Olefin hydroformylation heterogeneous Co-based catalyst and preparation method thereof

A heterogeneous catalyst, olefin hydroformyl technology, applied in the direction of carbon monoxide reaction preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low yield of the target product, Achieve good recycling performance, not easy to lose, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

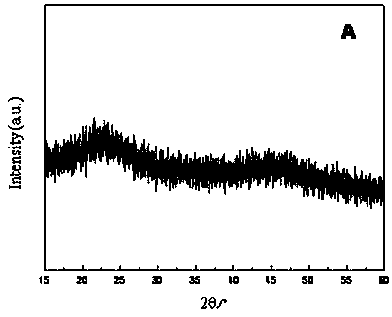

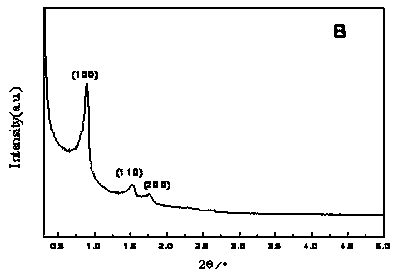

Image

Examples

Embodiment 1

[0045] Prepare 0.1mol / L cobalt chloride solution. Weigh 1.6g of NiCl 2 ﹒ 6H 2 O, dissolve in 68mL of 0.1mol / L cobalt chloride solution, add 2g of carrier SBA-15, stir for 24h, and sonicate for 2h. Evaporate to dryness in a stirrer, dry in a vacuum oven at 80 °C for 10 h; in a nitrogen atmosphere, roast at 350 °C for 5 h, transfer the obtained powder to a three-necked flask, add 68 mL of deionized water, N 2 Stir evenly under the ice-water bath under the atmosphere, prepare 0.1mol / L sodium borohydride solution, measure 28mL of the solution and add it dropwise to the three-necked flask, and react for 0.5h after the addition is completed; wash the obtained suspension until neutral Then use water and ethanol to wash 3 times to obtain the desired catalyst Na-Ni-Co-B / SBA-15. 1-hexene hydroformylation activity evaluation: feed gas composition CO: H 2 = 1:1, the reaction temperature is 120 o C, the rotation speed is 1200 r.p.m, the reaction pressure is 5MPa, and the reaction time...

Embodiment 2

[0047] Prepare 0.1mol / L cobalt chloride solution. Weigh 0.8g of FeCl 3 ﹒ 6H 2 O, dissolve in 68mL of 0.1mol / L cobalt chloride solution, add 2g of carrier MCM-41, stir for 24h, and sonicate for 2h. Evaporate to dryness in a stirrer, dry in a vacuum oven at 80 °C for 10 h; in a nitrogen atmosphere, roast at 350 °C for 5 h, transfer the obtained powder to a three-necked flask, add 68 mL of deionized water, N 2 Stir evenly under the ice-water bath under the atmosphere, prepare 0.1mol / L potassium borohydride solution, measure 24mL of the solution and add it dropwise to the three-necked flask, and react for 0.5h after the addition is completed; wash the obtained suspension until neutral Then wash with water and ethanol for 3 times to obtain the required catalyst K-Fe-Co-B / MCM-41. 1-octene hydroformylation activity evaluation: feed gas composition H 2 : CO= 1:1, the reaction temperature is 120 o C, the rotation speed is 1200 r.p.m, the reaction pressure is 5MPa, and the reaction...

Embodiment 3

[0049] Prepare 0.1mol / L cobalt chloride solution. Weigh 0.5g of RhCl 2 ﹒ 6H 2 O, dissolve in 68mL of 0.1mol / L cobalt chloride solution, add 2g carrier ZSM-5, stir for 24h, and sonicate for 2h. Evaporate to dryness in a stirrer, dry in a vacuum oven at 80 °C for 10 h; in a nitrogen atmosphere, roast at 350 °C for 5 h, transfer the obtained powder to a three-necked flask, add 68 mL of deionized water, N 2 Stir evenly under the ice-water bath under the atmosphere, prepare 0.1mol / L calcium borohydride solution, measure 20mL of the solution and add it dropwise to the three-necked flask, and react for 0.5h after the addition is completed; wash the obtained suspension until neutral It is then washed with water and ethanol for 3 times to obtain the desired catalyst Ca-Rh-Co-B / ZSM-5. Evaluation of 1-octene hydroformylation activity: feed gas composition H 2 : CO= 1:1, the reaction temperature is 120 o C, the rotation speed is 1200 r.p.m, the reaction pressure is 5MPa, and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com