Simple and convenientindustrial method for recovering Co element from NdFeBmagnetwaste materials

An industrial method, neodymium-iron-boron technology, applied in the field of comprehensive utilization of waste resources, can solve the problems of difficulty in reflecting economic benefits, combining together, and high recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

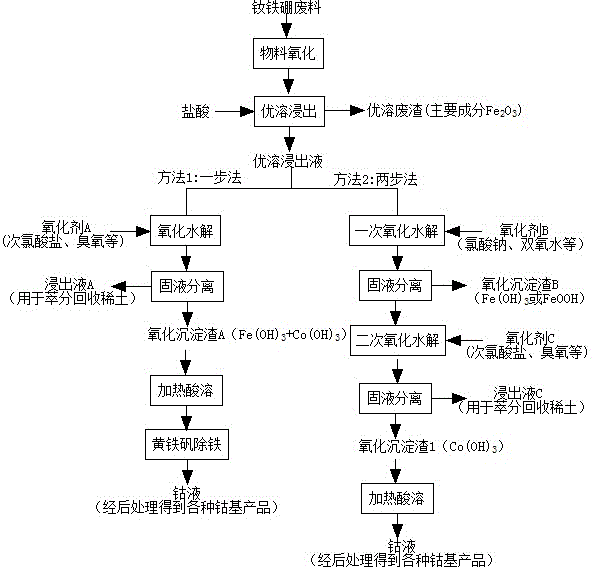

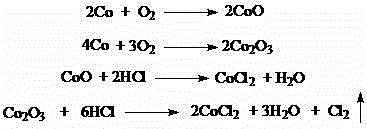

Method used

Image

Examples

Embodiment 1

[0066] Take a batch of scraps from the machining process of NdFeB permanent magnet materials. After testing, the above-mentioned metal elements in every 100g of NdFeB scrap include: 31.03g of rare earth elements (the main component is Nd, including Pr, Dy, Gd), 60.01g of Fe element content, 4.36g of Co element content, Al Element content 0.40g.

[0067] Take 1000Kg of the above-mentioned batch of NdFeB waste materials, grind and pulverize them through a ball mill to an average particle size of less than 300 mesh, and oxidize and roast the pulverized materials in a rotary kiln (calcination temperature 700 ° C, roasting time 1 hour), and then The oxidized and roasted material is leached with 2.7N concentration of hydrochloric acid (leaching temperature is 85°C, and the pH value of the leaching end point is controlled to be 2.0). According to process statistics, the consumption in Yancheng is about 1.8 cubic meters.

[0068] The Yourong leachate was tested, and the content of C...

Embodiment 2

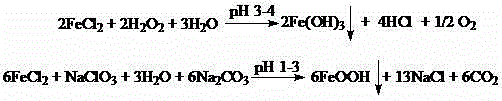

[0076] Take another part of Yourong leachate in Example 1, and carry out oxidative hydrolysis according to the two-step process.

[0077] Firstly, sodium chlorate is used as the oxidizing agent for primary oxidation hydrolysis, and the Yourong leachate is heated to 90°C, and sodium chlorate solution is continuously added to it, and after the precipitation begins to appear, the speed of adding the sodium chlorate solution is slowed down; Sampling and analysis is carried out when the precipitate is precipitated. When the residual concentration of Fe in the liquid phase system of the leach solution is controlled below 0.2mg / L, the reaction is stopped, and pressure filtration is carried out immediately for separation to obtain the leachate after the primary oxidation hydrolysis and the primary oxidation precipitation residue. According to the process statistics, the amount of sodium chlorate used is 7.10Kg (66.67mol); the calculation shows that the theoretical equivalent of sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com