Ni-Fe-Ga-Co high-temperature magnetic-drive memory alloy

A technology of 1. ni-fe-ga-co and memory alloy, which is applied in the field of memory alloy and can solve the problems that magnetic drive shape memory materials cannot satisfy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

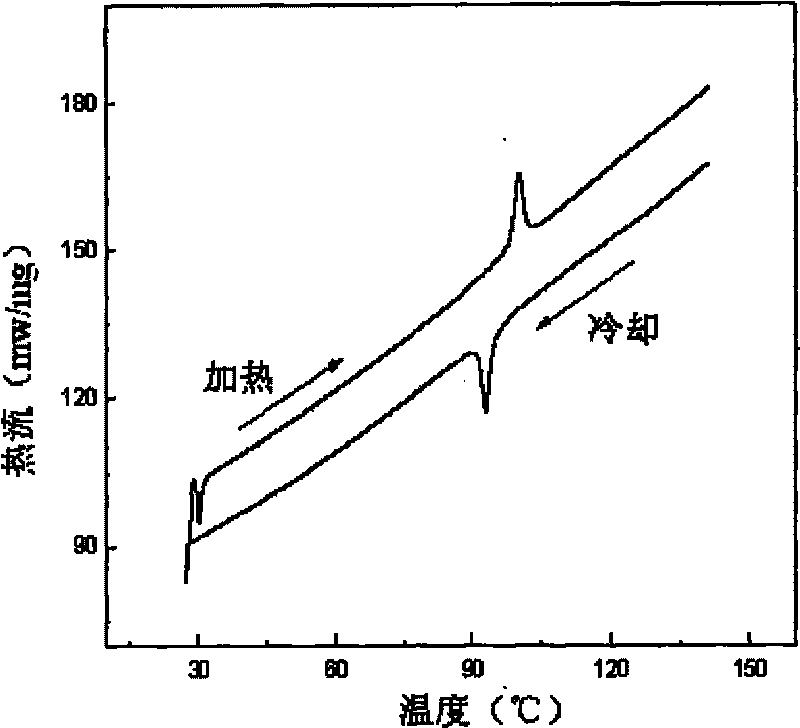

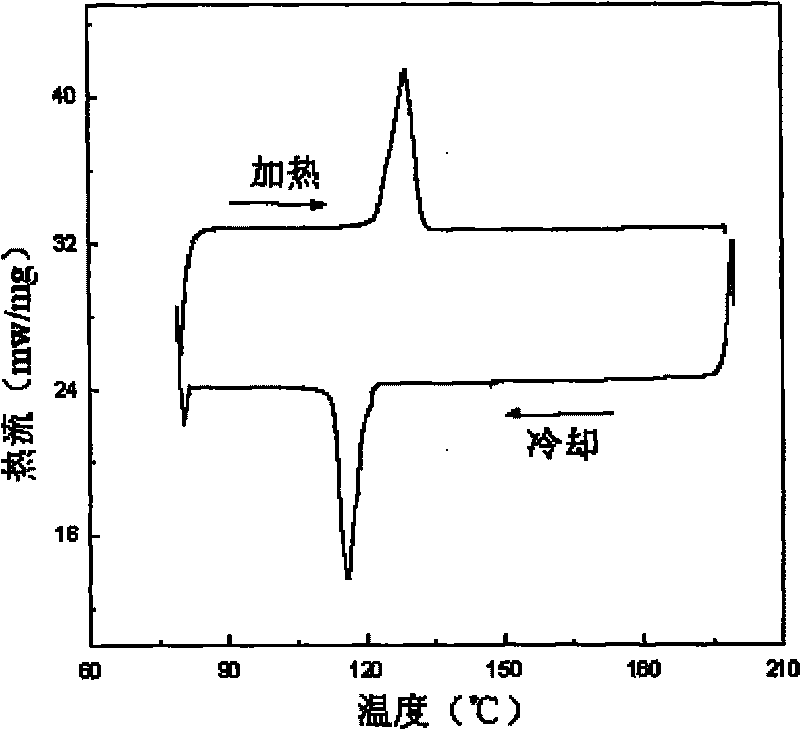

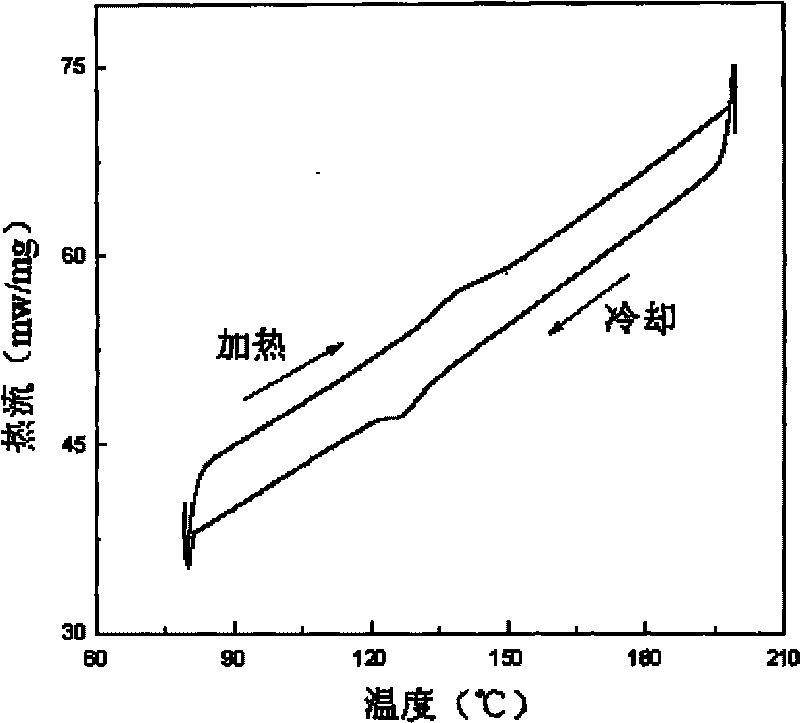

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: In this embodiment, the molecular formula of Ni-Fe-Ga-Co high-temperature magnetic drive memory alloy is Ni 56 Fe 17 Ga 27-x co x , the value of x in the molecular formula is 2-6.

[0009] In this embodiment, the preparation method of Ni-Fe-Ga-Co high-temperature magnetically driven memory alloy is as follows: 1. Electrolytic nickel, iron, gallium and electrolytic cobalt are respectively placed in a vacuum degree of 5×10 -3 Smelting under the condition of Pa for 2 minutes to obtain nickel elemental ingots, iron elemental ingots, gallium elemental ingots and cobalt elemental ingots, respectively pulverize each elemental ingots, and ultrasonically clean them in acetone for 20 to 30 minutes to obtain broken nickel material, iron scrap, gallium scrap and cobalt scrap; two, nickel scrap, iron scrap, gallium scrap and cobalt scrap are mixed according to the molar ratio of 56:17:(27-x):x to obtain the mixed material, put the mixture in a vacuum of 4×10 -2 Un...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the value of x in the molecular formula is 2.1-5.9. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the value of x in the molecular formula is 2.3-5.8. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com