FeSiBAlNiCo block high-entropy alloy and preparation method thereof

A high-entropy alloy high-volume technology, applied in the field of FeSiBAlNiCo bulk high-entropy alloys and its preparation, can solve the problems of looseness, complex process, and difficult control of the structure and properties of high-entropy alloy materials, and achieve outstanding corrosion resistance. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

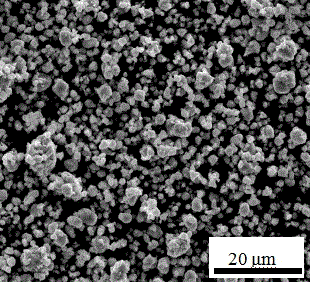

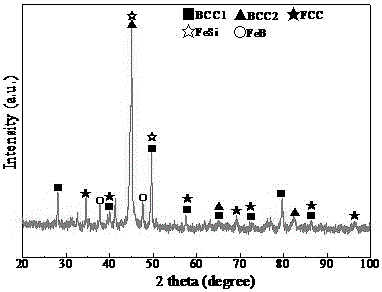

[0039] Preparation of high-entropy alloy powder: Take Fe, Si, B, Al, Ni, Co metal powders at a molar ratio of 1:1:1:1:1:0.2, and the purity of the powders is above 99.7%. Put the powder in a stainless steel ball mill tank, use 304 stainless steel balls as the ball mill medium, evacuate the ball mill tank, fill it with argon, and then perform mechanical alloying for 140 hours at a speed of 350 rpm and a ball-to-material ratio of 15:1. Get FeSiBAlNiCo 0.2 High entropy alloy powder. The morphology of the high-entropy alloy powder obtained after ball milling for 140 h is as follows figure 1 shown. From figure 1 It can be seen that the obtained high-entropy alloy powders are nearly spherical particles, and most of the particle sizes are below 2 μm.

[0040] Spark plasma sintering: FeSiBAlNiCo after mechanical alloying for 140 hours 0.2 The high-entropy alloy powder was packed in a cylindrical graphite mold with a diameter of 15 mm, placed in a spark plasma sintering furnace un...

Embodiment 2

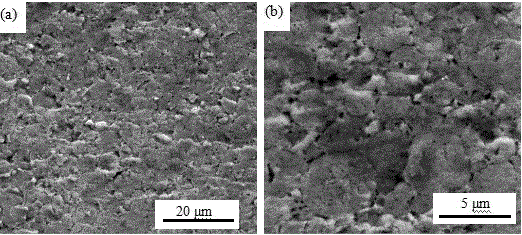

[0046] Preparation of high-entropy alloy powder: Take Fe, Si, B, Al, Ni, and Co powders at a molar ratio of 1:1:1:1:1:0.8, and the purity of the powders is above 99.7%. Put the powder in a stainless steel ball mill tank, use 304 stainless steel balls as the ball mill medium, evacuate the ball mill tank, fill it with argon, and then perform mechanical alloying for 140 hours at a speed of 350 rpm and a ball-to-material ratio of 15:1. Get FeSiBAlNiCo 0.8 High-entropy alloy powder, its morphology is as follows Figure 6 shown. It can be seen from the figure that the obtained high-entropy alloy powder is a spherical particle with a particle size below 3 μm.

[0047] Spark plasma sintering: FeSiBAlNiCo after mechanical alloying for 140 hours 0.8 The high-entropy alloy powder is packed in a cylindrical graphite mold with a diameter of 15 mm, placed in a spark plasma sintering furnace under the protection of an argon atmosphere, heated to 850 °C, pressurized to 90 MPa, and kept for...

Embodiment 3

[0053] Preparation of high-entropy alloy powder: Take Fe, Si, B, Al, Ni, Co metal powders in equimolar ratios, and the purity of the metal powders is above 99.7% (the stated % is a mass percentage; the same below). Put the powder in a stainless steel ball mill tank, use 304 stainless steel as the ball mill medium, evacuate the ball mill tank, fill it with argon, and then perform mechanical alloying for 140 hours at a speed of 350 rpm and a ball-to-material ratio of 15:1 , to obtain FeSiBAlNiCo high-entropy alloy powder. The morphology of the FeSiBAlNiCo high-entropy alloy powder obtained by ball milling for 140 h is as follows Figure 11 shown. It can be seen from the figure that the obtained high-entropy alloy powder is a nearly spherical particle with a particle size below 2 μm.

[0054] Spark plasma sintering: Put the FeSiBAlNiCo high-entropy alloy powder after mechanical alloying for 140 hours into a cylindrical graphite mold with a diameter of 15mm, put it in a spark pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com