Thin film processing device

A processing device and film technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of affecting film production efficiency, low degree of automation, and high labor intensity, and achieve simple structure, reduce labor intensity, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

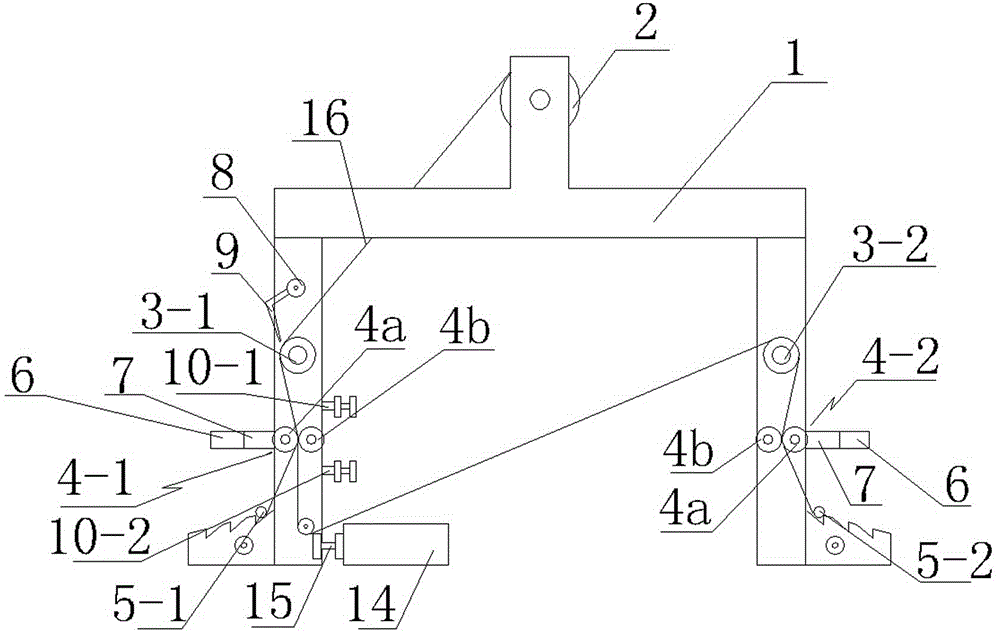

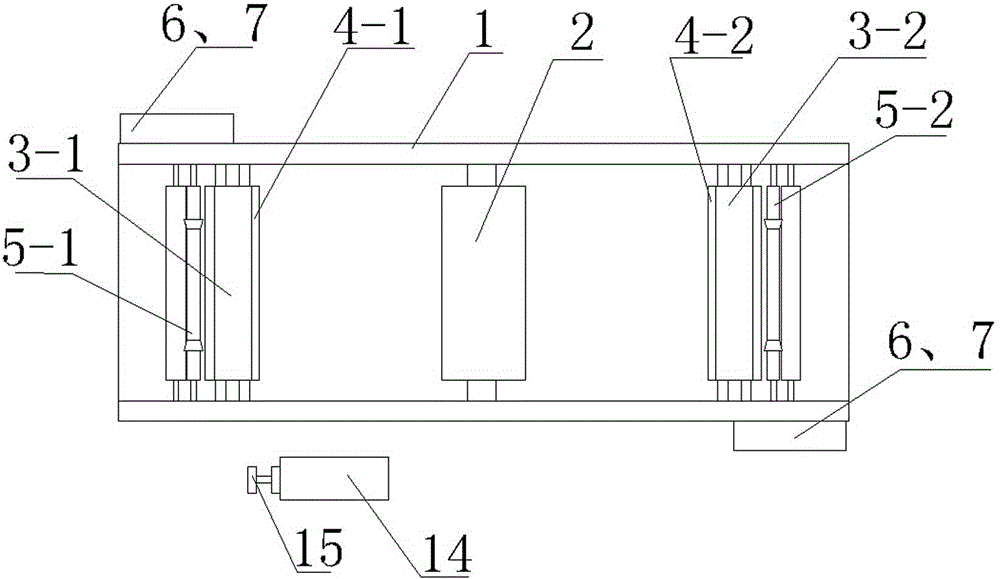

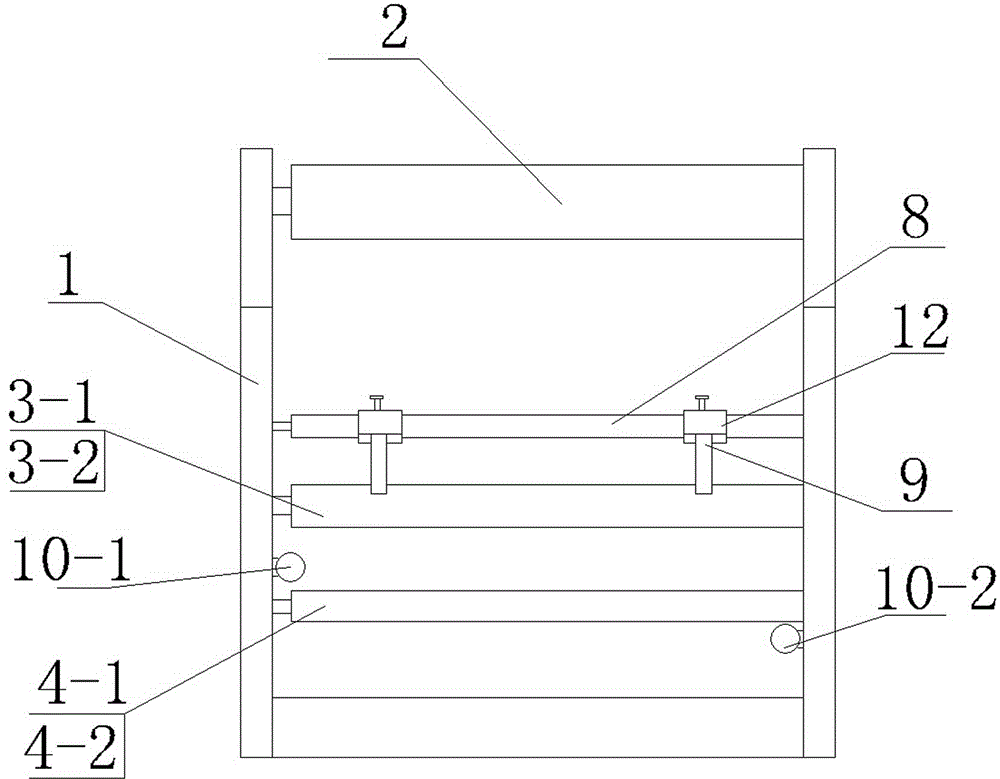

[0010] See figure 1 , figure 2 , image 3 , a film processing device, which includes a support 1, the upper end of the support 1 is provided with a first winding roll 2, and the two sides of the first winding roll 2 on the support 1 are respectively provided with intermediate rolls 3-1, 3-2, pressing Roller 4-1, 4-2 and the second winding roller 5-1, 5-2, pressure roller 4-1, 4-2 comprise driving roller 4a and driven roller 4b, driving roller 4a connects drive unit, drive unit Respectively include a motor 6, the motor 6 is connected to the reducer 7, the reducer 7 is connected to the driving roller 4a, the upper end of the middle roller 3-1 on the upper side of the support 1 is provided with a cutter shaft 8, the lower end is provided with a transition roller 17, and the cutter shaft 8 The two ends are respectively provided with a cutter 9, and the lower ends of the two ends of the corresponding cutter shaft 8 on the support 1 are respectively provided with waste winding tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com