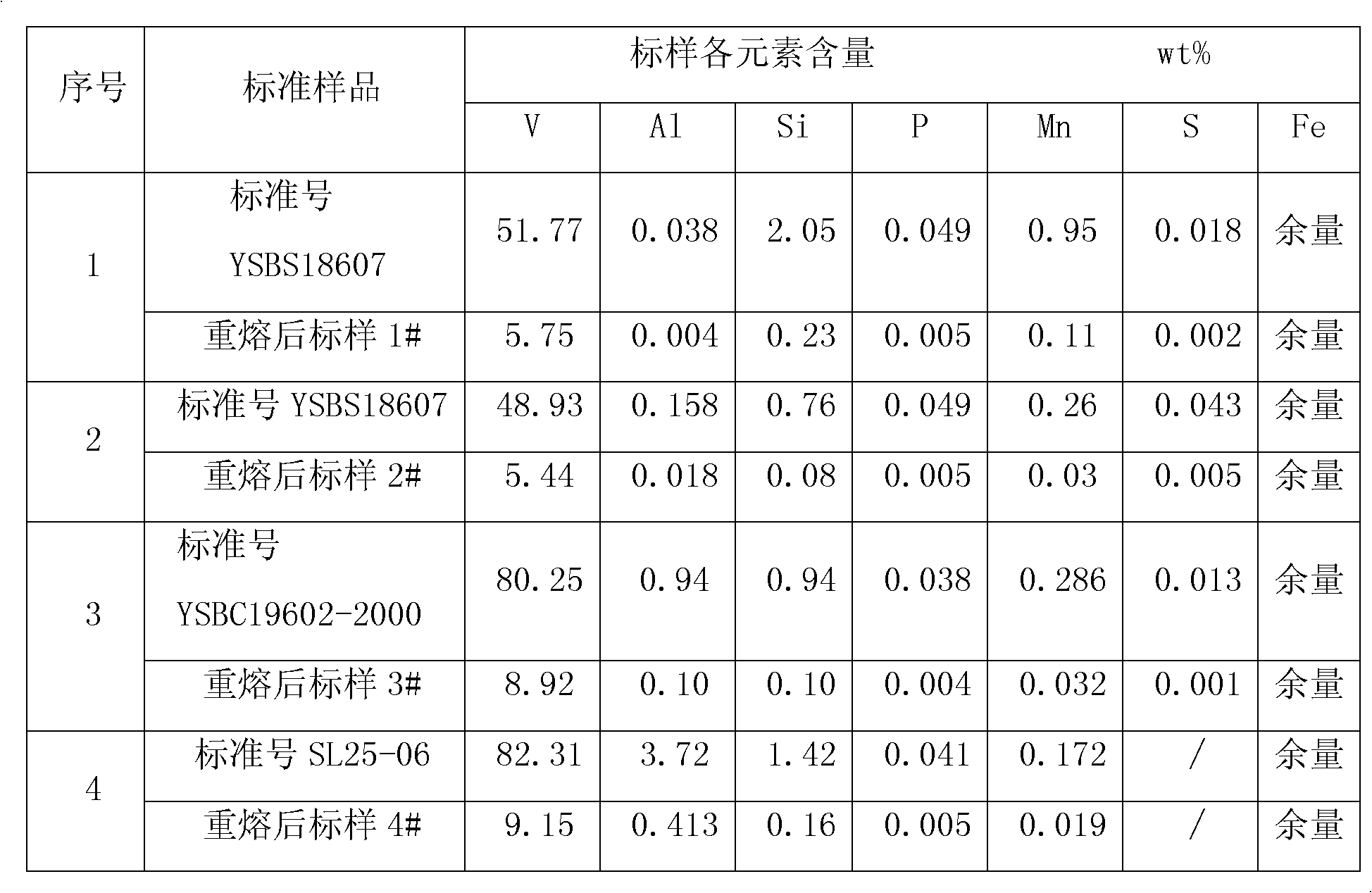

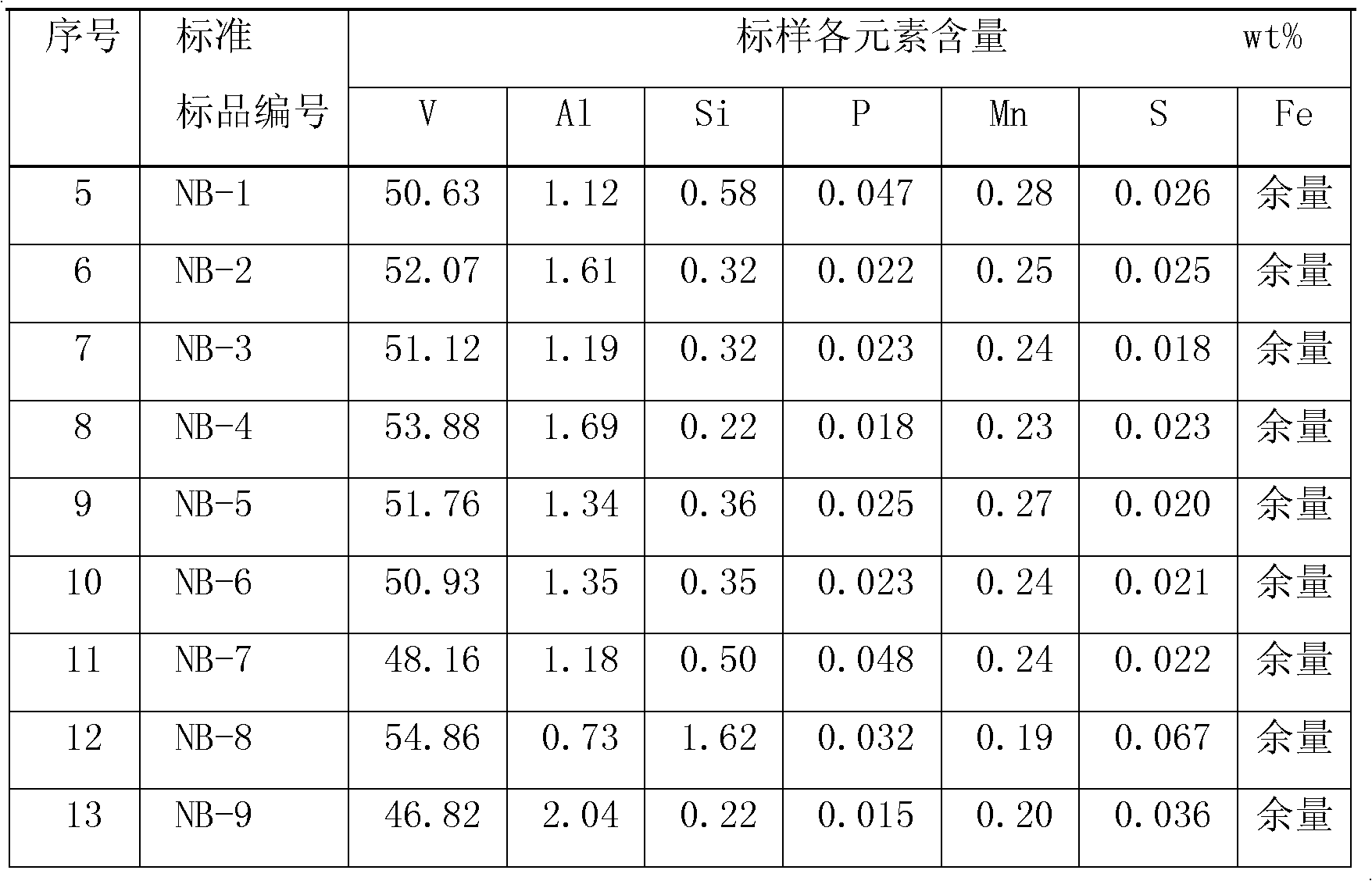

[0027] (2) Preparation of calibration standard samples

[0028] A, the calibration standard sample of low content adopts vanadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com