Floor panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

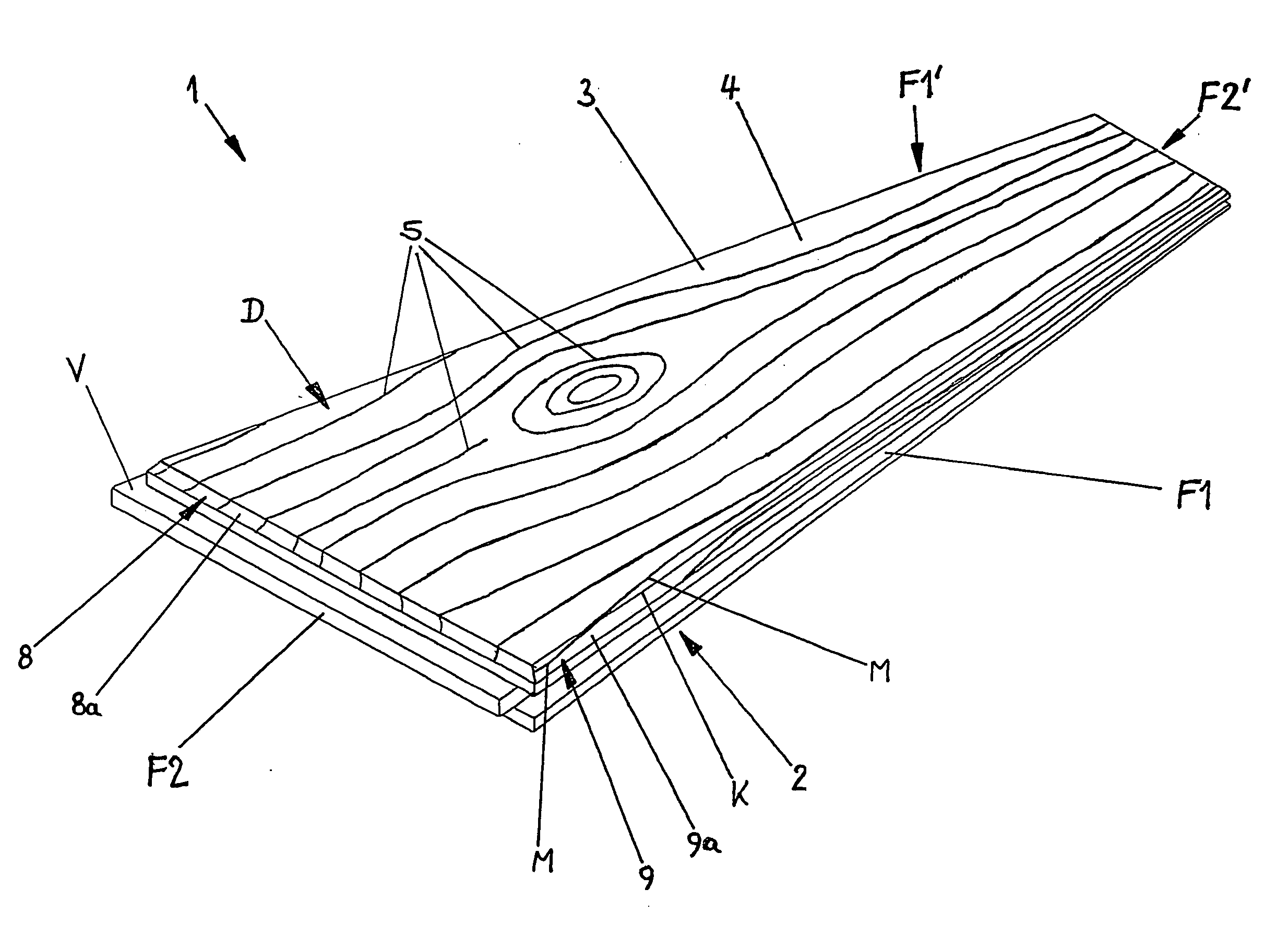

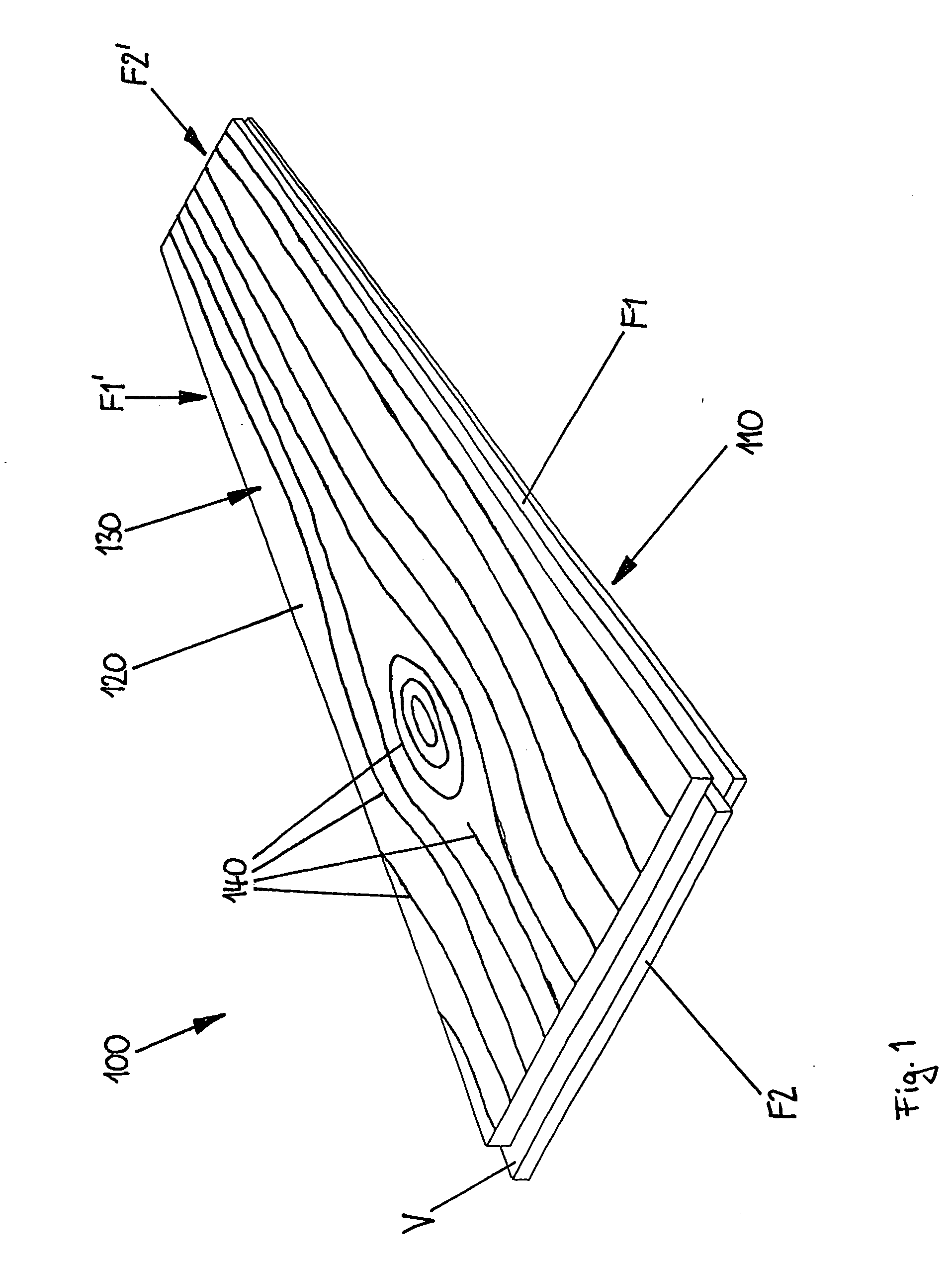

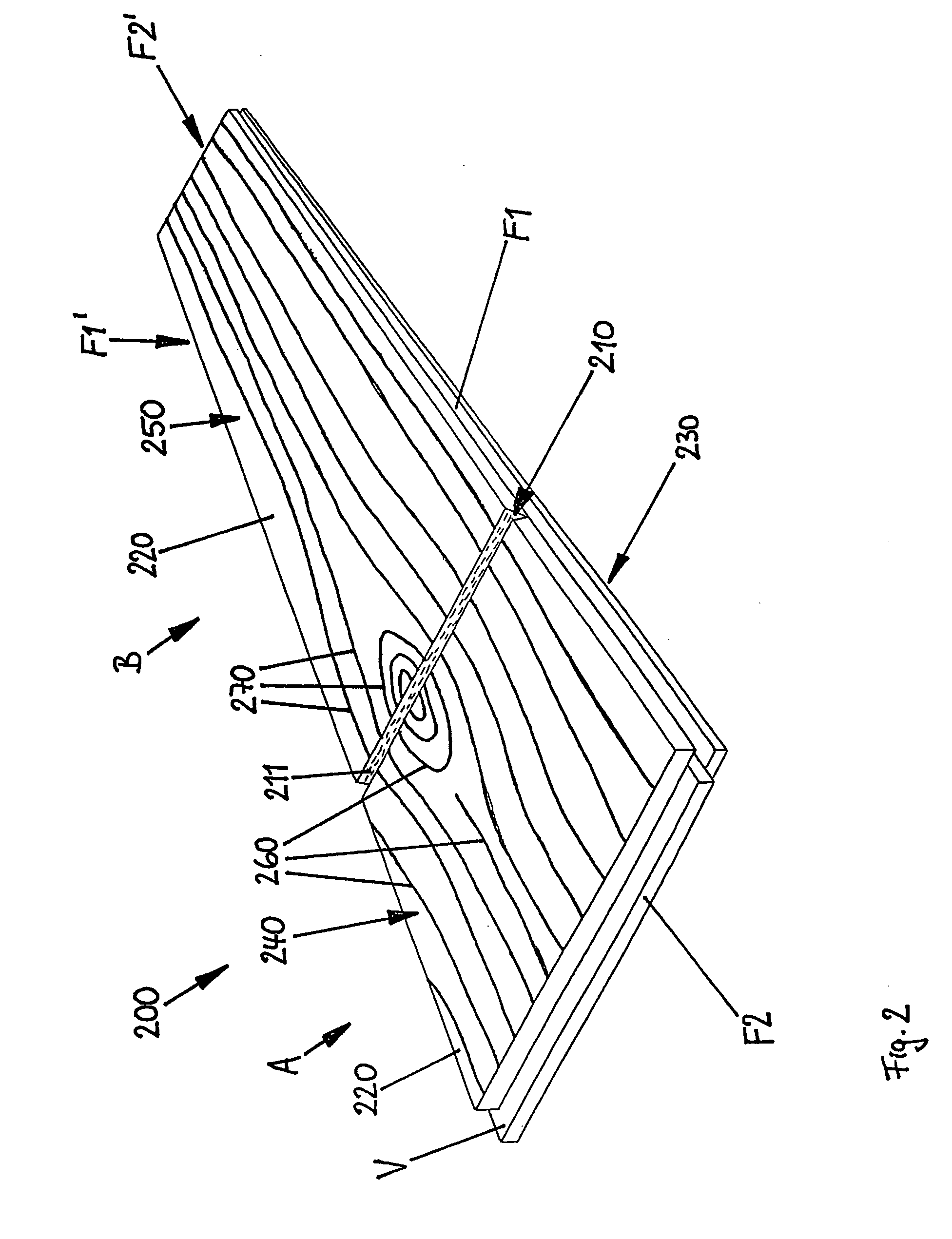

[0053] FIGS. 1 to 4 show floor panels without obtuse edges. FIGS. 5 to 9 show floor panels with obtuse edges. An obtuse edge involves removal of material at a side edge portion of a top side of the floor panel. The removal of material results in the formation of a protection surface, which makes the side edge portion of the floor panel less susceptible to damage.

[0054] Respective edge locking profiles are illustrated at each of the edges of all floor panels in FIGS. 1 to 9. Arranged at the oppositely disposed edges are respective corresponding edge locking profiles F1, F1′ and F2, F2′. A plurality of those floor panels can be joined by means of the edge locking profiles F1, F1′ and F2, F2′ to afford a floor surface because further floor panels can be locked to a floor panel at all sides. The edge locking profiles F1, F1′ and F2, F2′ are shown in FIGS. 1 to 9 by way of example in the form of tongue-and-groove profiles which have an elastically bendable locking means V and V1, V2, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com