Non-film jig and application of non-film process in manufacturing process of chip on board (COP)

A fixture and process technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as adhesion and inability to be removed, reduce the proportion of black spots, improve cleaning yield, and improve cleaning yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

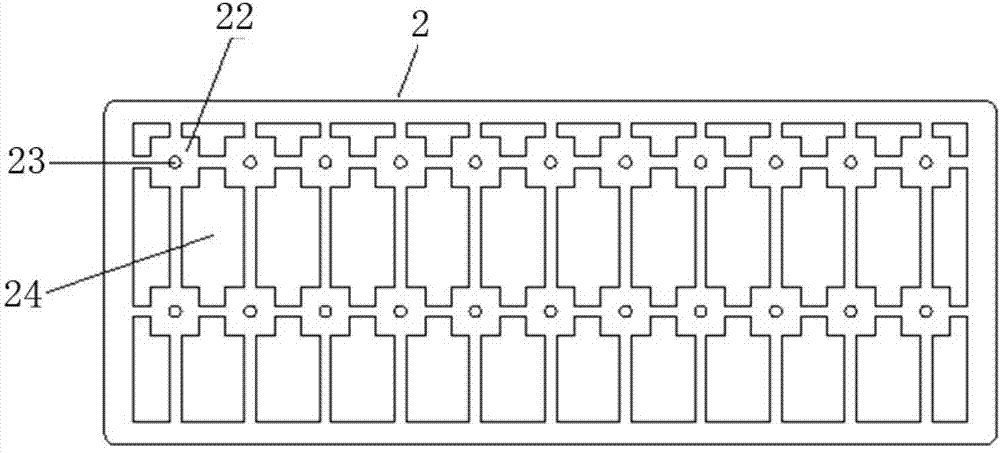

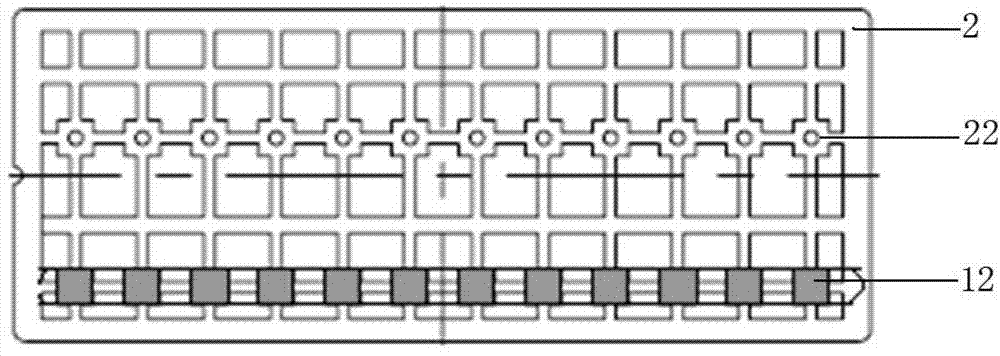

[0017] figure 1 It is a schematic diagram of the filmless metallurgical tool in the embodiment of the present invention, such as figure 1 As shown, the filmless fixtures used in the cleaning and cleaned in the COB process include a frame 2, a bearing surface 22, and a hollowed out part 24. The bearing surface 22 is evenly arranged in the frame, and its center position is provided with a A hollow portion 24 is formed between the glue hole 23 and the bearing surface 22 .

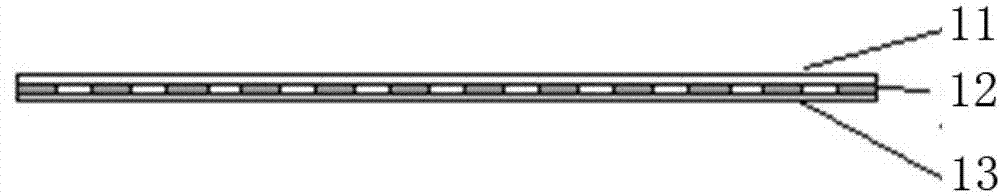

[0018] figure 2 It is a schematic diagram of the double-sided adhesive tape in the embodiment of the present invention. The double-sided adhesive tape used for cleaning in the COB process includes a first release film 11, an adhesive tape 12, and a second release film 13. The adhesive tape 12 is arranged in sections. The adhesive force between the first release film 11 and the adhesive tape 12 is smaller than that of the second release film 13 .

[0019] Wherein, the adhesive tape 13 corresponds to the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com