Reproduction method for sodium-base flue gas desulfurization liquid

A technology for desulfurization liquid and flue gas, which is applied in the regeneration field of sodium-based flue gas desulfurization liquid, can solve the problems of increasing the power consumption of flue gas desulfurization system, and achieve the effect of comprehensive utilization of resources and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

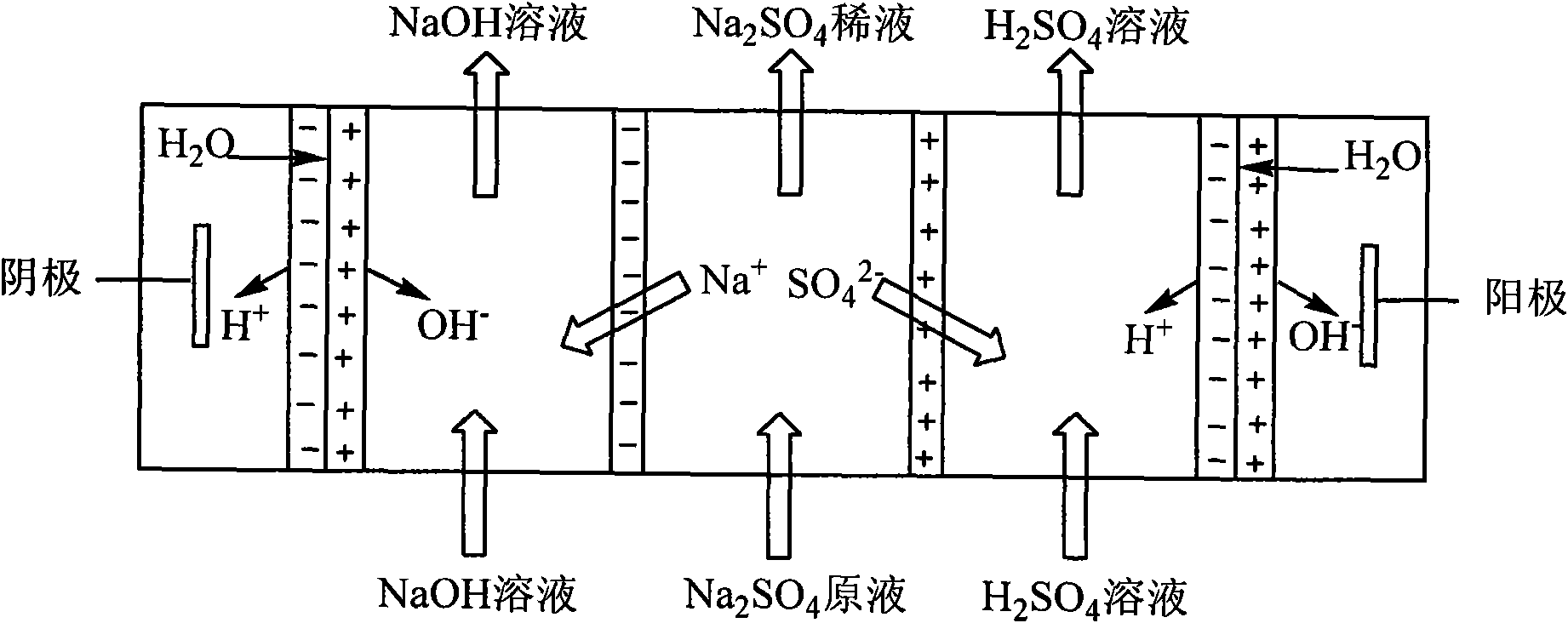

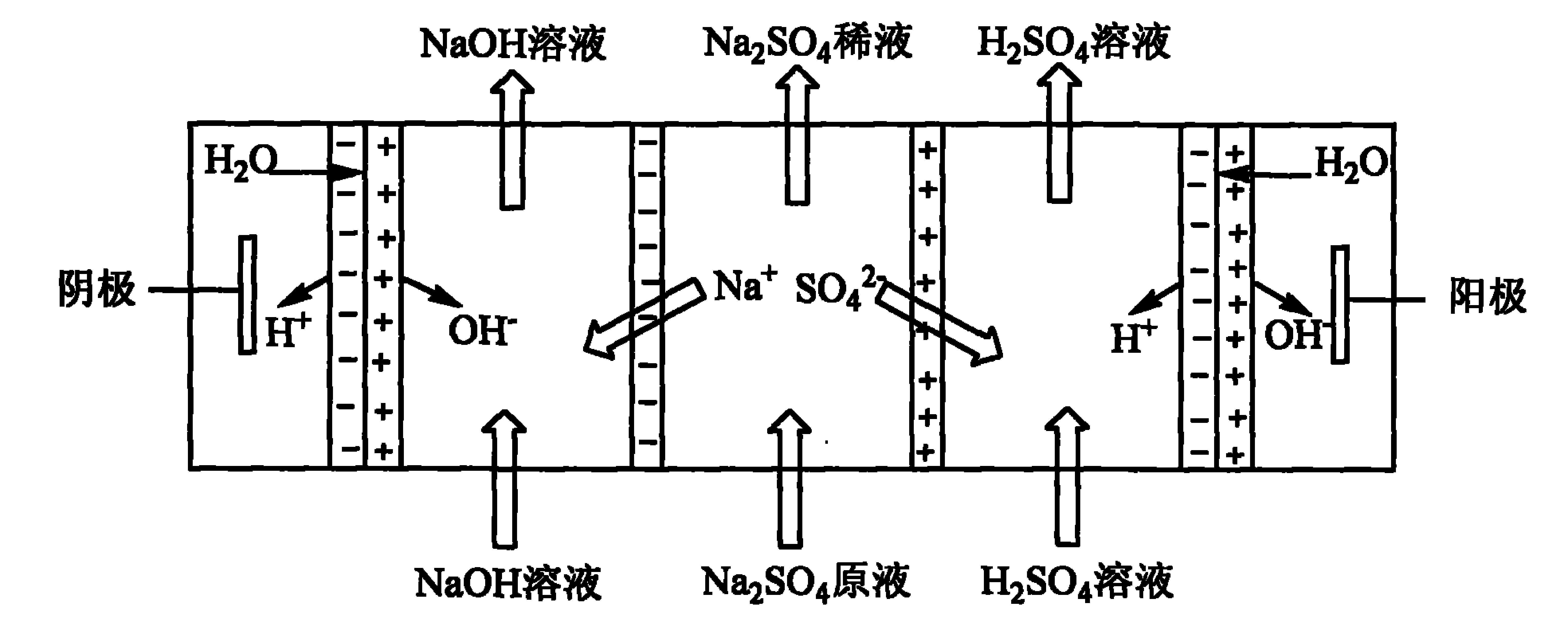

Embodiment 1

[0030] The pH value of the desulfurization solution containing 3.3% sodium sulfite and 0.37% sodium bisulfite in a volume of 2 L was adjusted with sulfuric acid to control the pH value to 6. Air is ventilated into the desulfurization liquid through the air blast head, and the ventilation rate is 2.5L / min·L desulfurization liquid. The aeration oxidation time was maintained for 3 hours, the oxidation rate reached 100%, and a sodium sulfate solution with a concentration of 4% was obtained. According to attached figure 1 , using heterogeneous bipolar membrane-polyethylene heterogeneous anion exchange membrane-polyethylene heterogeneous cation exchange membrane-heterogeneous bipolar membrane to separate the electrolytic cell into alkali chamber, salt chamber and acid chamber. The electrode is a titanium electrode coated with ruthenium. Inject sodium sulfate solution with a concentration of 4% and a volume of 2L into the salt chamber, respectively inject sodium hydroxide and sulfu...

Embodiment 2

[0032]The operating steps are the same as in Example 1, and the operating conditions are as follows: the desulfurization solution containing 5.8% sodium sulfite and 0.65% sodium bisulfite with a volume of 2 L is adjusted to pH 4 with sulfuric acid, and the ventilation rate is 1 L / min·L for desulfurization solution, the aerated oxidation time was maintained for 2.5 hours, the oxidation rate reached 100%, and a sodium sulfate solution with a concentration of 7% was obtained. Inject the sodium sulfate solution with a concentration of 7% and a volume of 2L into the salt chamber of the bipolar membrane electrolytic cell, respectively inject sodium hydroxide and sulfuric acid solutions with a concentration of 1.5% and a volume of 0.5L into the alkali chamber and the acid chamber, and turn on electricity to start The initial current density is 35mA / cm 2 . After 3.5 hours of electrolysis, the electrolytic conversion rate of sodium sulfate reached 67%, the concentration of sodium hydr...

Embodiment 3

[0034] The operating steps are the same as in Example 1, and the operating conditions are as follows: the desulfurization solution containing 8.3% sodium sulfite and 0.92% sodium bisulfite with a volume of 2 L is adjusted to pH 5 with sulfuric acid, and air is ventilated at a rate of 2 L / min·L for desulfurization solution, the aerated oxidation time was kept for 1.5h, the oxidation rate reached 100%, and the sodium sulfate solution with a concentration of 10% was obtained. Inject the sodium sulfate solution with a concentration of 10% and a volume of 2L into the salt chamber of the bipolar membrane electrolytic cell, respectively inject sodium hydroxide and sulfuric acid solutions with a concentration of 1% and a volume of 0.5L into the alkali chamber and the acid chamber, and turn on electricity to start The initial current density is 50mA / cm 2 . After 7.5 hours, the electrolytic conversion rate of sodium sulfate reached 80%, the concentration of sodium hydroxide in the alka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com