Process for removing smoke dust by wet ammonia flue gas desulphurization and device thereof

A fume and ammonia process technology, applied in the field of environmental protection, can solve the problems of complex equipment structure, high energy consumption, large system resistance, etc., and achieve the effects of simple process and system, improved processing efficiency, and low operating cost.

Active Publication Date: 2011-02-16

JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

View PDF2 Cites 50 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are some problems in these two processes. The former has complex equipment structure, large floor area, large system resistance and hig

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

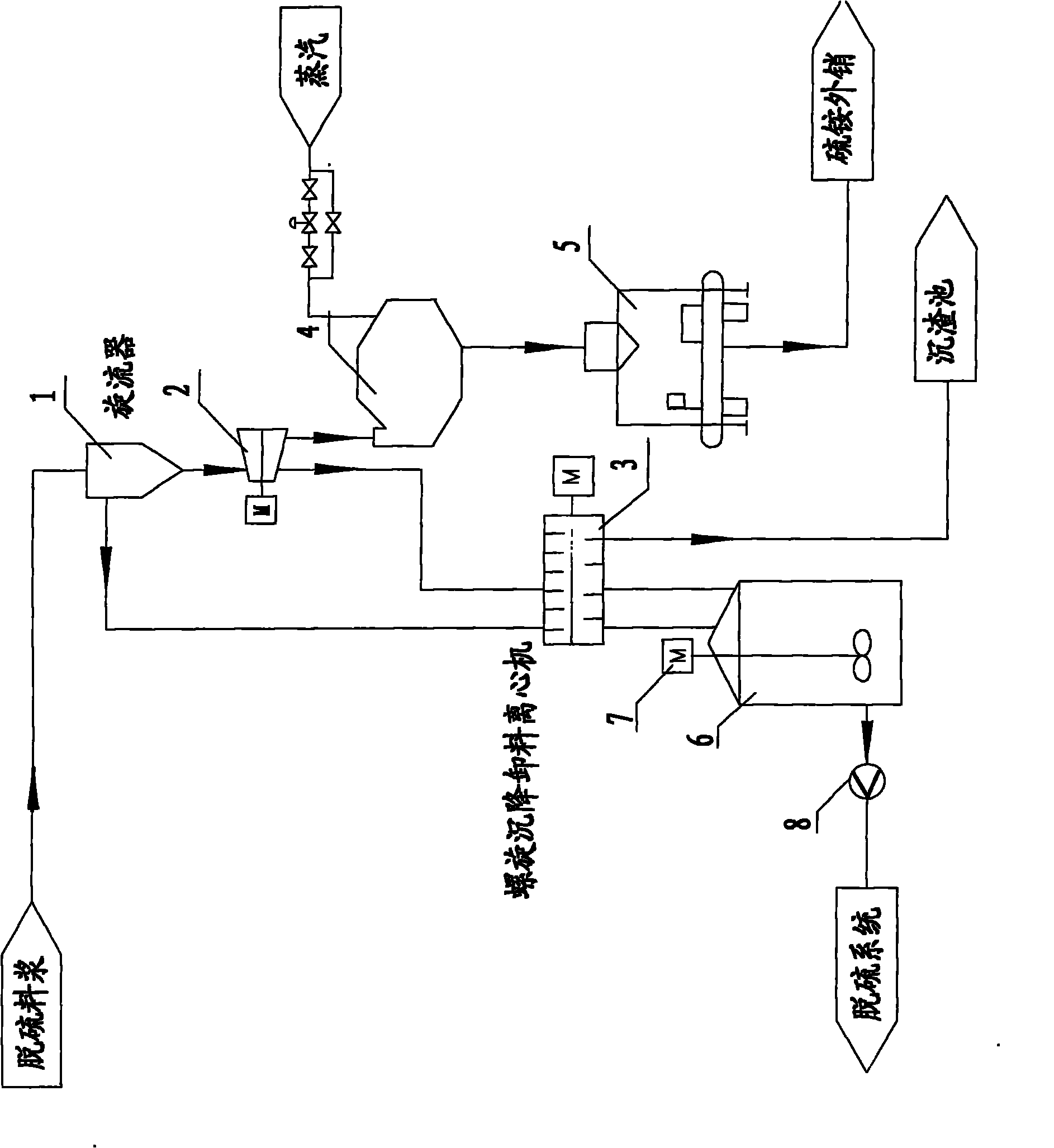

The invention provides a process for removing smoke dust by wet ammonia flue gas desulphurization. The smoke dust removing process comprises two processes, namely, smoke dust removal and ammonium sulfate post-treatment, wherein the ammonium sulfate post-treatment process is that desulfurated ammonium sulfate slurry which is generated by a desulphurization system is delivered to a cyclone separator, a lower overflow vent of the cyclone separator is connected with the inlet of a centrifugal machine, and a solid outlet of the centrifugal machine is connected with a drier; and the smoke dust removing process is that liquid of an upper overflow vent of the cyclone separator and a liquid outlet of the centrifugal machine are connected with filtering separation equipment, and liquid enters a recirculating tank or a liquid tank for next circulation after dust in the liquid is removed by the filtering separation equipment. A device for removing dust by wet ammonia desulphurization comprises the cyclone separator, a centrifugal machine, the drier, the filtering separation equipment, an ash settling pond, a circulating tank or the liquid tank with a stirring device, is used for combining theammonium sulfate post-treatment and dust removal, and has simple process and system, small occupied area and low operation cost.

Description

technical field [0001] The invention belongs to the field of environmental protection and relates to a smoke and dust removal process, in particular to a smoke and dust removal process and a device thereof in a wet ammonia flue gas desulfurization process. Background technique [0002] With the development of industry and the concentration of population, the ambient air has been polluted more and more seriously. Among the gaseous pollutants that pollute the atmosphere, SO 2 It is the most important pollutant, with the largest quantity, the most extensive impact area, and the most difficult to control. According to the statistics of the State Environmental Protection Administration, since 1996, my country's annual SO 2 With emissions exceeding 15.5 million, China has become the world's largest emitter. my country's land area affected by acid rain has exceeded 30%, and the annual economic loss has exceeded 100 billion yuan. On the other hand, our country is a large agricul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01C1/245B01D53/50B01D53/78

Inventor 徐长香罗静傅国光

Owner JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com