Hand-held terminal product appearance ceramic thin type member and production method thereof

A technology for hand-held terminals and thin parts, applied in the field of ceramic product manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

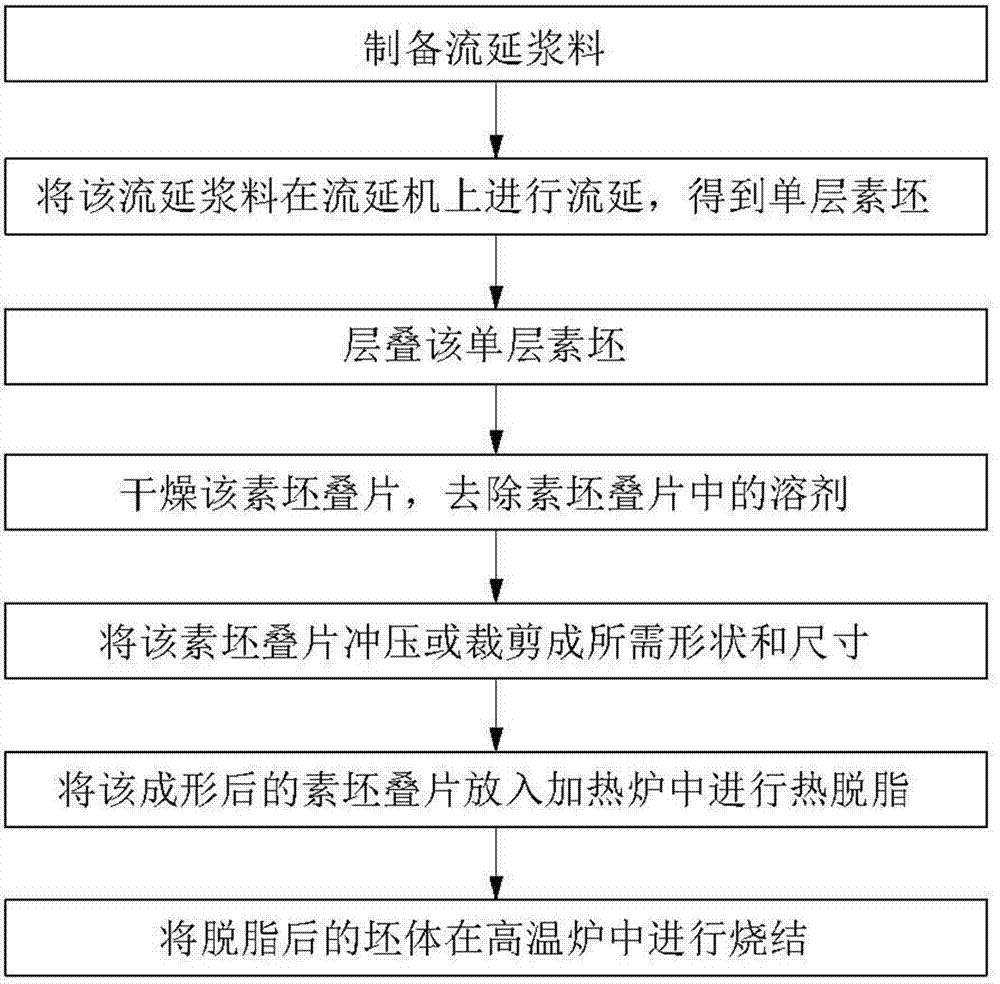

Method used

Image

Examples

preparation example Construction

[0014] In one embodiment, the preparation method of the casting slurry may include the following steps:

[0015] Weigh the ceramic powder, dispersant, solvent, binding agent and plasticizer of the above ratio;

[0016] Add the ceramic powder, dispersant and a part of the solvent into the ball mill tank, and perform the first ball mill for 12-20 hours to obtain a uniform initial slurry;

[0017] Put binder, plasticizer and remaining solvent into the ball mill tank, mix with the initial slurry, and perform second ball milling for 10-20 hours to obtain the required casting slurry.

[0018] The flow-casting slurry has suitable viscosity, which is beneficial to flow-casting to form a uniform and stable thin blank. The viscosity of the cast slurry can be 5~30Pa. s.

[0019] The ceramic powder can be zirconia, alumina or zirconia-toughened alumina composite powder, with an average particle size of 0.1 micron to 1 micron. The ceramic powder can have better wear resistance than met...

Embodiment 1

[0036] In this embodiment, the ceramic powder is made of zirconia ceramic powder, the average particle size of the powder is 0.2-0.3 microns, and the specific surface area is 11 m 2 / g.

[0037] (1) Casting slurry preparation and defoaming

[0038] Put 96.8g of zirconia ceramic powder, 60ml of ethanol and acetone mixture, 1.6ml of triolein, 2ml of n-butanol and ethylene glycol mixture (volume ratio 1:1), into the ball mill tank for the first ball mill , the time is 16 hours; 8.3g polyvinyl butyral, the mixed solution of 9.4ml polyethylene glycol and dibutyl phthalate, the mixture of 10ml ethanol and methyl ethyl ketone, add in this ball mill jar, carry out the second ball milling for 13 hours to obtain cast slurry.

[0039] The casting slurry was placed in a closed container, and rotated at a high speed for 10 minutes at a speed of 2200 r / min, so that the air bubbles in the slurry floated on the surface of the slurry and burst.

[0040] (2) casting

[0041] The casting spe...

Embodiment 2

[0054] In this example, the ceramic powder is made of zirconia toughened alumina ceramic composite powder, the average particle size of the powder is 0.3-0.5 microns, and the specific surface area is 8 m 2 / g.

[0055] (1) Casting slurry preparation and defoaming

[0056] 87.8g of zirconia ceramic powder and zirconia / alumina composite powder (among them the mass fraction of alumina is 10%), mixed with 55ml of ethanol and acetone, 1.4ml of triolein, 1.5ml of n-butanol and ethyl alcohol The diol mixture (volume ratio 1:1) was added to the ball mill tank for the first ball milling for 13 hours; a solution of 7.5g polyvinyl butyral, 8.7ml dibutyl phthalate, 9.5 mL of the mixture of ethanol and acetone was added into the ball mill jar, and the ball mill was carried out for the second time for 11 hours to obtain cast slurry.

[0057] The zirconia / alumina (10wt% alumina) composite powder casting slurry was placed in a closed container, and rotated at a high speed for 5 minutes at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com