Preparation method of porous ceramic material, porous ceramic material and application of porous ceramic material

A technology of porous ceramics and raw materials, applied in the direction of ceramic products, applications, ceramic molding machines, etc., can solve problems such as complex structure, low service life, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

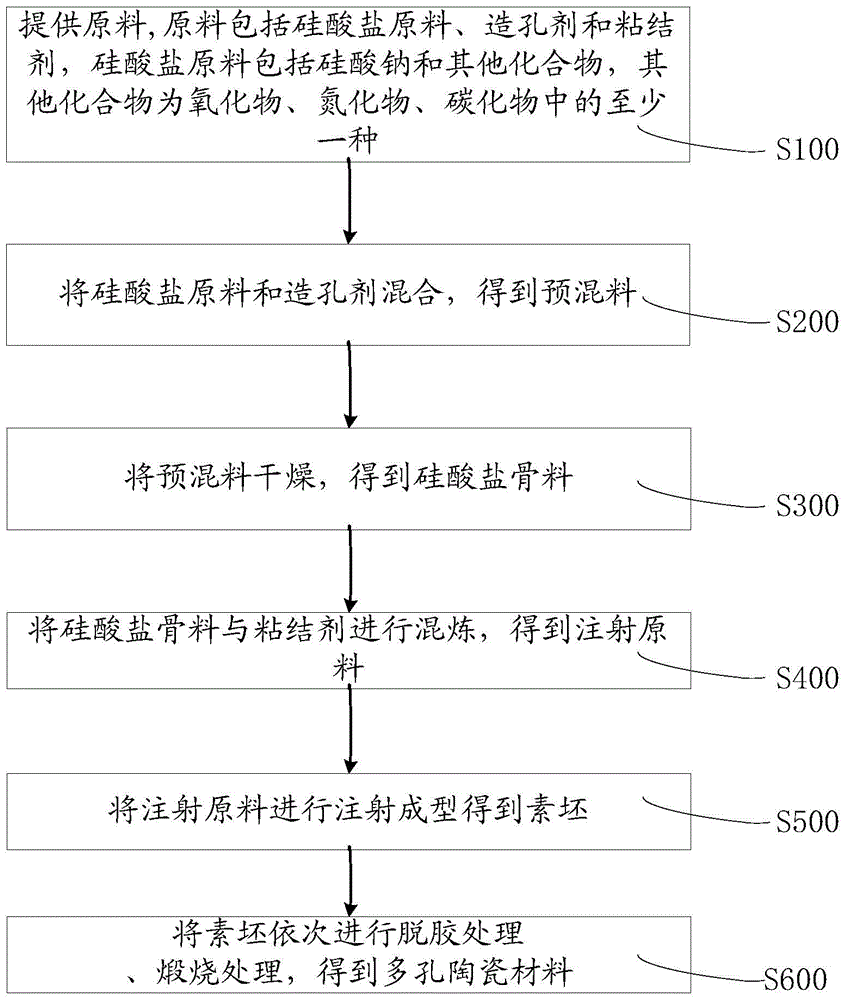

[0028] refer to figure 1 , a method for preparing porous ceramics in one embodiment, comprising the following steps:

[0029] Step S100: Provide raw materials.

[0030] The raw materials include silicate raw materials, pore formers and binders, the silicate raw materials include sodium silicate and other compounds, and the other compounds are at least one of oxides, nitrides and carbides. The resource-rich and non-polluting inorganic silicate material is used as the aggregate of the porous ceramic material, and the sintering conditions are relatively mild, which can be sintered at a lower temperature, air atmosphere and normal pressure.

[0031] In particular, oxides include alumina, zirconia, silica, iron oxide, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, and the like.

[0032] In particular, the nitride includes silicon nitride and the like.

[0033] In particular, carbides include silicon carbide, boron carbide, and the like.

[0034] In particular, o...

Embodiment 1

[0082] After grinding the alumina powder through an 80-mesh sieve, take 400g of alumina powder, add 60g of 80-100-mesh wood chips, and mix them in a ball mill for 30 minutes, then add industrial water glass with a modulus of 2.6 (the main component is sodium silicate ) 230g, mixed and stirred for 30min to obtain a premix.

[0083] Dry the premixed material in a drying oven at 80°C for 400 minutes to obtain a dried silicate aggregate.

[0084] Preheat the mixer to 220°C, add 20g of polypropylene to the mixer until the polypropylene is completely melted, then cool to 170°C, then add 400g of silicate aggregate, 300g of paraffin, and mix for 1 hour; continue to add 40 g of stearic acid and 40 g of dibutyl phthalate were mixed for 2 hours to obtain raw materials for injection.

[0085] The injected raw materials are cooled and pelletized by crocodile crushing equipment. The pelletized injection raw materials were put into the hopper of the injection molding machine, and injection...

Embodiment 2

[0089] After grinding zirconia through a 60-mesh sieve, take 400g of zirconia, add 80g of wood chips of 60-80mesh, and mix them in a ball mill for 40 minutes, then add 160g of industrial water glass with a modulus of 2.8, and mix and stir for 20 minutes to obtain the prepared product. mix.

[0090] Dry the premixed material in a drying oven at 100°C for 300 minutes to obtain a dried silicate aggregate.

[0091] Preheat the mixer to 220°C, add 40g of polypropylene to the mixer until the polypropylene is completely melted, then cool to 170°C, then add 400g of silicate aggregate, 280g of paraffin, and mix for 1 hour; continue to add 40 g of stearic acid and 40 g of dibutyl phthalate were mixed for 2 hours to obtain raw materials for injection.

[0092] Cool the raw materials for injection and cut them into pellets. The pelletized injection raw materials were put into the hopper and injection molded to obtain a green body. The injection temperature was 140° C., the injection pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com