High-Q microwave dielectric ceramic material and preparing method thereof

A microwave dielectric ceramic, a new type of technology, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of high price, high sintering temperature, and restrictions on large-scale commercial application of materials, and achieve good performance stability and repeatability, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

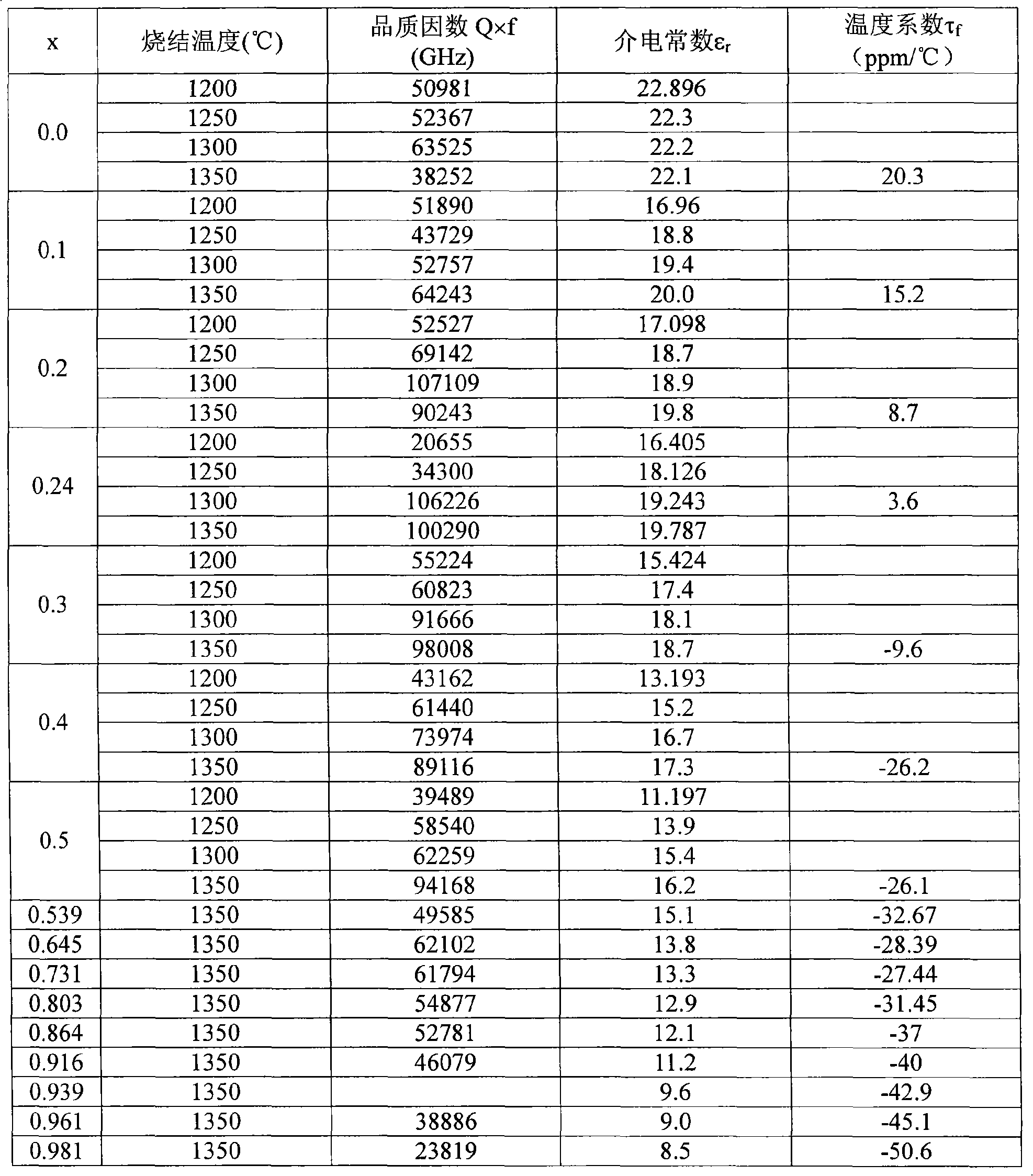

[0019] Embodiment one: according to (1-x) Li 2 TiO 3 -xMgO (x=0~0.981) chemical equation, convert the mass of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%), TiO 2 (97%), MgO (99.9%). The weighing quality is as follows: Table 1

[0020] Table 1. (1-x)Li 2 TiO 3 -xMgO ingredient list (unit: g):

[0021] x

MgO

Li 2 CO 3

TiO 2

0.0

0.0000

54.9619

58.3932

0.1

3.1395

52.8071

56.1039

0.24

5.2012

30.1959

32.7031

0.2

6.7340

50.3400

53.4828

0.3

10.8900

47.4877

50.4524

0.4

15.7501

44.1520

46.9085

0.5

21.5098

40.1989

42.7086

0.539

15.0350

23.5751

25.5325

0.645

20.0306

20.2116

21.8897

0.731

24.9998

16.8659

18.2663

0.803

...

Embodiment 2

[0026] Embodiment two: according to Li 2+x Ti 1-4x Nb 3x o 3 (x=0~0.10) chemical equation, convert the quality of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%), TiO 2 (97%), Nb 2 o 5 (99.9%), as shown in Table 3:

[0027] Table 3.Li 2+x Ti 1-4x Nb 3x o 3 Ingredients list (unit: g):

[0028] x

Li 2 CO 3

TiO 2

Nb 2 o 5

0.00

53.9165

58.3932

0.0000

0.02

53.5367

52.8151

5.7205

0.04

53.1695

47.4222

11.2511

0.06

52.8143

42.2054

16.6011

0.07

39.4808

29.7453

14.4084

0.08

52.4705

37.1562

21.7793

0.10

52.1376

32.2666

26.7937

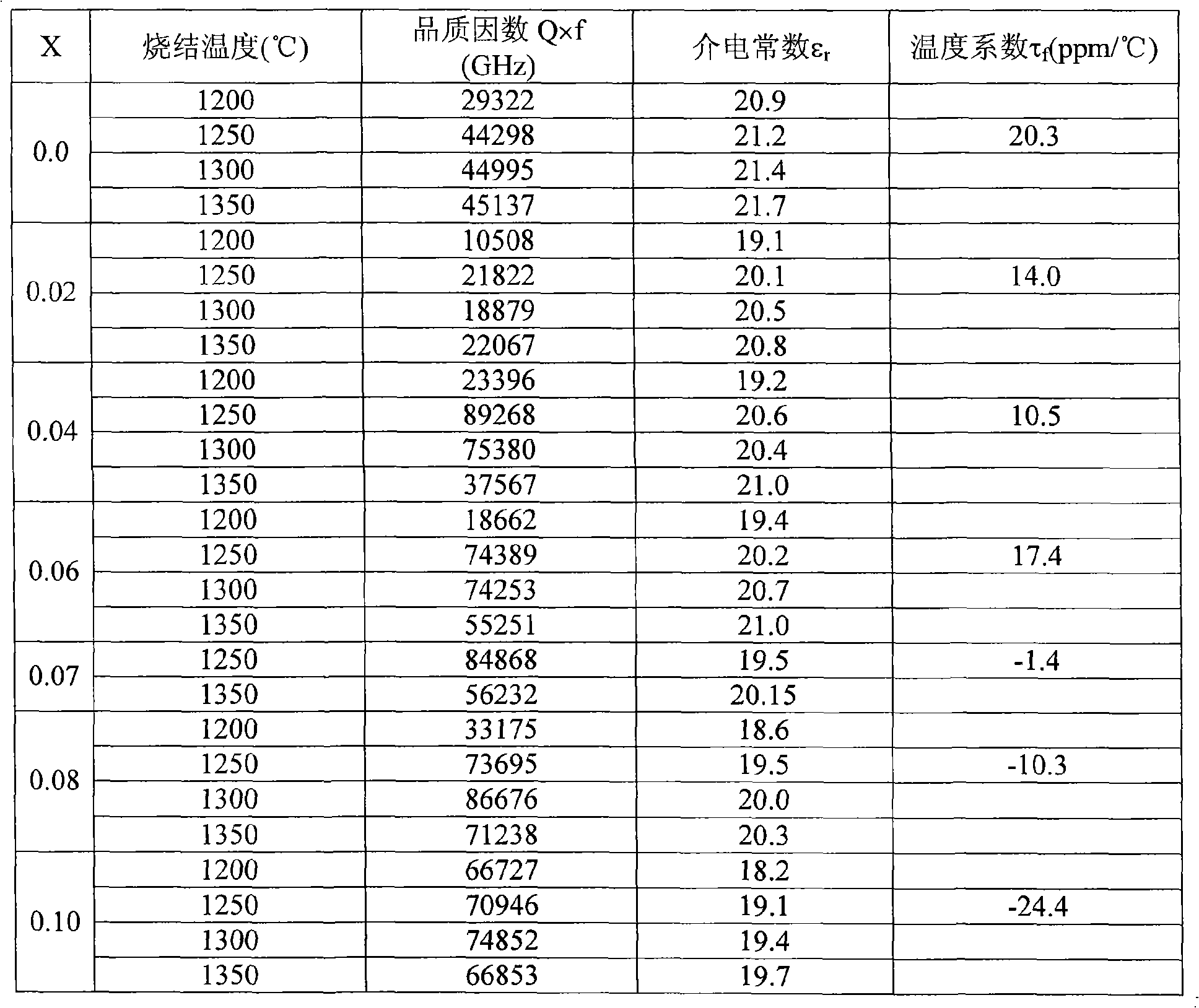

[0029] The material preparation process and testing method are the same as in Example 1. The results are shown in Table 4:

[0030] Table 4.Li 2+x Ti 1-4x Nb 3x o...

Embodiment 3

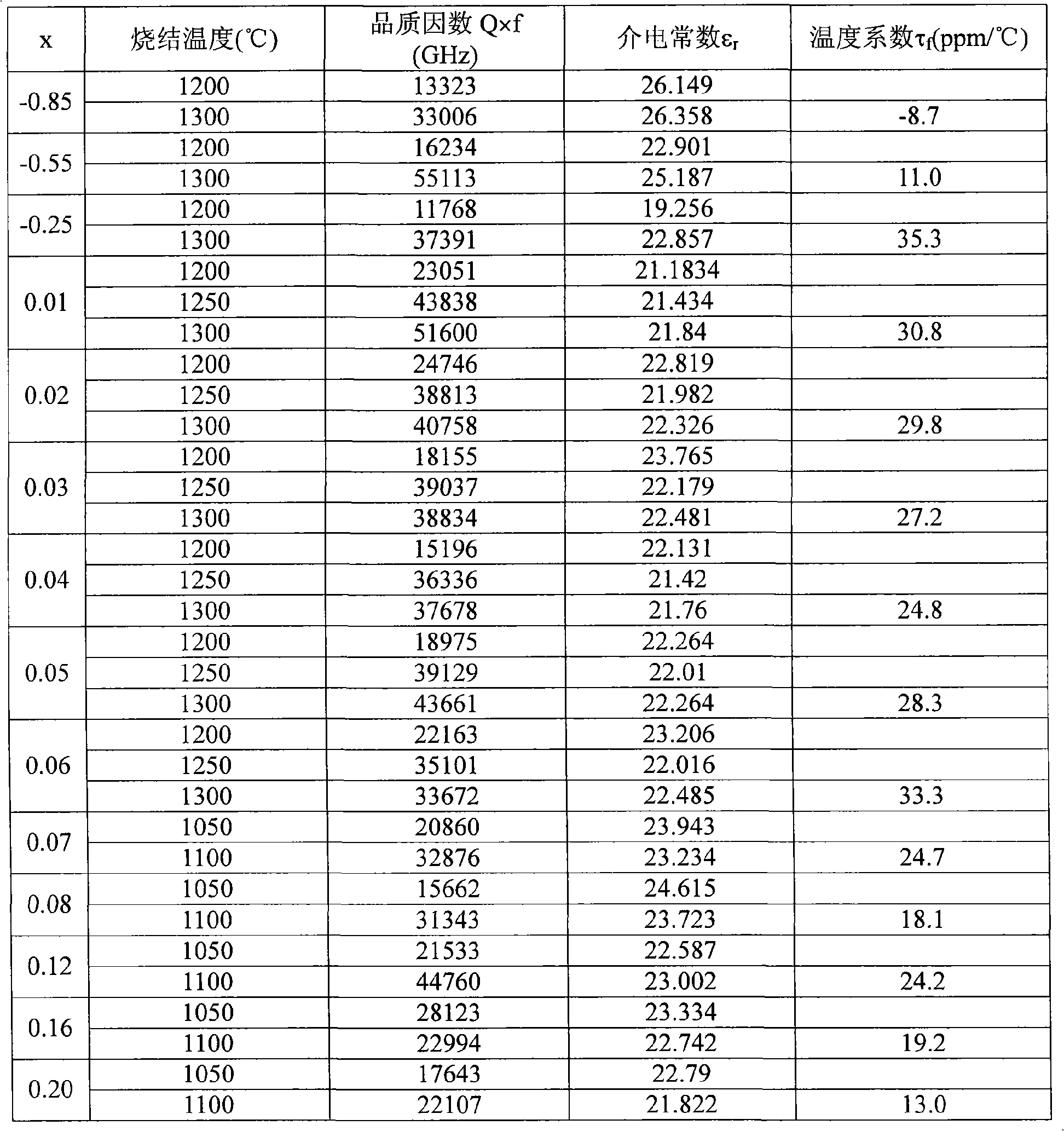

[0032] Embodiment three: according to Li 2+x TiO 3 (x=-0.85~0.20) chemical equation, convert the quality of each raw material required, and then accurately weigh each analytical pure raw material: Li 2CO 3 (99.9%), TiO 2 (97%), as shown in Table 5:

[0033] Table 5.Li 2+x TiO 3 (x=-0.85~0.20) Ingredients list (unit: g)

[0034] x

Li 2 CO 3

TiO 2

-0.85

19.3763

36.4957

-0.55

24.4309

36.4957

-0.25

29.4856

36.4957

0.01

33.8663

36.4957

0.02

34.0348

36.4957

0.03

34.2033

36.4957

0.04

34.3718

36.4957

0.05

34.5403

36.4957

0.06

34.7088

36.4957

0.07

34.8773

36.4957

0.08

35.0458

36.4957

0.12

35.7197

36.4957

0.16

36.3937

36.4957

0.20

37.0676

36.4957

[0035] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com