Compound metal oxide and nitride catalyst for low-temperature selective catalytic reduction of ammonia

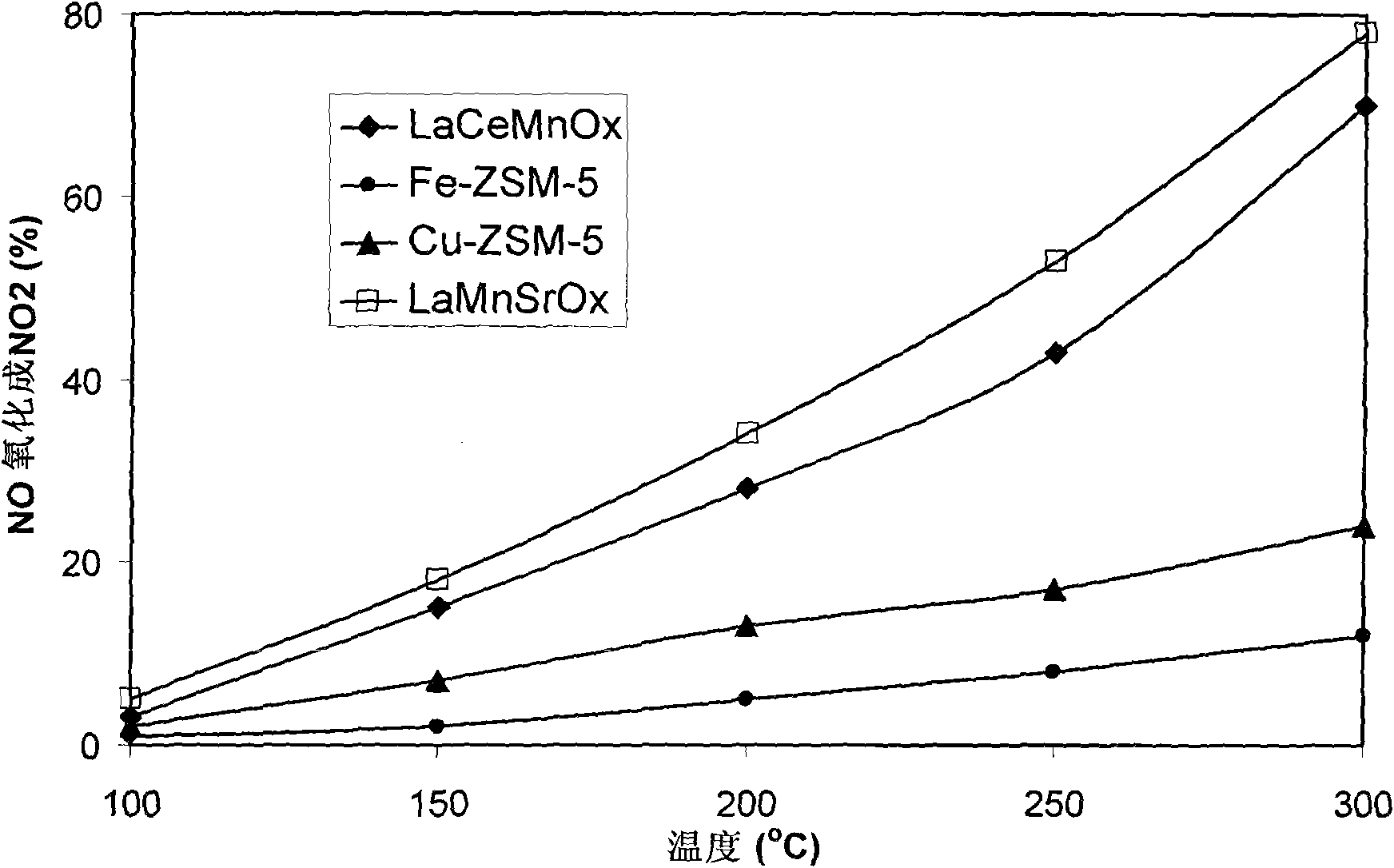

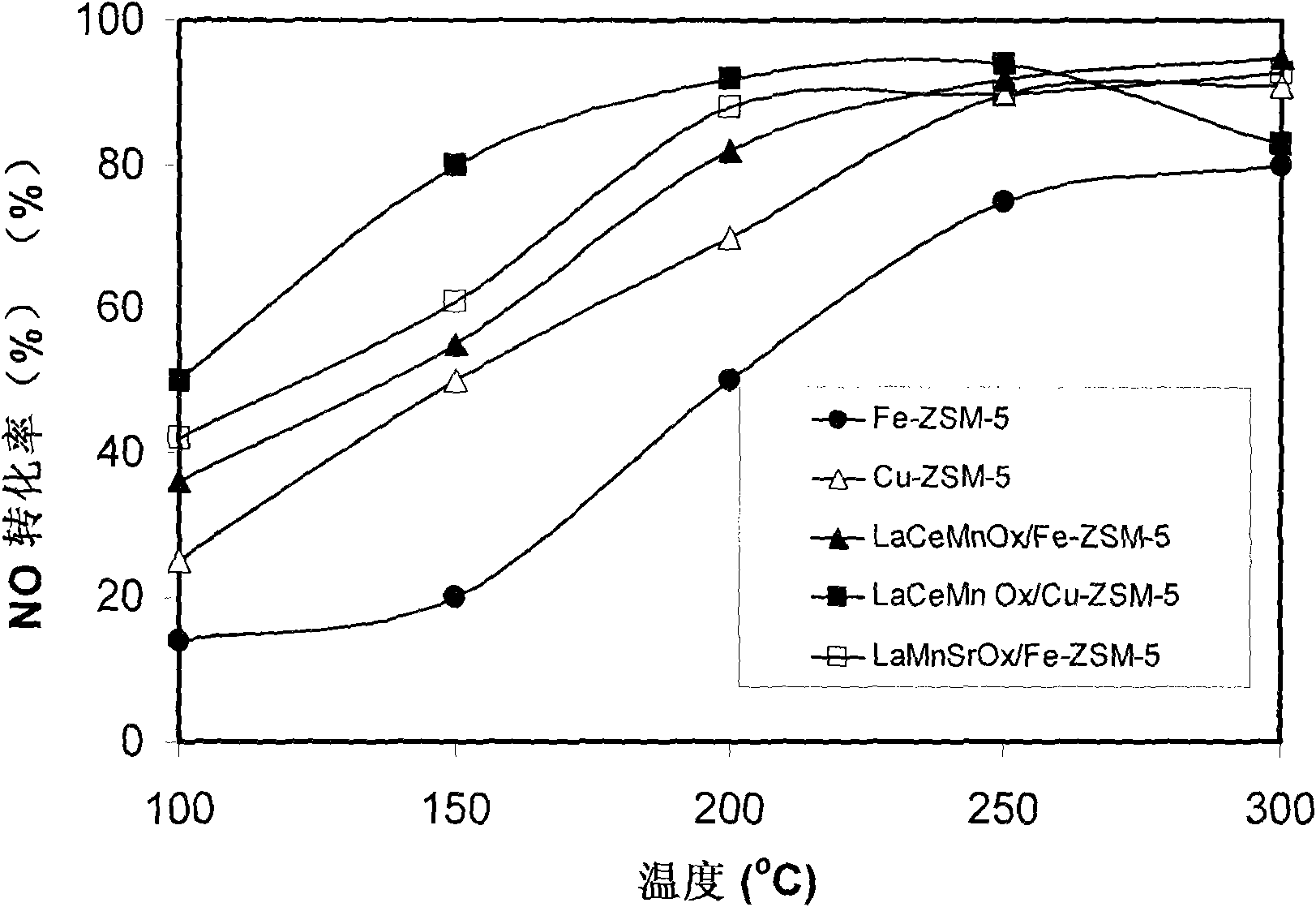

A composite metal and oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problem of short catalyst life, low catalyst activity at low temperature, blocking downstream pipelines, etc. Problems, to achieve the effect of easy industrialization of SCR technology, increase conversion rate, and increase reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1. Preparation of A-B-C Composite Metal Oxide

[0031] Under stirring conditions, different proportions of metal nitrates (dissolved in deionized water, the solution uses NaOH as a precipitant, aged for 4-6 hours, washed with deionized water, filtered, and finally in the air at 400-1000 ° C Roast for 1-24 hours to get A-B-C composite metal oxide

[0032] Amount added / final

product structure

La(NO 3 ) 3

(mol)

Ce(NO 3 ) 3

(mol)

Mn(NO 3 ) 2

(mol)

Sr(NO 3 ) 2

(mol)

Example 1

0.01

0

0.01

0

La2O3-Mn2O3

Example 2

0.009

0.001

0.01

0

La2O3-Mn2O3-Ce2O3

Example 3

0.009

0

0.01

0.001

La2O3-Mn2O3-SrO

Example 4

0.005

0.003

0.01

0.002

La2O3-Mn2O3-Ce2O3-SrO

[0033] 2. Preparation method of copper and iron molecular sieve catalyst

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com