Preparation method for MOF-based Co-doped tin dioxide gas-sensitive nano material as well as product and application

A nanomaterial, tin dioxide technology, applied in tin oxide, analytical materials, measurement devices, etc., can solve the problems of p-n junction reduction, gas sensing performance limitation, etc., to achieve improved gas sensing response, controllable Co doping amount, Responsive recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Measure 40mL of deionized water and 20mL of N,N-dimethylformamide (DMF) into a flask, and stir evenly;

[0023] (2) 1g tin protochloride hexahydrate (SnCl 2 ∙6H 2 O), 0.2g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ∙6H 2 (2) and 0.5mL terephthalic acid (PTA) are added in the flask, fully stirred at room temperature;

[0024] (3) Transfer the solution in the beaker to the reaction kettle, react at 160~200°C for 30min, filter the reacted precipitate, wash and dry;

[0025] (4) After drying, place it in a muffle furnace and bake at 500°C for 10h at a heating rate of 5°C / min to obtain Co-doped SnO 2 Gas-sensitive nanomaterials.

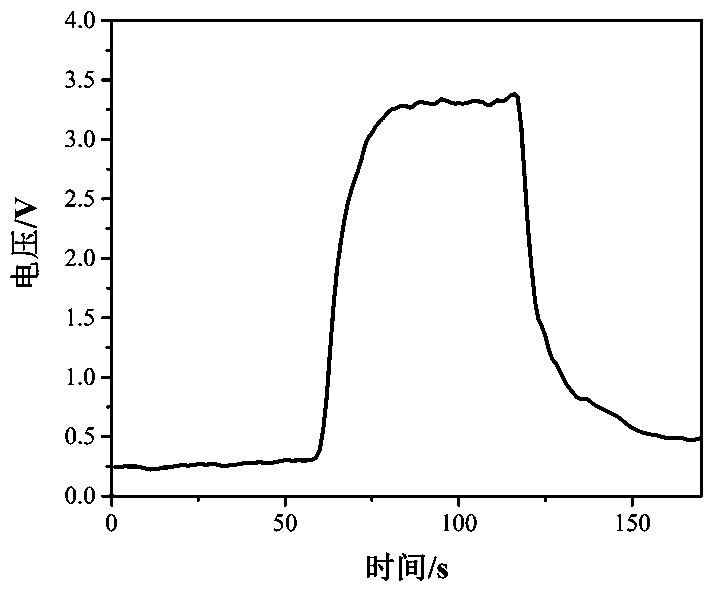

[0026] figure 1 Co-doped SnO for the present invention 2 Real-time response curve of gas-sensing nanomaterials to 10 ppm acetone gas, operating temperature. Among them, the sensitivity reaches 36.89, the response time is about 14s, and the recovery time is about 8s.

Embodiment 2

[0028] (1) Measure 30mL of deionized water and 20mL of N,N-dimethylformamide (DMF) into a flask and stir evenly;

[0029] (2) 0.8g tin protochloride hexahydrate (SnCl 2 ∙6H 2 O), 0.1g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ∙6H 2 (2) and 0.4mL terephthalic acid (PTA) were added in the flask, stirred at room temperature;

[0030] (3) Transfer the solution in the beaker to the reaction kettle, and react at 160~200°C for 25 minutes; filter the precipitate, wash and dry;

[0031] (4) After drying, place it in a muffle furnace and bake at 600°C for 15h at a heating rate of 5°C / min to obtain Co-doped SnO 2 Gas-sensitive nanomaterials.

Embodiment 3

[0033] (1) Measure 35mL of deionized water and 15mL of N,N-dimethylformamide (DMF) into a flask, and stir evenly;

[0034] (2) 0.9g tin protochloride hexahydrate (SnCl 2 ∙6H 2 O), 0.15g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ∙6H 2 (2) and 0.3mL terephthalic acid (PTA) were added in the flask, stirred at room temperature;

[0035] (3) Transfer the solution in the beaker to the reaction kettle, and react at 160~200°C for 40 minutes; filter the precipitate, wash and dry;

[0036] (4) After drying, put it in a muffle furnace and bake at 600°C for 8h, and the heating rate is 2°C / min to obtain Co-doped SnO 2 Gas-sensitive nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com