Rectification tower automatic control and optimization method

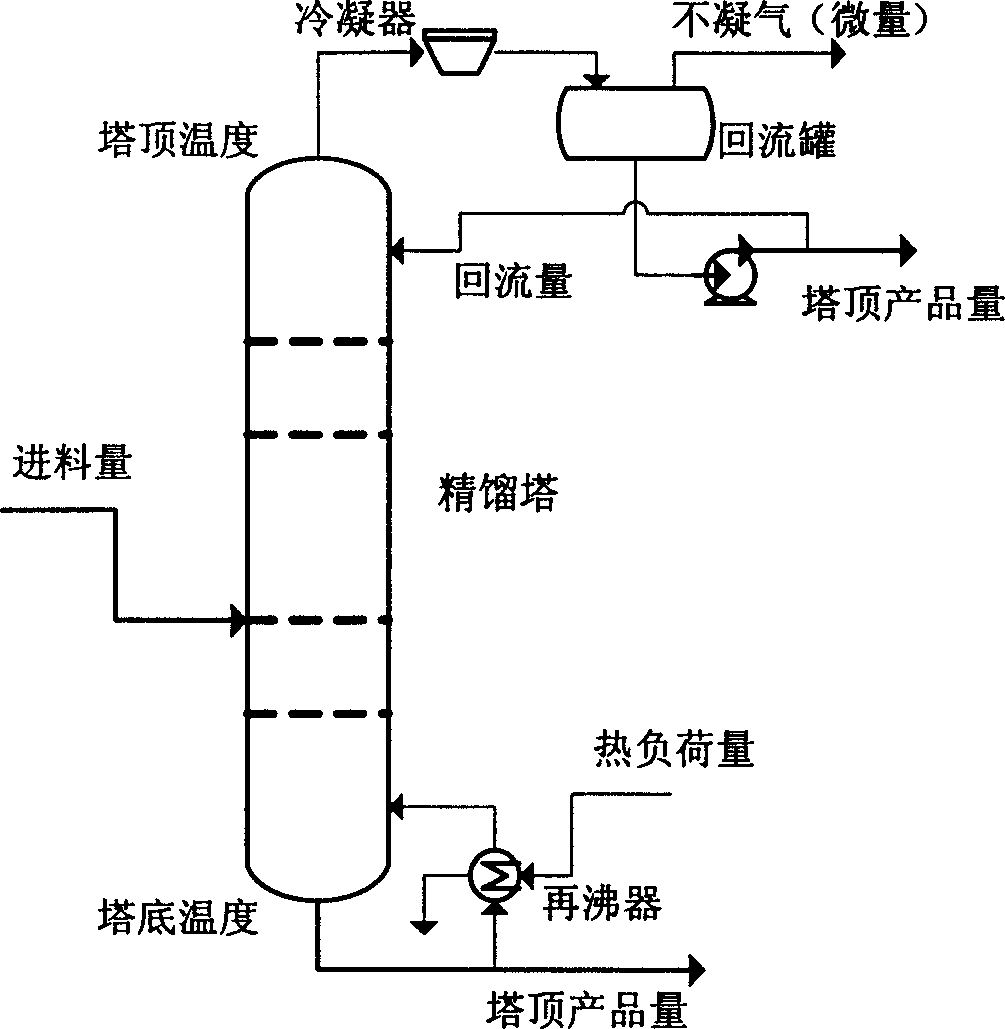

An optimization method and technology of rectification tower, applied in the direction of distillation adjustment/control, etc., can solve problems such as unfavorable soft sensor control scheme, unstable operation, oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

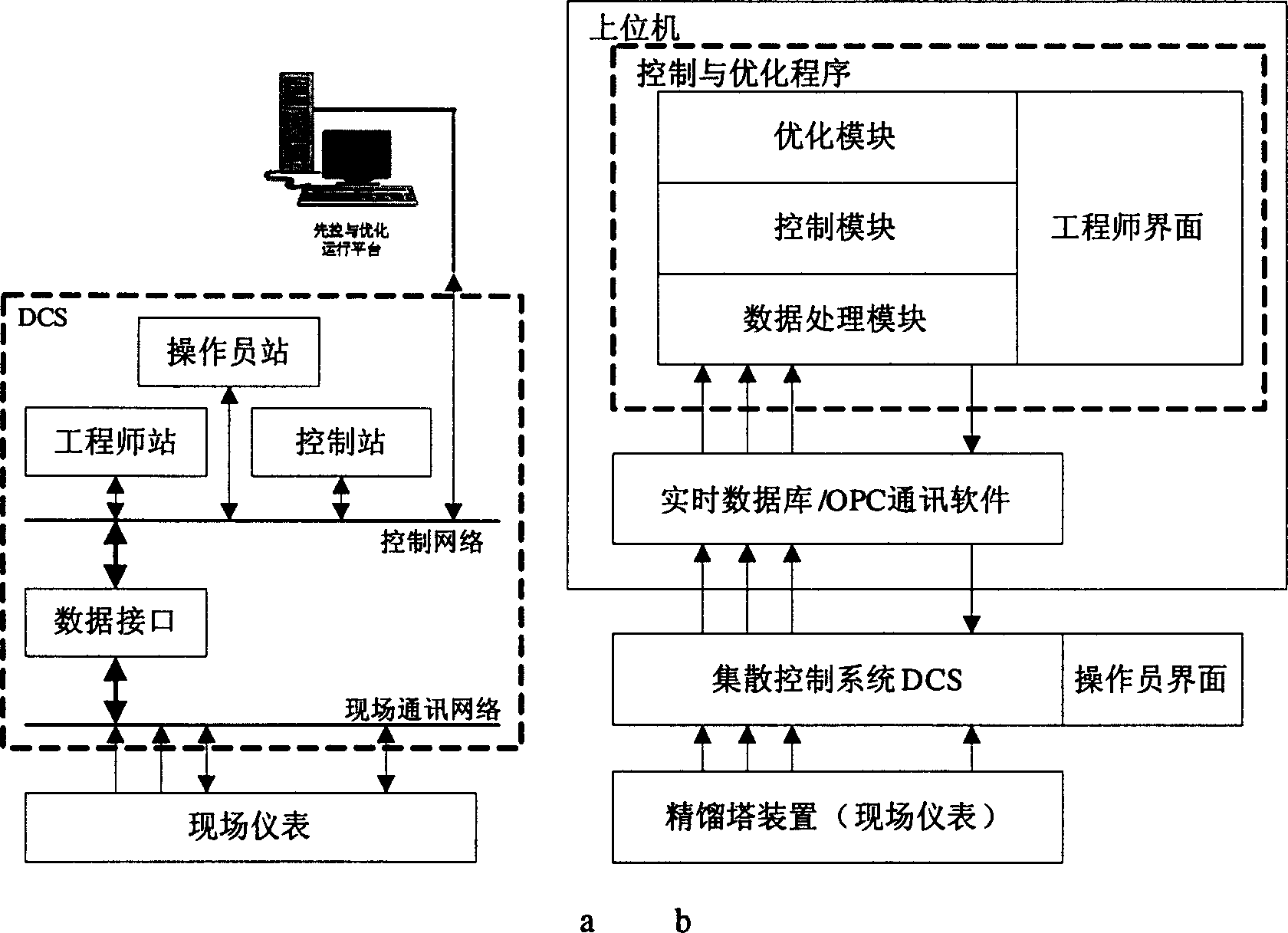

Method used

Image

Examples

Embodiment Construction

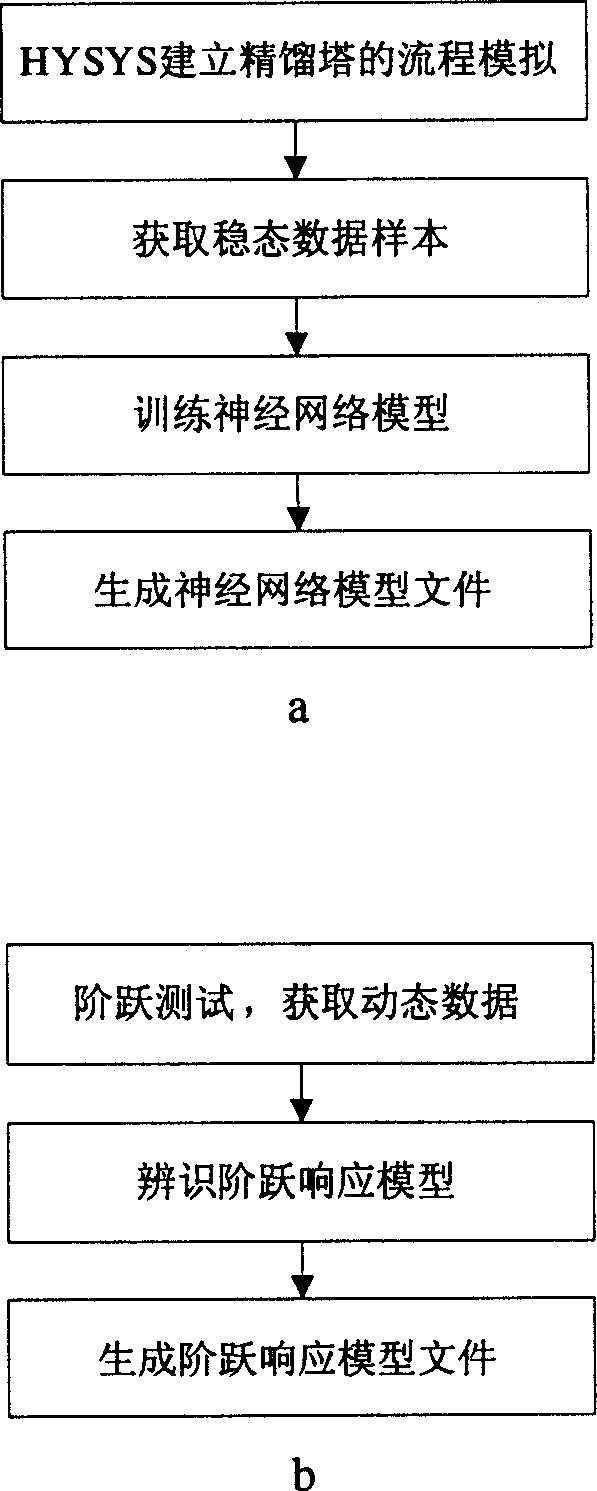

[0088] Establishment of Optimal Agent Model (Neural Network Model)

[0089] Process simulation software or other mechanism analysis models simulate various chemical process units through mechanism modeling. Through parameter adjustment, sufficient accuracy can be achieved to guide production. Due to the use of the mechanism method, the accuracy of the simulation of the actual unit process can be guaranteed in a wide range. However, due to the complexity of the mechanism calculation, the amount of calculation is relatively large, it is difficult to use online, and the software is expensive.

[0090] This shortcoming can be overcome by using process simulation software or other mechanism analysis models to provide input and output data reflecting large-scale changes in the production process, performing statistical model training, and obtaining a simple proxy model that can be used online. At the same time, using process simulation software or other mechanism analysis model dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com