Inner-layer dry film production method

A production method and inner layer dry film technology are applied in the exposure method of radiation-sensitive masks, the removal of conductive materials by chemical/electrolytic methods, photolithography/patterning, etc., which can solve the difficulty of DDR4 circuit production and processing. The problem of low resolution of the film can be solved, and the effect of reducing the reduction of the resolution of the dry film and the reduction of the exposure cost can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

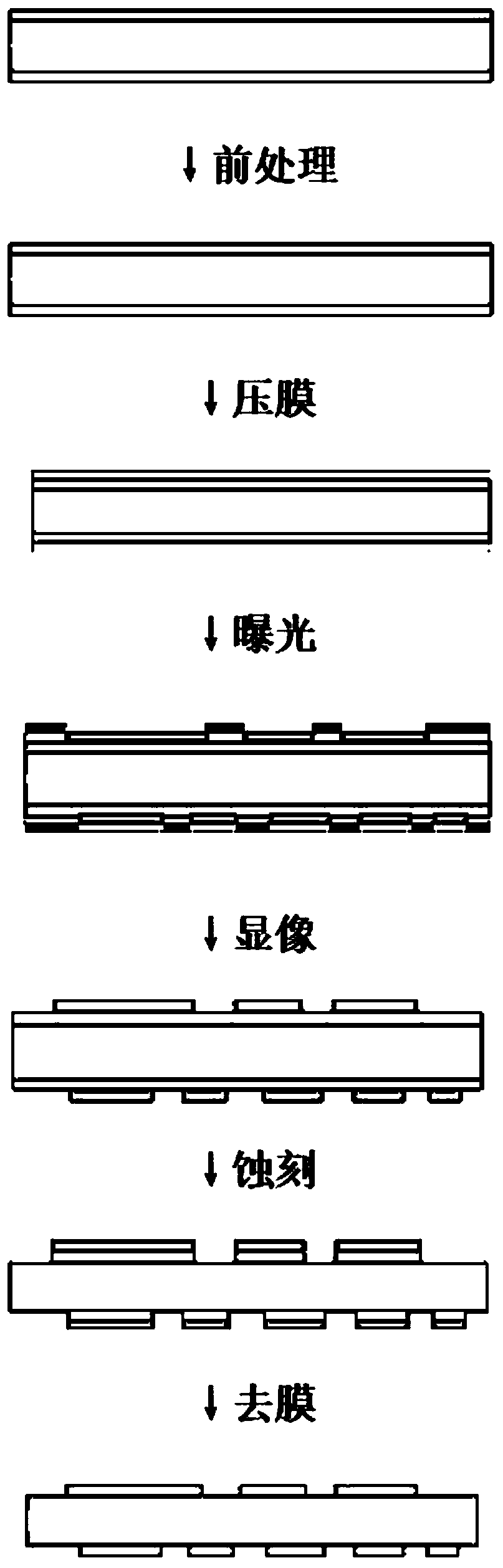

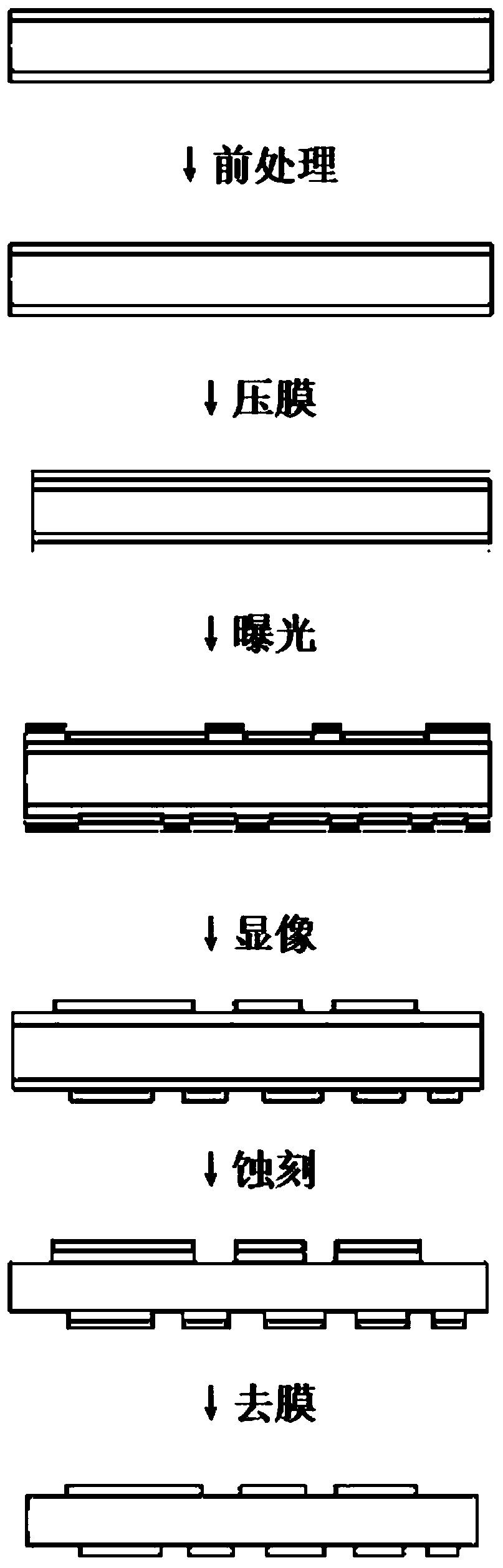

[0027] Step 1: Pre-treatment: Carry out roughening pre-treatment in baking and chemical treatment on the surface of the board, remove water vapor and organic volatiles by baking, release internal stress, promote cross-linking reaction, increase the dimensional stability of the board, and chemically stabilize In order to improve the mechanical strength and mechanical strength, chemical substances such as SPS and other acidic substances are used to uniformly erode the copper surface by chemical treatment, remove grease and oxides and other impurities on the copper surface, increase the roughness of the copper surface, and increase the adhesion of the dry film;

[0028] Step 2: Film pressing: first peel off the polyethylene protective film from the dry film, and then paste the dry film resist on the copper clad board under heat and pressure, and the resist layer in the dry film will be changed by heat Soft, increased fluidity, with the help of the pressure of the hot pressing whee...

Embodiment 2

[0034] Step 1: Pre-treatment: Carry out roughening pre-treatment in baking and chemical treatment on the surface of the board, remove water vapor and organic volatiles by baking, release internal stress, promote cross-linking reaction, increase the dimensional stability of the board, and chemically stabilize In order to improve the mechanical strength and mechanical strength, chemical substances such as SPS and other acidic substances are used to uniformly erode the copper surface by chemical treatment, remove grease and oxides and other impurities on the copper surface, increase the roughness of the copper surface, and increase the adhesion of the dry film;

[0035] Step 2: Film pressing: first peel off the polyethylene protective film from the dry film, and then paste the dry film resist on the copper clad board under heat and pressure, and the resist layer in the dry film will be changed by heat Soft, increased fluidity, with the help of the pressure of the hot pressing whee...

Embodiment 3

[0041] Step 1: Pre-treatment: Carry out roughening pre-treatment in baking and chemical treatment on the surface of the board, remove water vapor and organic volatiles by baking, release internal stress, promote cross-linking reaction, increase the dimensional stability of the board, and chemically stabilize In order to improve the mechanical strength and mechanical strength, chemical substances such as SPS and other acidic substances are used to uniformly erode the copper surface by chemical treatment, remove grease and oxides and other impurities on the copper surface, increase the roughness of the copper surface, and increase the adhesion of the dry film;

[0042]Step 2: Film pressing: first peel off the polyethylene protective film from the dry film, and then paste the dry film resist on the copper clad board under heat and pressure, and the resist layer in the dry film will be changed by heat Soft, increased fluidity, with the help of the pressure of the hot pressing wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com