Adsorbent for adsorptive desulfurization of fuel oil

An adsorption desulfurization and adsorbent technology, applied in the direction of refined hydrocarbon oil, petroleum industry, silicate, etc., can solve the problems of gasoline octane number loss and gasoline octane number loss, etc., to improve low-temperature flow performance, increase octane The effect of alkane number and depressing freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

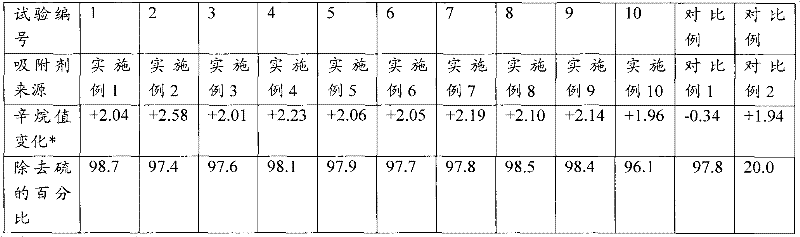

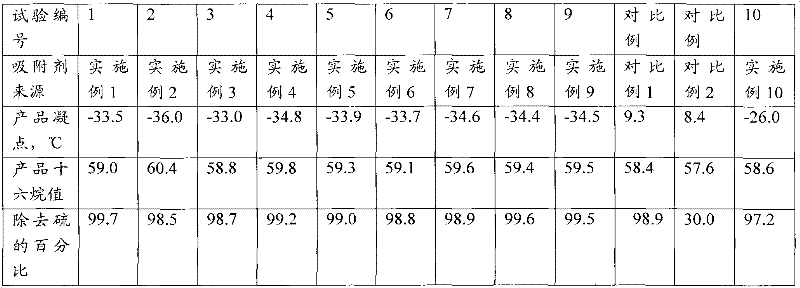

Examples

preparation example Construction

[0026] A preferred preparation method of the sorbent composition provided by the invention comprises the following steps:

[0027] (a) Zinc oxide source, oxide carrier source and AEL structure aluminophosphate molecular sieve are mixed;

[0028] (b) granulating the mixture obtained in step (a) to form granules;

[0029] (c) roasting or drying the particles obtained in step (b);

[0030] (d) impregnating the calcined particles obtained in step (c) with a promoter metal compound;

[0031] (e) drying and calcining the impregnated granules obtained in step (d); then

[0032] (f) reducing the composition obtained in step (e).

[0033] According to the preferred preparation method, the obtained adsorbent composition not only has a good desulfurization effect, but also has a better effect of increasing the octane number and lowering the freezing point of diesel oil. in:

[0034] The zinc oxide source described in step (a) may be present in the form of zinc oxide or in the form o...

Embodiment 1

[0046] 7.5 kg of kaolin (SiO 2 Content 45.6 wt%, Al 2 o 3 Content 38.5% by weight, product of Suzhou China Kaolin Company), 20.2 kg of zinc oxide (ZnO content 99.8% by weight, product of Zibo Haishun Zinc Industry Co., Ltd.), 3.5 kg of aluminum sulfate octadecahydrate (content 99.0% by weight, chemical reagent of Sinopharm Group Co., Ltd.) and 3.4 kilograms of SAPO-11 (Si: Al: P molar ratio = 1: 9: 10) molecular sieves were put into a grinder and ground for 15 minutes to form a mixture, and the mixture was mixed with deionized water to obtain a solid content of 30% by weight slurry, adding 15.58 kg of acetic acid with a concentration of 3% by weight, stirring for 1.5 hours, spray-dried and shaped, dried at 150°C for 4 hours, and then roasted at 650°C for 2 hours to obtain a particle size of 40-200 μm Carrier particles, denoted as carrier A. 15.3 kilograms of cobalt nitrate hexahydrate (content 99.0% by weight, Sinopharm Chemical Reagent Co., Ltd.) were dissolved in 4.6 kilo...

Embodiment 2

[0048] Put 8.8 kilograms of zinc oxide (ZnO content 99.8% by weight, product of Zibo Haishun Zinc Co., Ltd.) and 5.5 kilograms of CoAPO-11 (Co: Al: P molar ratio = 1: 9: 10) molecular sieve into the grinder and grind for 15 Minutes to form a mixture, this mixture with 42.9 kg of acidic silica sol (SiO 2 Content 25.5% by weight, Qingdao micro-nano silica gel Technology Co., Ltd., pH value 2.1) and deionized water are mixed for beating to obtain a slurry with a solid content of 35% by weight, then add deionized water therein, and stir for 2 hours to obtain a solid The slurry with a content of 30% by weight was then spray-dried to shape, dried at 150°C for 4 hours, and then calcined at 650°C for 2 hours to obtain carrier particles with a particle size of 40-200 μm, which were designated as carrier B. 15.7 kilograms of nickel nitrate hexahydrate (content 98.0% by weight, Sinopharm Chemical Reagent Co., Ltd.) were dissolved in 4.6 kilograms of hot (85° C.) deionized water to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com