Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent low temperature reduction chromate salt

A technology of chromium oxide green and reducing agent, which is applied in the direction of chromium oxide/hydrate, fibrous filler, etc., can solve the problems of high energy consumption, complex reaction equipment, high reaction temperature, etc., and achieve zero emission, simple equipment and good process conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

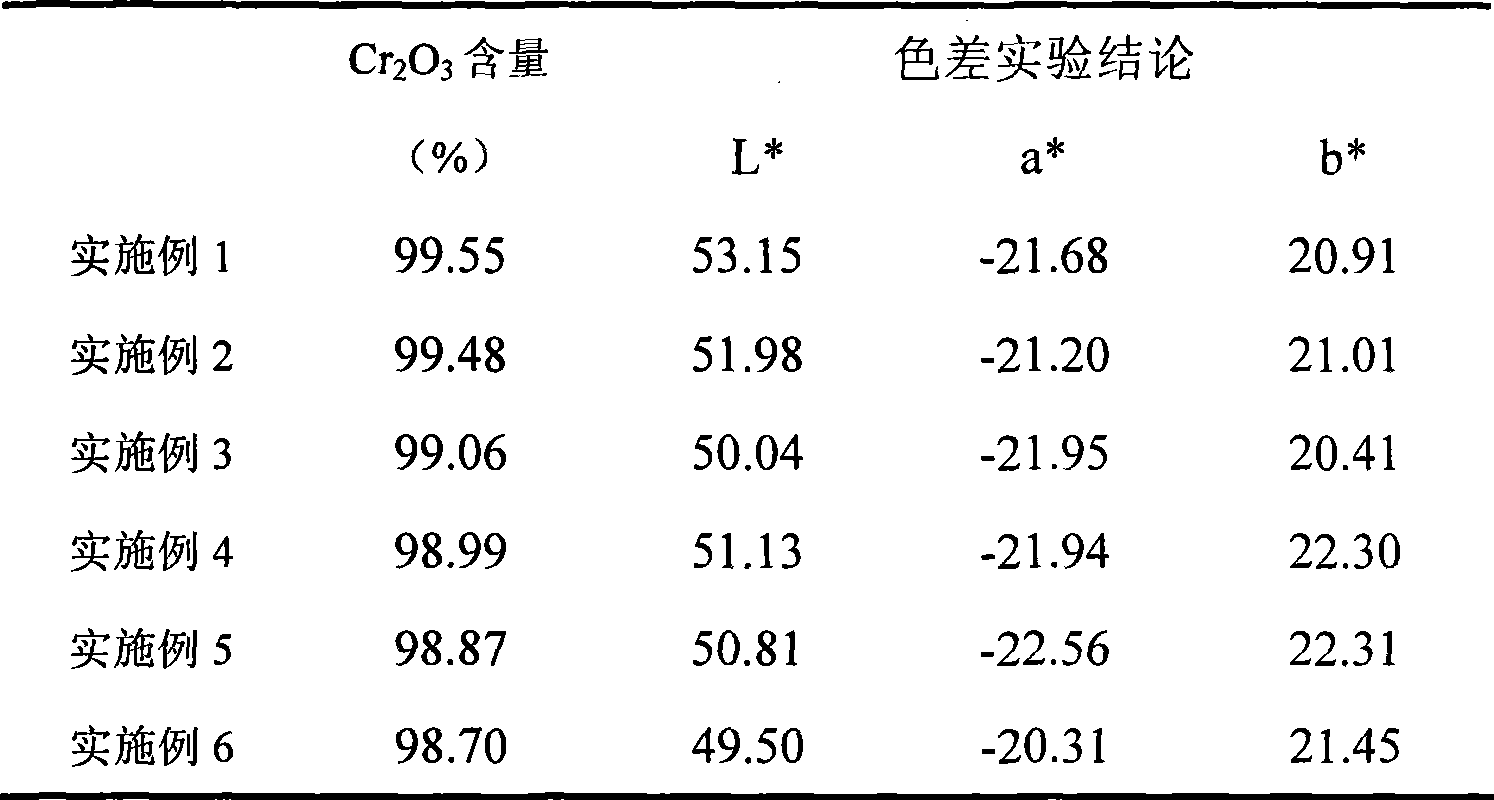

Examples

Embodiment 1

[0015] The reduction of 100kg potassium chromate is carried out in an electrothermal rotary reduction furnace, using hydrogen as the reducing gas, the reduction temperature is 450°C, the reduction time is 2h, and the hydrogen flow rate during the reduction process is 40Nm 3 / h.

[0016] After the reduction product is cooled, three-stage countercurrent washing is used. The liquid-solid volume ratio during the washing process is 1.00-1.05, and the washing temperature is 60°C. After washing, use a plate and frame filter press to filter, and the moisture content of the filter cake is 25%. After filtration, the KOH is recovered for recycling. filter cake with 0.5w% P 2 o 3 、HBO 3 , Zn(NO) 3 , SiO 2 、TiO 2 Ball milling and mixing in a ball mill, and the mixed material enters a rotary kiln for activation and sintering at a sintering temperature of 900°C and a sintering time of 3 hours. After sintering, the material is countercurrent washed, spin flash dried, and after drying, ...

Embodiment 2

[0018] The reduction of 100kg of sodium chromate is carried out in an electrothermal rotary reduction furnace, using natural gas as the reducing gas, the reduction temperature is 400°C, the reduction time is 1.5h, and the natural gas flow rate during the reduction process is 60Nm 3 / h.

[0019] After the reduction product is cooled, three-stage countercurrent washing is used. The liquid-solid volume ratio during the washing process is 1.00-1.05, and the washing temperature is 70°C. After washing, use a plate and frame filter press to filter, and the moisture content of the filter cake is 25%. After filtration, the KOH is recovered for recycling. Filter cake with 1.0w% Al 2 o 3 、H 3 PO 4 , SiO 2 、K 2 TiO 3 , Sb 2 o 3 , ZnO is ball milled and mixed in a ball mill, and the mixed material is sent into a rotary kiln for activation and sintering at a sintering temperature of 950°C and a sintering time of 2.5 hours. After sintering, the material is countercurrent washed, sp...

Embodiment 3

[0021] The reduction of 100kg potassium chromate is carried out in an electrothermal rotary reduction furnace, using coal gas as the reducing gas, the reduction temperature is 500°C, the reduction time is 1h, and the gas flow rate during the reduction process is 80Nm 3 / h.

[0022] After the reduction product is cooled, three-stage countercurrent washing is used. The liquid-solid volume ratio during the washing process is 1.00-1.05, and the washing temperature is 80°C. After washing, use a plate and frame filter press to filter, and the moisture content of the filter cake is 25%. After filtration, the KOH is recovered for recycling. filter cake with 1.5w% H 3 PO 4 , Al(OH) 3 、TiO 2 , SiO 2 , ZnO is ball milled and mixed in a ball mill, and the mixed material is sent into a rotary kiln for activation and sintering. The sintering temperature is 1000°C and the sintering time is 2h. After sintering, the material is countercurrent washed, spin flash dried, and after drying, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com