Catalytic cracking fume desulfuration wastewater treatment process

A desulfurization wastewater, catalytic cracking technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low impact capacity, high effluent COD, long residence time, etc. , to achieve the effect of strong impact resistance, stable water quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

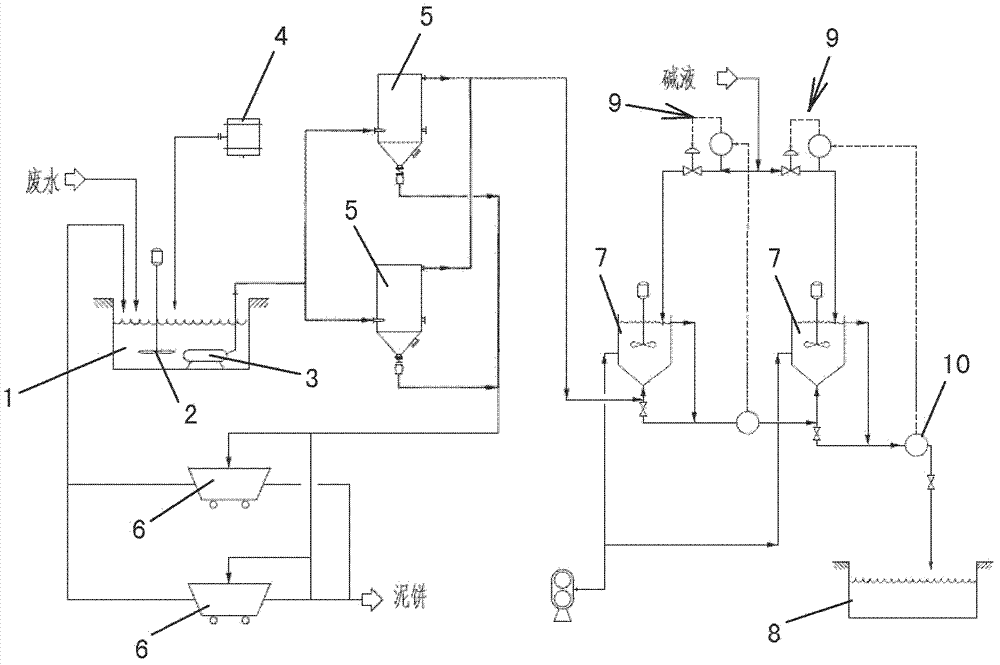

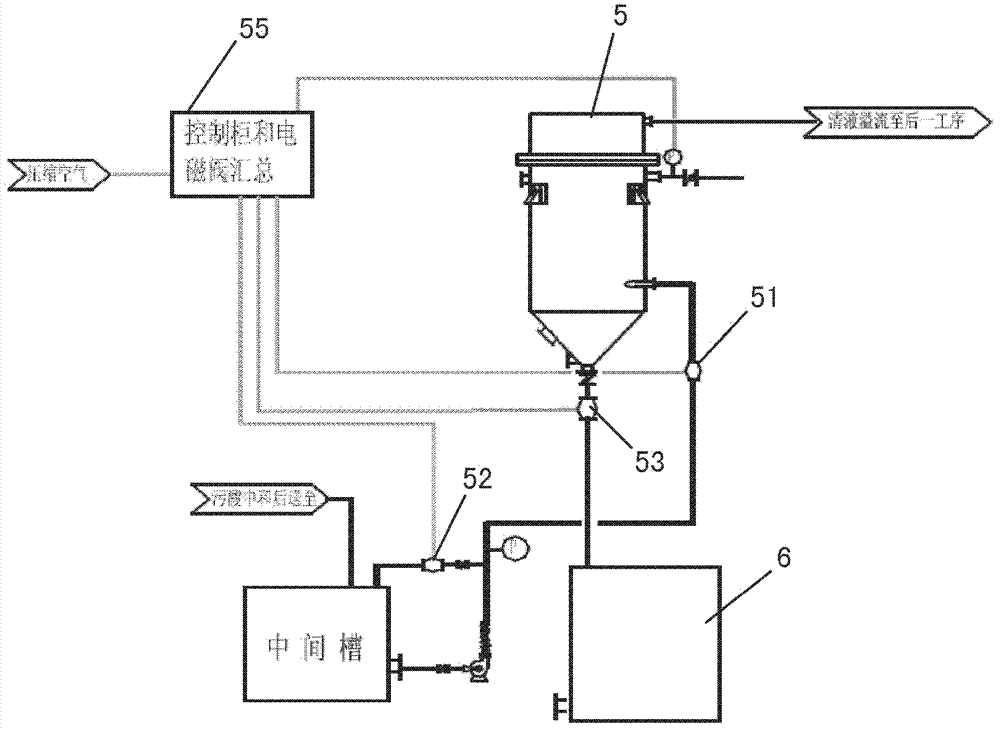

[0013] Such as figure 1 As shown, the desulfurization waste slurry, that is, the wastewater after catalytic cracking flue gas desulfurization, enters the slurry pool 1, mixes with the flocculant from the flocculant tank 4, and stirs in the slurry pool 1 with the mixer 2 to mix the wastewater and the flocculant evenly. The mixed waste water enters the expanded tube filter 5 by means of the delivery pump 3 (two sets are arranged side by side in the figure), and a coagulation reaction occurs at the lower end of the expanded tube filter 5, flocculating the tiny particles to form a large The flocs are then filtered through the filter membrane of the expanded tube filter 5 to achieve solid-liquid separation.

[0014] The bulging tubular filter 5 is a bulging tubular filter (for detailed composition, please refer to Chinese utility model patent CN200320104591.4, announcement number CN2650851), which is similar to the Gore membrane filter and mainly consists of a cylindrical shell, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com