Calcium silicate/hydroxylapatite composite biological ceramic material and preparation method and application thereof

A composite bioceramic and hydroxyapatite technology, applied in medical science, prosthesis, etc., can solve the problems of high purity requirements, long time-consuming, poor degradability of biological materials, etc., and achieve the effect of controllable mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

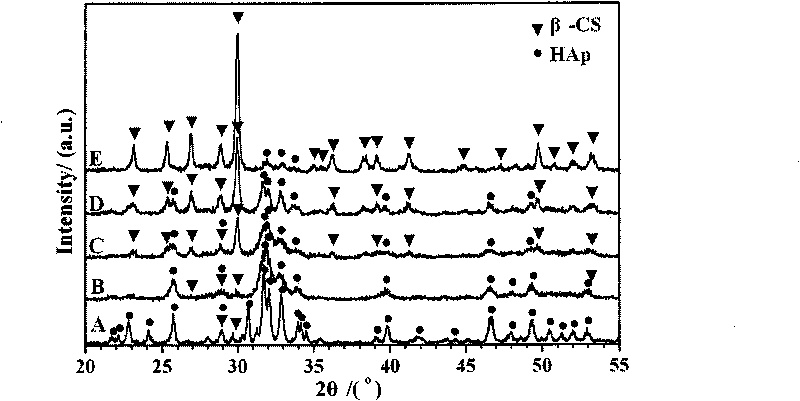

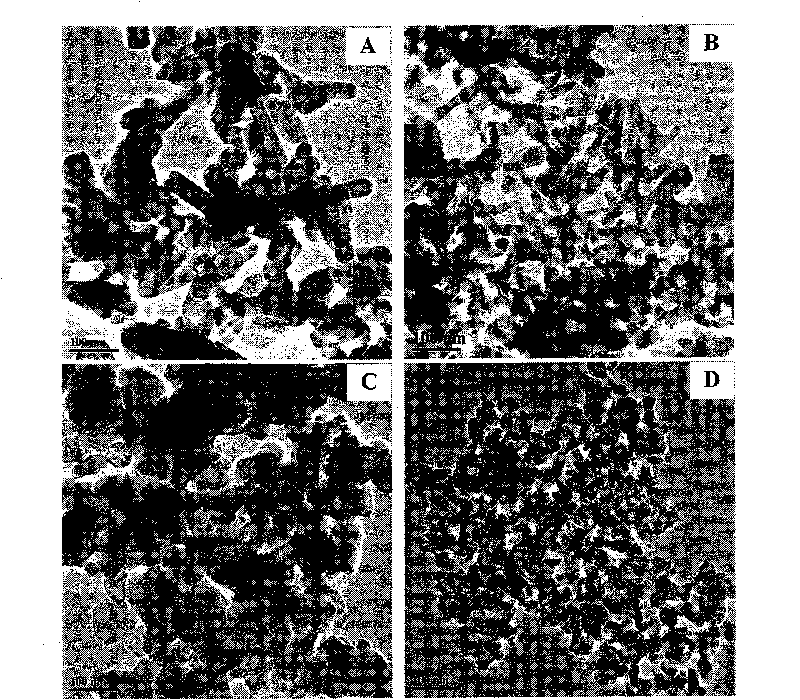

Embodiment 1

[0046] The powder raw material preparation method used is as described above. Take 58.80 grams of Ca(NO 3 ) 2 Dissolved in 500mL deionized water, and adjusted to pH=11 with 1:1 ammonia water, 19.73 grams of (NH 4 ) 2 HPO 4 Dissolve in 500mL deionized water to get (NH 4 ) 2 HPO 4 aqueous solution. The above (NH4 ) 2 HPO 4 The aqueous solution was added dropwise to the Ca(NO 3 ) 2 In the solution, the pH value of the reaction system was maintained at 11 with a 1:1 ammonia solution during the feeding process, and the stirring was continued for 24 hours after the addition, and the hydroxyapatite nano-powder was obtained by filtration, and the hydroxyapatite nano-powder was dispersed in 500 mL to remove deionized water, and dissolved 50.89 g Ca(NO 3 ) 2 , to obtain a white suspension dispersed with hydroxyapatite nanopowder; 500mL of pH 11.0 and 61.25g of Na 2 SiO 3 The aqueous solution was added dropwise to the above suspension, and the pH of the reaction system was...

Embodiment 2

[0052] The powder raw material preparation method used is as described above. Take 211.68 grams of Ca(NO 3 ) 2 Dissolved in 1800mL deionized water, and adjusted to pH=11 with 1:1 ammonia water, 71.01g of (NH 4 ) 2 HPO 4 Dissolve in 1000mL deionized water to get (NH 4 ) 2 HPO 4 aqueous solution. The above (NH 4 ) 2 HPO 4 The aqueous solution was added dropwise to the Ca(NO 3 ) 2 In the solution, the pH value of the reaction system was maintained at 11 with a 1:1 ammonia solution during the feeding process, and the stirring was continued for 24 hours after the addition, and the hydroxyapatite nano-powder was obtained by filtration, and the hydroxyapatite nano-powder was dispersed in 200 mL to remove ionized water, and dissolved 20.36 g Ca(NO 3 ) 2 , to obtain a white suspension dispersed with hydroxyapatite nanopowder; 200mL of pH 11.0 and 24.50 Na 2 SiO 3 The aqueous solution was added dropwise to the above suspension, and the pH of the reaction system was kept ...

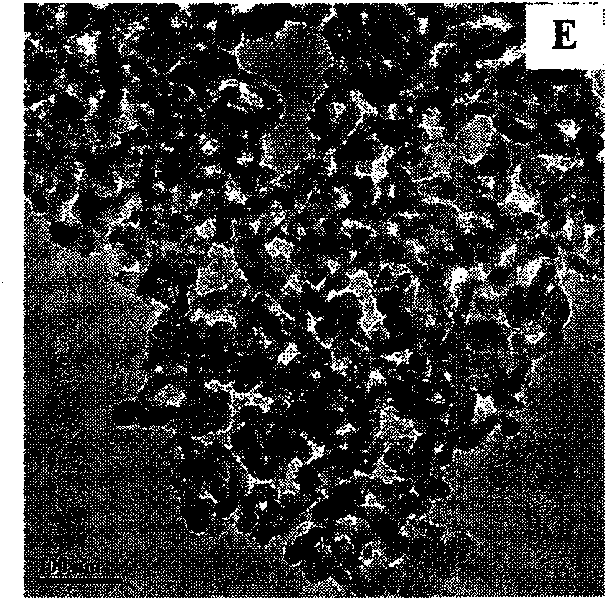

Embodiment 3

[0058] The powder raw material preparation method used is as described above. Take 23.52 grams of Ca(NO 3 ) 2 Dissolved in 200mL of deionized water, and adjusted to pH=11 with 1:1 ammonia water, 7.89g of (NH 4 ) 2 HPO 4 Dissolve in 120mL deionized water to get (NH 4 ) 2 HPO 4 aqueous solution. The above (NH 4 ) 2 HPO 4 The aqueous solution was added dropwise to the Ca(NO 3 ) 2 In the solution, the pH value of the reaction system was maintained at 11 with a 1:1 ammonia solution during the feeding process, and the stirring was continued for 24 hours after the addition, and the hydroxyapatite nano-powder was obtained by filtration, and the hydroxyapatite nano-powder was dispersed in 1800mL to remove ionized water, and dissolved 183.24 g Ca(NO 3 ) 2 , to obtain a white suspension dispersed with hydroxyapatite nanopowder; 800mL of pH 11.0 and dissolved with 220.50g of Na 2 SiO 3 The aqueous solution was added dropwise to the above suspension, and the pH of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com