Method for preparing fiber-containing silicon dioxide aerogel composite thermal insulation material

A technology of silica and thermal insulation materials, which is applied in the field of thermal insulation materials, can solve the problems of difficult material strength, low mechanical strength of materials at high temperature, and high manufacturing costs, so as to avoid supercritical drying, facilitate mass production, and improve thermal insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

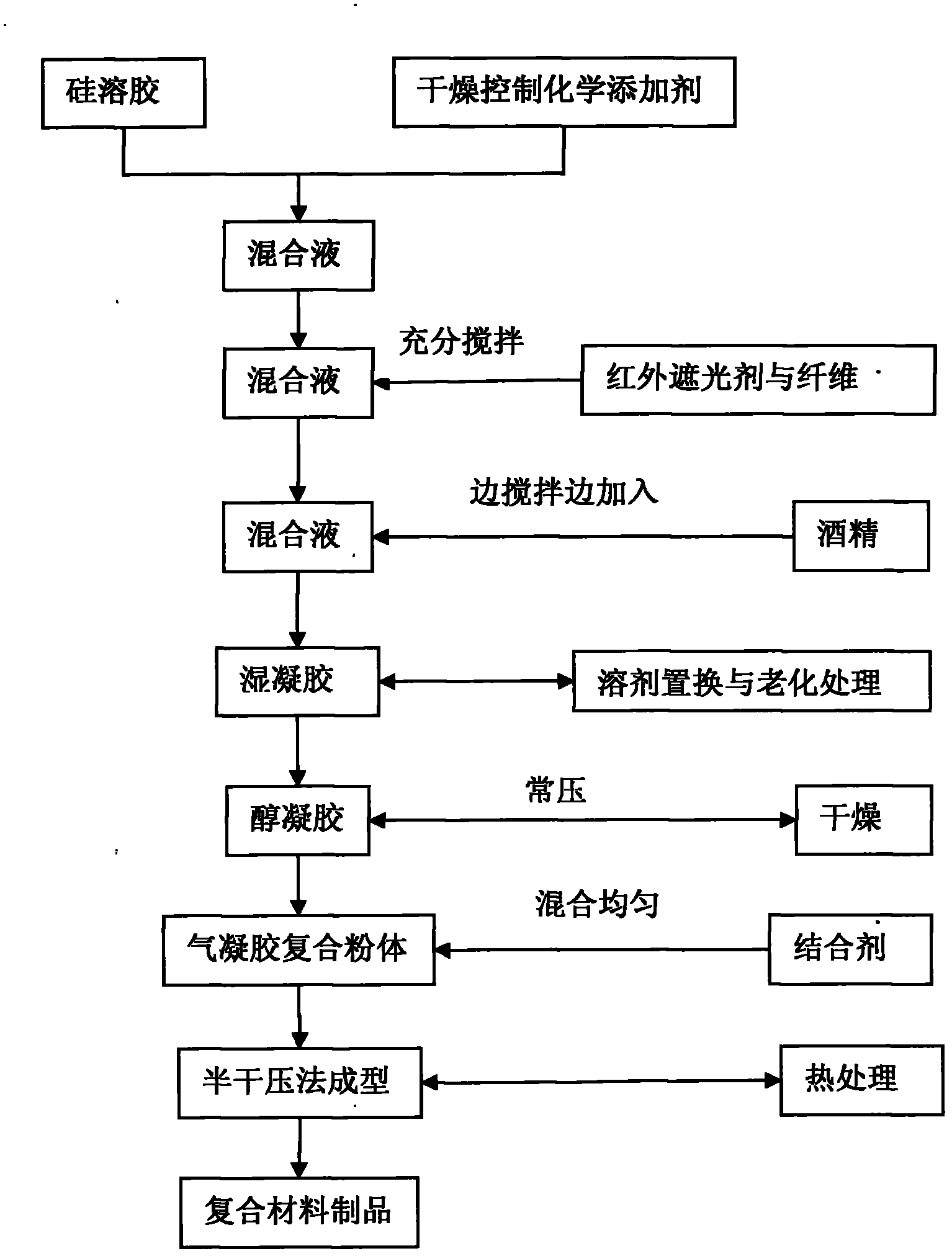

Method used

Image

Examples

Embodiment 1

[0034] Mix industrial silica sol (silicon dioxide content 25%), industrial alcohol, potassium hexatitanate whiskers, ethylene glycol, and glass fiber at a mass ratio of 1:0.65:0.05:0.015:0.075 to prepare fiber-containing carbon dioxide Silica airgel composite powder precursor. First, weigh a certain amount of silica sol, stir it with a DC mixer, add ethylene glycol, potassium hexatitanate whiskers, and glass fiber in sequence, and finally slowly add industrial alcohol until it gels. After the precursor solution is gelled, it is soaked and replaced with industrial alcohol, placed in a mixture of alcohol and tetraethyl orthosilicate (the volume ratio of orthosilicate and alcohol is 1:4) for aging, solvent replacement again, and finally placed in an oven The silica airgel composite powder containing fiber was obtained by drying at 70°C. Add 1% silica sol to the composite powder, add alcohol to adjust the degree of dryness and wetness of the powder, and press 2Mpa semi-dry press ...

Embodiment 2

[0036]Industrial silica sol, industrial alcohol, titanium dioxide micropowder, PEG400, and alumina fiber are fully mixed in a mass ratio of 1:0.85:0.01:0.005:0.08 to form a fiber-containing silicon dioxide airgel composite powder precursor solution. First, weigh a certain amount of silica sol, stir it with a DC mixer, add PEG400, titanium dioxide micropowder, alumina fiber in sequence, and finally add industrial alcohol slowly until it gels. After the precursor solution is gelled, it is soaked and replaced with industrial alcohol, aged in a mixture of alcohol and tetraethyl orthosilicate, solvent replaced again, and finally dried in an oven at 50°C to obtain a silica airgel composite containing fibers Powder. Add 3% aluminum sol to the composite powder, add alcohol to adjust the degree of dryness and wetness of the powder, press the hydraulic press with 5Mpa semi-dry pressing method, heat treatment at 400°C for 1 hour, and then the silica airgel composite containing fibers can...

Embodiment 3

[0038] Fully mix industrial silica sol, industrial alcohol, zinc oxide micropowder, formamide, and aluminum silicate fiber at a mass ratio of 1:0.7:0.045:0.035:0.09 to form a fiber-containing silicon dioxide airgel composite powder precursor solution. First, weigh a certain amount of silica sol, stir it with a DC mixer, add formamide, zinc oxide micropowder, and aluminum silicate fiber in sequence, and finally slowly add industrial alcohol until it gels. After the precursor solution is gelled, it is soaked and replaced with industrial alcohol, aged in a mixture of alcohol and tetraethyl orthosilicate, and replaced by solvent again, and finally dried in an oven at 150°C to obtain a silica airgel composite containing fibers Powder. Add 3% silica sol to the composite powder, add alcohol to adjust the dryness and wetness of the powder, press the hydraulic press with 2Mpa semi-dry pressing method, heat treatment at 300°C for 5 hours, and then the silica airgel composite containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com