Low-sulfur flue gas desulfurization and denitrification apparatus

A technology for desulfurization, denitrification, and flue gas, which is applied in gas treatment, separation methods, and dispersed particle separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

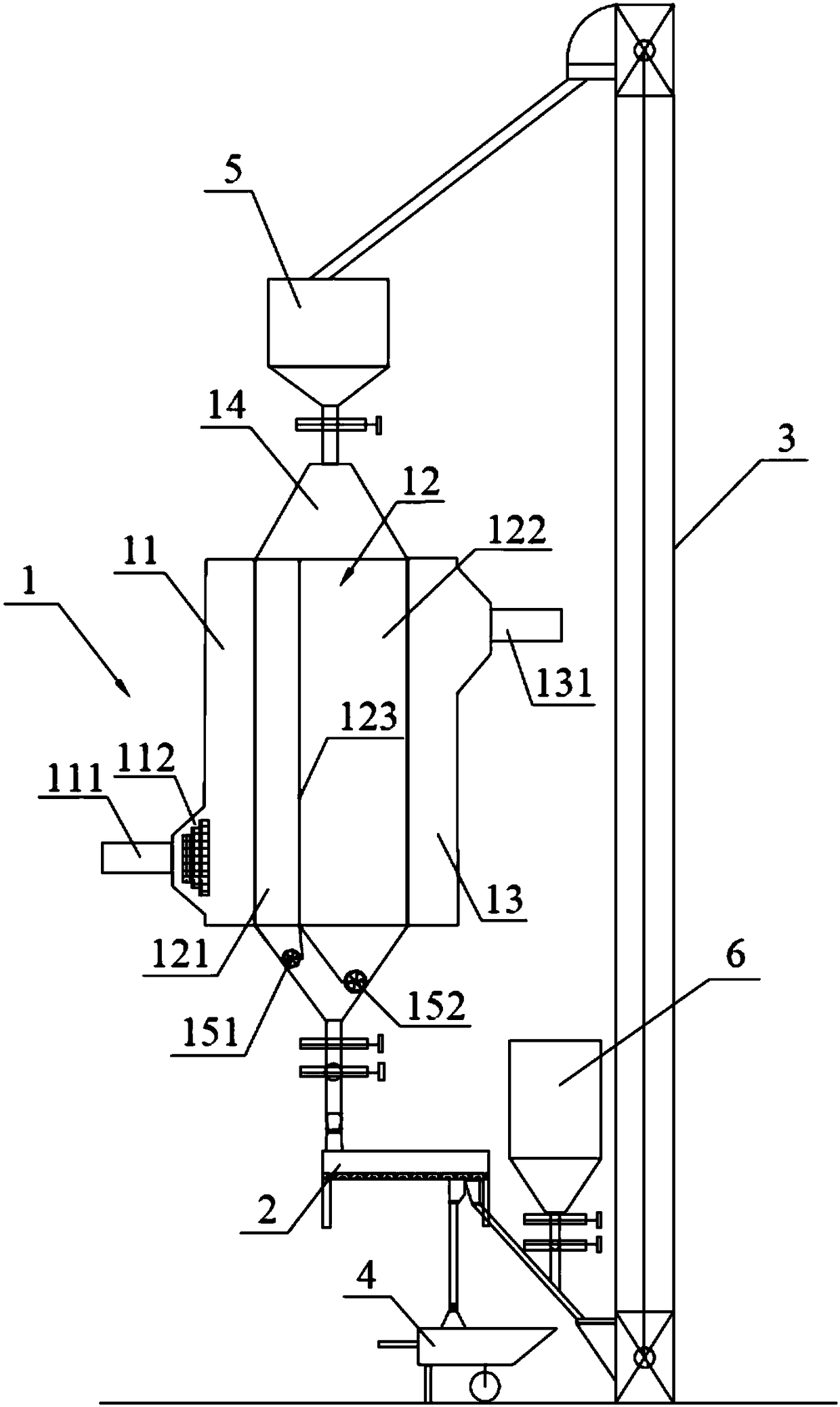

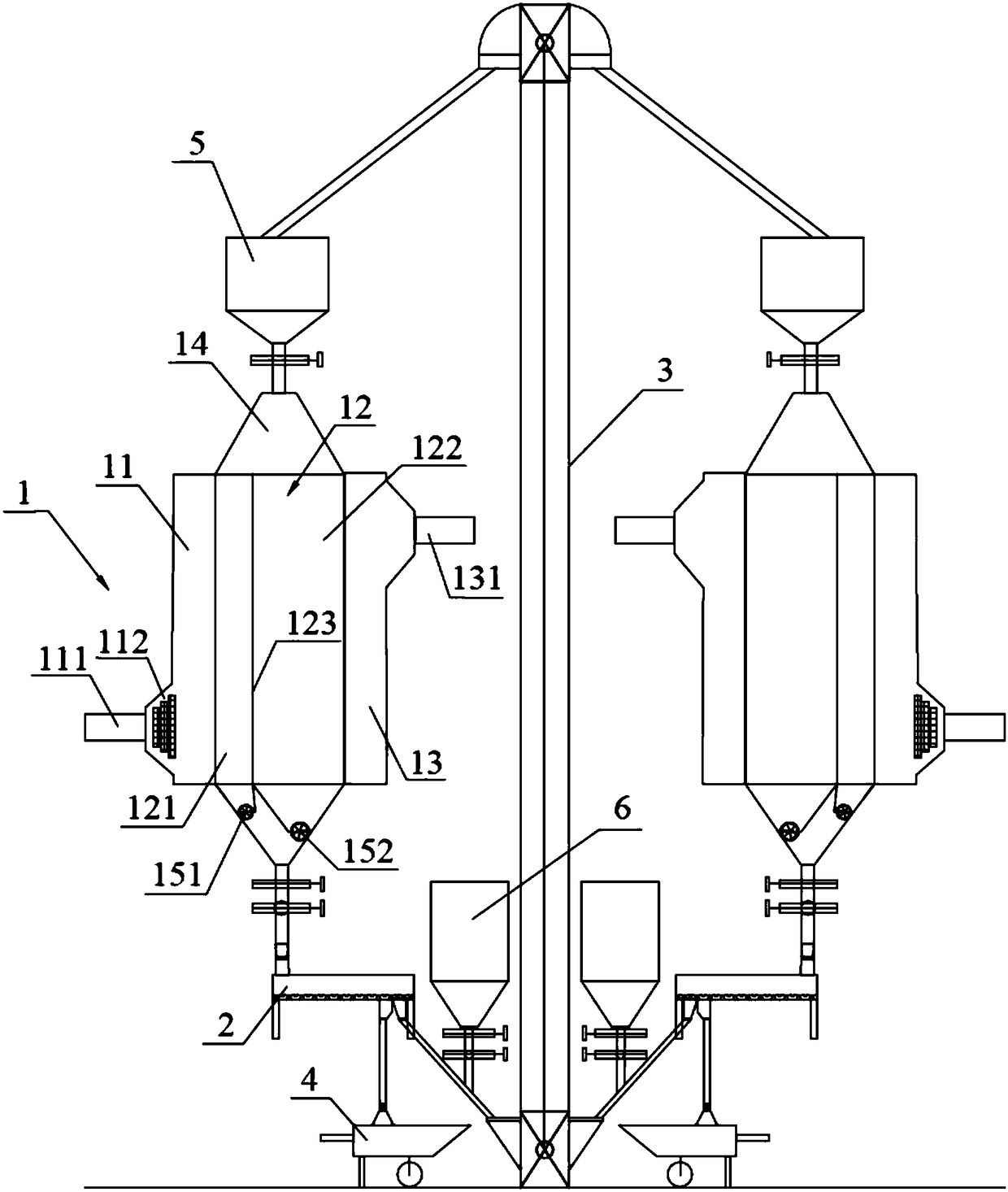

[0028] Such as figure 1 As shown, a low-sulfur flue gas desulfurization and denitrification device provided by an embodiment of the present invention includes an adsorption tower 1, a vibrating screen 2, a conveying mechanism 3, a recovery vehicle 4, a buffer bin 5, and a feeding bin 6, wherein:

[0029] The conveying bin 6 provides fresh activated carbon for the entire desulfurization and denitrification device. The fresh activated carbon or the activated carbon separated by the vibrating screen 2 and can be directly recycled is transported to the adsorption tower 1 through the conveying mechanism 3 for desulfurization and denitrification purification treatment. The desulfurization and denitrification device provided by the invention does not rely on the analysis process, and has a simple process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com