Method for preparing titanium polyacetylacetonate precursor sol spinning solution, titanium oxide continuous fiber and titanium oxide nanofiber

A technology of sol spinning solution and titanium precursor, which is applied in the direction of spinning solution preparation, dry spinning method, fiber treatment, etc., can solve the problem of difficult preparation of high-quality titanium oxide fiber, limit the popularization and application of titanium oxide powder, and make sol spinnable It has the advantages of easy separation and collection, good spinnability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A preparation method of polyacetylacetonate titanium precursor sol spinning solution, comprising the following steps:

[0068] (1) Preparation of polyacetylacetonate titanium precursor

[0069] According to the molar ratio of tetrabutyl titanate: glacial acetic acid: water = 1:3:1, weigh 100g tetrabutyl titanate, 52.94g glacial acetic acid and 5.29g water, fully stir and react for 3h to obtain a golden yellow solution. It was placed in a flask and concentrated under reduced pressure at a temperature of 65°C for 6h until a dry solid product was obtained, which was dissolved in 200g of anhydrous methanol; the molar ratio of tetrabutyl titanate: acetylacetone: water = 1: 1:0.5 Add 29.41g of acetylacetone and 2.65g of water, stir and react for 3 hours to obtain a golden-red solution, that is, titanium polyacetylacetonate solution, put the golden-red solution in a flask, and concentrate under reduced pressure at a temperature of 65°C for 6 hours until A dry solid product, n...

Embodiment 2

[0078] A preparation method of titanium oxide nanofibers, comprising the following steps:

[0079] (i) Preparation of polyacetylacetonate titanium precursor sol spinning solution

[0080] Adopt the method in embodiment 1 to prepare polyacetylacetonate titanium alloy precursor sol spinning liquid, be used for electrospinning;

[0081] (ii) Electrospinning

[0082] The polyacetylacetonate titanium precursor sol spinning solution obtained in step (i) is placed in the syringe with a stainless steel needle in the spinning device, at a temperature of 25 ° C, a relative humidity of 55%, an applied voltage of 15 kV, and a stainless steel needle Model 5#, the feeding speed of the syringe is 2.5mL / h, and the distance between the stainless steel needle and the drum of the fiber collection device is 20cm, electrospinning is carried out, and the precursor of titanium polyacetylacetonate is obtained by drawing and collecting through the drum body fibers.

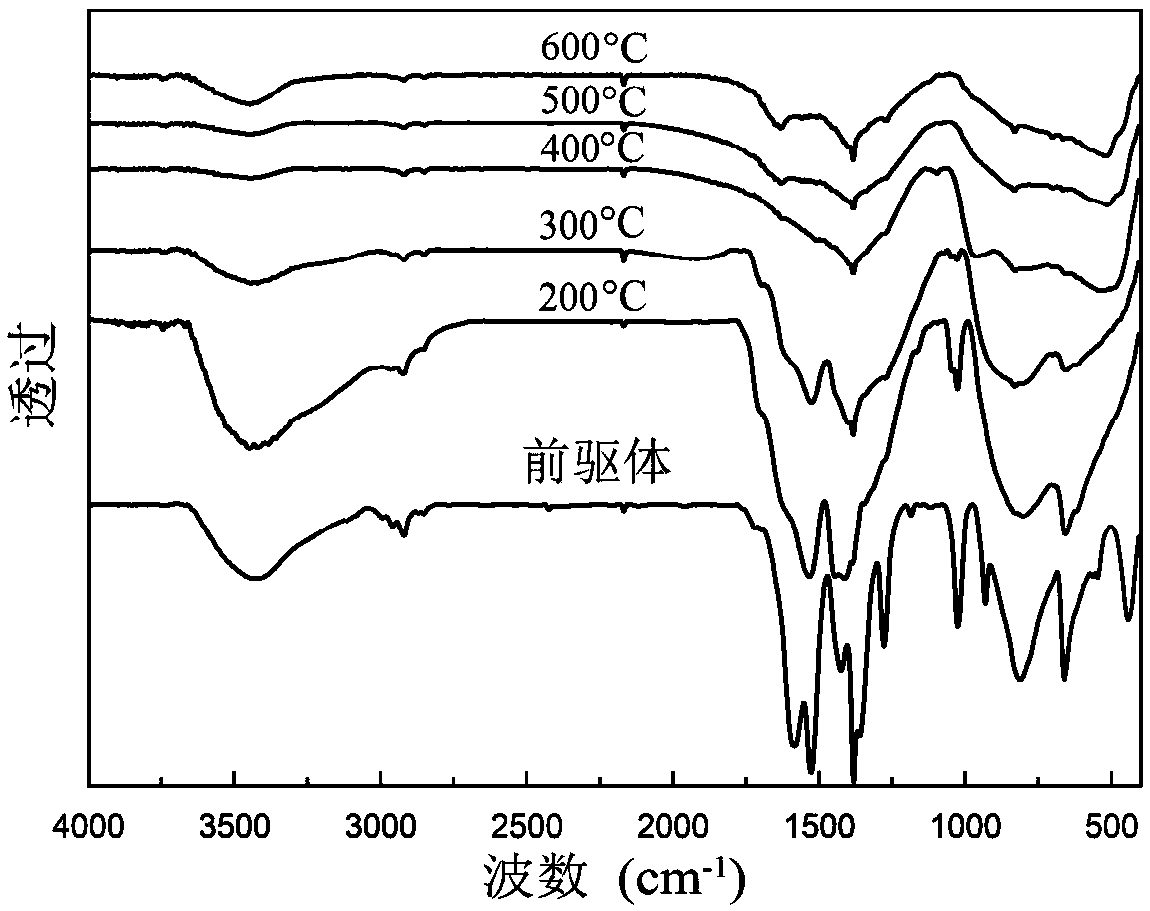

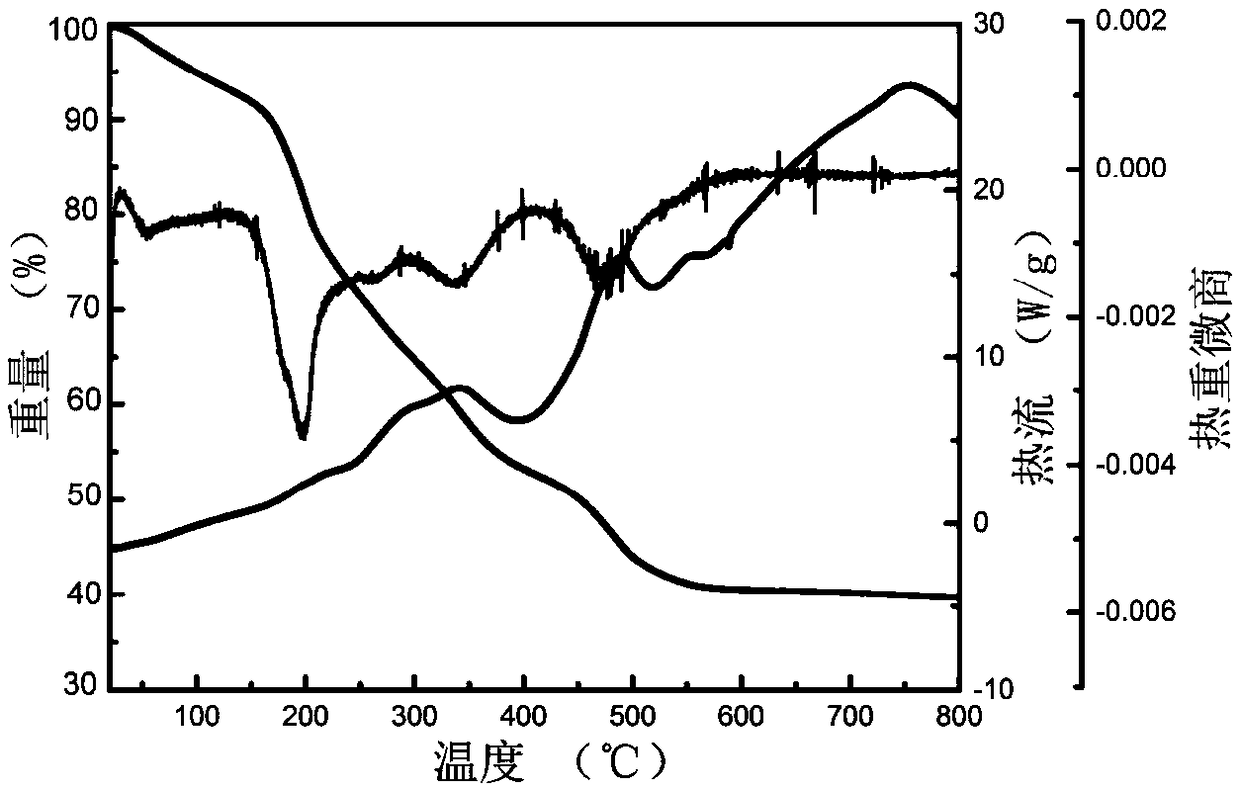

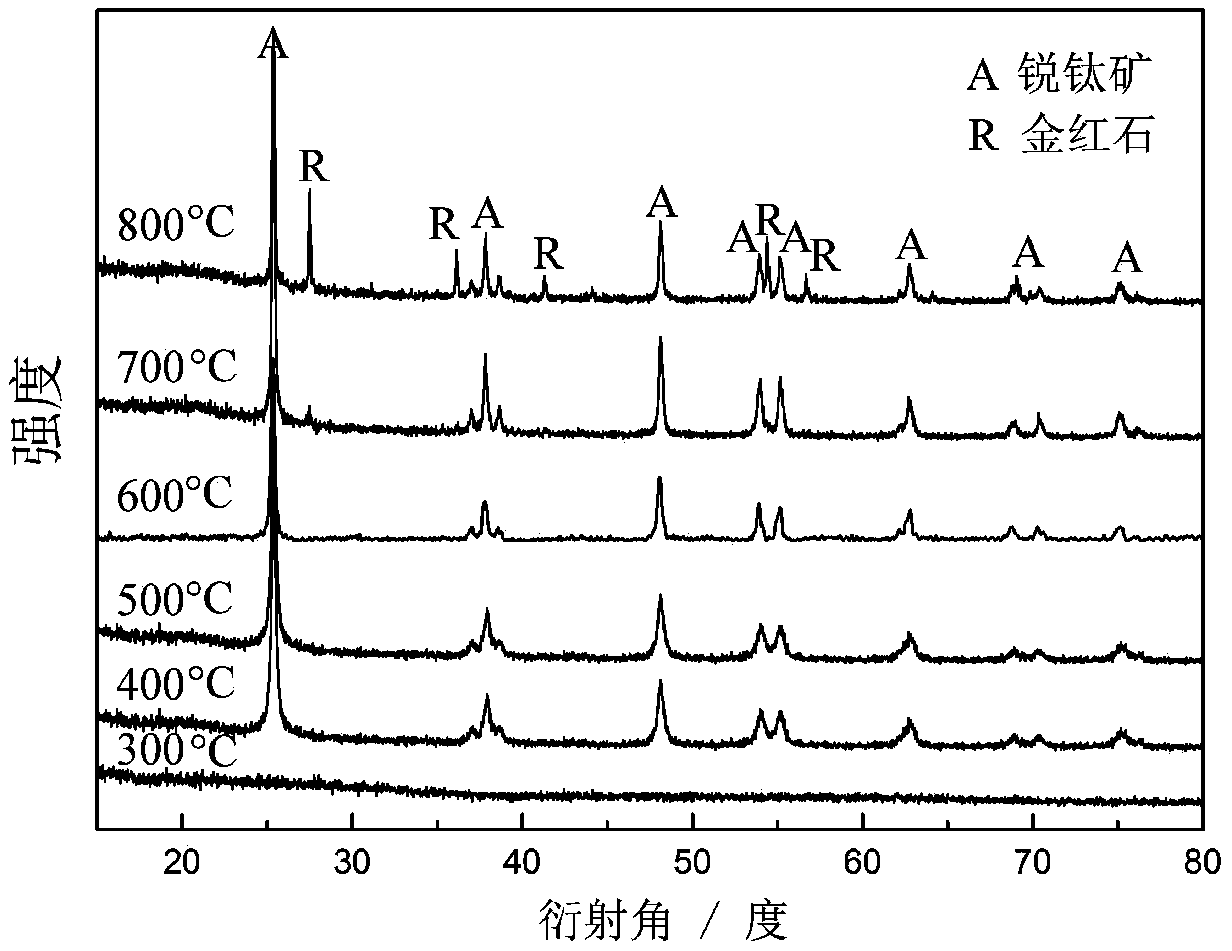

[0083] (iii) heat treatment

[0...

Embodiment 3

[0086] A kind of preparation method of titanium oxide continuous fiber, comprises steps as follows:

[0087] (a) The method in Example 1 is adopted to prepare the polyacetylacetonate titanium precursor sol-spinning solution, and then concentrate to obtain a sol-spinning solution with a viscosity of 75Pa·s (measured at 20° C.) by evaporating the solvent under reduced pressure. in dry spinning;

[0088] (b) Dry spinning

[0089] Place the sol spinning solution prepared in step (a) in the spinneret of the spinning device, vacuum defoaming at a temperature of 30°C for 10min, at a temperature of 30°C and a relative humidity of 40%, use a cylinder of nitrogen The method is to apply a pressure of 1.8MPa to the spinning solution, extrude it in a 0.04mm niobium-tantalum alloy spinneret, and obtain continuous fibers of polyacetylacetonate-titanium precursor after drawing and collecting;

[0090] (c) Preprocessing

[0091] The precursor continuous fiber obtained in step (b) is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com