Ferrite magnetic material and manufacturing method thereof

A manufacturing method and technology of ferrite magnets, which are applied in the manufacture of inductors/transformers/magnets, magnetic objects, and inorganic material magnetism, etc., can solve the problems of expensive rare earth materials, declining market competitiveness, and rising production costs, and achieve production Low cost, improved magnetic properties, and the effect of increasing the amount of solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

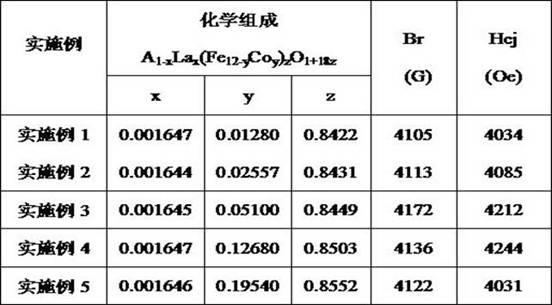

Embodiment 1 to Embodiment 5

[0011] The traditional SrO·nFe2O3 permanent magnet ferrite powder is produced by using the known permanent magnet ferrite calcined material manufacturing process, wherein n=5.95, and the average particle size of the powder is 3~5μm.

[0012] Weigh 5000 grams of the above-mentioned permanent magnet ferrite powder, divide it into 5 parts, each part is 1000 grams, and use it as the main raw material of Embodiment 1 to Embodiment 5. All add the batching of following weight in every part of permanent magnet ferrite powder: take the weight of 1000 grams of permanent magnet ferrite powder as a basis, respectively claim the calcium carbonate 1% (10 grams) of the weight ratio of permanent magnet ferrite powder ), silicon dioxide 0.3% (3 grams), boric acid 0.3% (3 grams), SrCO 3 1.0% (10g), La 2 o 3 0.03% (0.3 grams), in addition the Co added in embodiment 1 to embodiment 5 2 o 3 The weights are 0.1% (1 gram), 0.2% (2 grams), 0.4% (4 grams), 1.0% (10 grams), 1.55% (15.5 grams). ...

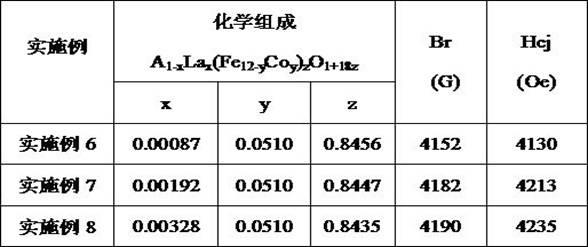

Embodiment 6 to Embodiment 8

[0020] Using the known manufacturing process of permanent magnet ferrite calcined material, the traditional SrO nFe is manufactured 2 o 3 Type permanent magnet ferrite powder, where n=5.95, and the average particle size of the powder is 3~5μm.

[0021] Weigh 3000 grams of the above-mentioned permanent magnet ferrite powder, divide it into 3 parts, each part is 1000 grams, and use it as the main raw material of Embodiment 6 to Embodiment 8. All add the batching of following weight in every part of permanent magnet ferrite powder: take the weight of 1000 grams of permanent magnet ferrite powder as a basis, respectively claim the calcium carbonate 1% (10 grams) of the weight ratio of permanent magnet ferrite powder ) silicon dioxide 0.25% (2.5 grams), boric acid 0.35% (3.5 grams), SrCO3 1.0% (10 grams), Co2O3 0.4% (4 grams), in addition in embodiment 6 to the weight of La2O3 added in embodiment 8 Respectively 0.016% (0.16 grams), 0.035% (0.35 grams), 0.06% (0.6 grams).

[0022...

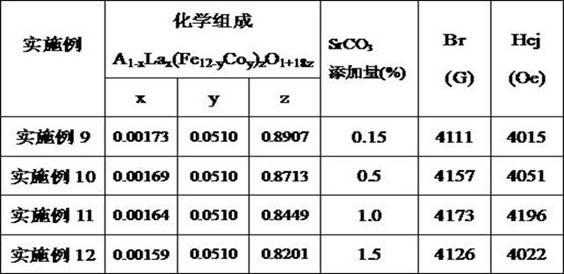

Embodiment 9 to Embodiment 12

[0029] Using the known manufacturing process of permanent magnet ferrite calcined material, the traditional SrO nFe is manufactured 2 o 3 Type permanent magnet ferrite powder, where n=5.95, and the average particle size of the powder is 3~5μm.

[0030]Weigh 4000 grams of the above-mentioned permanent magnet ferrite powder, divide it into 4 parts, each part is 1000 grams, and use it as the main raw material of Examples 9 to 12. All add the batching of following weight in every part of permanent magnet ferrite powder: take the weight of 1000 grams of permanent magnet ferrite powder as a basis, respectively claim the calcium carbonate 1% (10 grams) of the weight ratio of permanent magnet ferrite powder ) silicon dioxide 0.3% (3 grams), boric acid 0.3% (3 grams), La 2 o 3 0.03% (0.3 g), Co 2 o 3 0.4% (1 gram), additional SrCO added in Example 9 to Example 12 3 The weights are 0.15% (1.5 grams), 0.5% (5 grams), 1% (10 grams), 1.5% (15 grams).

[0031] According to La 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com